CETEC Sparta 625A User manual

www.SteamPoweredRadio.Com

I

,,...

-----------------....."'II

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

TECHNICAL

MANUAL

Model

625A

FM

Transmitter

PROPRIETARY

NOTICE

Sparta Electronic

Corporation

proprietary

data

is

contained

herein.

Neither

this

document

nor

the

information

contained herein shall be disclosed

to

others

for

manufacturing

or

any

other

purpose except

as

authorized in

writing

by

Sparta Electronic Corporation.

C1974

098-7042 25.00

!5B!51

FLORIN·P

AKIN

ROAD

ACRAM

NTC,

CALIFORNIA

A OIVI

IO

N Of

CO

M

..

U

T[R

(

QUl,.M(NT

CORl'ORATION

aa

www.SteamPoweredRadio.Com

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

WARNING

THIS UNIT CONTAINS HIGH

VOLTAGE,

HIGH CURRENT

POWER

SUPPLIES.

Potentials up to 8000 volts* at lethal

current

levels are present and exposed to mainte-

nance personnel working with power

on

and

interlocks defeated.

When maintenance requires

working

with

power on and

unit

open, exercise extreme

caution. Stand on insulated surface. Work

with only one hand inside unit. Use only high

voltage insulated tools. Have second person

standing by at all times.

*

Depending upon

transmitter

being used.

~(p~Lf~

ELECTRONIC CORPORATION

www.SteamPoweredRadio.Com

I

·I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

Model

625A

TABLE

of

CONTENTS

Section

I

GENERAL

INFORMATION

.•....•.•..•••••••••••••••••••••••••••

l-1.

INTRODUCTION

....••.•••••.••••••..••.•••••••••••.••••

l-2.

GENERAL

DESCRIPTION

•••••••••••••••••••••••••••••.•••

l-2

.1.

Physical

Characteristics

•••••••.•.••..••••.••••••

1-2.2.

Functional

Characteristics

••••••••.••••••.••.••••

l-3.

MODULE EQUIPMENT

•••.••.•••••••••.••••••••••••••••••

II

INSTALLATION

..••••••••••••••.•••••••••.•••••.•••••••.••••••

III

IV

098-7042

2-1.

INSTALLATION PLANNING

••••..•••••••.••••••.••••••••••

2-1.

l.

Environmental

Requirements

..•...•.•••••.••••••••

2-1.

2.

Space

Requirements

••.••••••••..•••••••.•••.••••

2-1.3.

Power

Requirements

•.••••••••••..•••••••••••••••

2-1.

4.

Cooling

Requirements

..••••.•.••••••••••••••••••

2-2.

UNPACKING

AND

INSPECTION

•••.•..•••..•••••••.••..•••

2-3.

HIGH

VOLTAGE

POWER SUPPLY INSTALLATION

•••••••.•••••.

2-3.

l.

Model

602A

Driver

•....•••.•.••••••.••.••.••••••

2-4.

INPUT

AND

OUTPUT CONNECTIONS

..••••••••••••••••••••

2-4.

l.

RF

Input/Output

Connections

•••••••••••••••••••••

2-4.

2.

PA

Primary

Power

and

Grounding

•••••••••.••••••••

2-4

.3.

Driver

Primary

Power

••••••••••••.•••••••••••.•••

2-4

.4.

Exciter

Input

Signal

Connections

.••••••••••••••.••

2-4.

5.

Cabinet

Interconnections

••..••••••••••••••..••••

2-4.

6.

PA

Tube

Installation

...••••.•••••••••••••••...•.

2-5.

REMOTE

CONTROL CONNECTIONS

.•••..••.•••••••••.••••

2-5

.1.

Stereo/SCA

Remote

Control

••.•.•••••••••••••••••

2-5.

2.

PA

Remote

Control

•••.••••.•••••••••.••••••.•.•.

2-5.

3.

PA

Remote

Metering

.••••••••••••••••••••••••••••

2-5

.4.

Driver

Section

••••••.••••••••••••••••••••••••••

OPERATION

••.••••••••••.••.••••••.••••••.•••••••••••••••••

3-1.

PA

CONTROLS AND INDICATORS

•••••.•••••.•••••••••••••

3-1.1

Driver

Section

••.•.•••••••••••••••.•••••••••••••

3-2.

INITIAL TURN-ON PROCEDURES.

••.•••••••.•.••.•••.•••••

3

-2

•l ,

Preliminary

Che

ck

s

••••.••••••.••••••••••••••.••

3-2.

2.

Initial

Turn On

...•.••••.•••••.••••••••••••.•••.

3-3.

TUNING PROCEDURE

.••..••••••••••••••••••••••.•••••••

PRINCIPLES OF

OPERATION

•••••.•••••••••••••••••••••••••••••

4-1.

GENERAL

••..•••..•••••.••••.•••••.••••.••••••••••••.•

4-2,

CONTROL

AND

OVERLOAD

PROTECTION CIRCUITS ,

.•••.••••

4-3.

OVERLOAD

AND

AUTOMATIC

RECYCLE

CIRCUITS

••.•••.••••

4-4.

POWER SUPPLIES

••..••..•....•••••.••••••••••••••

,

••.•

4-5.

RF

AMPLIFIER CIRCUIT

ANALYSIS

..•••••••••.•••••••••••••

4-6.

METERING CIRCUIT

ANALYSIS

.•••••••••.•.••••••••••••••

4-6

.1.

PA

Meter

Circuits

••.•••••••••••••••••••••••••••

Front

Matter

l-1

l-1

l-1

1-2

l-2

l-4

2-l

2-1

2-l

2-l

2-1

2-1

2-1

2-4

2-4

2-4

2-4

2-6

2-6

2-6

2-6

2-7

2-7

2-7

2-7

2-7

2-7

3-l

3-l

3-l

3-5

3-5

3-6

3-7

4-l

4-l

4-1

4-2

4-3

4-4

4-4

4-4

www.SteamPoweredRadio.Com

Model

625A

Section

V

VI

Figure

2-1

2-2

2-3

3-1

3-2

3-3

3-4

3-5

3-6

3-7

3-8

3-9

3-10

3-11

5-1

5-2

5-3

5-4

098-7042

4-7.

4-6.2.

4-6.3.

Power

Output

and

VSWR

measurement.

•.•.•.•••••••

PA

Filament

and

Elapsed

Time

Meter

Circuit.

•••....

POWER CONTROL

•••••.•...••••.•.••••••••••.••••.••..•

MAINTENANCE

•••.....•••.•••••••••••••.•.•.•••••••••••••••

5-1.

PERIODIC INSPECTION AND MAINTENANCE

••.••.•.•••••••

5-1.1.

Air

Filters

•••.••.••.•••••••••.•••••••••••.••••

5-1.

2.

Anode

Coolers

•...•...•.•.•..••.•..••..••.••.••

5-2.

REMOVAL

AND REPIACEMENT

OF

AMPLIFIER

TUBES

•••••••.•

5-3.

OVERLOAD

REIAY

ADJUSTMENT

.•..••..•••.••••••...•••.•

5-3.

1.

Driver

Section

Overload

Relay

Adjustment

•..••••.•

5-3.

2.

PA

Grid

Overload

•..••..••.••••••••.•••.•••••••

5-3

.3.

PA

Plate

Overload

............................

.

5-3

.4.

Automatic

Power

Control

Adjustment

•••.••••.•••••

5-3.

5.

VSWR

Adjustment

•.•••••.••••••.•••.•••.•••.•••

REPIACEABLE

PARTS

6-1.

ORDERING INFORMATION

•••••.•••••••.•.•••••••••••••••

6-2.

PARTS

LOCATION

•.••..•..•••••••••••••••••••••••••••••

6-3.

TABLES

OF

REPLACEMENT

PARTS

••••••••••.••••••••••••••

LIST

of

ILLUSTRATIONS

Title

Model

625A

FM

Transmitter

-

Top

View -

Floor

Space

•••••••••••.

Model

625A

FM

Transmitter

Front

and

Side

View

.••••..•.•••..•••

H.

V.

Transformer

-

T-203

••••••.••••••••.•••••••••••••.•.•••

Front

View -

Component

Location

.••.•.•••.•••••••••••••••••••

Control

Chassis

-

Component

Location

•••..•..••••••.••••••••.

VSWR

Protedtion

Board,

Automatic

Power

Control

Board,

Motor

Driver

Board

...••••••••.••..••••.•••••••••.••••••••.••.•••

Base

Plate

Assembly

•••..•.•••..•••.•••.••.•.•••••••••••.•••

Resistor

Panel

.•••••••••••••••.••••••••••••••••••••••••.•••

Contactor

Panel

.••.•••••••••••••••••••.••••••••••••••.•••••

Transformer

Va

ult

••••••.••••••.••••..••••••.••.•••••.•..•••

Al-A2-A3

Mother

Board

....•...•.•••..•••••••.••••••••.•••••

Al Board -

VSWR

Protection

Circuit

••......•.••••••••.••••••••

A2

Board -

Automatic

Power

Control

.••••••.•••.•.•.•••.•••••••

A3

Motor

Driver

.••.•....•.....•.••.••...•...••..•••..•.••••

Schematic

Diagram

RF

and

Power

Supply

Section

(071-0263)

••••••

Schematic

Diagram

Control

Ladder

and

Overload

Sect

(071-0265)

••

Model

602A FM

Transmitter

used

as

625A

Driver

(071-0264)

••••••

Control

Ladder

(O

71-0191-02)

••••••••.•••••••••••••••••••••••

Front

Matter

Page

4-5

4-5

4-5

5-1

5-1

5-1

5-1

5-1

5-2

5-2

5-2

5-2

5-3

5-3

6-1

6-1

6-1

6-1

2-2

2-3

2-5

3-2

3-11

3-11

3-12

3-13

3-14

3-15

3-16

3-16

3-17

3-17

Attachment

Attachment

Attachment

Attachmert

iv

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

www.SteamPoweredRadio.Com

I

I

I

I

I

I

I

I

I.

I

I

I

I

I

I

I

I

I

I

Mo

del

6

25

A

TA

BL

E

1-1

1-2

3-1

3- 2

3- 3

6- 1

6- 2

098-7042

{

LIST

of

TAB

L

ES

Titl

e

Phys

ica

l

Charac

t

eristics

.•..

.

•..••.•••••••.••••••••••.••••••••

Fu

nc

tio

n

al

Characteristics

•.•.••••.••••.••••.••••••••••••••••••

O

perating

Controls

and

lndicators

-

PA

Secti

on

•...•..••••••••••••

Typi

ca

l

Operating

Voltages

and

Currents

•••••••••••••••••••••••••

Effi

ciency

Curve

••••.••••.•••••••••••••.•••.•••••••••••••••••

List

of

Manufactures

••.••••..••••.••.••.••••.•••.•••••••••••.•

Re

pl

aceable

Parts

List

••.•

•

•••••••••••••••••••••••••••••••••••

'

Front

Mat

ter

1-2

1- 3

3- 3

3-9

3-10

6- 2

6-

3

V

www.SteamPoweredRadio.Com

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

Model

625A

1-1

. INTRODUCTION

SECTION I

G

ENERAL

INFORMATION

Section

I

This

manual

contains

information

required

to

install,

operate,

and

maintain

the

SPARTA

Model

625A

FM

Transmitter.

