CGC SpaceKeeper SKH008 Owner's manual

July7th,2010

Installation

Operation

Maintenance

HybridHorizontal

HeatPump

Spacekeeper

Models:SKH008–SKH060

July7th,2010

TableofContents

1.INFORMATION.................................................................................................................................1

Handling/Storage..........................................................................................................................................1

Weight/Dimension/Clearances.....................................................................................................................2

2.INSTALLATION..................................................................................................................................3

GeneralInstallChecklist................................................................................................................................5

Location/Placement/Piping..........................................................................................................................6

CondensateDrainConnection......................................................................................................................7

Wiring............................................................................................................................................................8

3.OPERATION......................................................................................................................................9

BoardDescription.......................................................................................................................................10

Fan...............................................................................................................................................................11

HeatOperation...........................................................................................................................................11

CoolStartUp...............................................................................................................................................11

CoolOperation............................................................................................................................................12

OperationalAlgorithm................................................................................................................................14

ThermostatConnection..............................................................................................................................14

ShutdownOutput........................................................................................................................................15

FaultAlarmOutput.....................................................................................................................................15

4.COMMISSION&STARTUP.............................................................................................................17

5.MAINTENANCE...............................................................................................................................20

SKH008‐SKH018WiringDiagram..............................................................................................................21

SKH020‐SKH060WiringDiagram..............................................................................................................22

6.APPENDIXA(DETAILS)...................................................................................................................23

SKH008‐SKH018.........................................................................................................................................24

SKH020‐SKH036.........................................................................................................................................25

SKH042‐SKH060.........................................................................................................................................26

HybridHorizontalSpacekeeper–InstallationOperationMaintenanceManual

INFORMATION

R090303InstallationOperationMaintenanceManualissubjecttochangewithoutnoticePage1

Handling

Caremustbetakeninhandlingthehorizontalunitandotheraccessoriestoensurethatthis

equipmentdoesnotsustainanydamage.

Theprotectiveshippingpackagingshouldremainontheunituntilitisreadyforinstallation.

Duringconstruction,theunitmustnotberunandshallbeshelteredfromcontaminantsand

debrissuchasdrywalldust,woodchips,andpaintthatcoulddamagethefanorblockthe

cooling/heatingcoilwhichmayresultindiminishedperformance.

Storage

Theunitmustbestoredinanuprightpositionatalltimes.

Failuretomaintaintheunitinanuprightpositionmayresultinpermanentdamagetotheunit.

Droppingthechassisorexposingittoextremeshockorvibrationmayalsoresultinpermanent

damagetotheinteriorcomponentsandpiping.

Theunitshouldbestoredinanon‐corrosiveenvironmentshelteredfromconditionsofextreme

temperatureorhumidity.Subjectingtheunittoconditionsofthisnaturemayresultin

significantlyreducedperformance,reliability,andoperationallife.

Theunitisintendedforinterioruseonlyandshouldbestoredindoorsatalltimestoprotectit

fromtheelementsandtohelpeliminatethepotentialgrowthofindoorairquality(IAQ)

contaminants.

Ifindoorstorageisnotpossible,theequipmentmaybestoredoutdoorsduringthesummer

monthsonly,ifthefollowingprovisionsaremet:

1. Theequipmentmustbeplacedonadrysurface,orraisedoffthegroundinamanner

whichallowsforair‐circulationbeneaththeunit.

2. Awaterprooftarpmustbeusedtocovertheequipmentinordertoprovideprotection

fromtheelements.

3. Continuousventilationtotheunitsmustbeprovidedtohelppreventmoisture

accumulationontheinteriorandexteriorsurfaces.Moisturebuildupon,orwithinthe

unit’sinsulationmayresultinmicrobialgrowththatcanleadtoodorsandserious

health‐relatedIAQproblems.

4. Theunitsmustbestoredintheiroriginalpackaging.

HybridHorizontalSpacekeeper–InstallationOperationMaintenanceManual

INFORMATION

R090303InstallationOperationMaintenanceManualissubjecttochangewithoutnoticePage2

5. Theindividualunitsshallnotbestackedontopofoneanother.

6. Iftheunitwaspreviouslyinuse,ensurethatallwaterinthecoilhasbeenblownoutand

thatallhoseconnectionsarepluggedduringstorage.

