CETAC Aridus II User manual

CETAC Aridus II™ Desolvating Nebulizer

System

Manual Part Number 480144 rev2

Operator’s Manual

COPYRIGHT

© 2009, 2011 CETAC Technologies

480144 rev2 , August, 2011

CETAC Technologies authorizes its customers

to reproduce, transmit, or store this document

in its entirety, including this page, for the

express purpose of installing, operating, or

maintaining the product described herein.

CETAC Technologies

Customer Service & Support

14306 Industrial Road

Omaha, Nebraska 68144, USA

Phone (800) 369-2822 (USA only)

Phone (402) 733-2829

Fax (402) 733-1932

E-mail [email protected]

REVISIONS

CETAC Technologies strives to provide the

scientific community with an unparalleled

combination of effective technology and

continuing value. Modular upgrades for

existing instruments will continue to be a

prime consideration as designs progress.

CETAC Technologies reserves the right to

revise this document and/or improve

products described herein at any time without

notice or obligation. Warranty registration

entitles the named owner exclusively to

manual change pages/new editions as they

are published.

TRADEMARK ACKNOWLEDGEMENTS

DuPont™, Kapton®, Teflon®, Tefzel® and

Viton® are trademarks or registered

trademarks of E.I. du Pont de Nemours and

Company.

All other marks are the property of their

respective owners.

3

Contents

1Introduction ........................................................................................................... 5

About This Book..................................................................................................................... 6

Aridus II™System Overview..............................................................................................6

Aridus II™ Specifications.................................................................................................... 7

Where to Go for More Information................................................................................ 8

2Preparing for Installation..................................................................................9

Choosing a Location..............................................................................................................9

Space Requirements......................................................................................................... 9

Power Requirements........................................................................................................ 9

ICP-MS Requirements........................................................................................................10

Gas Requirements ...............................................................................................................10

Unpacking the Aridus II™.................................................................................................11

Aridus II™Packaging...........................................................................................................11

3Installing the Aridus II™ .................................................................................. 13

Establishing External Connections ..............................................................................13

Connecting the Aridus II™to the Power Source .................................................13

Connecting the Aridus II™to the ICP-MS...............................................................13

Connecting the Aridus II™Drain Tubing....................................................................17

Connecting the ASX-112FR Autosampler to the Power Source......................17

Connecting the ASX-112FR Autosampler to the Host Computer ...................18

Connecting the Nebulizer to the Aridus II™..............................................................18

QuickWash Fast Washout Accessory..........................................................................21

4Verifying Installation ....................................................................................... 23

Initial Operating Procedure ............................................................................................23

ICP-MS Operation ................................................................................................................24

System Optimization..........................................................................................................24

Aridus II™Optimization Procedure..............................................................................24

5Using the Aridus II™ Desolvating Nebulizer System............................... 27

Establishing Optimal Operating Conditions ............................................................27

Establishing the Lab Environment ..........................................................................27

Replacing Aridus II™Components................................................................................28

Sample Transfer Line: Teflon®-Lined PVC Tubing ..........................................28

Peristaltic Pump Tubing: 3-Stop Gray/Gray 1.3mm I.D. ..............................28

Startup Procedure...............................................................................................................28

Shutdown Procedure .........................................................................................................29

Temperature Controller Operation .............................................................................29

Switching from Organic Samples to Aqueous Samples and Aqueous

Samples to Organic Samples..................................................................................30

6Maintaining the Aridus II™ ............................................................................. 31

Cleaning the Aridus II™......................................................................................................31

Daily External Cleaning................................................................................................31

Daily Internal Cleaning.................................................................................................32

ASX-520 Autosampler Operator’s Manual

Contents

4

Maintaining the Nebulizer and Spray Chamber.....................................................32

Using the C-Flow PFA Nebulizer Flush Kit ...........................................................33

Main Fuse Replacement....................................................................................................33

Spray Chamber and Desolvator Fuse Replacement.............................................34

Rinse Procedure for the Membrane Desolvator....................................................34

Removal of the Membrane Desolvator Modular Assembly ..............................35

Cleaning the Membrane Desolvator............................................................................39

7Troubleshooting the Aridus II™ .................................................................... 43

Temperature Controller Problems..............................................................................43

Temperature controllers and gas flow controllers do not illuminate. ....43

Display of temperature controller reads “Er 4.”................................................43

Temperature controller reads room temperature...........................................44

Temperature controller stops illuminating.........................................................44

Gas Flow Controller Problems.......................................................................................44

Sweep gas controller does not read zero..............................................................44

Argon sweep gas controller will not provide a reading of 3.0 or reading

is unstable..................................................................................................................44

Nitrogen gas controller will not provide 20 mL/min of nitrogen flow or

flow is unstable........................................................................................................44

Nebulizer / Plasma Problems ........................................................................................44

Poor and/or unstable aerosol generation ...........................................................44

Sample flow rate problems .........................................................................................45

Poor precision...................................................................................................................45

High elemental oxide levels ........................................................................................46

Excessive nitrogen-containing polyatomic ion interferences......................46

Nebulizer self-aspiration stops..................................................................................46

Plasma Problems.................................................................................................................46

Plasma flickers excessively or is unstable.............................................................46

Returning the Product to CETAC for Service ..........................................................47

Shipping the Product .....................................................................................................47

Product Warranty Statement....................................................................................47

Returned Product Procedures ...................................................................................48

Returned Product Warranty Determination ......................................................48

8Safety and Regulatory Information.............................................................. 51

Characteristics......................................................................................................................51

Environmental Characteristics .................................................................................51

Electrical Characteristics.............................................................................................52

Safety Notices........................................................................................................................53

Power Cord Set Requirements and Maintenance .............................................53

Mains Disconnect.............................................................................................................53

Cleaning Instructions.....................................................................................................54

Operating Environment................................................................................................54

Explanation of Caution and Warning Notices....................................................55

Avertissements en Français............................................................................................56

Electromagnetic Interference........................................................................................58

Explanation of Regulatory Marks.................................................................................58

9Glossary ................................................................................................................ 59

5

1Introduction

The Aridus II™ Desolvating Nebulizer System is designed primarily for ICP

mass spectrometry. The Aridus II™ incorporates a C-Flow PFA microconcentric

nebulizer, which provides low sample flow rates (approx. 50, 100, or 200

microliters/min.). The nebulizer is constructed entirely of inert materials and

is suited for use with acidic and alkaline solutions. Solutions may contain nitric

acid (HNO3), hydrochloric acid (HCl), hydrofluoric acid (HF), or ammonium

hydroxide (NH4OH).