Section

I

describes

the

transmitter

and

lists

its

specifications,

Section

II

provides

installation

instructions,

Section

III

contains

operating

procedures

and

Section

IV

describes

the

principle

of

operation.

Maintenance

procedures

and

troubleshooting

diagrams

are

contained

in

Section

V,

and

replaceaole

parts

are

identified

and

listed

in

Section

VI

. A

complete

operating

and

servicing

manual

covering

the

Model

680

FM

Exciter

and

Model

602

FM

transmitter

is

provided

separately

.

1-2.

GENERAL

DESCRIPTION

The

Model

625A

FM

Transmitter

(Figure

2-2)

provides

an

output

of

25

kilowatts

in

the

frequency

range

from 88

to

108

MHz,

and

is

type-accepted

by

the

Federal

Communications

Commission

under

Part

73,

Broadcast

Services.

As

shown

in

figure

1-1,

the

transmitter

consists

basically

of

three

sections

. The

left-hand

section

contains

the

FM

exciter

and

driver,

together

with

associated

metering,

control

and

power

circuitry.

This

section

is

denominated

DRIVER

throughout

this

instruction

book

and

consists

of

a

complete

and

independent

one

2.5

K:N

transmitter,

model

602A .

The

second

section

contains

the

power

amplifier

(PA)

and

its

associated

metering,

control,

and

high

voltage

filtering

components

. The

right-hand

section

is

the

transformer

vault

and

it

contains

the

plate

transformer,

H .

V.

rectifiers

and

contactors

plate.

The

PA

cavity

is

cooled

by

a

high-speed

blowers

and

each

of

the

two

cabinet

sections

are

scavenged

of

incidental

warm

air

by

ventilating

fans

. The

circuit

design

of

the

blower

furnishing

air

to

the

PA

cavity

is

such

that

it

will

continue

to

run

for a

preset

interval

after

the

transmitter

is

shut

down

to

remove

residual

heat.

The

Model

625A

design

includes

such

features

as

automatic

power

control

and

automatic

overload

recycling.

Once

the

transmitter

has

been

tuned

to

its

authorized

rated

power

output,

the

automatic

power

control

circuit

maintains

this

RF

output

level

regardless

of

mains

power

fluctuations.

The

overload

recycle

circuit

automatically

restores

the

transmitter

to

normal

operation

following

a

momentary

current

overload

in

the

monitored

circuits

.

Consecutive

recycling

is

limited

to

three

times

within

30

seconds

following

the

operation

of

any

overload

relay.

If

the

overload

exists

after

a maximum

of

3

recycles,

the

transmitter

high-voltage

circuits

will

remain

off

until

the

overload

is

reset

manually.

Tally

lights

mounted

on

the

driver

and

PA

control

panels

are

triggered

by

their

associated

overload

relay

.

These

lamps

will

remain

lighted

after

a

momentary

overload

to

identify

the

circuit

where

the

overload

occurred.

Only

three

transmitti

ng

tubes

are

used

in

the

high-level

stages:

a

4X150A

tetrode

(driver),

a 5CX1500A

pentode

(driver) ,

an

d a 3CX15000A7

triode

(PA).

RF

excitation

is

provided

by

the

Model

680

FM

Exciter,

which

is

an

all-solid-state

unit

that

provides

monaural,

stereophonic

and

Subsidiary

Communications

A

uthorization

(SCA)

modes

of

operation

in

accordance

with

FCC

and

international

standards.

The M

odulation

m

ethod

is

"direct

FM"

with

no

mixers

or

multipliers

after

the

modulated

oscillator

.

Connections

are

provided

to

allow

remote

transmitter

mas

ter

start,

plate

power

on-off,

and

power

trim.

Provisions

are

also

included

for

remote

metering

of

PA

pla

te

voltage,

plate

current

and

power

output.

098-7042

1

-1

www.SteamPoweredRadio.Com

Mcx:lel 625A

Section

I

1-2

.1.

Physical

Characteristics

Physical

characteristics

of

the

Mcx:lel 625A

excluding

the

Model

680

FM

Exciter,

are

given

in

table

1-1.

Physical

characteristics

of

the

Mcx:lel

680

and

Mcx:lel 602A

are

given

in

paragraph

1-2

.1

of

its

individual

operating

and

servicing

manual.

Table

1-1.

Physical

Characteristics

Cabinet

Dimensions:

Transformer

Vault:

Weight:

Cabinet

Style:

Input/Output

Connections

a.

RF

Output:

b.

Audio

Inputs:

Cooling

Provisions

a.

Driver

Cavity:

b.

PA

Cavity:

c.

Cabinet:

Ambient

Temperature:

Altitude:

Humidity:

1-2.

2.

Functional

Characteristics

75

inches

high,

68

inches

wide,

24

inches

deep

36

inches

high,

34

inches

wide,

24

inches

deep

2750

pounds

Two

enclosed

steel

cabinets;

access

provided

through

hinged

front

panels

and

rear

cabinet

doors.

One

transformer

vault.

3-V8

inch

coaxial

line

flange

Barrier

strip

One

1-phase

530 cfm

blower

Two

1-phase

530

cfm

blower

One

1-phase

750 cfm

fan

(PA

section)

One

1-phase

750 cfm

fan

(Transformer

vault)

To

50°

C,

(122°F);

continuous

duty

at

rated

power

output

To

7,500

feet;

continuous

duty

at

rated

power

output

0

to

95%

Functional

characteristics

of

the

Model

625A

excluding

the

Model

680

FM

Exciter,

are

given

in

table

1-2.

Functional

characteristics

of

the

Model

680

are

given

in

paragraph

1-2.

2

of

its

individual

operating

and

servicing

manual.

098-7042

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

www.SteamPoweredRadio.Com

I

·I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

Model

625A

Section

I

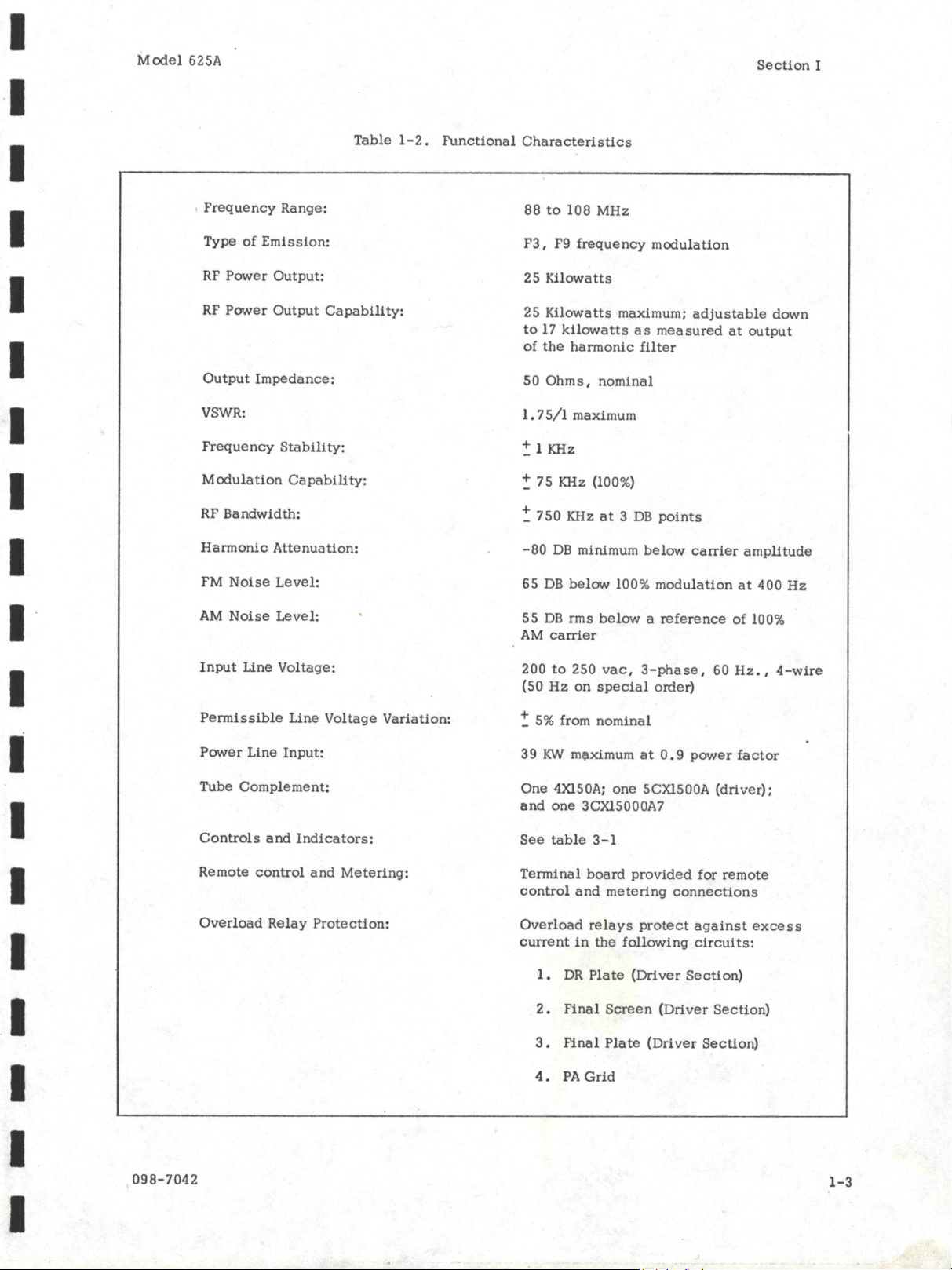

Table

1-2.

Functional

Characteristics

,

Frequency

Range:

Type

of

Emission:

RF

Power

Output:

RF

Power

Output

Capability:

Output

Impedance:

VSWR:

Frequency

Stability:

Modulation

Capability:

RF

Bandwidth:

Harmonic

Attenuation:

FM

Noise

Level:

AM

Noise

Level:

Input

Line

Voltage:

Permissible

Line Voltage

Variation:

Power

Line

Input:

Tube

Complement:

Controls

and

Indicators:

Remote

control

and

Metering:

Overload

Relay

Protection:

098-7042

88

to

108

MHz

F3,

F9

frequency

modulation

25

Kilowatts

25

Kilowatts

maximum;

adjustable

down

to

17

kilowatts

as

measured

at

output

of

the

harmonic

filter

50

Ohms,

nominal

I.

7

5/1

maximum

~

1

KHz

~

7

S

KHz

(100%)

~

750

KHz

at

3

DB

points

-80

DB

minimum

below

carrier

amplitude

65

DB

below

100%

modulation

at

400

Hz

55

DB

rms

below

a

reference

of

100%

AM

carrier

200

to

250

vac,

3-pha

se,

60

Hz.

,

4-wire

(SO

Hz

on

special

order)

~

5%

from

nominal

39

KY-I

ml;lximum

at

0.