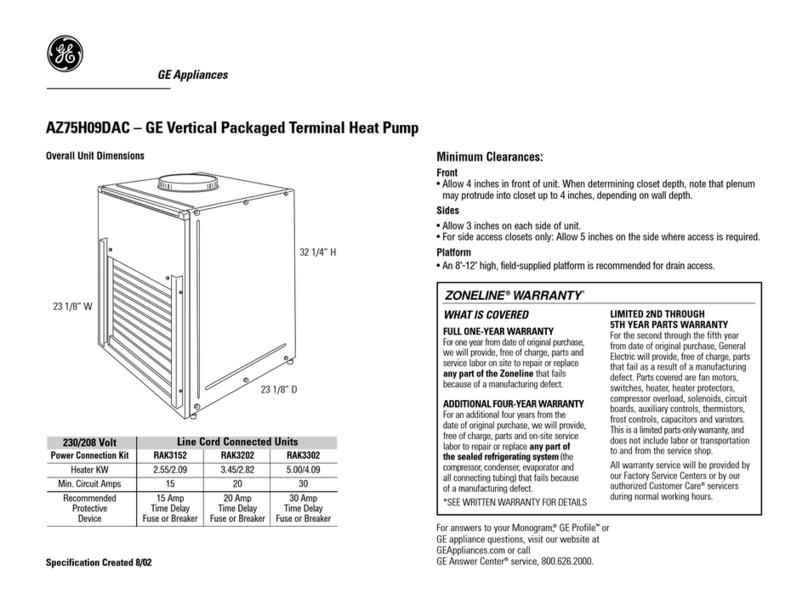

Weight/Dimensions/Clearances

Weight:

Model008010012015018020024030036042048060

Weight

(lb)130130135150160205235235235375300375

UnitDimensions:

SeeAppendixA‐Details

UnitClearances:

SeeAppendixA‐Details

HybridHorizontalSpacekeeper–InstallationOperationMaintenanceManual

INSTALLATION

R090303InstallationOperationMaintenanceManualissubjecttochangewithoutnoticePage3

HybridHorizontalSpacekeeper–InstallationOperationMaintenanceManual

INSTALLATION

R090303InstallationOperationMaintenanceManualissubjecttochangewithoutnoticePage4

TheInstallationofHybridHorizontalSpaceKeeperunitsandaccessoriesmustbeinaccordance

withlocalcodesandallregulationsofallrelevantgoverningauthoritieshavingjurisdiction.The

followinginstallationproceduresarerecommendedbytheManufacturer.Itisthe

responsibilityoftheinstallingcontractortocomplywithallapplicablecodesandregulations.

HybridHorizontalSpacekeeper–InstallationOperationMaintenanceManual

INSTALLATION

R090303InstallationOperationMaintenanceManualissubjecttochangewithoutnoticePage5

LEFTRETURN

AIRFILTER

ARR.3BACK

SUPPLYAIRARR.1RIGHT

SUPPLYAIR

COMPRESSORAND

CONTROLACCESS

PANEL

DELIVERYANDGENERALINSTALLATIONCHECKLIST

ThelistbelowsummarizesthestepsrequiredtosuccessfullyinstallaCGCHorizontal

SpaceKeeperunit.

1. Removepackagingandinspecttheunit.Checkforshippingdamageormaterial

shortage;fileafreightclaimandnotifyyoursalesrepresentativeifdamageordeficiency

isfound.

2. Verifythemodel.

3. Verifythatthepowersupplycomplieswiththenameplatespecification.

4. Connectproperlysizedandprotectedpowersupplywiringtothedisconnect(not

supplied).

