Channel Lock VJC607PF-C 2001 User manual

CAUTION: FOR YOUR SAFETY Read and understand

this manual before use. Keep this manual for future

reference.

SAVE THIS MANUAL FOR FUTURE REFERENCE

Pay close attention to the Rules for Safe Operation, Warnings, and

Cautions. You will enjoy years of safe, reliable service if you use your

tool properly and only for the purpose for which it is intended.

VJC607PF-C 2001

TABLE OF CONTENTS

SECTION PAGE

Safety Instructions and Warnings . . . . . . . . . . . . . . . . . 1

Double Insulation Instructions . . . . . . . . . . . . . . . . . . 2

Extension Cord . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Unpacking and Checking Carton Contents . . . . . . . . . . . . 4

General Assembly Instructions . . . . . . . . . . . . . . . . . . 5

Dry Vacuum Operation . . . . . . . . . . . . . . . . . . . . . . . 6

Liquid Vacuum Operation . . . . . . . . . . . . . . . . . . . . . 7

Blowing Operation . . . . . . . . . . . . . . . . . . . . . . . . . 8

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Installing & Cleaning Cartridge Filters . . . . . . . . . . . . . . 9

Installing & Cleaning Foam Sleeve Filter . . . . . . . . . . . . . 9

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Exploded View and Parts List . . . . . . . . . . . . . . . . . . . 11

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Thank you for purchasing this Channellock® wet/dry vacuum cleaner. Feel

engineered for optimal performance.

This vacuum is capable of picking up liquids

and dry materials.

FOR YOUR SAFETY: CAREFULLY READ AND UNDERSTAND ALL

INSTRUCTIONS

WARNING! THE POWER CORD ON THIS PRODUCT

CONTAINS LEAD, A CHEMICAL KNOWN IN THE STATE

OF CALIFORNIA TO CAUSE BIRTH DEFECTS OR OTHER

REPRODUCTIVE HARM. WASH HANDS AFTER HANDLING.

1

SAFETYINSTRUCTIONS & WARNINGS

IMPORTANT SAFETY INSTRUCTIONS

Read and understand all instructions before using this vacuum. Read and

understand this owner’s manual and all labels on the Wet/Dry Vacuum cleaner

before operating. Safety is a combination of common sense, staying alert and

knowing how your vacuum works. Use this Wet/Dry Vac only as described in this

manual. To reduce the risk of personal injury or damage to your Wet/Dry Vac, use

only Channellock® recommended accessories.

For Household Use Only.

SAVE THIS MANUAL FOR FUTURE REFERENCE.

WARNING: TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK OR INJURY:

• Do not run vac unattended.

•

paints, natural gas, hydrogen, or explosive dusts like coal dust, magnesium

vapors or dust.

• Do not vacuum anything that is burning or smoking, such as cigarettes,

matches, or hot ashes.

• Keep cord away from heated surfaces.

• Do not expose to rain. Store indoors.

• Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

• Do not use with damaged cord, plug or other parts.

• If your Wet/Dry Vac is not working as it should, has missing parts, has been

dropped or damaged, left outdoors or dropped into water, return it to an

independent service center.

• Do not pull or carry by cord, use cord as handle, close a door on cord, or pull

cord around sharp edges or corners.

• Do not run Wet/Dry Vac over cord.

• Do not handle plug or the Wet/Dry Vac with wet hands.

• To reduce the risk of health hazards from vapors or dusts, do not vacuum toxic

materials.

• Do not use or store near hazardous materials.

•

when vacuuming liquids as described in the operation section of this manual.

• Do not allow to be used as a toy. Close attention is necessary when used by or

near children.

• To reduce the risk of injury from accidental starting, unplug power cord before

• Do not leave Wet/Dry Vac unattended when plugged in. Unplug from outlet

when not in use and before servicing.

2

• Turn off Wet/Dry Vac before unplugging.

• Do not put any object into ventilation openings. Do not vacuum with any

ventilation openings blocked; keep free of dust, lint, hair or anything that may

•

and moving parts.

• To reduce the risk of falls, use extra care when cleaning on stairs.

When using as blower:

• Direct air discharge only at work area.