9

power

factor

One

4Xl50A;

one

SCXlS00A

(driver);

and

one

3CX1S000A7

See

table

3-1

Terminal

board

provided

for

remote

control

and

metering

connections

Overload

relays

protect

against

excess

current

in

the

following

circuits:

1.

DR

Plate

(Driver

Section)

2.

Final

Screen

(Driver

Section)

3.

Final

Plate

(Driver

Section)

4.

PA

Grid

1-3

www.SteamPoweredRadio.Com

Model

625A

Section

I

Table

1-2.

Functional

Characteristics

(Continued)

Overload

Indicators:

5.

PA

Plate

6.

VSWR

One

overload

indicator

and

six

overload

tally

lights.

(See

table

3-1)

Other

Protective

Devices:

Eight

Panel-mounted

fuses

and

two

internal

circuit

breakers.

Two

additional

fuses

mounted

on

rear

panel

of

exciter.

1-3.

MODULE EQUIPMENT

The

Model

680

FM

Exciter

is

standard

equipment

and

provides

the

capability

of

monaural

FM

operation.

The

following

units,

which

are

available

from

SPARTA

ELECTRONIC CORPORATION

provide

the

Model

625A

with

the

capability

of

stereophonic

and

SCA

operation:

a.

Stereo

Generator

-

Model

682

b.

SCA

Generator

-

Model

683 (41

or

67

KHz)

When

operating

in

the

monaural

mode,

the

41

KHz

and

67

KHz

SCA

units

may

be

used

individually

or

simultaneously.

When

operating

in

the

stereophonic

mode,

the

41

KHz

generator

must

be

muted.

However,

the

67

KHz

generator

can

be

used

in

combination

with

the

stereo

generator

in

any

mode

of

operation

without

program

interruption

if

an

optional

5 KHz

filter

kit

is

installed.

The 5 KHz

filter

kit

(091-5971-01)

may

be

specified

for

initial

installation

by

SPARTA

ELECTRONIC

CORPORATION

or

it

can

be

added

to

the

SCA

module

at

a

later

date.

The

kit

consists

of

a

low-pass

filter

which

limits

the

SCA

input

band-width

to

5 KHz.

In

addition

to

the

input

filter,

the

sub-carrier

deviation

should

be

limited

to

6%

to

avoid

interference

with

the

stereo

channel.

098-7042

1-4

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

www.SteamPoweredRadio.Com

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

Model

625A

SECTION

II

INSTALLATION

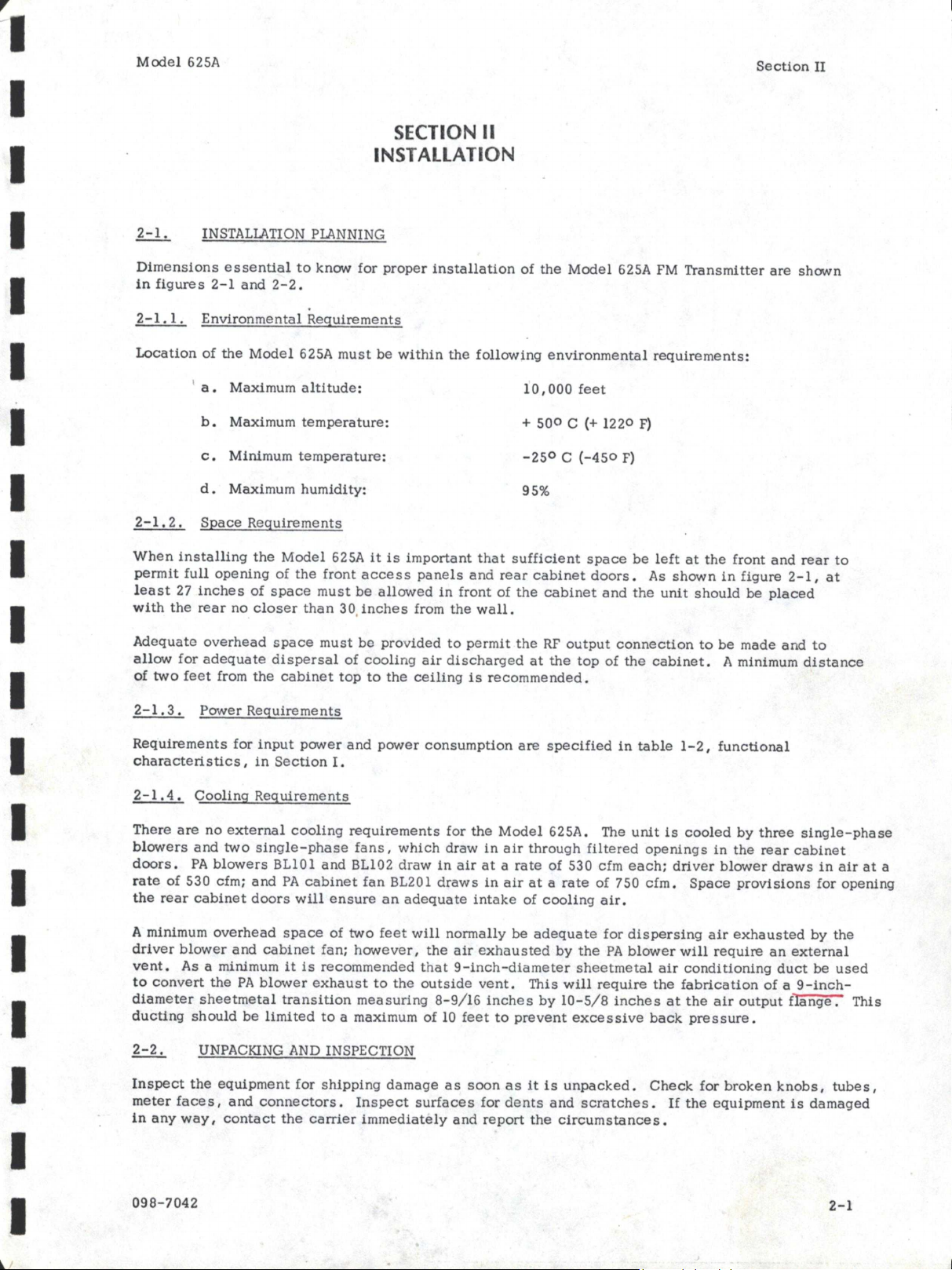

2-1.

INSTALI.ATION PI.ANNING

Section

II

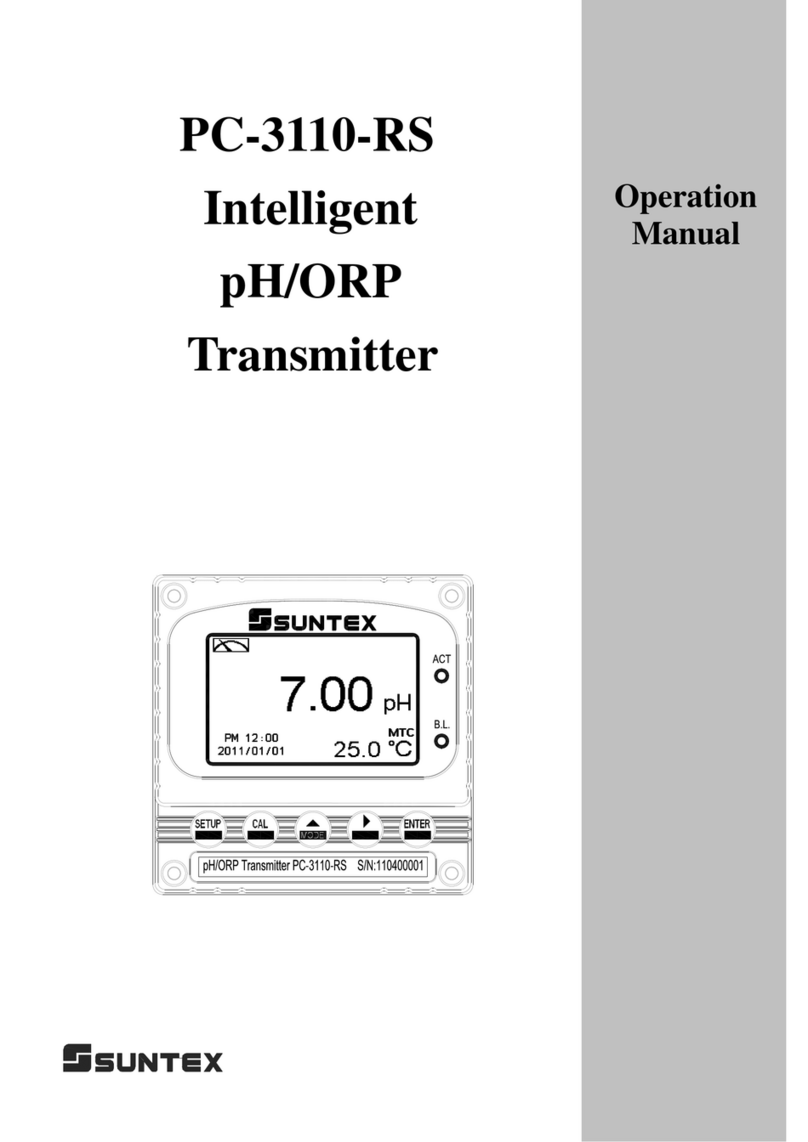

Dimensions

essential

to

know

for

proper

installation

of

the

Model

625A FM

Transmitter

are

shown

in

figures

2-1

and

2-2.

2-1.1.

Environmental

Requirements

Location

of

the

Model

625A

must

be

within

the

following

environmental

requirements:

'

a.

Maximum

altitude:

10,000

feet

b.

Maximum

temperature:

+

500

C (+

1220

F)

c.

Minimum

temperature:

-250

C

(-450

F)

d.

Maximum

humidity:

95%

2-1.

2.

SEace

Requirements

When

installing

the

Model

625A

it

is

important

that

sufficient

space

be

left

at

the

front

and

rear

to

permit

full

opening

of

the

front

access

panels

and

rear

cabinet

doors.

As

shown

in

figure

2-1,

at

least

27

inches

of

space

must

be

allowed

in

front

of

the

cabinet

and

the

unit

should

be

placed

with

the

rear

no

closer

than

30,

inches

from

the

wall.

Adequate

overhead

space

must

be

pro

v

ided

to

permit

the

RF

output

connection

to

be

made

and

to

allow

for

adequate

dispersal

of

cooling

air

discharg

ed

at

the

top

of

the

cabinet.

A minimum

distance

of

two

feet

from

the

cabinet

top

to

the

ceiling

is

recommended.

2-1.

3.

Power

Requir

e

ments

Requirements

for

input

power

and

power

consumption

are

specified

in

table

1-2,

functional

characteristics,

in

Section

I.

2-1.4.

Cooling

Requirements

There

are

no

external

cooling

requirements

for

the

Model

625A. The

unit

is

cooled

by

three

single-phase

blowers

and

two

single-phase

fans,

which

draw

in

air

through

filt

e

red

openings

in

the

rear

cabinet

doors.