5. Installpropergroundingwirestoanearthground.

Figure1

FRONT

HybridHorizontalSpacekeeper–InstallationOperationMaintenanceManual

INSTALLATION

R090303InstallationOperationMaintenanceManualissubjecttochangewithoutnoticePage6

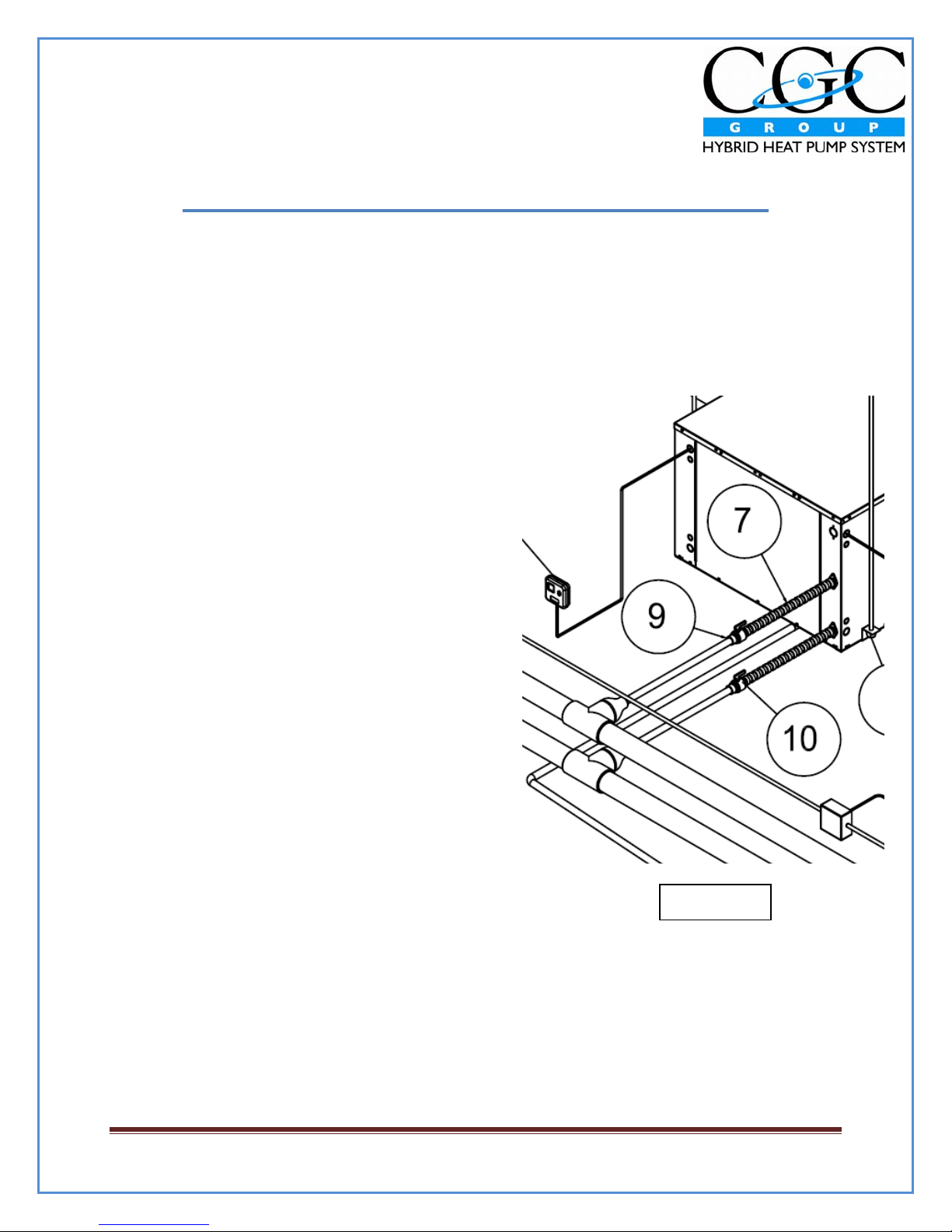

LOCATION

1. Determinefuturehorizontalmount

locationwithclearancesshownin

appendixA.

2. Locatetheunitinanindoorarea.Theair

temperaturesurroundingandbeing

suppliedtotheunitmustbeabove45°F

(7°C)atalltimes.Donotlocatetheunitin

areassubjecttofreezing.

PLACEMENT

1. Positiontheunitandfastentoceiling

ensuringtheunitisleveled.Extension

Rods(notsuppliedbyCGC)andRubber

isolatorsaretobeused.DONOTblock

accesspanelswithmountingrods.

2. Meetspecifiedclearancestoprovide

roomforremovalofallaccesspanels.

3. Provideaccesstowatervalvesand

fittings,aswellasscrewdriveraccessto

theunitsidepanels,dischargeaircollar,

andallelectricalconnections.

PIPING

CAUTION:Pipingmustcomplywithallapplicable

codesandregulations.

1. Installisolationvalvesateachunittopermit

unitremovalforservicing.

2. DONOTbendorkinksupplylinesorhoses(If

supplied).Supplyandreturnhosesarefitted

withswiveljointfittingsatoneendtoallow

removalforfutureservicing.

Figure2

HybridHorizontalSpacekeeper–InstallationOperationMaintenanceManual

INSTALLATION

R090303InstallationOperationMaintenanceManualissubjecttochangewithoutnoticePage7

HybridHorizontalSpacekeeper–InstallationOperationMaintenanceManual

INSTALLATION

R090303InstallationOperationMaintenanceManualissubjecttochangewithoutnoticePage8

NOTE:Insulationofthewaterpipingloopisnotrequiredexceptwherepipingrunsthrough

unheatedareasorareasontheexteriorofthebuilding.Thenormalloopoperating

temperaturerangeis85°F(29°C)to120°F(49°C).