• Do not use Wet/Dry Vac as a sprayer.

• Do not direct air at bystanders.

• Keep children away when blowing.

• Wear safety goggles.

DOUBLE INSULATION INSTRUCTIONS

WARNING: TO REDUCE THE RISK OF ELECTRIC SHOCK - DO

NOT EXPOSE TO RAIN. STORE INDOORS.

This Wet/Dry Vac is double-insulated, eliminating the need for a separate

grounding system. Use only identical replacements parts. Read the instructions

for Servicing Double-Insulated Wet/Dry Vacs before servicing. Use this Wet/Dry

Vac as described in this manual. Observe the following warnings that appear on

the motor housing of your Wet/Dry Vac.

DOUBLE INSULATED -GROUNDING NOT REQUIRED - WHEN

SERVICING USE ONLY IDENTICAL REPLACEMENT PARTS.

WARNING: FOR YOUR OWN SAFETY, READ AND UNDERSTAND

OPERATOR’S MANUAL. DO NOT RUN UNATTENDED. DO NOT

PICK UP HOT ASHES, COALS, TOXIC, FLAMMABLE OR OTHER

HAZARDOUS MATERIALS, DO NOT USE AROUND EXPLOSIVE

LIQUIDS OR VAPORS.

CAUTION:

• et/Dry

separately).

3

EXTENSION CORDS

When using an extension cord with your Wet/Dry Vac refer to the following table

to determine the required A.W.G. wire size. Before using the cleaner make sure

the power cord and extension cord are in good working conditions. Make repairs

or replacements before using the vacuum cleaner. Only use extension cords that

are rated for outdoor use.

Length of Extension Cord

25 Feet 50 Feet 100 Feet 150 Feet

110V - 120V 7.5 Meters 15.25 Meters 30.5 Meters 45.7 Meters

AMPS A.W.G Wire Size

0-6 18 16 16 14

7-10 18 16 14 12

11-12 16 16 14 12

13-16 14 12 NOT RECOMMENDED

• For household use only.

• To reduce the risk of electric shock-unplug before cleaning or servicing.

•

CAUTION: TO REDUCE THE RISK OF INJURY FROM MOVING PARTS -

UNPLUG BEFORE SERVICING.

WARNING: SERVICING OF DOUBLE-INSULATED WET/DRY

VACUUMM WITH A DOUBLE-INSULATED WET/DRY VACUUM,

TWO SYSTEMS OF INSULATION ARE PROVIDED INSTEAD

OF GROUNDING. NO GROUNDING MEANS IS PROVIDED ON

A DOUBLE-INSULATED APPLIANCE, NOR SHOULD A MEANS FOR

GROUNDING BE ADDED. SERVICING A DOUBLE INSULATED WET/DRY

VACUUM REQUIRES EXTREME CARE AND KNOWLEDGE OF THE SYSTEM,

AND SHOULD BE DONE ONLY BY QUALIFIED SERVICE PERSONNEL.

REPLACEMENT PARTS FOR A DOUBLE-INSULATED WET/DRY VACUUM

MUST BE IDENTICAL TO THE PARTS THEY REPLACE. YOUR DOUBLE-

INSULATED WET/DRY VAC IS MARKED WITH THE WORDS ‘DOUBLE

INSULATED’ AND THE SYMBOL (SQUARE WITHIN A SQUARE) MAY

ALSO BE MARKED ON THE APPLIANCE.

