SSEEFF,,PPEEFF&&GGEEFFEEXXHHAAUUSSTTFFAANNSSDDIIRREECCTTDDRRIIVVEE

RREEAADDAANNDDSSAAVVEETTHHEESSEEIINNSSTTRRUUCCTTIIOONNSSFFOORRFFUUTTUURREERREEFFEERREENNCCEE

RREEAADDAANNDDSSAAVVEETTHHEESSEEIINNSSTTRRUUCCTTIIOONNSSFFOORRFFUUTTUURREERREEFFEERREENNCCEE

AASSSSEEMMBBLLYYIINNSSTTRRUUCCTTIIOONNSS

MMOODDEELLSSSSEEFF--1100TTHHRROOUUGGHHSSEEFF--2244

CCoonntteennttss::Pre-assembled guard mount fan, shutter, shutter

mounting hardware kit, package of mounting screws.

To mount shutter to fan assembly:

1. Shutter mounting hardware kit includes: 4 rubber vibration

isolators, 4 nylon inserts, 4 screws (#12 x 1”) and 4 rubberized

washers.

2. Insert screws into washers - rubber side down.

3. Place nylon inserts into square holes of corner gussets at

rear of shutter.

4. Place shutter face down (gusset side up). Center vibration

isolators over nylon inserts.

5. Place fan assembly on shutter so that wire hooks on fan

guard are centered over vibration isolators and nylon

inserts. Junction box must be positioned at bottom with

shutter blades opening upwards.

6. Secure fan assembly to shutter using screws and washers.

7. Ensure that fasteners are snug. Do not over tighten to

avoid stripping nylon inserts.

MMOODDEELLSSEEFF--3300

CCoonntteennttss::Pre-assembled guard mount fan, shutter, shutter

mounting hardware kit, package of mounting screws.

To mount shutter to fan assembly:

1. Shutter mounting hardware kit includes: 4 rubber vibration

isolators, 8 rubber inserts, 8 screws (#8-32 x 11/2”) and 8

rubberized washers.

2. Insert screws into washers - rubber side down.

3. Place rubber inserts into round holes of corner gussets at

rear of shutter. It may be necessary to twist and push or tap

lightly to seat rubber inserts properly.

4. Place shutter face down (gusset side up). Center vibration

isolators over rubber inserts.

5. Place fan assembly on shutter so that wire hooks on fan

guard are centered over vibration isolators and nylon

inserts. Junction box must be positioned at bottom with

shutter blades opening upwards.

6. Secure fan assembly to shutter using screws and washers.

7. Ensure that fasteners are snug. Do not over tighten to

avoid pulling out rubber inserts.

MMOODDEELLSSPPEEFF--1

100TTHHRROOUUGGHHPPEEFF--3300

CCoonntteennttss::Pre-assembled panel mount fan.

MMOODDEELLSSGGEEFF--1100TTHHRROOUUGGHHGGEEFF--3300

CCoonntteennttss::Pre-assembled guard mount fan.

IINNSSTTAALLLLAATTIIOONN&&MMAAIINNTTEENNAANNCCEEGGUUIIDDEE

CCAAUUTTIIOONN!!TTHHEESSEEFFAANNSSAARREEDDEESSIIGGNNEEDDFFOORRGGEENNEERRAALL

VVEENNTTIILLAATTIIOONNUUSSEEOONNLLYY..DDOONNOOTTUUSSEETTOOEEXXHHAAUUSSTTCCOORRRROO--

SSIIV

VEE,,HHAAZZAARRDDOOUUSSOORREEXXPPLLOOSSIIVVEEMMAATTEERRIIAALLSSAANNDDVVAAPPOORRSS..

BBEEFFOORREEIINNSSTTAALLLLAATTIIOONN

WWAARRNNIINNGG!!TTOORREEDDUUCCEETTHHEERRIISSKKOOFFFFIIRREE,,EELLEECCTTRRIICCAALL

SSHHOOCCKK,,OORRIINNJJUURRYYTTOOPPEERRSSOONNSS,,PPLLEEAASSEEOOBBSSEERRVVEETTHHEE

FFOOLLL

LOOWWIINNGGSSAAFFEETTYYPPRREECCAAUUTTIIOONNSS::

1. TThhiissffaannhhaassrroottaattiinnggppaarrttss!!Turn impeller by hand to ensure

that it rotates freely.

2. Ensure that electrical service to fan is locked in the

“OOFFFF” position to prevent power from being switched on

accidentally. When the service disconnecting means

cannot be locked, securely fasten a prominent warning

device such as a tag to service panel.

3. Do not re-establish power supply until fan and activation

device are completely installed.

4. Installation work, including electrical wiring, must be

performed by a qualified person in accordance with all

applicable codes and standards, including local fire codes.

5. Check voltage at fan to see that it corresponds to fan motor

nameplate rating.

6. Fan is intended to be hard wired to a properly rated

electrical circuit, and must be properly grounded. Do

not use an extension cord.

7. Fan motor is equipped with thermal overload protection,

which causes fan to shut off automatically if motor overheats.

If this should happen, immediately disconnect and lock power

supply to fan. DDoonnoottaatttteemmppttttoowwoorrk

koonnffaannwwiitthhoouuttddiissccoonn--

nneeccttiinnggppoowweerrssuuppppllyy;;ffaannmmaayyrreessttaarrttwwiitthhoouuttwwaarrnniinngg!!

8. Fan should not be turned on and off rapidly.

9. Do not use fan with a solid state speed control device.

10. Do not allow fan to become wet or damp.

11. Do not block air intake or exhaust from fan.

12. Do not allow foreign objects to enter fan and come in

contact with fan blades.

SSPPEEEEDDSSEELLEECCTTOORRSSWWI

ITTCCHH

Fan is equipped with either a 2-speed or 3-speed pull chain switch,

allowing user to select desired airflow. Pulling a speed selector

switch repeatedly will cause fan speed to cycle as follows:

22--SSppeeeeddSSwwiittcchh::

OFF – FIRST SPEED – OFF – SECOND SPEED – OFF

33--SSppeeeeddSSwwiittcchh::

OFF – HIGH – MEDIUM – LOW – OFF

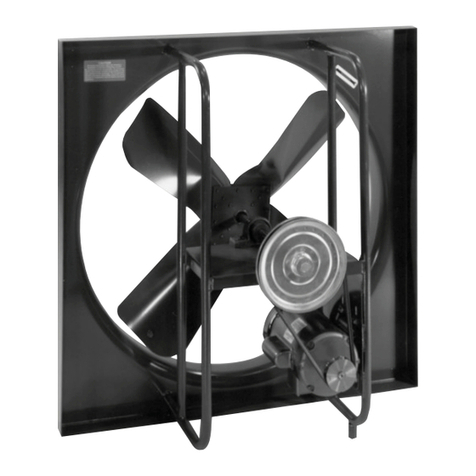

SSEEFFSSHHUUTTTTEERRMMOOUUNNTTFFAANNPPEEFFPPAANNEELLMMOOUUNNTTFFAANNGGEEFFGGUUAARRDDMMOOUUNNTTFFAANN