HybridVerticalStack–InstallationOperationMaintenanceManual

OPERATION‐DETAILED

R090303InstallationOperationMaintenanceManualissubjecttochangewithoutnoticePage13

operationuntilthecontrolsarepowereddownforatleast20seconds,whilea

softlockoutisacompressorshutdownthatwillberestoredoncetheconditions

causingtheshutdownhavebeenrectified.

d. Duringcompressoroperation,refrigeranttemperature,systemfluid

temperatureanddischargeairtemperaturearecontinuouslymonitored.Ifthe

refrigeranttemperaturedropsbelow35°F,compressoroperationwillbe

disabled.After10minutesanautoresetoccursandthecompressorwillbe

enabledassoonasthetemperaturerisesabove60°F.Actualcompressorrestart

willbedelayedaminimumof5minutesbytheanti‐recycletimer.Aflashcodeof

2willbeinitiateduponalowrefrigeranttemperatureshutdown.

e. Iftheoutgoingsystemfluidtemperaturerisesabove140°F,compressorstartup

willbedisabled.After10minutesanautoresetoccursandthecompressorwill

beenabledassoonasthetemperaturedropsbelow115°F.Theoutgoingsystem

fluidsensorismountedontheleavingfluidpipe.Actualcompressorrestartwill

bedelayedaminimumof5minutesbytheanti‐recycletimer.Aflashcodeof3

willbeinitiateduponahighoutgoingsystemfluidtemperatureshutdown.

f. Ifthedischargeairtemperaturedropsbelow50°Fcompressoroperationwillbe

disabled.After10minutesanautoresetoccursandthecompressorwillbe

enabledassoonasthetemperaturerisesabove60°F.Thedischargeair

temperaturesensorismountedonthefanhousing.Actualcompressorrestart

willbedelayedaminimumof5minutesbytheanti‐recycletimer.Aflashcodeof

4willbeinitiateduponalowdischargeairtemperatureshutdown.

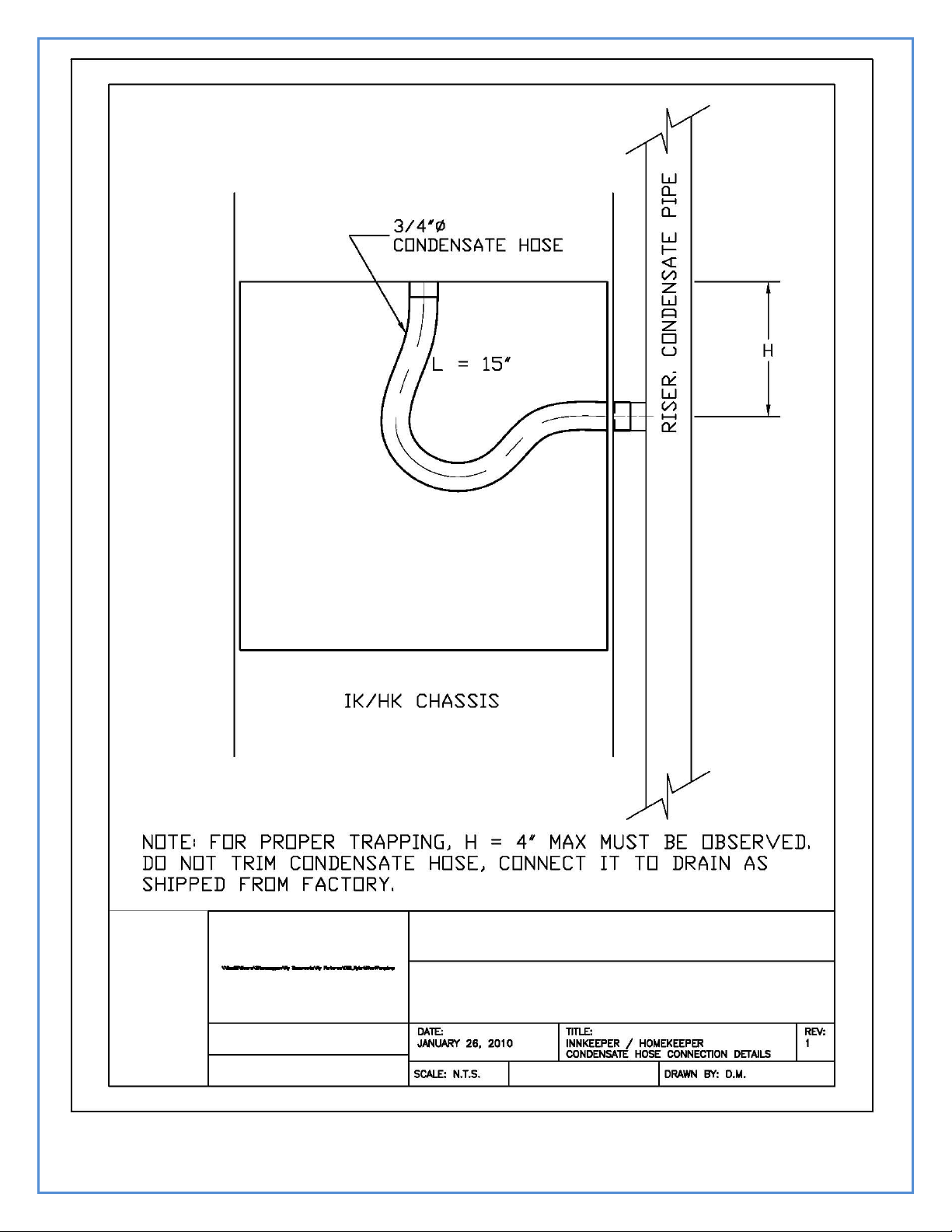

g. Thecondensatelevelsensorisa100ohmthermistorthatisheatedfor15

secondsevery4minutes.Itstemperatureismeasuredatthebeginningofthe

heatcycle,andagainattheendoftheheatingcycle.Ifthecondensatelevelrises

abovethesensoritwillnotwarmupduringthewarmupcycle,andthe

temperaturechangewillbeinsignificant.Itisthislackoftemperaturechange

thatthecontrollerseesasanimpendingcondensateoverflow.Whenhigh

condensatelevelisdetected,compressoroperationisimmediatelyterminated,

andatthesametimethefanisstoppedfor30seconds,andthenrestarted.At

thistimeaflashcodeof7willbeintiated.The4minutecyclewillcontinueuntil

thecoolingcallisnolongerinplace.Ifthecondensateleveldropsbelowthe

sensor,compressoroperationwillbereturnedtonormal.However,ifthe

condensatelevelstaysabovethesensorformorethan15minutes,thefault

alarmwillbetriggered.Thisfaultsignalwillautomaticallyresetoncethe

condensatelevelgoesbelowthesensor.