I. OWNER'S SECTION

LIFT TRUCK MODIFICATIONS

lSi

l

24

1

0

3000

,b

-kSF3<.l:FTFL:t

1340

hilEE-SLF

t

"~?+

3700

rnm

600

rnm

,

0

nm

1

Q

;>;,:,:8ca

147 n_ 30 ~n

1

c

r

2590

b

l~~~~~!\i"~':~

/7

B

i/

nt

l

IIIYkJ

PC

"F

I

3700

rnm

1

760

mrn

3

rnrn

1

I

IMPRCPER OPERATION OR MAINTENANCECOULD RESULT

AWARNINGl~

~NJURYOR

DEATP TRAINED

OPARATORSONLY

v

READ 3PERATORS MANUAL FIRST

57847

U1391 71

Standard mast

FSV mast

(Full-Free

L~ft

Three-Stagemast)

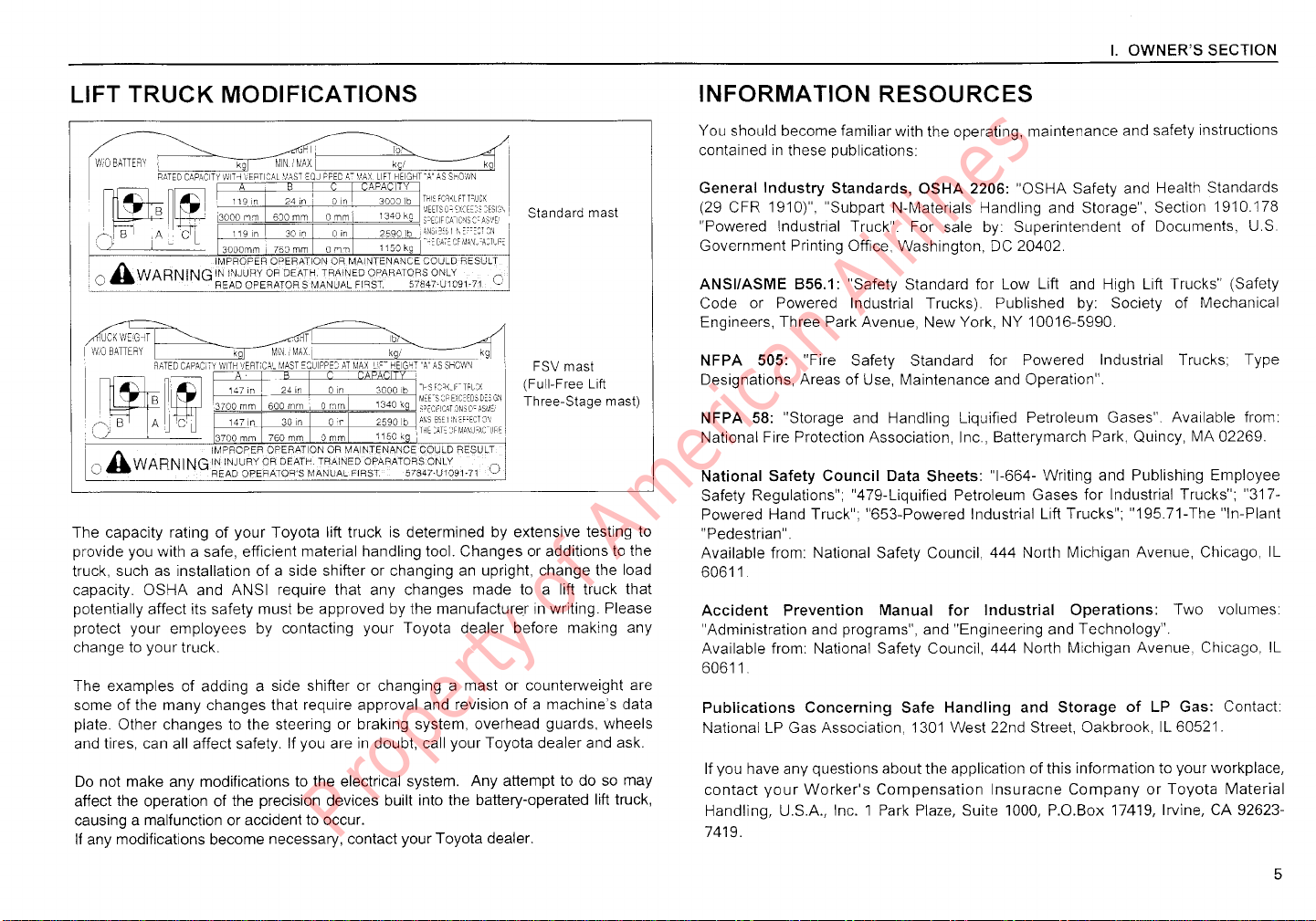

The capacity rating of your Toyota lift truck is determined by extensive testing to

provide you with a safe, efficient material handling tool. Changes or additions to the

truck, such as installat~onof a side shifter or changing an upright, change the load

capacity. OSHA and ANSI require that any changes made to a lift truck that

potentially affect its safety must be approved by the manufacturer in writing. Please

protect your employees by contacting your Toyota dealer before making any

change to your truck.

The examples of adding a side shifter or changing a mast or counterweight are

some of the many changes that require approval and revision of a machine's data

plate. Other changes to the steering or braking system, overhead guards, wheels

and tires, can all affect safety. If you are in doubt, call your Toyota dealer and ask.

Do not make any modifications to the electrical system. Any attempt to do so may

affect the operation of the precision devices built into the battery-operated lift truck,

causing a malfunction or accident to occur.

If any modifications become necessary, contact your Toyota dealer.

INFORMATION RESOURCES

You should becomefamiliar with the operating, maintenance and safety instructions

contained in these publications:

General Industry Standards, OSHA

2206:

"OSHA Safety and Health Standards

(29 CFR 191O)", "Subpart N-Materials Handling and Storage", Section 1910.178

"Powered lndustr~alTruck". For sale by: Superintendent of Documents, U.S

Government Printing Office, Washington, DC 20402.

ANSllASME B56.1: "Safety Standard for Low Lift and High L~ftTrucks" (Safety

Code or Powered lndustrial Trucks). Published by: Society of Mechanical

Engineers,Three Park Avenue, New York, NY 10016-5990.

NFPA

505:

"Fire Safety Standard for Powered lndustrial Trucks; Type

Designat~ons,Areas of Use, Maintenance and Operation".

NFPA 58: "Storage and Handling Liquified Petroleum Gases". Ava~lablefrom:

National Fire Protection Association, Inc.,Batterymarch Park, Quincy, MA 02269.

National Safety Council Data Sheets: "1-664- Writing and Publishing Employee

Safety Regulations"; "479-Liquified Petroleum Gases for lndustrial Trucks"; "317-

Powered Hand Truck"; "653-Powered lndustrial Lift Trucks"; "195.71-The "In-Plant

"Pedestrian".

Available from: National Safety Council, 444 North Michigan Avenue, Chicago, IL

60611

Accident Prevention Manual for lndustrial Operations: Two volumes.

"Administration and programs", and "Eng~neer~ngand Technology".

Available from: National Safety Council, 444 North Michigan Avenue, Ch~cago,IL

60611.

Publications Concerning Safe Handling and Storage of

LP

Gas: Contact.

National LP Gas Association, 1301 West 22nd Street, Oakbrook, IL 60521

If you have any questions about the application of this informationto your workplace,

contact your Worker's Compensation lnsuracne Company or Toyota Material

Handling, U.S.A., Inc.

1

Park Plaze, Suite 1000, P.O.Box 17419, I~ine,CA 92623-

7419.

Property of American Airlines