Sensitivity is improved with the Aridus II™ system by enhancing analyte

transport efficiency and reducing solvent loading to the plasma. With

conventional pneumatic nebulization, injected water vapor causes oxide and

hydride polyatomic ion interferences in ICP-MS; organic solvent vapor loading

causes carbide polyatomic ion interferences as well as plasma instability and

carbon deposition on ICP-MS sampling cones. Using the Aridus II™ system for

sample introduction greatly reduces these problems. It is strongly noted that

the degree of sensitivity enhancement is dependent on the type of ICP-MS used

and the area of application.

Functionally, liquid sample is nebulized into a PFA spray chamber using a

C-Flow PFA microconcentric nebulizer operating at a sample uptake rate of

approximately 100 µL/min and an argon nebulizer gas flow rate of 0.7 to 1.1

L/min. The spray chamber is heated to help reduce the formation of solvent

droplets inside the spray chamber. The spray chamber is also drained by a

built-in peristaltic pump. The nebulizer gas flow then transports the aerosol

from the spray chamber to a heated inert fluoropolymer tubular membrane.

Solvent vapor passes through the membrane and is removed by an exterior

flow of Ar gas (sweep gas). Analyte continues through the middle of the

membrane tube to the ICP-MS instrument. An external view of the Aridus II™

Nebulizer System is shown in Figure 1-1.

Aridus II™ Operator’s Manual

6

About This Book

This document describes the procedures for installing, using, and maintaining

the nebulizer system.

This manual covers the following products:

CETAC Aridus II™ Desolvating Nebulizer System

CHEMICAL INJURY HAZARD

The Aridus II™ Desolvating Nebulizer System is intended for use only by

qualified operators who have been trained in safe laboratory practices.

Make sure you know the hazards associated with all of the chemicals you

are using, and take the appropriate precautions. Exposure to laboratory

chemicals may result in serious injury.

Aridus II™System Overview

Figure 1-1. Aridus II™Desolvating Nebulizer System.

WARNING

Aridus II™ Operator’s Manual

Chapter 1: Introduction

7

The following standard components/accessories are included with each

Aridus II™ system:

ICP-MS interface kit: All parts to interface to the operator’s ICP-MS,

including torch adapter, fittings, and tubing.

Rinse kit: Contains membrane rinse accessories and a tubing kit that

connects to the necessary ports.

Spare fuse kit: Contains replacement fuses for the Aridus II™.

Gas-line tubing kit: Contains all the necessary tubing to interface the

argon sweep gas and nitrogen addition gas to the Aridus II™.

C-Flow PFA Nebulizer: One low-flow microconcentric nebulizer. A 100

microliter/min nebulizer is standard. A 50 microliter/min or a 200

microliter/min nebulizer are also available.

Nebulizer Flush Kit: Flush kit for cleaning the C-Flow PFA nebulizer.

NOTE:

Contact CETAC Technologies if you need additional accessories or added

features to integrate the Aridus II™with your analytical system or if your

laboratory has unique requirements. Research and development of new

features and accessories for the Aridus II™, often inspired by customer

requests, is a continuing activity of CETAC Technologies.

Aridus II™ Specifications

Nebulizer: CETAC C-Flow PFA, 50, 100 or 200 µL/min

Inert Desolvating Membrane:

•Ar Sweep Gas: 0 to 8.0 L/min

•Nitrogen Gas: 0 to 50 mL/min

•Membrane Oven Temperature: 160°C

Spray Chamber: PFA with pumped drain

•Spray Chamber Temperature: 110°C

Voltage (Switch-Selectable):

•120 VAC +/- 10%, 50/60 Hz, 6A

•220 VAC +/- 10%, 50/60 Hz, 3A

Dimensions (Without Autosampler):

•33.6 cm W x 24.8 cm H x 55.9 cm D (13.2 in W x 9.8 in H x 22 in D)

•Weight: 10.5 kg (23.1 lbs)

Aridus II™ Operator’s Manual

8

Where to Go for More Information

In addition to this manual, you can refer to the following resources:

New versions of this manual may be available under “Service and Support”

on CETAC’s Web site:

www.cetac.com

CETAC Technologies Customer Service and Support:

Phone: 1 (800) 369-2822 (USA only)

1 (402) 733-2829

Fax: 1 (402) 733-1932

E-mail: custse[email protected]

The software and hardware manuals for the ICP-MS instrument you are

using.

9

2Preparing for

Installation

Before you install the Aridus II™nebulizer system, you should evaluate the

physical arrangement of the laboratory to choose a suitable location. Once you

choose a location, you must carefully unpack the system prior to beginning the

installation.

Choosing a Location

Choosing a location for the Aridus II™involves evaluating the laboratory

environment for the availability of space and power. For the Aridus II™to

function optimally, the location you select must meet specific requirements

associated with each of these items. The following sections discuss space and

power requirements.

Space Requirements

Most analytical applications benefit from the shortest sample flow path. A one

meter length of Teflon® lined PVC tubing is provided to connect the Aridus II™

to the ICP-MS torch. Place the Aridus II™sample out port less than one meter

from the ICP-MS torch. The system without the ASX-112FR autosampler is 34

cm x 25 cm x 56 cm (W x H x D). Adequate space should be allowed for proper

ventilation.