WIRING

1. Wireroomtemperaturesensortoelectricalpanelasindicatedonthewiringdiagram.

2. Connectpower.

HybridHorizontalSpacekeeper–InstallationOperationMaintenanceManual

OPERATION

R090303InstallationOperationMaintenanceManualissubjecttochangewithoutnoticePage9

CAUTION:

Toavoidfouledmachinery,extensiveunitcleanup,andvoidwarranty,donotoperateunits

withoutairfiltersinplace,anddonotoperateunitsduringtheconstructionprocess.

TheCGCGroupHybridHeatPumpprovidesyearroundcoolingandheatingascontrolledbythe

unitthermostatorbyadirectdigitalcontroller.

TheCGCGrouphybridheatpumpprovidescoolingwithawater‐cooledrefrigerationcircuit,

andprovidesheatingusingahydroniccoil.Thecompressoroperatesinthecoolingmodeonly

andshutsdownduringtheheatingmodeprovidingforquieteroperation,extendedcompressor

life,andareductioninenergyconsumption.

Toensurecorrectoperation,centralizedequipmentlocatedwithinthebuildingmechanical

roomisautomaticallycontrolledtoprovideeachheatpumpunitwithwaterthatisatthe

appropriatetemperature.

HybridHorizontalSpacekeeper–InstallationOperationMaintenanceManual

OPERATION

R090303InstallationOperationMaintenanceManualissubjecttochangewithoutnoticePage10

Theunitcircuitboardincorporatessixrelayoutputswiththefollowingfunctions:

•K1–Auxiliaryrelayforcoolingvalveonatwo‐valveunitorheatvalveonadehumidification

unit.

•K2–HeatingRelay

•K3–AlarmRelay

•K4–CompressorRelay

•K5–LowFanorFanRelayforbeltdriveunits

•K6–HighFanorCompressor#2onbeltdriveunits

Eachoftheserelayshave,inparallel,agreenLEDindicatorthatlightsupwhentherelayis

energized.

Thecircuitboardincorporatesdigitalinputsthatareopto‐coupledtoa24VACsource.Thesehave

amberLEDindicatorslocatedneartheinputlocationswhicharelitwhentheinputisclosed.The

inputsinclude:

•HighPressureSwitch

•LowPressureSwitch

•HeatCall(Wonthermostatterminal)

•CoolCall(Yonthermostatterminal)

•FanCall(Gonthermostatterminal)

•Auxiliary(Aonthermostatterminal)

•Compressorshutdown(24VACsignalthruO/O).Providingacontinuous24Vpotentialto

O/Owillterminateandpreventcompressoroperation.Thiscanbeusedforduty‐cycling,

minimizingpowerconsumptionduringanemergencypowerperiodorduringsufficiently

lowoutdoorairtemperatureswhichallowforfreecooling–allwhilemaintainingthe

heatingfunction.

•Unitshutdown(24VACsignalthruA/O).Providingacontinuous24VACpotentialtoA/Owill

terminateandpreventunitoperation.Thiscanbeusedforanightshutdown.Onboth

arrangementsasingle24VACsignalcanshutdownmanyunits.¼VAisrequiredperunit.

Finally,theboardhasfouranaloginputsprovidedviathermistors.Theseinputsareasfollows:

•Ta–DischargeAirTemperature

•Tr–RefrigerantTemperature

•Tw–OutgoingWaterTemperature

•Co–CondensateLevel

Ta,Tr,AndTware10kOhmNTPthermistors,whileCoisa100OhmNPTthermistor.These

InputsdonothaveLEDindicators.

HybridHorizontalSpacekeeper–InstallationOperationMaintenanceManual

OPERATION

R090303InstallationOperationMaintenanceManualissubjecttochangewithoutnoticePage11

FAN

1. Acallon“G”forfanonthethermostatterminalstripwillcausethefantooperate

continuouslyonlowfanspeedthroughK5onmultispeedunits.

2. Acallon“W”forheatonthethermostatterminalstripwillalsocausethefantooperate

onlowspeed.Iftheheatingcallisstillpresentaftera10minuteperiod,themultispeed

unitswillswitchthefantohighspeedthroughRelayK6.

3. Acallon“Y”forcoolingonthethermostatterminalstripwillcausethefanonmulti‐

speedunitstoimmediatelystepuptohighspeedthroughRelayK6.

4. Fanoperationwillterminatewheneverallcallsaredropped.

5. Whenthefanisoperatingathighspeed,bothrelaysareenergizedalongwiththeir

associatedLEDindicators.

HEATINGOPERATION

1. Acallon“W”forheatwillactivatethefanatlowspeed.Itwillalsosimultaneously

energizetheheatrelayK2anditsassociatedLED.TherelayK2willprovide24VACfused

powerdirectlytotheheatvalve.