PA

blowers

BLl0l

and

B1102

draw

in

air

at

a

rate

of

530 cfm

each;

driver

blower

draws

in

air

at

a

rate

of

530 cfm;

and

PA

cabinet

fan

B1201

draws

in

air

at

a

rate

of

750

cfm.

Space

provisions

for

opening

the

rear

cabinet

doors

will

ensure

an

adequate

intake

of

cooling

air.

A

minimum

overhead

space

of

two

feet

will

normally

be

adequate

for

dispersing

air

exhausted

by

the

driver

blower

and

cabinet

fan;

however,

the

air

exhausted

by

the

PA

blower

will

require

an

external

vent.

As a minimum

it

is

recommended

that

9-inch-diameter

sheetmetal

air

conditioning

duct

be

used

to

convert

the

PA

blower

exhaust

to

the

outside

vent.

This

will

require

the

fabrication

of

a

9-inch-

diameter

sheetmetal

transition

measuring

8-9/16

inches

by

10-5/8

inches

at

the

air

output

flange.

This

ducting

should

be

limited

to

a maximum

of

10

feet

to

prevent

excessive

back

pressure.

UNPACKING

AND

INSPECTION

Inspect

the

equipment

for

shipping

damage

as

soon

as

it

is

unpacked.

Check

for

broken

knobs,

tubes,

meter

faces,

and

connectors.

Inspect

surfaces

for

dents

and

scratches.

If

the

equipment

is

damaged

in

any

way,

contact

the

carrier

immediately

and

report

the

circumstances.

098-7042

2-1

www.SteamPoweredRadio.Com

N

I

N

0

U)

(X)

I

'3

0

,::,.

N

~

>-3o

0 a.

'C

ro

c::::-

-

a,

-.:I

ro

N

....

~

(/1

IQ

>

• I -.:I

~;:'.!~

.,_ 0

>-3

0

.,

.,

QI

Cl)

::,

'C

(I)

QI 3

(')

-

ro

,..

m

.,

.

I;

----

.....

',

',

''

zsf'

\ \\\

\

\

I

I

I

I

l

I

I

IX·UJI

C/IUCTION4L

CO(JPL£R

I /

-

✓

Z03--

(REV£RS£)

/

/

J

/OZ.

RF.

OCliPUT

✓

IOI

,LT;:7

Ll:J

I r

l---e4

l='-t-

.JZOl(t=ORW,MI))

L1·

IIMMONIC

FIL

TE~

·

JZ04

(FORWI/RI>)

./203

(R£V£RSG)

12"

I''

7'1a

--

..

:--,-

4"

S"

Cl)

ro

(')

...

-

0

::,

.....

.....

sr

I.

--1

sf"

1--

. I

IJRIVl:R

J'GCTIOAI I I

~

l?.4, -SEt.r/011/ L I I

POWE~

.J'dPl'tY

SEcr101v

I \

z3"

-----

I 1 ,oJ

/ \

FRONT

I \

I \

31" I I / \

I \

/

,,

I _J

'="

/ '

;:,,.

/ ' &

/ '

ro

/ '

.,_

, '

- - .

a,

- - -

68"

- - - - · • • J -1"

~

816

11

--

--

---

1

--

-- -

--

I- ---- - -

www.SteamPoweredRadio.Com

Model

625A

Section

II

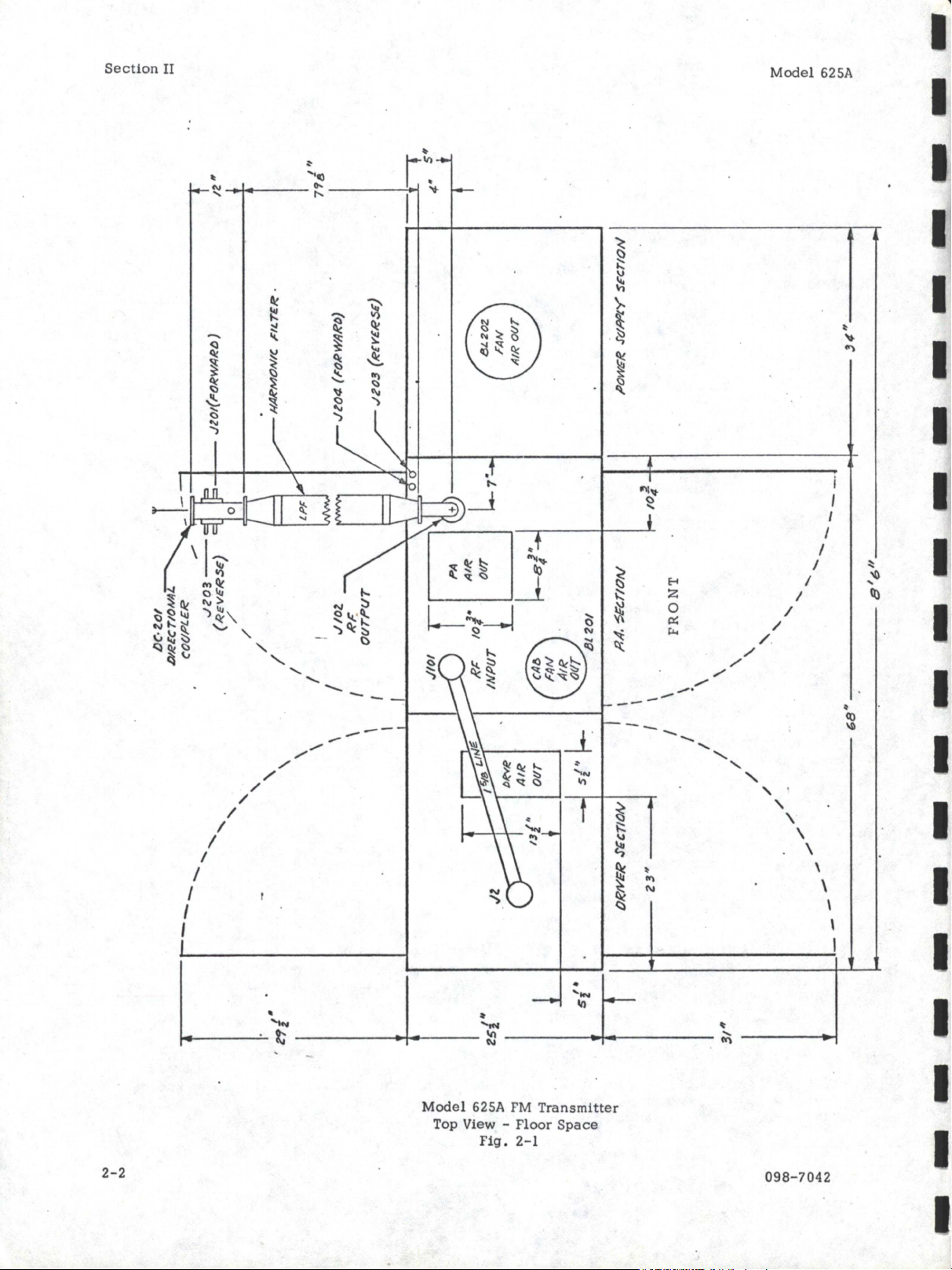

HIGH-VOLTAGE

POWER

SUPPLY

INSTALLATION

The

high-voltage

power

supply,

transformer

and

filter

choke

due

to

its

heavy

weight,

is

crated

separately

for

shipment.

After

the

transmitter

enclosure

has

been

positioned

to

its

operational

location,

install

the

high-voltage

power

supply

as

follows:

a.

If

packaged,

uncrate

high-voltage

power

supply

and

remove

wooden

pallets.

b.

At

rear

of

transmitter,

remove

kick

plate

at

bottom

of

PA

section.

c.

Install

high-voltage

power

supply

filter

choke

1201

into

PA

cabinet

with

terminals

facing

the

rear.

(Figure

3-4)

.

d.

Install

HV

plate

transformer

with

terminals

facing

front

of

transformer

vault

(Figure

3-4).

Make

filter

choke

connections

following

numbered

wires.

e.

Make

connections

of

high-voltage

power

supply

as

follows:

(1)

Connect

the

one

14

AWG

gauge

HV

wire

to

B+

terminal

(wire

and

terminal

#1).

(2)

Connect

the

one

14

AWG

wire

to

B-

terminal

(wire

and

terminal

#2).

f.