Power Requirements

Place the Aridus II™within 1.2 meters of the power outlet. The Aridus II™is

provided with a voltage selection switch on the bottom panel, right front. The

voltage may be selected as either 100-120 VAC +/- 10%, 50/60 Hz, 6A or 220-

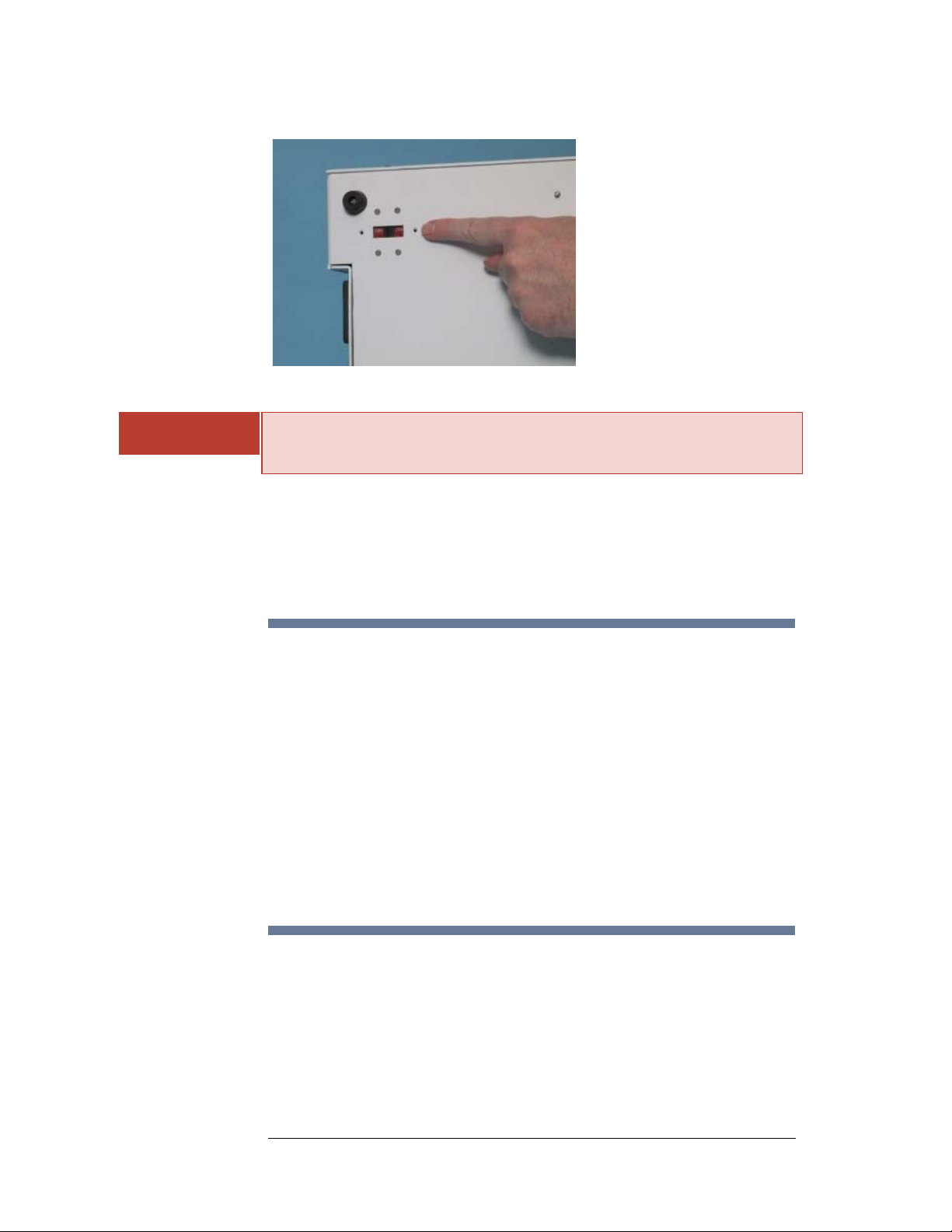

240 VAC +/- 10%, 50/60 Hz, 3A. See Figure 2-1.

Aridus II™ Operator’s Manual

10

Figure 2-1. Voltage Selection Switch

SHOCK AND FIRE HAZARD

The system must be plugged into an outlet which has a protective ground

connection.

Ensure that you position the system so that the location where the power

supply cord plugs into it is easily accessible (is not blocked) and it can be

quickly disconnected if needed. In case of hazard, the system should be

disconnected from the power source.

Do not apply power until ready to operate the system.

ICP-MS Requirements

To achieve optimum performance with the Aridus II™, the ICP-MS system must

meet factory specifications from your vendor and be in good operating

condition. Check the ICP-MS performance using the standard sample

introduction system before Aridus II™installation. If the sensitivity, oxide ratios

and overall performance do not meet instrument specifications, consult the

ICP-MS Operator’s Manual. If ICP-MS performance specifications are met, then

begin installation of the Aridus II System.

In order for the C-Flow PFA nebulizer to properly self-aspirate, a minimum

argon gas pressure of 420 kPa (60 psi, 4.2 bar) is required in the nebulizer gas

line. Ensure that the Ar gas supply for the C-Flow PFA nebulizer is from a

known, good supply. The argon nebulizer gas supply from the host ICP-MS is

typically used for the C-Flow nebulizer.

Gas Requirements

The argon gas supply for the Aridus II™sweep gas may be teed in from the

main ICP-MS instrument argon gas supply. Nitrogen gas must be supplied from

an external source at a pressure of at least 350 kPa (50 psi, 3.5 bar). Nitrogen

with a minimum purity of 99.995% should be used.

WARNING

Aridus II™ Operator’s Manual

Chapter 2: Preparing for Installation

11

Unpacking the Aridus II™

Inspect external packaging upon receipt for signs of physical damage from

rough handling or abuse during shipment. Inspect all items during unpacking

and notify the carrier immediately of any visible or concealed damage. Remove

packing checklist from the shipping container, and check off items against it.

Leave accessories in the packing until you are ready to install them on the

Aridus II™.

Aridus II™Packaging

The Aridus II™ system is shipped in several containers:

Once container holds the Aridus II™ Desolvating Nebulizer System.

A second container holds the 15 L trap bottle, the ICP-MS interface kit, and

the Aridus II™completion kit. This container also holds the QuickWash fast

washout accessory, if ordered.

A third container holds the ASX-112FR autosampler, if ordered.

If the system is shipped or removed from storage during cold weather, allow

the packaged equipment to equilibrate to room temperature before opening

and exposing to warm, humid air. It is usually sufficient to provide four to eight

hours for this purpose.

EQUIPMENT DAMAGE FROM CONDENSATION

If condensation forms on or inside the Aridus II™, allow it to dry thoroughly before

connecting it to a power source and operating it. Failure to do so may cause

equipment damage.