COOLSTARTUP

1. Acallon“Y”forcoolinginitiatesaseriesofcheckspriortothestartupofthe

compressor.Thesechecksinclude:

a. PowerONtimer–Compressoroperationisdelayedforapproximately5minutes

afterrestorationofpower.Thispreventsallunitsfromcomingonlineatthe

sametimewhenpowerisrestored.Italsopreventscompressorjoltingwith

intermittentpower.

b. Anti‐Recycletimer–Thereisa5‐minuteanti‐recycledelaytimerthatallowsthe

refrigerationcycletoachievepressureequalizationsothatthecompressoris

unloadeduponstartup.

c. HighPressureSwitch–Thehighrefrigerantpressureswitchmustbeclosedprior

tostart.LED11willbeON.

d. LowPressureSwitch–Thelowpressureswitchoperatesprimarilyasalossof

chargeprotector.ItmustbeclosedforcompressorstartupanditsLED12willbe

ON.Thepressureswitchhasa5minutetimeignoresubsequenttostart‐up.In

somesituations,particularlywhentheunitiscold,thepressureswitchwillopen

HybridHorizontalSpacekeeper–InstallationOperationMaintenanceManual

OPERATION

R090303InstallationOperationMaintenanceManualissubjecttochangewithoutnoticePage12

duringstart‐up.Iftheswitchdoesnotremakewiththe5minuteignoreperiod,

thecompressorwillimmediatelybestopped.

e. AirtemperaturesensorTa–SensorTawillpreventcompressoroperationifthe

airflowingthroughtheunitisbelow60°F(15°C).

f. WatertemperaturesensorTw–SensorTwwillpreventcompressoroperationif

theoutgoingfluidtemperatureisabove140°F(60°C).

g. RefrigeranttemperaturesensorTr–SensorTrwillpreventcompressor

operationifthecoiltemperatureisbelow35°F(2°C).

h. AnyoftheabovefaultswillbeindicatedwiththeDiagnosticCodedescribed

undertheDIAGNOSTICSsection.

COOLOPERATION

1. Monitoringoftherefrigerantcyclecontinuesduringoperationofthecompressor.The

followingmalfunctionswillcausethecompressortoshutdown:

a. Iftheheadpressureexceedsthesetpointofthehighpressureswitch,theswitch

willopenandthecontrolboardwillterminatethecompressoroperationwithin

10seconds.Atthistimeaflashcodeof6willbeinitiatedonthereddiagnostic

LED15.Compressoroperationwillberestoredinaccordancewiththe

“Intelligentreset”algorithm.

b. Ifthesuctionpressuredropsbelowthesetpointofthelowpressureswitch,the

switchwillopenandifitremainsopenbeyondthe5minuteignoreperiodafter

startup,compressoroperationwillbeterminatedwithin10seconds.

Compressoroperationwillberestoredinaccordancewiththe“IntelligentReset”

algorithm.Aflashcodeof5onthereddiagnosticLEDwillbeinitiatedatthis

time.

c. IntelligentResetAlgorithm–Ifaloworhighpressureswitchopensandremains

openformorethan10minutes,ahardlockoutwillbeinitiatedandthecooling

modewillbelockedoffuntilthecontrolsaremanuallyreset.Atthesametime

thefaultrelayK3willbesettoalarm;however,iftheopenswitchcloseswithin

10minutesarestartcycleisinitiated.Therestartcyclebeginswitha10minute

delayafterwhichifthereisacoolcallinplaceandallotherenablersarewithin

thestartparameters,thecompressorwillagainbeputintooperation.Should

eitherofthepressureswitchesopenagain,theshutdownprocedurewillcycle

again,followedbyarestart.Theintelligentresetwillallowtwoopenswitch

shutdownsandrestartsina24hourperiodandathirdshutdownwithin24

hourswillputtherefrigerationsystemintoafullandhardlockout,requiringa

HybridHorizontalSpacekeeper–InstallationOperationMaintenanceManual

OPERATION

R090303InstallationOperationMaintenanceManualissubjecttochangewithoutnoticePage13

powerdowntoreset.Iftwoorlessswitchopenshutdownsoccurwithina24

hourperiod,theywillbeerasedfrommemoryandwillnotcontributetoafuture

hardlockout.(Ahardlockoutwillpreventcompressoroperationuntilthe

controlsarepowereddownforatleast20seconds,andthegreenpowerlight

goesout.Asoftlockoutisacompressorshutdownthatwillberestoredoncethe

conditioncausingtheshutdownreturnstonormal.)