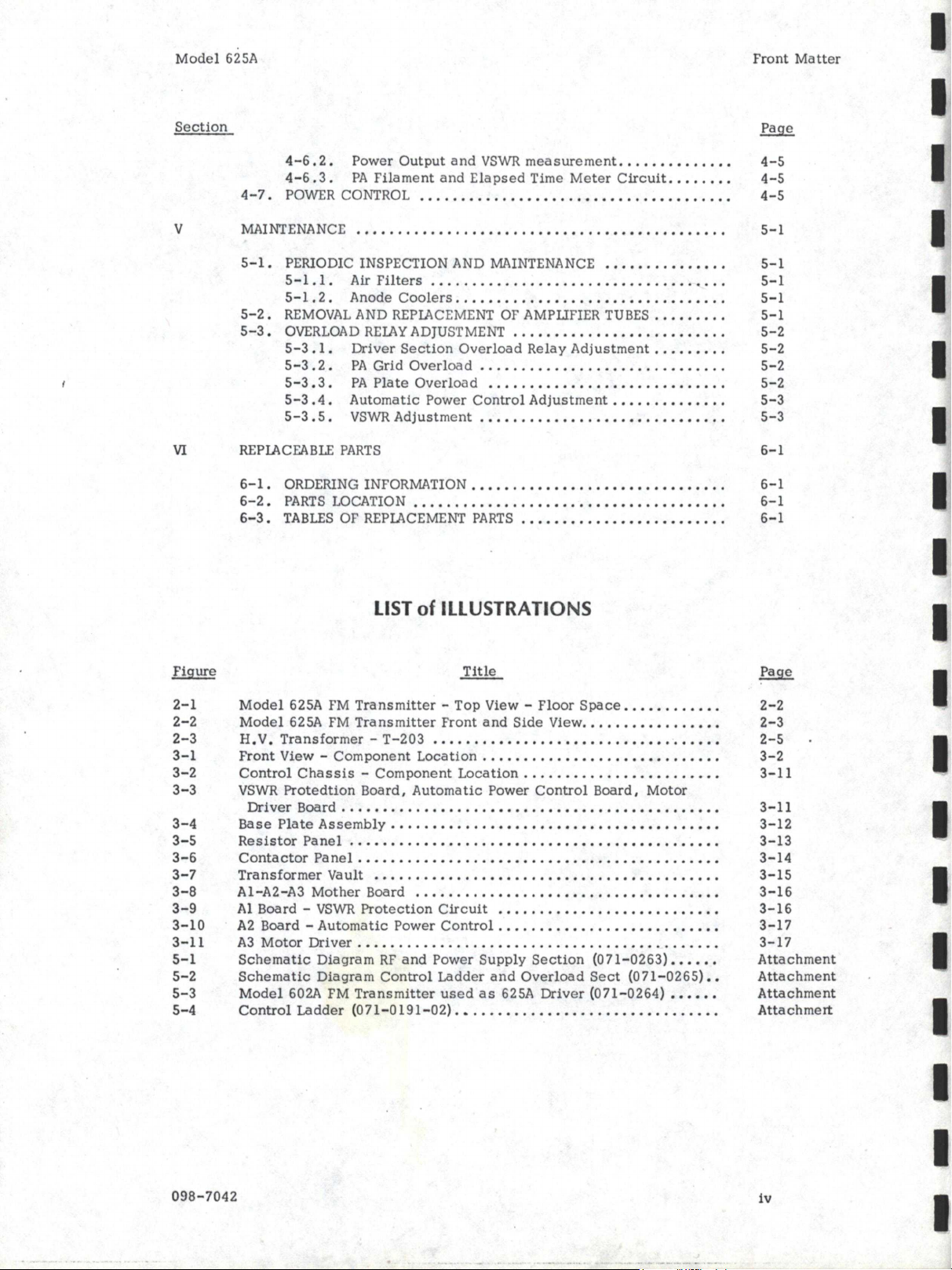

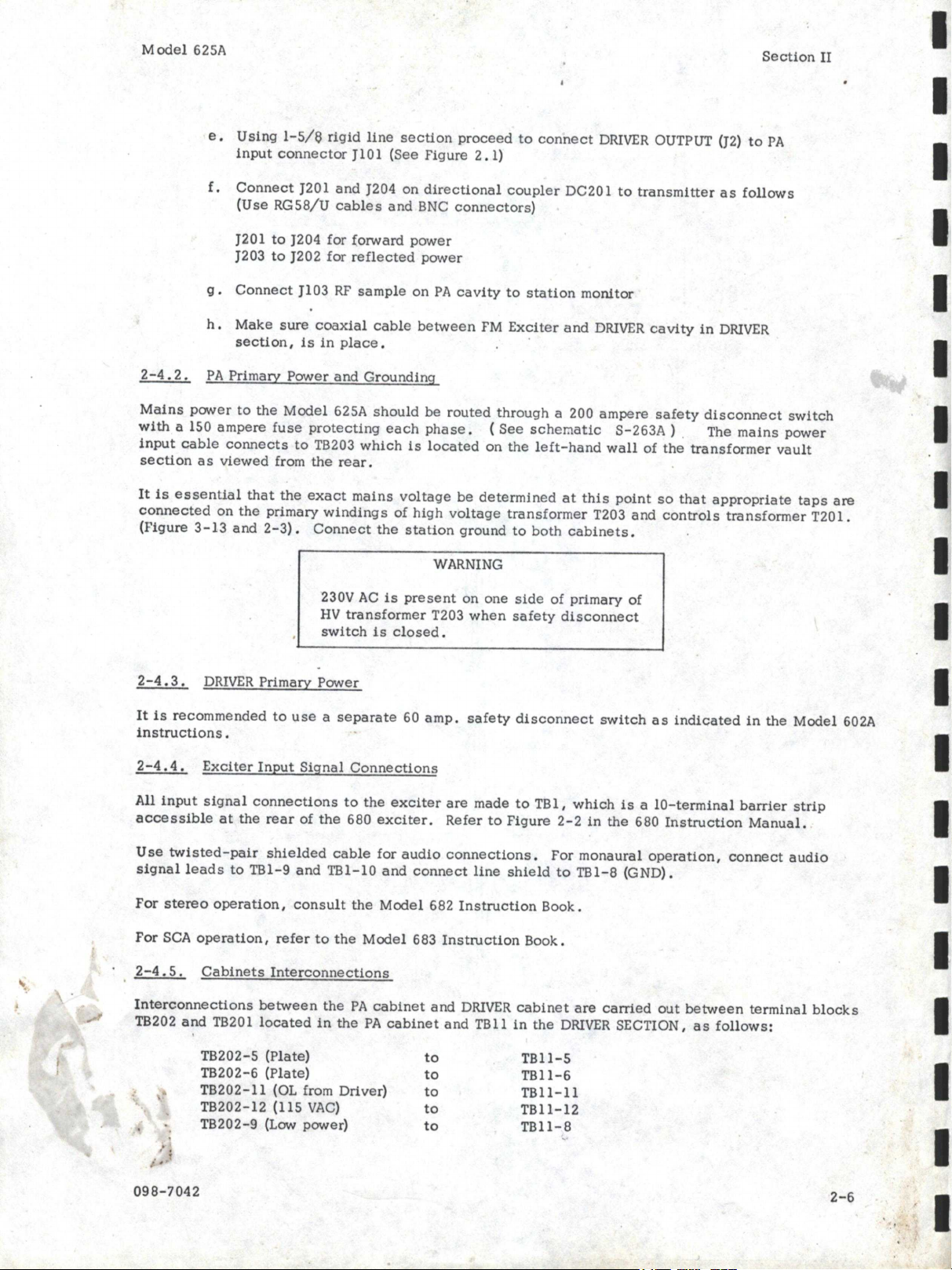

Refer

to

figure

2-3

and

schematic

diagram

S263A

and

connect

primary

leads

of

high-voltage

transformer

to

contactors

K20

l-K202

and

secondary

leads

to

H.

V.

rectifiers

CR20l

thru

CR206.

2-3.

l.

Refer

to

Model

602A

Instruction

Book

for

installation

details.

INPUT

AND

OUTPUT CONNECTIONS

With

the

exception

of

the

RF

output

and

the

power

monitor

inputs

from

the

directional

coupler,

all

inputs

and

outputs

of

the

Model

625A

are

routed

into

the

unit

through

the

two

3-inch

diameter

openings,

one

to

the

right

and

one

to

the

left,

on

the

base

of

the

cabinet.

The

RF

output

termination

is

a

3-1/8

inch

coaxial

line

flange

and

the

power

monitor

inputs

from

the

directional

coupler

are

BNC

receptables;

these

connectors

are

located

on

top

of

the

cabinet.

(See

Figure

2-1).

2-4

.1.

RF

Input/Output

Connections

The

RF

input

and

output

connections

of

the

Model

625A

are

made

as

follows

(See

Figure

2-1):

098-7042

CAUTION

Do

not

allow

the

combined

weight

supported

by

the

RF

output

termination

to

exceed

30

pounds.

Use

an

overhead

cable

hanger,

if

necessary

to

absorb

most

of

the

weight.

a.

Connect

and

bolt

in

place

a

90-degree,

3-1/8

inch

coaxial

coupling

to

the

RF

output

termination

on

top

of

the

cabinet

(Jl02).

b.

Connect

and

bolt

in

place

low-pass

filter

LPF

to

90-degree

coaxial

coupling.

c.

Connect

and

bolt

in

place

directional

coupler

DC20l

to

low

pass

filter

LPF.

d.

Using

3-1/8

inch

coaxial

cable,

connect

RF

output

of

directional

coupler

DC201

to

transmitting

antenna.

CAUTION

Ensure

that

the

antenna

has

a

VSWR

of

l.

7:1

or

less

otherwise

the

high

reflected

power

could

damage

the

R.

F.

cavity.

I

2-4

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

www.SteamPoweredRadio.Com

I

Model

625A

I

I

N

0

-

I I

I

I. \

~

+JO

0

-10

0 0 0

I

I

I

I

I

I

I

I

I

I

I

I

098-7042

I

.3300V

.33

O<JV

0 0

,

S£COND,4RY

'

208

230

:

00

0

-JO

208

0 0 I 0 0 0 0

I

I

230

208

-10

0

+10

Z3o

'208

-10

0 .