NOTE

Keep the factory packaging for use in case the product ever needs to be

returned or shipped to another location.

CAUTION

Aridus II™ Operator’s Manual

12

This page is intentionally blank.

13

3Installing the

Aridus II™

To install the Aridus II™, you must complete the tasks described in this chapter.

Ensure that the AC power is off (0 showing at the bottom edge of the

power switch) on the back of the Aridus II™before proceeding with

installation.

Establishing External Connections

The first step in the installation process involves connecting the Aridus II™to

the power source and to the ICP-MS instrument. The following sections

explain how to establish these connections.

Connecting the Aridus II™to the Power Source

Voltage-specified power cords are supplied with each Aridus II™.

Use only these power cords or exact replacements.

To connect the Aridus II™to a power source, plug the cord into the power

module located on the back panel of the Aridus II™. Then plug the cord into an

appropriate AC outlet (110 or 220 VAC ±10%, 50/60 Hz depending on the

voltage selection).

Connecting the Aridus II™to the ICP-MS

Depending on the ICP-MS manufacturer and model, a torch adapter is supplied

for interfacing the Aridus II™to the ICP-MS. Adapters are available for all ICP-

MS instruments.

1A length of ¼"O.D. Teflon®-lined PVC tubing is connected to the torch adapter.

Place the other end of this tubing onto the SAMPLE OUT port located on the

back of the Aridus II™. This end will be equipped with a threaded nut for

WARNING

WARNING

Aridus II™ Operator’s Manual

14

attachment to the threaded SAMPLE OUT port. The threaded nut should only

be finger-tightened onto the SAMPLE OUT port.

Make certain that the Teflon® lining in the sample out tubing is not blocking the

aerosol path to the ICP-MS torch. This can result in instability and lack of analyte

signal from the ICP-MS instrument.

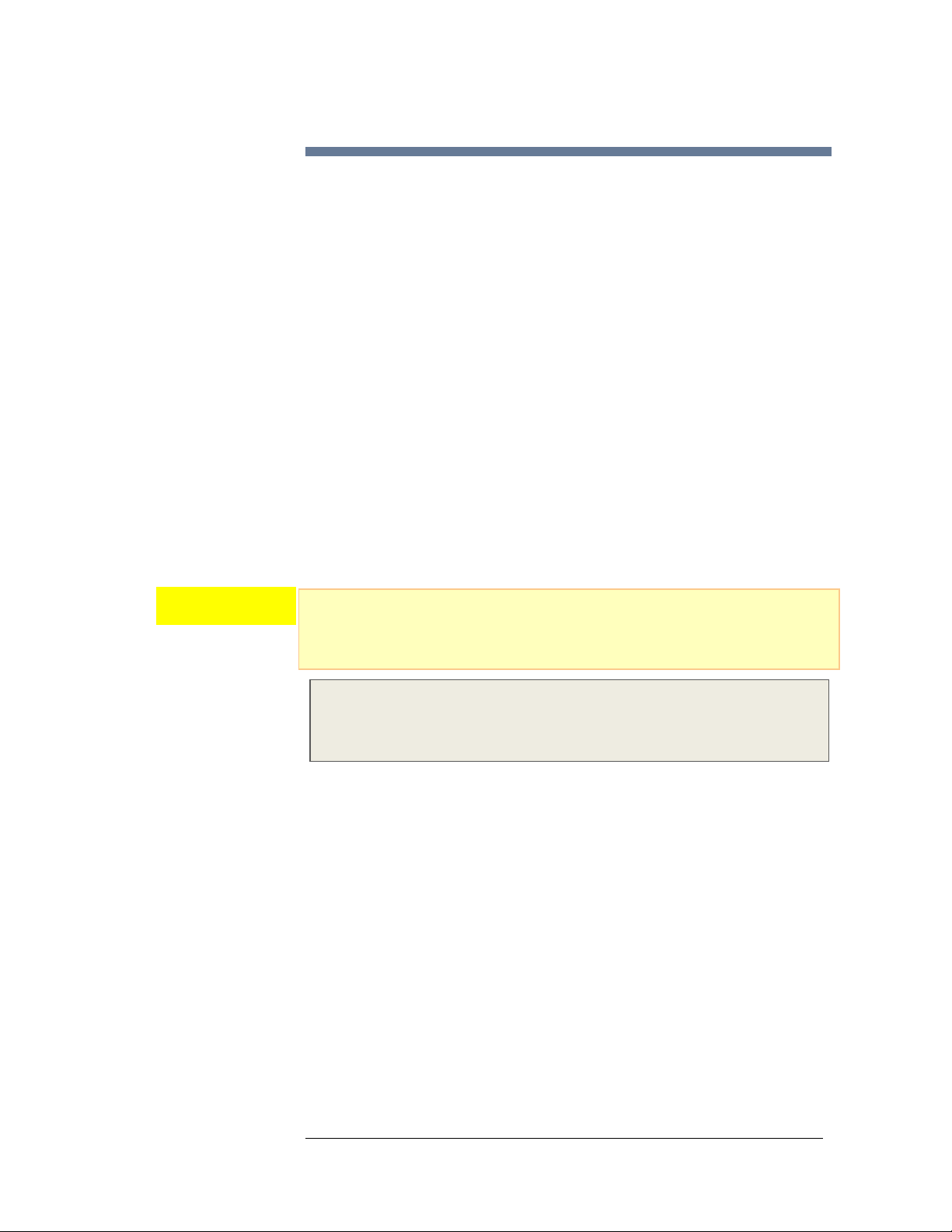

Attach the other end, containing the torch adapter, to the

ICP-MS torch/injector (Figure 3-1). Note that Figure 3-1 depicts the

attachment of the standard 12/5 glass joint. While this is a common type of

interface, the interface for the operator’s particular ICP-MS torch may be

different.

Figure 3-1. Connecting a torch adapter to the ICP-MS torch.

2The rinse port is shipped with a finger tight ¼-28 Tefzel®plug installed. The

rinse port should remain plugged except during cleaning/rinsing of the

membrane.