d. Duringcompressoroperation,refrigeranttemperature,systemfluid

temperatureanddischargeairtemperaturearecontinuouslymonitored.Ifthe

refrigeranttemperaturedropsbelow35°F,compressoroperationwillbe

disabled.After10minutesanautoresetoccursandthecompressorwillbe

enabledassoonasthetemperaturerisesabove60°F.Actualcompressorrestart

willbedelayedaminimumof5minutesbytheanti‐recycletimer.Aflashcodeof

2willbeinitiateduponalowrefrigeranttemperatureshutdown.

e. Iftheoutgoingsystemfluidtemperaturerisesabove140°F,compressorstartup

willbedisabled.After10minutesanautoresetoccursandthecompressorwill

beenabledassoonasthetemperaturedropsbelow115°F.Theoutgoingsystem

fluidsensorismountedontheleavingfluidpipe.Actualcompressorrestartwill

bedelayedaminimumof5minutesbytheanti‐recycletimer.Aflashcodeof3

willbeinitiateduponahighoutgoingsystemfluidtemperatureshutdown.

f. Ifthedischargeairtemperaturedropsbelow50°F,compressoroperationwillbe

disabled.After10minutesanautoresetoccursandthecompressorwillbe

enabledassoonasthetemperaturerisesabove60°F.Thedischargeair

temperaturesensorismountedonthefanhousing.Actualcompressorrestart

willbedelayedaminimumof5minutesbytheanti‐recycletimer.Aflashcodeof

4willbeinitiateduponalowdischargeairtemperatureshutdown.

g. Thecondensatelevelsensorisa100ohmthermistorthatisheatedfor15

secondsevery4minutes.Itstemperatureismeasuredatthebeginningofthe

heatcycle,andagainattheendoftheheatingcycle.Ifthecondensatelevelrises

abovethesensoritwillnotwarmupduringthewarmupcycle,andthe

temperaturechangewillbeinsignificant.Itisthislackoftemperaturechange

thatthecontrollerseesasanimpendingcondensateoverflow.Whenhigh

condensatelevelisdetected,compressoroperationisimmediatelyterminated,

andatthesametimethefanisstoppedfor30seconds,andthenrestarted.At

thistimeaflashcodeof7willbeinitiated.The4minutecyclewillcontinueuntil

thecoolingcallisnolongerinplace.Ifthecondensateleveldropsbelowthe

sensor,compressoroperationwillbereturnedtonormal.However,ifthe

condensatelevelstaysabovethesensorformorethan15minutes,thefault

HybridHorizontalSpacekeeper–InstallationOperationMaintenanceManual

OPERATION

R090303InstallationOperationMaintenanceManualissubjecttochangewithoutnoticePage14

alarmwillbetriggered.Thisfaultsignalwillautomaticallyresetoncethe

condensatelevelgoesbelowthesensor.

Note:Thelastflashcodewillbemaintainedinmemoryfor1weekoruntiltheunitcontrolsare

powereddown.Theflashcodewillcontinueuntiltheproblemhasclearedandthecompressorhas

beenputintooperation.Ifacoolingcallisinplace,itmustbedisengagedbeforethecauseofthe

lastalarmshutdowncanbeidentified.

OPERATIONALGORITHM

Thereareseveralcontrolalgorithmstopreventcyclingandproblematicoperation.Theseare:

1. DoubleCall–Ifthermostatconnectionsorsetupisincorrectresultinginasimultaneous

callforbothheatingandcooling,theunitwillnotoperate.Thisconditioncanbe

observedonthethermostatconnectionLEDs.(Note:Aheatpumpthermostatwill

presentthisscenario)

2. ReverseCycleCall–Poorlylocatedautomaticchangeoverthermostats(ie.thermostats

mountedonawalloppositeadischargegrill,orathermostatinadoorwaytooutside)

cantriggerheatingandcoolingmodechangesmanytimesanhour.TheCGCcontroller

hasa10‐minuteanti‐modechangetimerforbothheatingandcoolingmodechanges.

Thecontrollerwillnotacceptachangeinmodeuntil10minuteshaveelapsedsince

terminationoftheoppositecall.

THERMOSTATCONNECTIONS

TheCGCcontrolboardhasbeendesignedtooperatewithmoststandard24VACthermostats.

ThesearepoweredfromtheCGCboardwith24VACandsimplyswitchpowerONtoeachofthe

Heat(W),Cool(Y),Fan(G)orAux(A).Whilemostpresentdaythermostatsoperateinthismanner

thereareothersthatmayormaynotworkproperly.Thefollowingshouldbecheckedoutfor

satisfactoryperformancepriortoinstallation:

1. HeatPumpThermostat–Someheatpumpunitsdonothaveheatrelays(thereforeare

notcompatiblewithstandardthermostats)andrequire“HeatPumpThermostats”.

