CFM ADD-0911 User manual

Other CFM Fan manuals

CFM

CFM RMD-0807 User manual

CFM

CFM AXC Series Maintenance and service guide

CFM

CFM DVK-T Maintenance and service guide

CFM

CFM TF140-DC Maintenance and service guide

CFM

CFM TF140-EC Maintenance and service guide

CFM

CFM CF Maintenance and service guide

CFM

CFM FCU-08 User manual

CFM

CFM 165834 User manual

CFM

CFM APK-0906 User manual

CFM

CFM 109539 User manual

CFM

CFM TF100-EC Maintenance and service guide

CFM

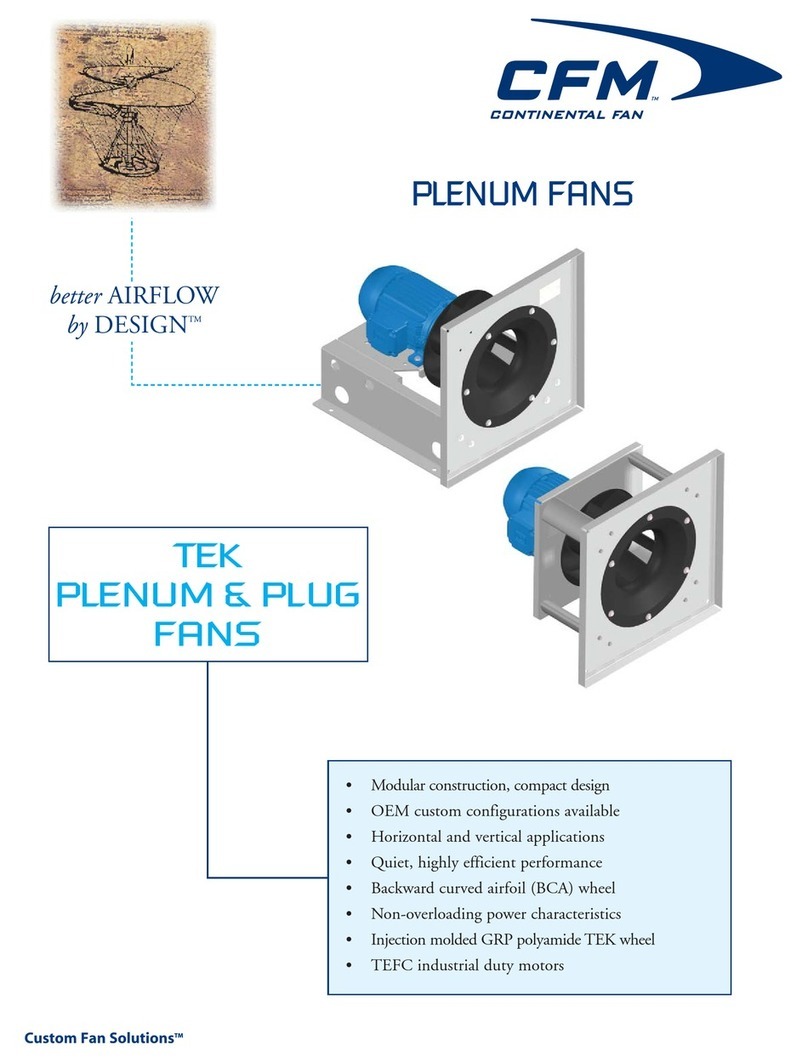

CFM TEK225H-H2 User manual

CFM

CFM GEF10 Operating and safety instructions

CFM

CFM TBF90 Installation and operating instructions