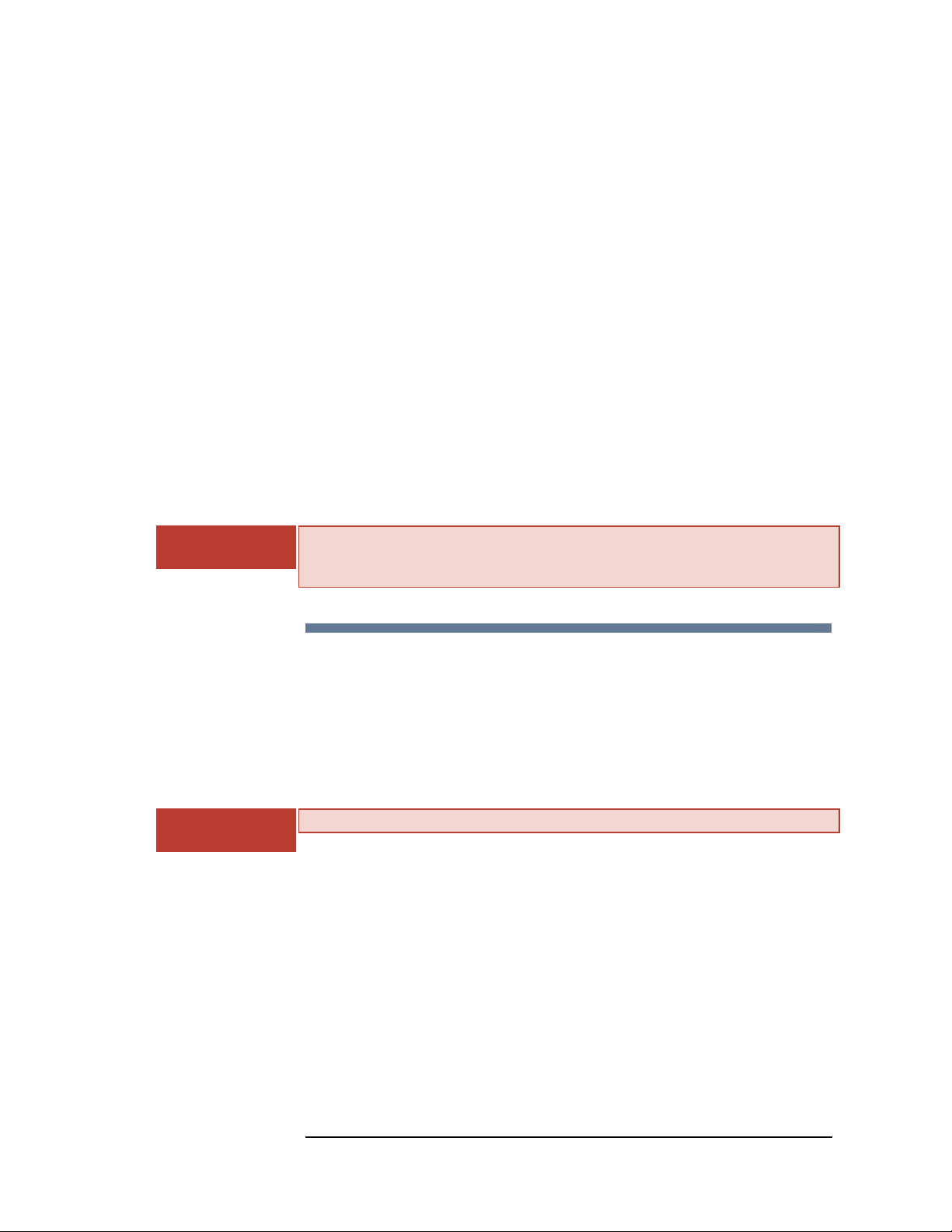

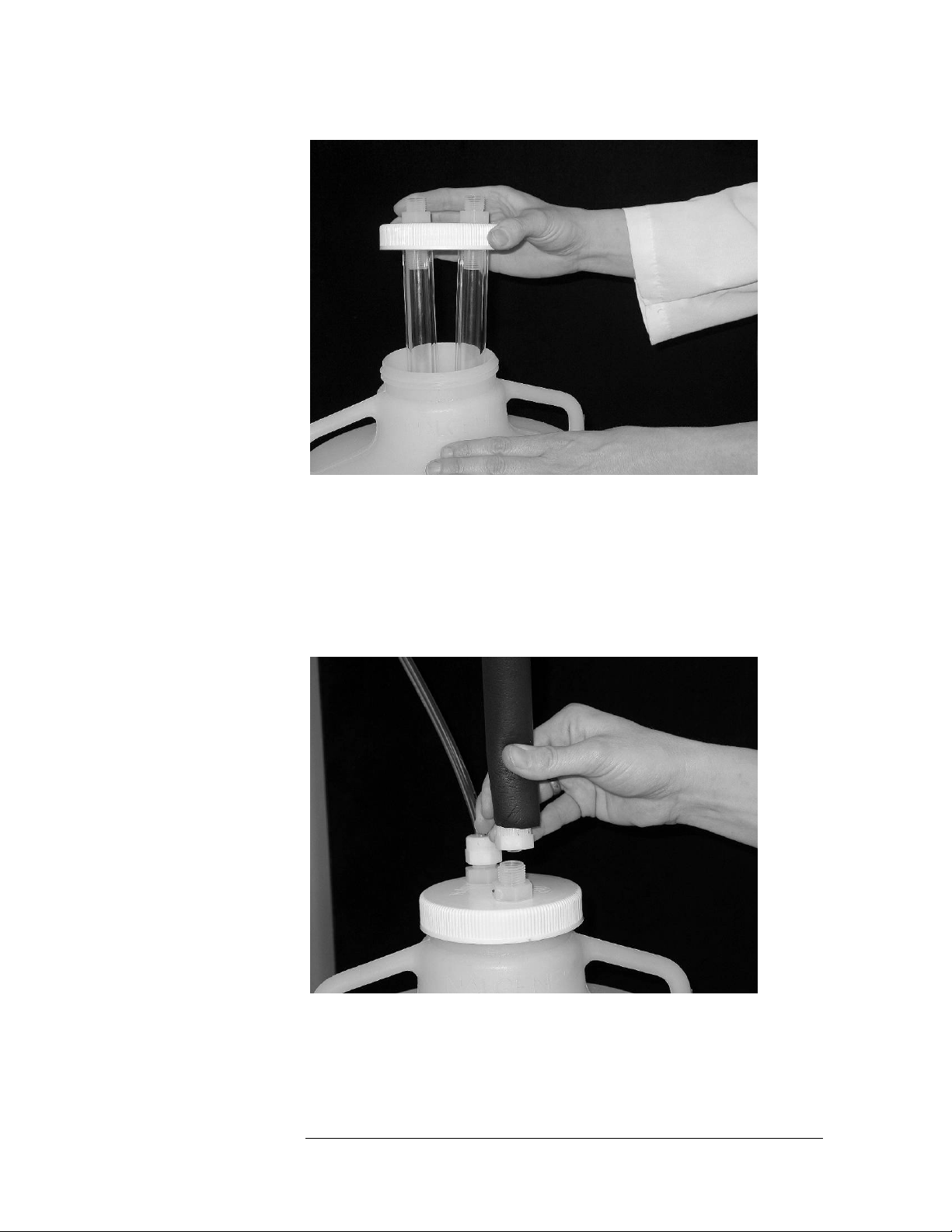

3Unscrew the lid of the 15 L trap bottle and carefully remove the packaging

around the two inner glass tubes. Replace the lid by screwing it down tight.

Then place the trap bottle on the floor or the bottom shelf of a laboratory cart.

See Figure 3-2.

CAUTION

Aridus II™ Operator’s Manual

Chapter 3: Installing the Aridus II™

15

Figure 3-2. Inner Glass Tubes – Trap Bottle.

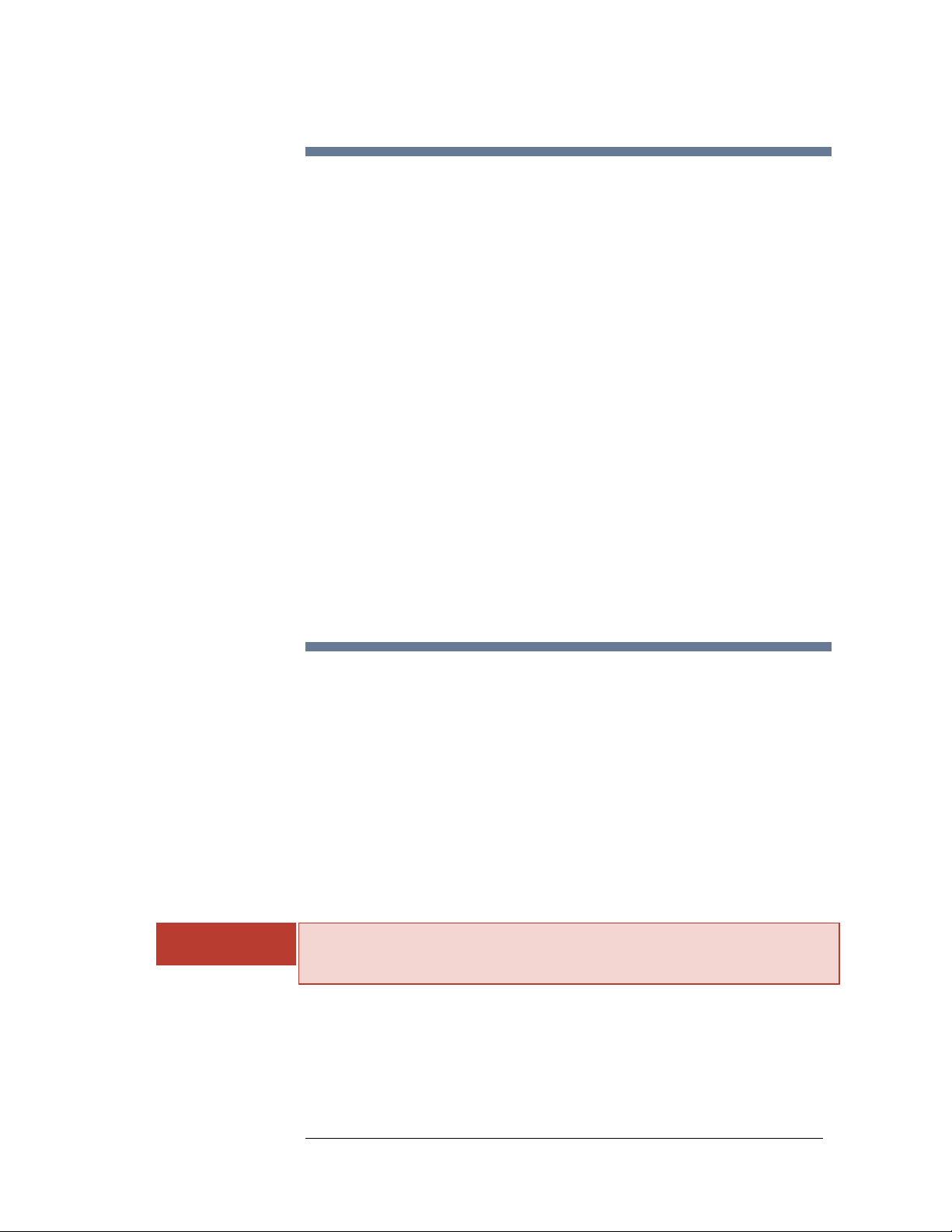

4Screw the ½"adaptor end of the insulated Teflon® line to the corresponding

½"threaded PFA fitting for the SWEEP GAS OUT port. Attach the ½" adaptor of

the other end of this line to the corresponding ½"threaded fitting on the lid of

the 15 L trap bottle. Then connect the trap bottle exhaust line to the remaining

port on the trap bottle lid. This line will carry solvent vapors to the vent.

Exhaust should be appropriately vented at atmospheric pressure. See Figures

3-3a and 3-3b.

Figure 3-3a. Attachment of Insulated Sweep Gas Out Line to Trap Bottle.

Aridus II™ Operator’s Manual

16

Figure 3-3b. Attachment of Sweep Gas Out Exhaust Line to Trap Bottle.