4

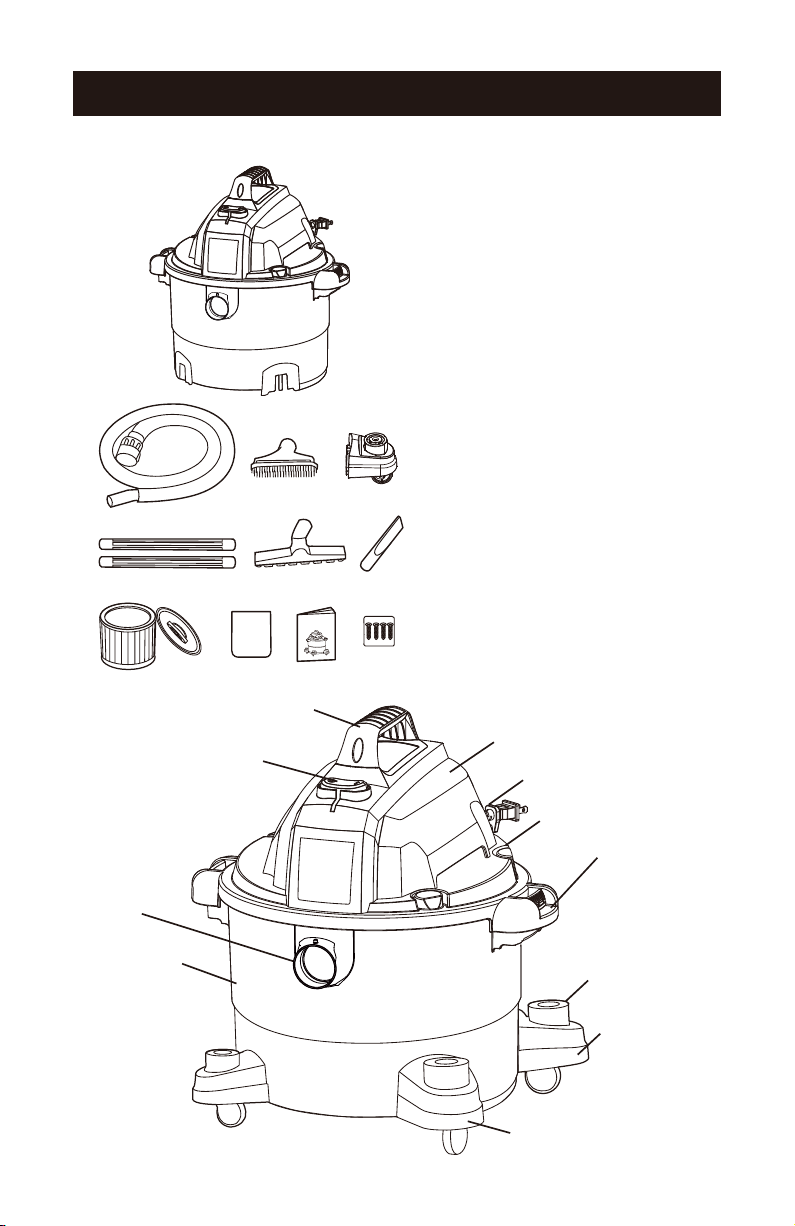

UNPACKING AND CHECKING CARTON CONTENTS

Key Description Qty

AVac Assembly ............ 1

BHose ................... 1

C2-in-1 Utility Nozzle.... .

.... .

. . . 1

DCaster Foot Assembly

4

E

F

Extension Wands ......... 2

G

Floor Brush/Squeegee . . . . . 1

H

Crevice Nozzle ........... 1

I

Cartridge Filter ........... 1

J

Foam Sleeve Filter ........ 1

K

4 Screws (Bag) ........... 1

Operator’s Manual ........ 1

NOTE: The hose and accessories for this

vacuum are 1.25" diameter.

Remove entire contents of carton. Check each item against the carton

contents list.

CD

B

E

J

H

G

IK

F

A

Blower Port

Accessory

Storage

Latch

Accessory Storage

Caster

Power Head

Caster Foot

Handle

On-Off Switc

Vacuum Port

Container

5

WARNING: DO NOT PLUG IN POWER CORD TO POWER OUTLET,

MAKE SURE PLUG IS DISCONNECTED BEFORE ASSEMBLING

THE WET/DRY VAC.