.,.,o

230

208

-10

0

+IO

N

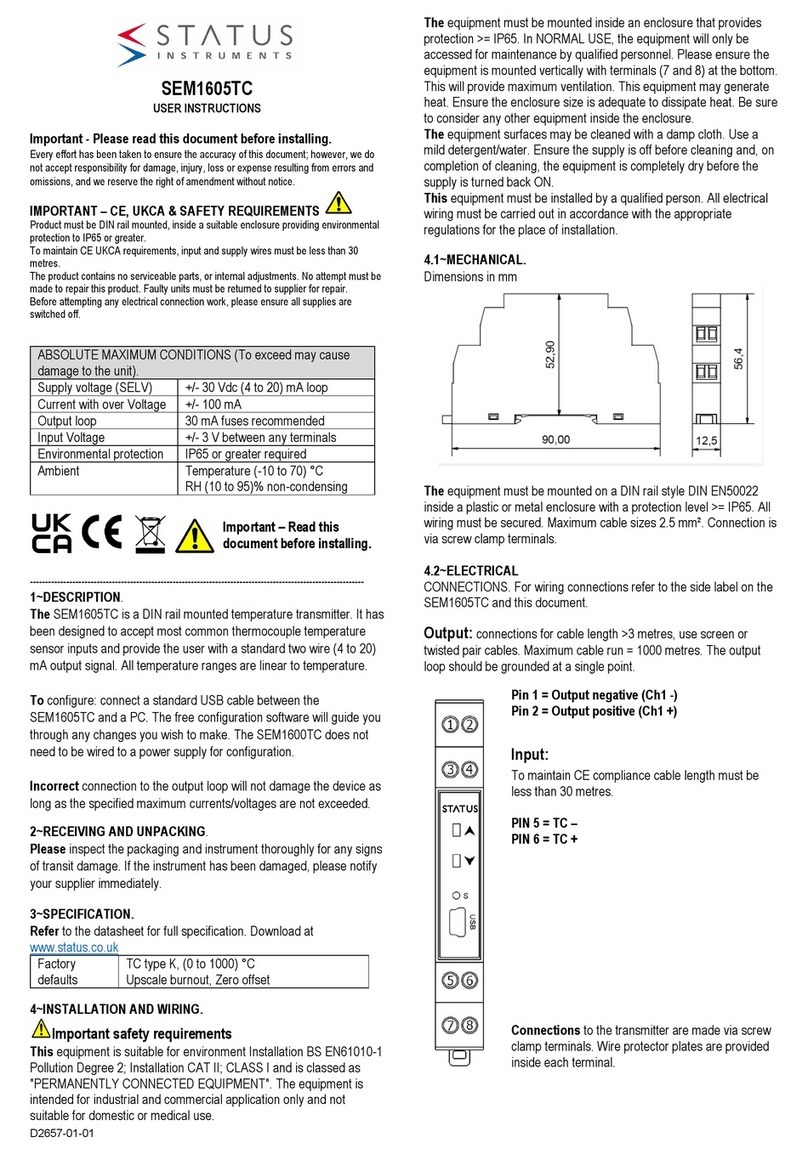

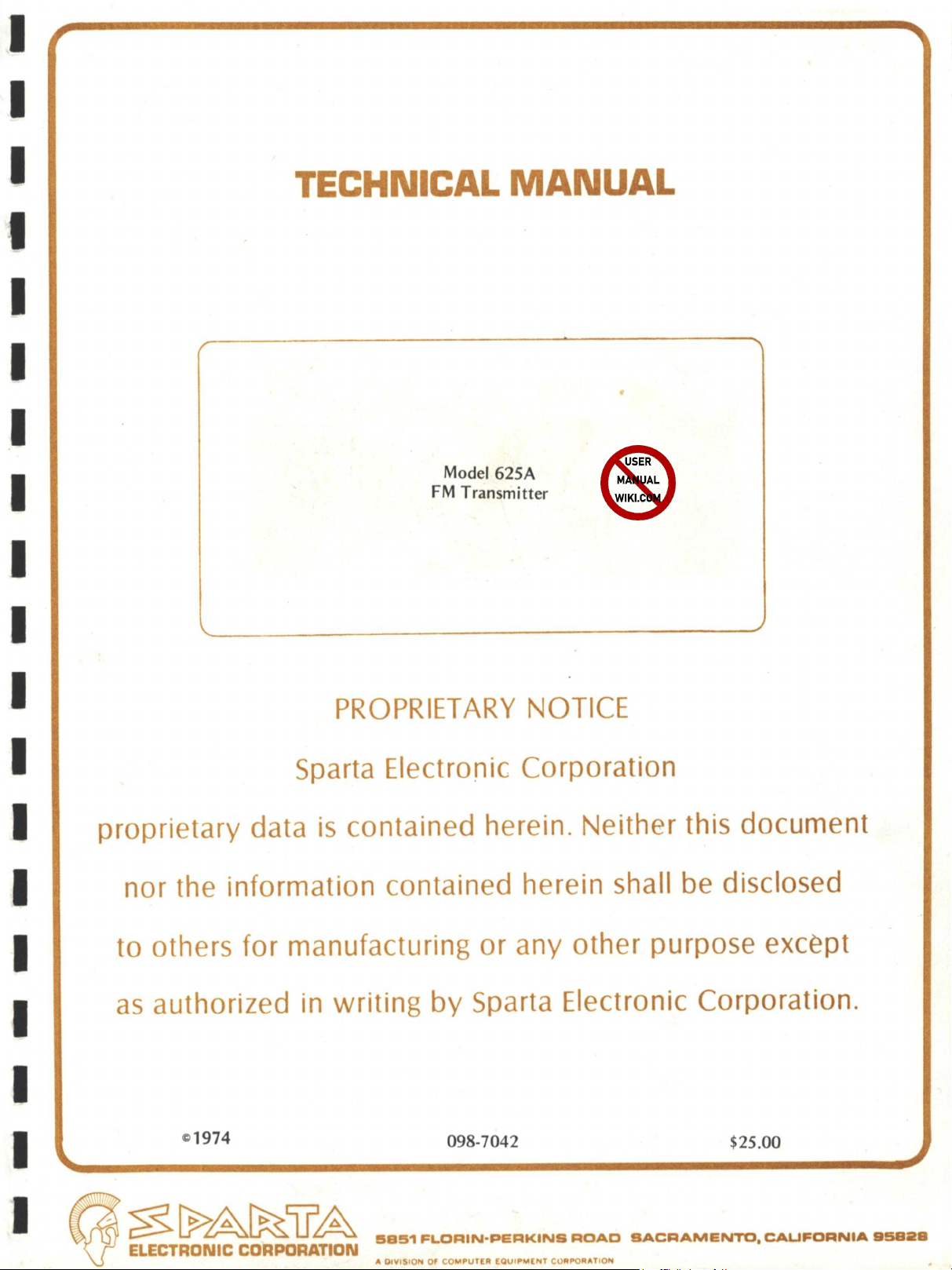

H.

V.

Transformer

-

T-203

Figure

2-3

Section

II

3300V

0

-\

I

J

230

I

+I0

0

-10

208

Z30

-

0 I 0 0 0 0 0

I

I

3300V

l·N

3:JOOV'l-N

3300Yl·N

2-5

www.SteamPoweredRadio.Com

Model

625A

Section

II

e.

Using

1-5/e

rigid

line

section

proceed

to

connect

DRIVER

OUTPUT (J2)

to

PA

input

connector

Jl0l

(See

Figure

2

.1)

f.

Connect

J201

and

J204 on

directional

coupler

DC201

to

transmitter

as

follows

(Use

RG58/U

cables

and

BNC

connectors)

J201

to

J204 for

!orward

power

J203

to

J202

for

reflected

power

g.

Connect

Jl03

RF

sample

on

PA

cavity

to

station

monitor

h.

Make

sure

coaxial

cable

between

FM

Exciter

and

DRIVER

cavity

in

DRIVER

section,

is

in

place.

2-4.

2.

PA

Primary

Power

and

Grounding

Mains

power

to

the

Model

625A

should

be routed

through

a 200

ampere

safety

disconnect

switch

with

a 150

ampere

fuse

protecting

each

phase.

(

See

scher:iatic

S-263A ) . The

mains

power

input

cable

connects

to

TB203

which

is

located

on

the

left-hand

wall

of

the

transformer

vault

section

as

viewed

from

the

rear.

It

is

essential

that

the

exact

mains

voltage

be

determined

at

this

point

so

that

appropriate

taps

are

connected

on

the

primary

windings

of

high

voltage

transformer

T203

and

controls

transformer

T201.

(Figure

3-13

and

2-3).

Connect

the

station

ground

to

both

cabinets.

WARNING

230V

AC

is

present

on

one

side

of

primary

of

HV

transformer

T203

when

safety

disconnect

switch

is

closed.

2-4.

3.

DRIVER

Primary

Power

It

is

recommended

to

use

a

separate

60

amp.

safety

disconnect

switch

as

indicated

in

the

Model

602A

instructions.

2-4.

4.

Exciter

Input

Signal

Connections

All

input

signal

connections

to

the

exciter

are

made

to

TBl,

which

is

a

IO-terminal

barrier

strip

accessible

at

the

rear

of

the

680

exciter.

Refer

to

Figure

2-2

in

the

680

Instruction

Manual.

Use

twisted-pair

shielded

cable

for

audio

connections.

For

monaural

operation,

connect

audio

signal

leads

to

TBl-9

and

TBl-10

and

connect

line

shield

to

TBl-8

(GND).

For

stereo

operation,

consult

the

Model

682

Instruction

Book.

For

SCA

operation,

refer

to

the

Model

683

Instruction

Book.

2-4.

5.

Cabinets

Interconnections

Interconnections

between

the

PA

cabinet

and

DRIVER

cabinet

are

carried

out

between

terminal

blocks

TB202

and

TB201

located

in

the

PA

cabinet

and

TBll

in

the

DRIVER

SECTION,

as

follows:

098-7042

TB202-5 (Plate)

TB202-6 (Plate)

TB202-ll

(OL from Driver)

TB202-12 (115

VAC)

TB202-9 (Low power)

to

to

to

to

to

TBll-5

TBll-6

TBll-11

TBll-12

TBll-8

2-6

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

www.SteamPoweredRadio.Com

I

I

I

I

I

I.

I

I

I

I

I

I

I

I

I

I

I

I

I

Model

625A

TB201-9

(

Cabin

et

Interlock)

TB201-10

(Cabinet

Interlock)

to

to

_

section

II

TBll-14

TBll-15

Interconnections

between

PA

cabinet

and

transformer

vault

are

carried

out

by

means

of

terminal

block

TB402

located

in

PA

cabinet

and

TB401

in

the

transformer

vault,

as

follows:

TB401-l

(Interlock)

to

TB402-l

TB401-2

(Interlock)

to

TB402-2

TB401-3

(230V

to

T202)

to

TB402-3

TB401-4

(230V

to

M205)

to

TB402-12

TB401-5

(Plate

DRIVER)

to

TB402-5

TB401-6

(to K201)

~o

TB402-6

TB401-7 (230V

to

M205)

to

TB402-7

TB401-8

(Plate

DRIVER)

·

to

TB402-8

TB401-9

(Plate

DRIVER

Low

Power)

to

TB402-9

TB401-10

(230V

to

M205)

to

TB402-10

'TB401-ll

(to K202)

to

TB402-ll

TB401-12

(230V

to

T202)

to

TB402-4

TB401-13

Not

Used

'

TB401-14

Not

Used

_TB401-15

Ground

to

·

TB402-15

2-4.6.

PA

Tube

Installation

Proceed

to

install

PA

tube

VlOl

into

socket.

The

tube

should

be

lowered

into

position

vertically

and

aligned

concentrically

with

the

coaxial

capacitor.

Care

must

be

exercised

in

order

to

properly

sit

the

base

of

the

tube

over

the

socket

contact

rings.

Then

exert

pre

s

sure

downward

until

the

tube

rests

on

four

metal

stops.

Connect

the

plate

choke.

2-5.

REMOTE CONTROL CONNECTIONS

2-5

.1.

Stereo/SCA

remote

control

Refer

to

the

682/683

Instruction

Manuals

for

remote

control

operation

of

these

units.

-2-5.

2.

PA

Remote

Control

Local-Remote

switch

S211 (See

figure

3-1)

allows

operation

from a

local

or

remote

position.

When

S211

is

set

to

REMOTE

all

front

panel

controls

are

disabled

and

power

control

functions

are

transferred

to

terminal

block

TB201. A

contact

closure

between

these

connections

provides

the

following

functions:

a.

TB201, 3

and

4:

Remote

master

on

and

off

b.

TB201, 5

and

6:

Remote

plate

on

and

off

c.

TB201, 7

and

8:

Remote

HI-

LO

d.

TB201,

11

and

12:

Remote

overload

reset

2-5.3.

PA

Remote

Metering

Connections

are

available

at

TB201

and

TB202

as

follows:

2-5.4.

a.

TB201-l

(Ground)

and

TB201-15:

PA

plate

voltage

readout

b.

TB202-l

and

TB202-2:

PA

Plate

current

readout

DRIVER

Section

Refer

to

Model

602A

instructions.

098-7042

2-7

www.SteamPoweredRadio.Com

I

I

I

I

I

I.

I

I

I

I

I

I

I

I

I

I

I

I

I

Model

625A .