5A minimum argon and nitrogen supply of 350 kPa (50 psi, 3.5 bar) is required

to operate the Aridus II™.The argon may be teed in from the ICP-MS

instrument argon supply using the ¼"union tee. Connect the ¼"O.D. tubing,

labeled ARGON and NITROGEN, to the respective supply ports on the back of

the Aridus II™. The ¼"O.D. tubing for each is simply inserted into the

corresponding press fit connectors. Simply push the tubing into its respective

connector until it is fully secure. Valves are supplied to turn off these gas

supplies when the Aridus II™is not in use (See Figure 3-4).

Figure 3-4. Attachment of Argon and Nitrogen Supply Lines.

Aridus II™ Operator’s Manual

Chapter 3: Installing the Aridus II™

17

Connecting the Aridus II™Drain Tubing

There is one liquid drain line to install on the back of the Aridus II™unit. To set

up this drain line:

1Obtain the peri-pump tubing kit from the Aridus II™completion kit.

2One bag inside the peri-pump tubing kit contains pre-cut tubing attached to

gray-gray color-coded peristaltic tubing. Remove this tubing from the bag.

3One of the tubing assemblies contains a tan-colored PEEK nut. Install the

PEEK nut into the threaded port labeled DRAIN on the back of the Aridus II™

unit. Tighten the PEEK nut so it is finger-tight.

4Install the gray-gray color-coded peristaltic tubing (already attached to the

PEEK nut via a length of Teflon®tubing) to the peristaltic pump mounted on

the back of the Aridus II™unit. Note that liquid from the drain port should flow

to the bottom of the peristaltic pump and out the top to waste. This is shown

by the arrows next to the pump.

5The outlet of the drain line may be placed in a suitable waste receptacle (such

as a beaker).

6Close the shoe of the peristaltic pump and adjust the tension against the pump

rotor head with the spring-loaded screw.

Connecting the ASX-112FR Autosampler to the

Power Source

To connect the ASX-112FR autosampler to a power source:

A voltage-specific external desktop power supply is supplied with each ASX-

112FR autosampler.

To connect the autosampler to a power source, plug the external desktop

power supply cord into the power connector located on the back panel of the

autosampler. Then, plug the power supply’s power cord into the power supply

and into a 100–240-VAC ±10%, 50/60-Hz utility power outlet.

It is important to use the appropriate power cord for your country. Contact

CETAC Technologies if you need a different power cord.

FIRE AND SHOCK HAZARD

Use only the provided desktop power supply. The power supply must be

plugged into an outlet which has a protective ground connection.

WARNING

Aridus II™ Operator’s Manual

18

Connecting the ASX-112FR Autosampler to the Host

Computer

You cannot operate the ASX-112FR autosampler until you establish a

communications interface between the autosampler and the host computer. It

is through this interface that the host computer directs the operation of the

ASX-112FR autosampler. Before connecting the ICP-MS, ensure the correct dip

switches are set for the ICP-MS interface, as described in the ASX-112

Autosampler Operators’ Manual. The ASX-112FR autosampler supports the

following three communications protocols:

The serial (RS-232C) protocol is the standard configuration. There is an

RS-232C serial port on the ASX-112FR, and a serial interface kit is shipped

with the autosampler.

The USB protocol is an optional configuration.

The parallel (IEEE-488) protocol is less common than the serial

configuration or USB. An IEEE-488 interface kit is available as an optional

accessory to the ASX-112FR. (Refer to the ASX-112FR Autosampler

Operator’s Manual for further instructions.)

Connecting the Nebulizer to the Aridus II™

1Loosen the top thumb screw on the front of the Aridus II™and open the front

door by pulling downward. See Figure 3-5.

Figure 3-5. Front Door of Aridus II – Open.