CFM

CFM 1000 230V User manual

CFM

CFM TF Series Maintenance and service guide

CFM

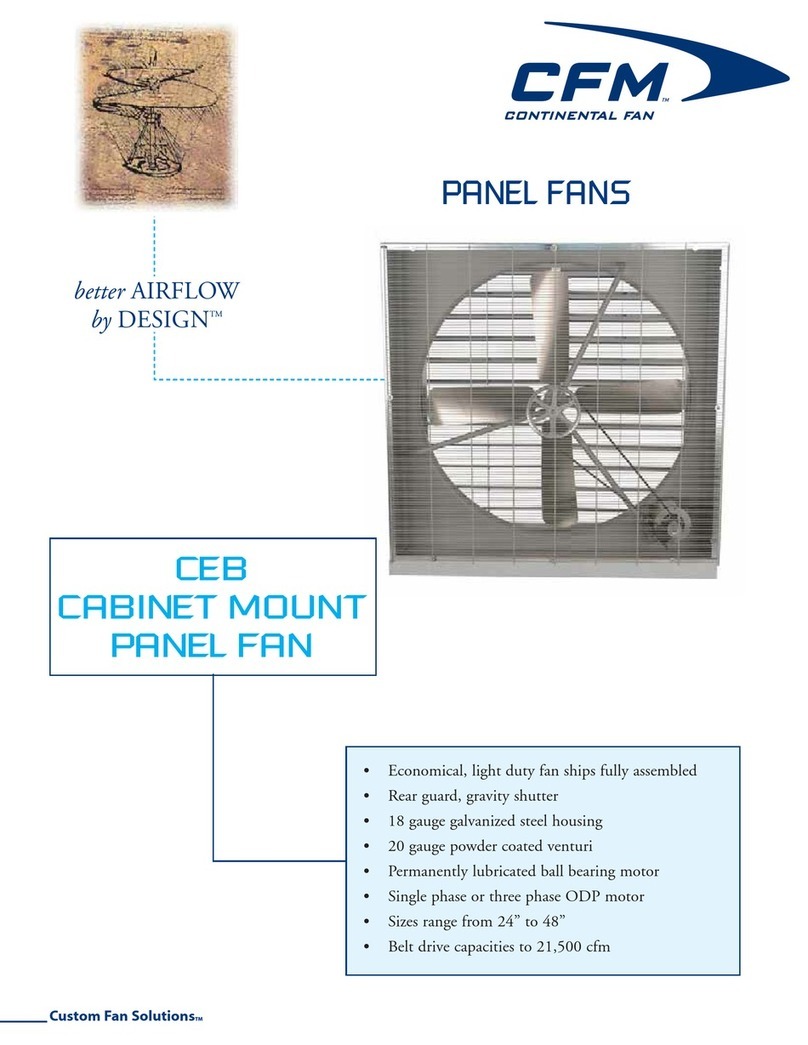

CFM CEB-0807 User manual

CFM

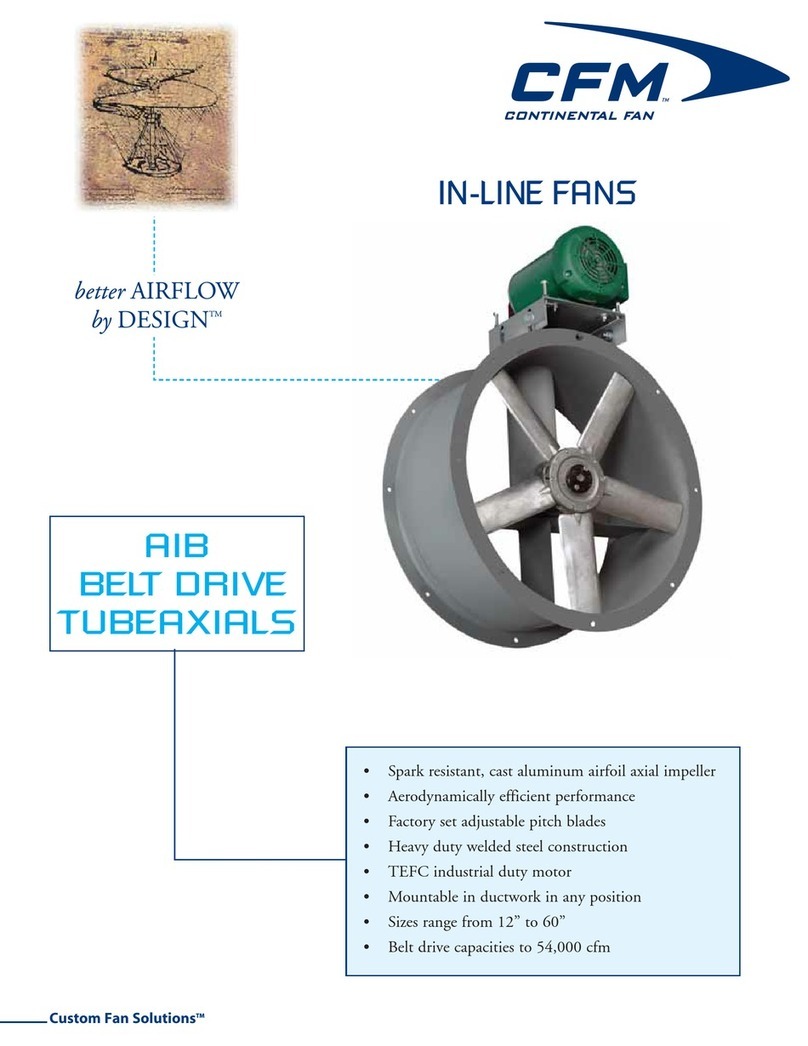

CFM AIB-1006 User manual

CFM

CFM 167193 User manual

CFM

CFM CF Maintenance and service guide

Popular Fan manuals by other brands

ELTA FANS

ELTA FANS H03VV-F installation guide

Hunter

Hunter 20714 Owner's guide and installation manual

Emerson

Emerson CARRERA VERANDA CF542ORB00 owner's manual

Hunter

Hunter Caraway Owner's guide and installation manual

Panasonic

Panasonic FV-15NLFS1 Service manual

Kompernass

Kompernass KH 1150 operating instructions