Thesethermostatscallforbothheatingandcoolingononeofthesignalwires.These

thermostatsarecompletelyincompatiblewithCGC’scontroller.

2. Mercurybulbthermostat‐Thistypeisproblematicbutcanbeused.Unfortunately,the

anticipatorsareaproblem.Heatanticipatorsmustbeinserieswithahighcurrentrelay

orvalvetofunction,sodonotperformonanelectroniccircuit.Thiswillresultinlarger

HybridHorizontalSpacekeeper–InstallationOperationMaintenanceManual

OPERATION

R090303InstallationOperationMaintenanceManualissubjecttochangewithoutnoticePage15

thannormaltemperatureswings.Thecoolanticipator,ifoversized,canbleedenough

currenttoindicateacoolingcallevenafterithasbeenterminated.

3. Batterypoweredthermostats–Thesethermostatsweredevelopedasreplacementsfor

oldmercurybulbthermostatsthathad4wireconnectionswhile24Velectronic

thermostatsrequired5wires.ThesewillworkwithaCGCboard,althoughCGCdoesnot

recommendthem.Theyrequireperiodicbatteryreplacement,whichissomethingthat

shouldbeavoidedifpossible.

4. Powerstealingthermostats–Thistypeofthermostatiselectronicandwasalso

developedasareplacementforoldmercurybulbthermostats.Thesetooare

problematicinthattheybleedasmallamountofcurrentdownthesignalwiresandthis

maybeinterpretedasasignalforheatorcool.

5. Triacswitchedcontrollers–Thisisacommonlyusedswitchingdeviceandallcontrollers

testedtodatehavefunctionedflawlessly.CGCrecommendsthatpriortoinstallationof

athirdpartysuppliedcontroller,itbecheckedforcompatibility.CGCcanconfirmthis.

6. Relayswitchedcontrollers–ThistypeofcontrollerworkswellwithCGCdevices.

SHUTDOWNOUTPUT

TheCGCboardhasanoptionalinputterminalstripthatallowsfortwotypesofremoteshutdown.

Thesearea)compressorshutdownandb)unitshutdown.

Theadvantageoftheseinputsisthatmanyunitscanbeconnectedinparallelandwhenpowered

byanindependent24VACsignaloneorbothoftheseactionscanbeimplemented.Commonuses

are:

a. Dutycyclingfordemandcontrol

b. Globalnightsetback

c. Heatingonlymodeduringemergencypowerperiods

TheCGCcontrollerisalsosetupsotheseshutdownfunctionscanbeinitiatedindividuallywithon

board24Vpower.Thiscapabilityallowsunitorcompressorshutdownbasedonadoorswitch,a

lightswitch,oroccupancyswitch.Aseparate24Vpowersupplyisrequirediftwoormoreunitsare

beingshutdown.

FAULTALARMOUTPUT

TheCGCboardisprovidedwithafaultalarmindicationandoutput.Thefaultalarmrelay

providesnormallyopenandnormallyclosedcontactsforuseintransmittingfaultconditions.

NOTE:ThefaultalarmisenergizedforNORMAL,andde‐energizedforfault.Assuch,iftheunit

HybridHorizontalSpacekeeper–InstallationOperationMaintenanceManual

OPERATION

R090303InstallationOperationMaintenanceManualissubjecttochangewithoutnoticePage16

isnotpowered,iftheboardfuseisblown,oriftheelectronicsaredamaged,afaultcondition

willbeindicated.

ThefaultrelayisparalleledwiththeFaultLEDwhichwillbeONwhennofaultconditionexists.

Otherfaultconditionsare:

d. Hardlockoutduetohighorlowpressureswitchbeingopenfor10minutesorlonger.

e. Hardlockoutduetothreehighorlowpressureshutdownsina24hourperiod.

f. Highlevelcondensateforaperiodinexcessof15minutes.

HybridHorizontalSpackeeper–InstallationOperationMaintenanceManual

COMMISSION&STARTUP

R090303InstallationOperationMaintenanceManualissubjecttochangewithoutnoticePage17

SystemFlushing:

Propersystemcleaningandflushingisanimportantaspectofthecommissioningandstartup

procedureforhybridunits.Ensurethesystemhasbeenflushedproperly.Thispreventsfouling

oftheunit’sheatexchangers.

NOTE:Hydroniccoilsarenot100%drainable.

SystemFluid:

Ensurethatsystemwatertemperatureiswithinanacceptablerangetofacilitatestart‐up(80‐

120°F)forcoolingand(100–140°F)forheating.