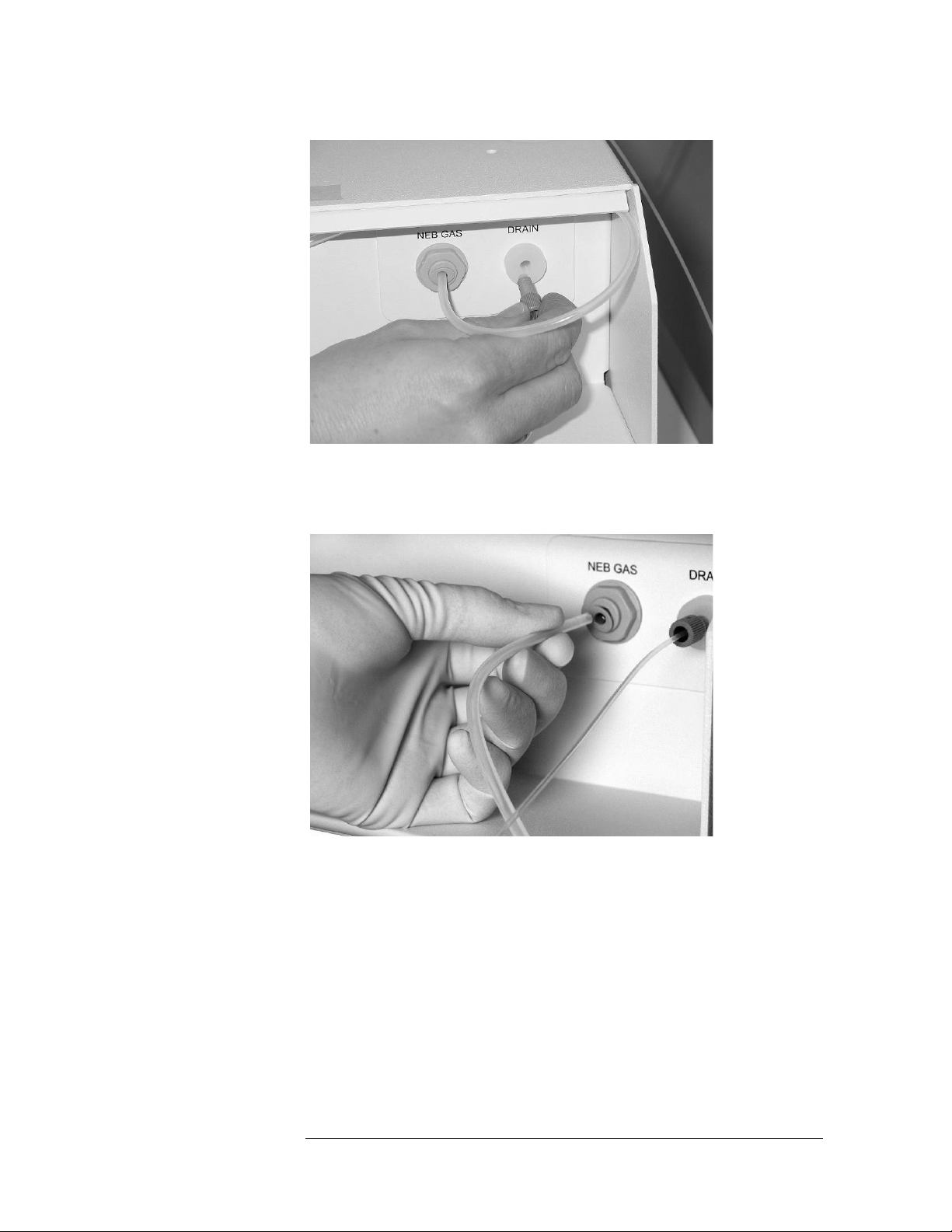

2Attach one end of the spray chamber drain line to the bottom of the spray

chamber. Attach the other end to the port labelled DRAIN. See Figure 3-6.

Aridus II™ Operator’s Manual

Chapter 3: Installing the Aridus II™

19

Figure 3-6. Attachment of Spray Chamber Tubing to Drain Port.

3Insert the nebulizer gas line (4mm O.D. tubing ) into the press-lock fitting

labelled NEB-GAS. See Figure 3-7.

Figure 3-7. Attachment of 4mm O.D. Tubing to NEB GAS Port.

Aridus II™ Operator’s Manual

20

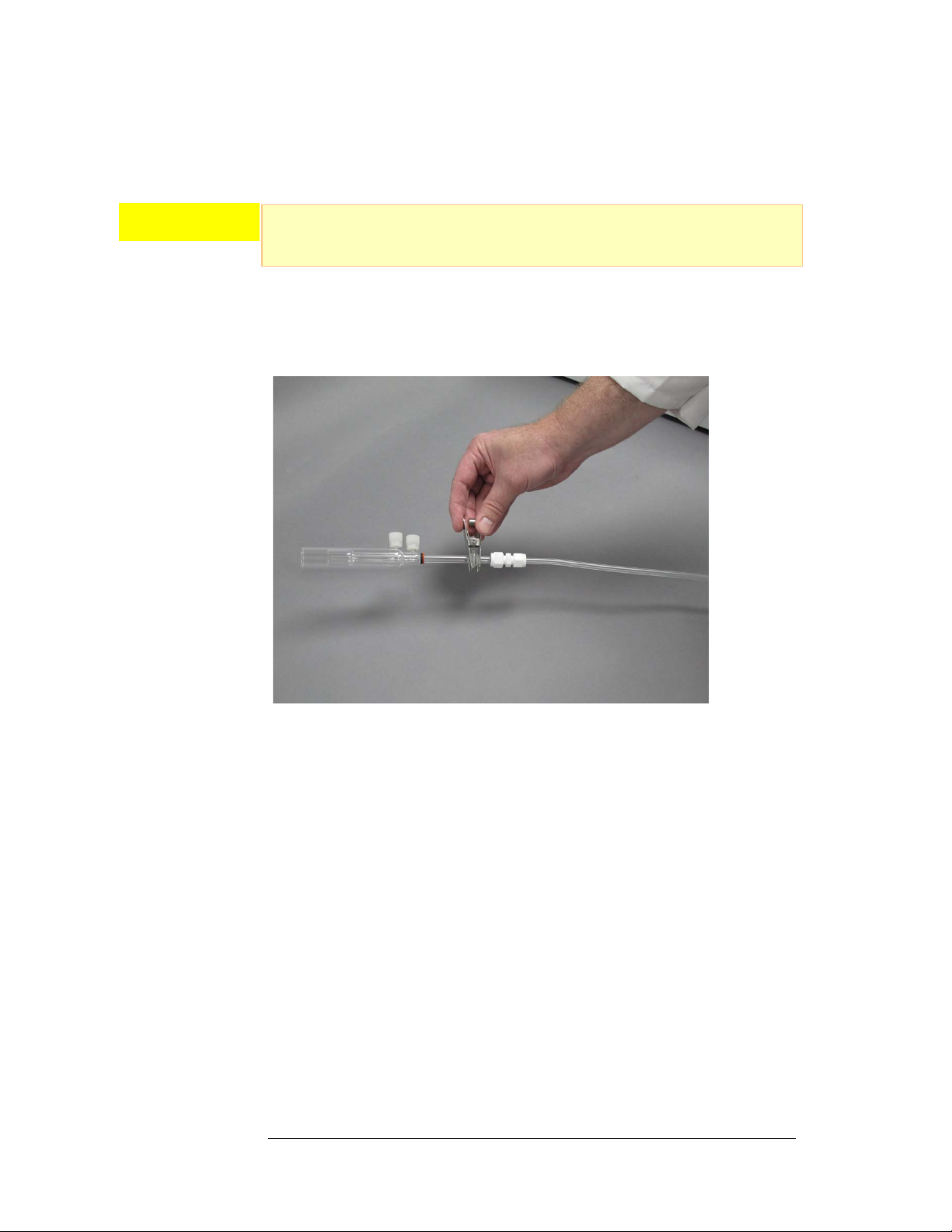

4Connect the other end of the nebulizer gas line to the side gas port of the

C-Flow PFA nebulizer. Insert the 4 mm tubing into the PFA nut and finger-

tighten the nut. See Figure 3-8.

Figure 3-8. Attachment of Nebulizer Gas Line to Gas Port of C-Flow PFA

Nebulizer.

5Insert the C-Flow PFA nebulizer into the spray chamber port. See Figure 3-9.

Ensure that the nebulizer is fully inserted through both o-rings.

Figure 3-9. Insertion of C-Flow PFA Nebulizer into Spray Chamber.

6Carefully set the C-Flow uptake line through the sample inlet notch in the

upper left front of the Aridus II™door. See Figure 3-10. Attach the sample probe

assembly to the ASX-112FR probe holder. (Refer to the ASX-112FR Operator’s

Manual for further instructions.)

Table of contents