SECTION

Ill

OPERATION

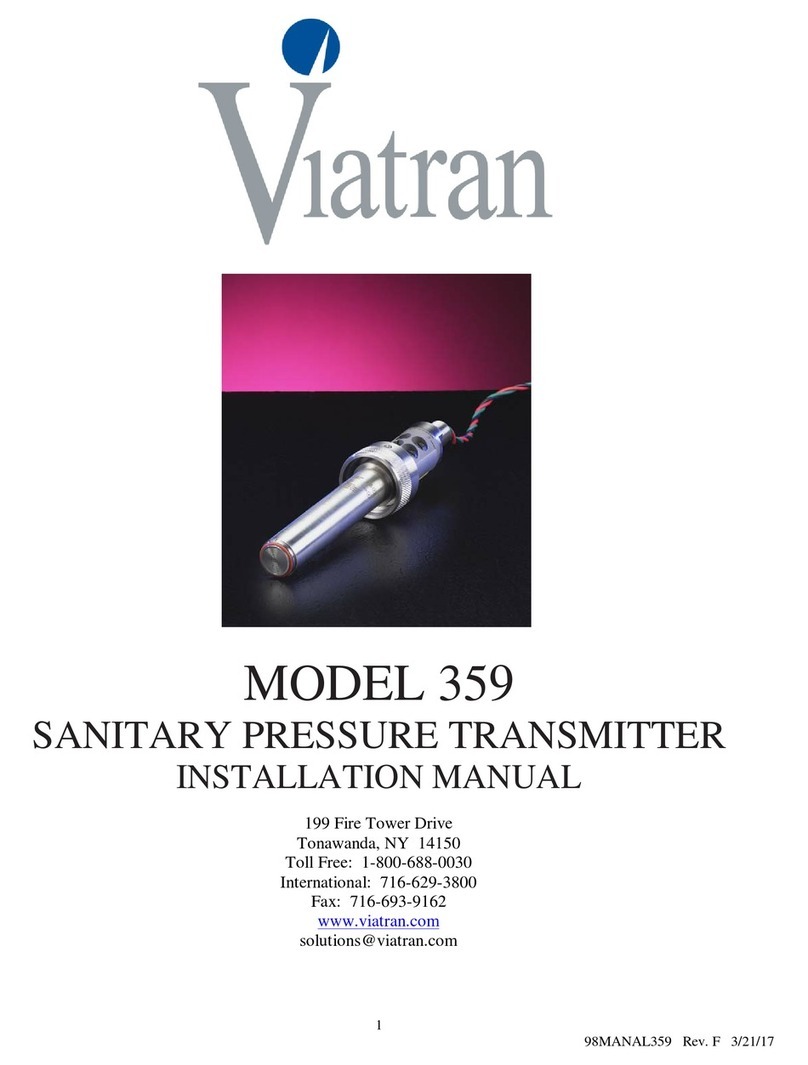

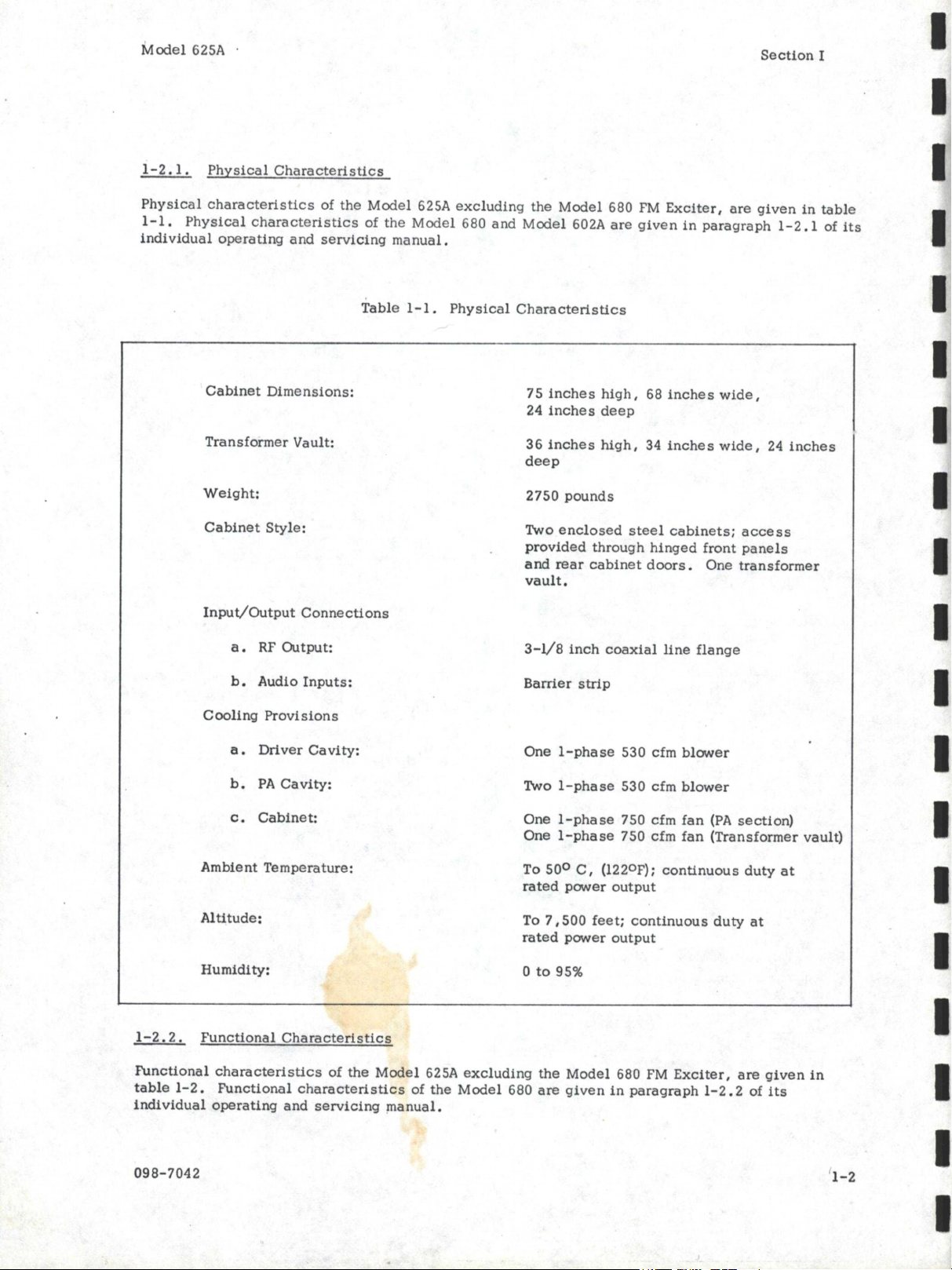

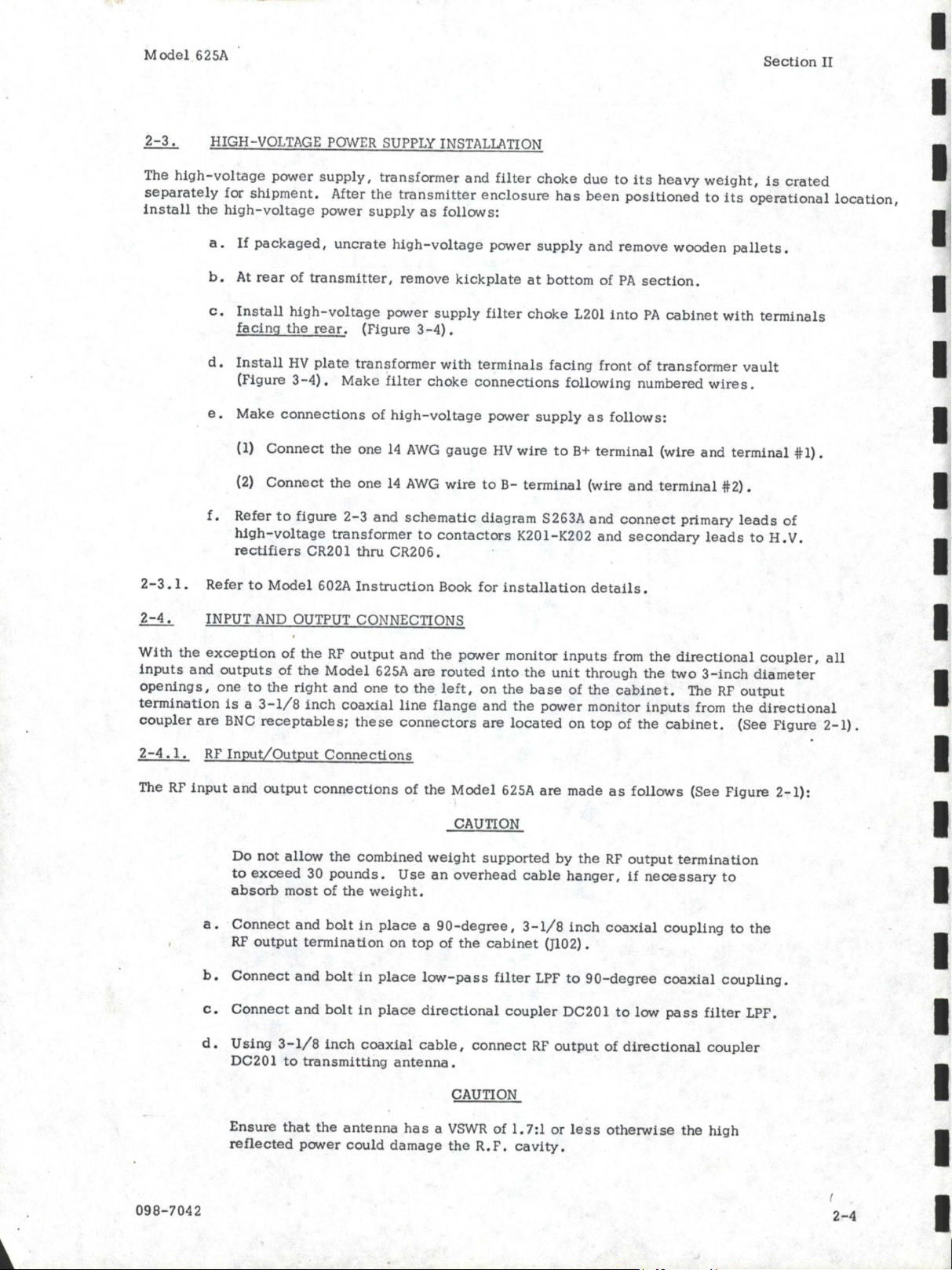

3-1.