SystemWaterpH:

SystemwatershouldhaveaneutralpHbalanceofapproximately7.5whichwillextendthelife

ofthehoses,heatexchangers,andotherwatersideaccessories.

WaterFlowRate:

Openallisolationvalvestotheunit.Ensurethattheenteringandleavingfluidtemperaturesof

thehybridunitinoperationareacceptable.Thereistypicallyan8to12degreedroporrisein

temperature,dependingonwhethertheunitisincoolingorheating.Underextreme

conditions,slightvariancesinthetemperaturemaybenoted.

FreezeProtectionfromWaterSystem:

Ensurethatfreezeprotectionisprovidedfortheoutdoorportionoftheloopwatersystem.

Inadequatefreezeprotectioncanleadtocoildamage.

NOTE:Apotentialissuemayariseduringconstructionwherethesystemfluidloopisdrained

afterbeingcleaned,flushedandtested.Hybridverticalstackunitswillnotcompletelydrain

andmayholdfluidinthecondenserorheatingcoil.Extensivedamagemayresulttointernal

componentsifthesystemfluidfreezesunlessadequateglycolisadded.

RemoveAirfromSystemFluidLoop:

Airinthesystemimpairsunitoperationandcancauseerosioninthesystempiping.

HybridHorizontalSpackeeper–InstallationOperationMaintenanceManual

COMMISSION&STARTUP

R090303InstallationOperationMaintenanceManualissubjecttochangewithoutnoticePage18

CleanUnitFilters:

Confirmthattheunitfiltersthatarebeingusedareclean.Thiscontributestotheproper

operationoftheunitbyensuringthatthereisadequateairflowacrossthecoil.

SAFETYNOTE:

Inthefollowingpartoftheprocedureitwillbenecessarytoaccesstheareasaroundthe

electricalwiringandthecircuitboard.Donotadjustorremoveanyboardconnectionsorwiring

connectionstoothercomponentswithoutfirstpoweringdowntheunit.OnolderSKH008to

018,thedisconnectwillbeapowerplugatareceptacle.Onmodelsizes20andpostOct7/2005

SKH008to018uptherewillbeaswitchdisconnect.Disconnectsareusuallywithinreachofthe

unit.Exercisecautionatalltimes.

VerifyFanRotation&CompressorOperation(3‐Phase):

WiththepowerOFF,removethefrontpanelandtheelectricalpanelcover.Removeany

thermostatblockandturnpowerONtotheunitwiththeelectricaldisconnect.

Ensurethatthecorrectstandbyprotocolisinplace‐thefollowingboardlightswillcomeonin

standby:Power,HP,LP,andAlarm.

Inspectthefansectiontoensurethatitisclearofanydebrisandthatthefanrotatesfreely.

CGC’sHorizontalSpacekeeperunitscomeequippedwitha3‐phasefanandcompressorthatare

matchedtoeachotheraswellastheotherinternalcomponents.Althoughinternalconnections

tothefanandcompressoraremadeatthefactory,variancesinpowersupplyinthefieldwill

requirethatbothcomponentsbetestedforcorrectoperation.Theprocedureisoutlined

below:

•Usingascrewdriverwithaninsulatedhandle,pushandholdinthemanualplastic

buttonofthefancontactorforafewseconds,makingsurenottotouchanyofthe

metalparts.Thiswillcausethefantorotate.

•Thecorrectrotationwillhavethefanvanesrotatingtowardsthehousingexit.

•Iftherotationisincorrect,powerOFFtheunitandswitchtwoofthethreewiresatthe

bottomofthecontactorthatfeedthefan.PowerONtheunitandagainusingthe

screwdriver,pressthecontactorforafewsecondstoactivatethefan.Therotation

shouldnowbereversed.

This manual suits for next models

11

Table of contents

Other CGC Heat Pump manuals

Popular Heat Pump manuals by other brands

AERMEC

AERMEC AN R407C Technical and Installation Booklet

Fondital

Fondital PROCIDA AWM X6 installation manual

sopra

sopra PASRW040-P-BP Installation instructions manual

Zehnder Rittling

Zehnder Rittling ComfoClime 24 Installer manual

Samsung

Samsung DV8 T 2 Series user manual

AQUAHEAT

AQUAHEAT TF200/3 operating manual

Cairox

Cairox R-AQUA HPB R290 user manual

Carrier

Carrier 50FF/FC 020-093 Installation, operation and maintenance instructions

Nibe

Nibe FIGHTER 640P Installation and maintenance instructions

Emerson

Emerson Copeland EazyCool ZX Series manual

Nibe

Nibe F1155 Series Installer manual

Lennox

Lennox HP29 Series Unit information