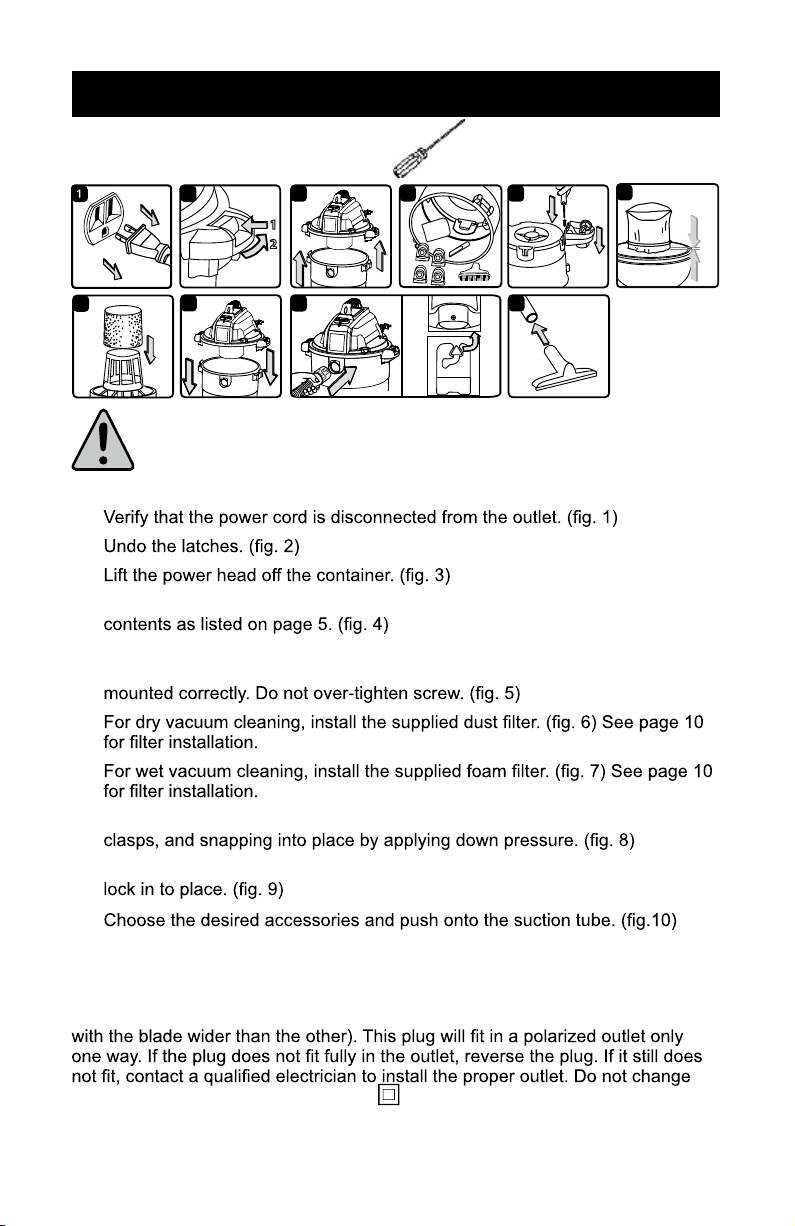

UNPACKING YOUR WET/DRY VACUUM & GENERAL ASSEMBLY

1.

2.

3.

4. Remove the contents from inside the container, make sure you have all

5. Turn the container upside down and insert the four caster feet into the slots

on the container and tighten with supplied screws. Verify that the casters are

6.

7.

8. Place the power head back on the container, aligning the top section with the

9. Insert the locking end of the hose into the port of the container and turn to

10.

POLARIZED PLUG

To reduce the risk of electrical shock, this appliance has a polarized plug (one

the plug in any way. Double insulation eliminates the need for the three wire

grounded power cord and grounded power supply system.

GENERAL ASSEMBLY INSTRUCTIONS

A Phillips head screwdriver is required.

2

2

1

5

4

3

7

8

9

10

6

6

WARNING: BE SURE TO READ, UNDERSTAND, AND APPLY

INFORMATION, ENTITLED ‘SAFETY INSTRUCTIONS & WARNINGS’.

DO NOT VACUUM IN AREAS WITH FLAMMABLE GASES, VAPORS,

OR EXPLOSIVE DUSTS IN THE AIR. FLAMMABLE GASES OR

VAPORS INCLUDE BUT ARE NOT LIMITED TO; LIGHTER FLUID, SOLVENT

TYPE CLEANERS, OIL-BASE PAINTS, GASOLINE, ALCOHOL OR AEROSOL

SPRAYS. EXPLOSIVE DUSTS INCLUDE BUT ARE NOT LIMITED TO; COAL,

MAGNESIUM, GRAIN OR GUN POWDER. TO REDUCE THE RISK OF HEALTH

HAZARDS FROM VAPORS OR DUST, DO NOT VACUUM TOXIC MATERIALS.