PA

CONTROLS

AND

INDICATORS

Section

III

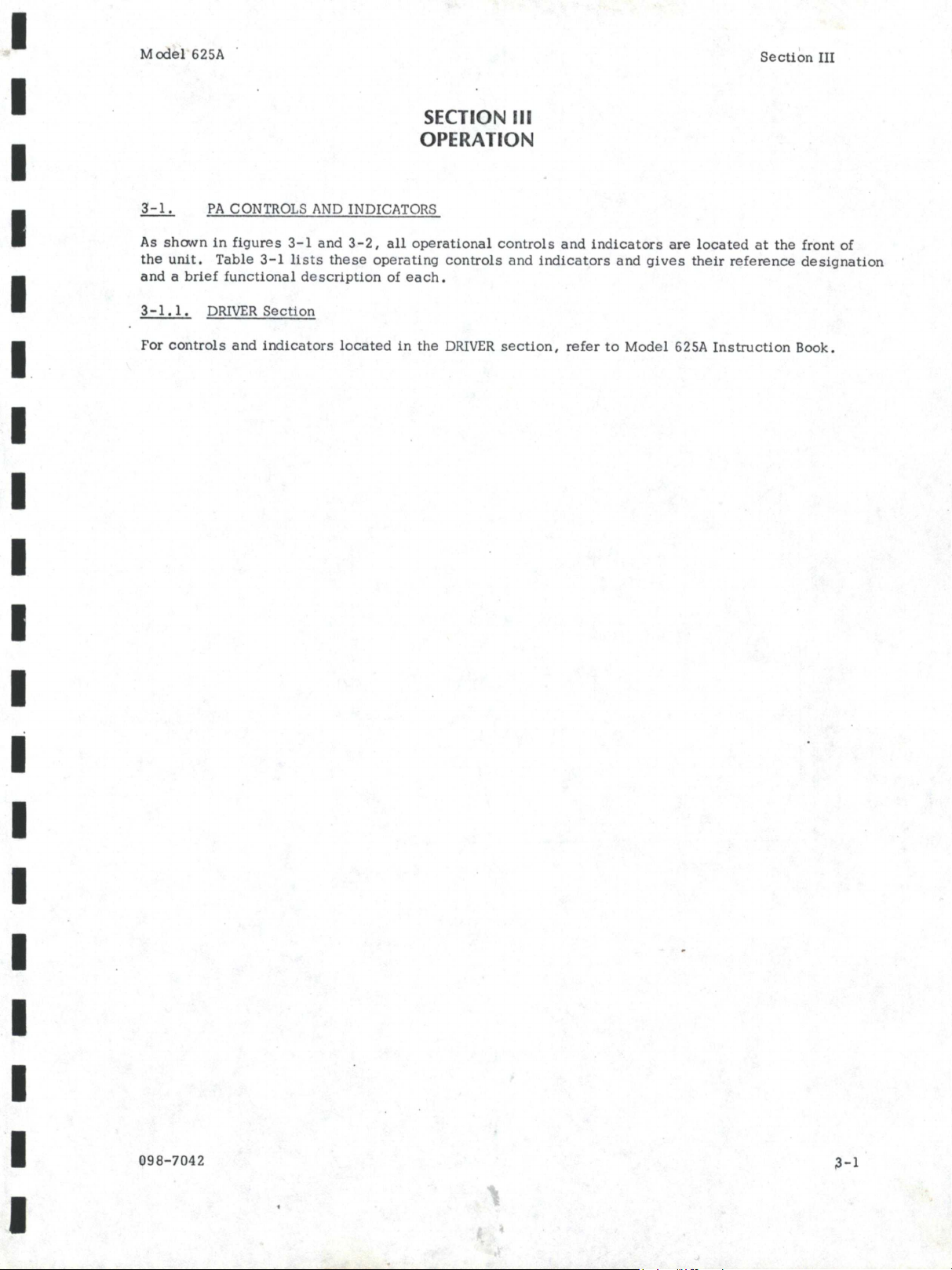

As

shown

in

figures

3-1

and

3-2,

all

operational

controls

and

indicators

are

located

at

the

front

of

the

unit.

Table

3-1

lists

these

operating

controls

and

indicators

and

gives

their

reference

designation

and

a

brief

functional

description

of

each.

3-1.1.

DRIVER

Section

For

controls

and

indicators

located

in

the

DRIVER

section,

refer

to

Model

625A

Instruction

Book.

098-7042

www.SteamPoweredRadio.Com

Section

III

ICJ

0

~26

3-2

CJ

CJ

CJj

000

0

FINAL

0

TUI/IN(,

Dl!VR

TUNING

0 0 0

0

0

0 0

S3 SB

la

. .

0 0 0

o.

SI

SIO

ss

Sf

MODEL

680

FM

EXCITER

MODEL

682.

STE~Eo

GEN.

~EL

683

~CA

C:,EIJ

,

.

0 0 0 0

□

C8/

DRIVER

SECTION

SEE

MODEL

60

2 A

1WSTRVCTION

800K

-DSZCG

~-

OSZ0

3

-oszos

I

!MZMI

!mo2j

-

(,(

0

!1112031

!M

20

6I

I

LIDS

",

I

......

L/04

~

I

OUTPc/T

q

lOADJNC,

OVTPfJT

TUNING

I C/02.

"IJJPr/T

TUNIN(r

()

·i

~

-

~~~

N

l'\J

N

._.

''""

-~r3rj--~~~

µjzos!

o o o !

11M.?•1!

o o o !

Mzo,

!

s?H(~,~

(~.j

$1.,

<:)~

......

~

~

'

....

Q

0

"'"'

N

NN

N

").,

..,

..,

V)

II)

-

0 0 0

0

Ff

'2

F3

Ff.

D

CBI

POWER

t4MPI.IFIEJ€ Sl:CTIOI/

Front

View -

Component

Location

Figure

3-1

Model

625A

R22/

A.PJl/ST

MZ06

FOR.

100

"/,

CAL.

'

PLATE

!mf

CBZ.

#lbll

VOL

7A4E

.POWGR

.SUPPi.'/'

,5/ie.TION

·

098-7042

•

•

•

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

www.SteamPoweredRadio.Com

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

Mcxiel

625A

Ref.

Des.

DS202

DS203

DS205

M204

M203

M202

M206

Ll04

Ll05

Cl02

M205

HM201

M201

T201

-

098-7042

Section

III

:fable

3-1.

Operating

Controls

and

Indicators

PA

Section

Panel

Nomenclature

Function

PA

METER

PANEL

(Fi

gure

3-1)

FIL

INTERLOCKS

PLATE

PA

GRID CURRENT

PA

PLATE

CURRENT

PA

PLATE

VOLTAGE

PA

POWER

OUT

I

Indicates

power

applied

to

filament

contactor

K204

and

consequently

to

PA

Filament

when

lit.

Indicates

time

delay

complete

·

and

PA

cabinet

interlock

switches

closed

when

lit.

Indicates

Plate

Voltage

applied

to

Vl0l

when

lit.

Provides

continuous

readout

of

PA

grid

current.

Provides

continuous

readout

of

PA

plate

current.

Provides

continuous

readout

of

PA

plate

voltage.

As

selected

by

PA

POWER OUT

switch

S213

provides

readouts

of

PA

forward

and

reflected

RF

power

output.

(VSWR).

(See

section

4-6.2.)

PA

CAVITY

FRONT

PANEL

(FIGURE

3-1)

'

.,

1

OUTPUT

TUI'JIING

• i

I

OUTPUT LOADING

INPUT TUNING

Tunes

Vl0l

plate

to

resonance.

Adjust

Vl0

1

plate

loading.

Tunes

the

input

circuit

of

Vl0l

to

resonance.

PA

CONTROL

PANEL

(FIGURE

l-1)

AC

LINE

VO

LTAGE

HOURS

PA

FILAMENT

VOLTAGE

PA

FILAMENT ADJUSTMENT

As

selected

by

AC

Line

Voltage

switch

S214,

provides

readouts

of

phase

to

phase

AC

line

voltage.

Provides

cumulative

transmitter

operating

time.

Provides

continuous

readout

of

PA

filament

voltage.

Adjust

PA

filament

voltage

as

monitored

by

M201.

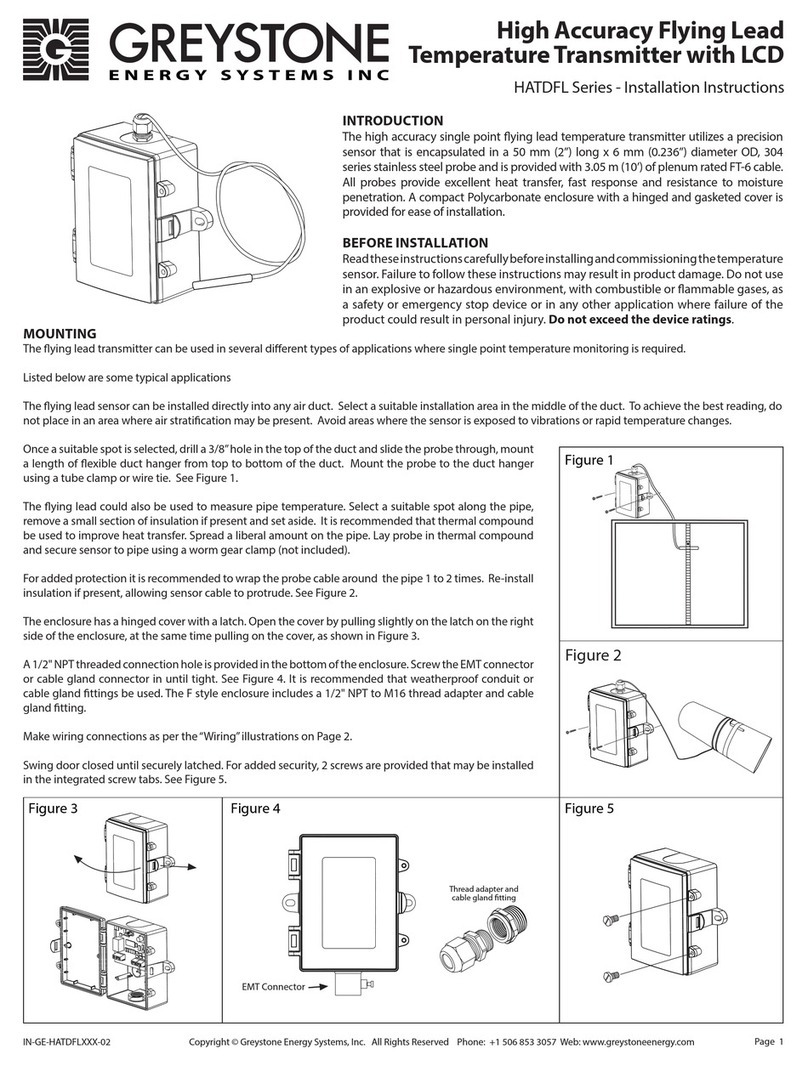

Popular Transmitter manuals by other brands

Greystone Energy Systems

Greystone Energy Systems HATDFL Series installation instructions

NEUTRIK

NEUTRIK xirium pro user manual

Nautel

Nautel VS300 quick start guide

Allstar

Allstar CKT-240 installation instructions

Magnetrol

Magnetrol PULSAR RADAR R86 Functional safety manual

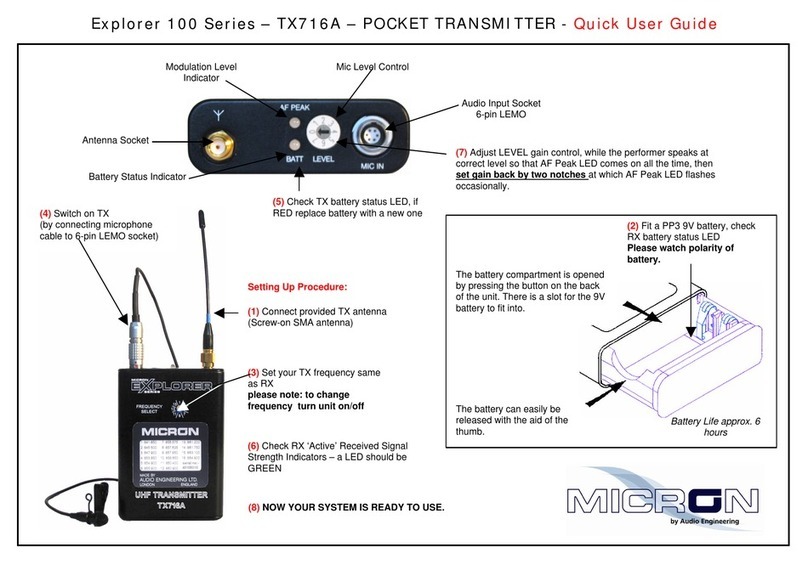

Micron

Micron POCKET TRANSMITTER TX716A Quick user guide