1.

2.

our

10 for installation instructions.)

3. Place the power head section back on the container, and secure it in place

OPERATING INSTRUCTIONS: DRY VACUUMING

4. Insert the locking end of the hose into the vacuum port on the power head and

lock in place. Push the required attachment onto the free end of the hose or

5.

6.

7. Once you have completed vacuuming, press the switch to the ‘O’ OFF position

and unplug the power cord from the outlet.

DRY-VACUUMOPERATION

DRY VACUUMING

O = OFF I = ON

DO NOT USE THE CARTRIDGE FILTER FOR LIQUID VACUUMING.

7

46

5

7

WARNING: BE SURE TO READ, UNDERSTAND, AND APPLY

INFORMATION, ENTITLED ‘SAFETY INSTRUCTIONS & WARNINGS’.

DO NOT VACUUM IN AREAS WITH FLAMMABLE GASES, VAPORS,

OR EXPLOSIVE DUSTS IN THE AIR. FLAMMABLE GASES OR

VAPORS INCLUDE BUT ARE NOT LIMITED TO; LIGHTER FLUID, SOLVENT

TYPE CLEANERS, OIL-BASE PAINTS, GASOLINE, ALCOHOL OR AEROSOL

SPRAYS. EXPLOSIVE DUSTS INCLUDE BUT ARE NOT LIMITED TO; COAL,

MAGNESIUM, GRAIN OR GUN POWDER. TO REDUCE THE RISK OF HEALTH

HAZARDS FROM VAPORS OR DUST, DO NOT VACUUM TOXIC MATERIALS.

1.

2.

DO NOT USE THE REUSABLE CLOTH FILTER FOR LIQUID VACUUMING.

OPERATING INSTRUCTIONS – WET VACUUMING

3.

4. Verify that the switch is in the ‘O’ OFF position before plugging the power cord

5.

6. After use, empty the container, clean and dry the inside and outside before

LIQUID VACUUM OPERATION

LIQUID VACUUM CLEANING

WARNING: DO NOT PLUG IN POWER CORD TO POWER OUTLET,

MAKE SURE PLUG IS DISCONNECTED BEFORE ASSEMBLING

THE WET/DRY VAC.

IMPORTANT! When vacuuming large quantities of liquids, do not immerse the

nozzle completely in the liquid; leave a gap at the tip of the nozzle opening to

action when the container reaches its maximum capacity. You will notice an

increase in motor speed. When this happens, turn off the machine, disconnect

from power supply, and drain the liquid into a suitable receptacle or drain. To

turn the machine off and remove plug from power supply. Empty the container,

clean and dry the inside and outside before storage.

REMEMBER!

6

5

8

MAINTENANCE

1.

2.

3.

4.

5.

6. Check the hose, attachments, and power cord to verify that they have not been

damaged.

BLOWING OPERATION

WARNING: ALWAYS WEAR SAFETY GOGGLES COMPLYING WITH

ANSI Z87.1 (OR IN CANADA, CSAZ94.3) BEFORE USING BLOWER.

WARNING: KEEP BYSTANDERS CLEAR FOR BLOWING DEBRIS.

WARNING: WEAR A DUST MASK IF BLOWING CREATES DUST

THAT MIGHT BE INHALED.

1. Verify that the power cord is disconnected from the outlet.

2. Make sure the container is empty before using as a blower.

3. Remove hose from the vacuum port.

4. Insert the locking end of the hose into the blowing port on the back side of the

5.

6.

7.

5

4

2

3

4

2

3

1

9

INSTALLING AND CLEANING FILTERS

Installing Cartridge Filter

1.

2. Remove power head and place in upside down position.

3. Install the cart

stops against the power head. ( g.2 & 3)

4.

Removing and Cleaning Cartridge Filter

1.

clockwise.

2.

3.

recommended.

4.

Installing Cartridge Filter.

5.

IMPORTANT:

ALWAYS USE DUST FILTER FOR DRY VACUUMING. If the machine is used

WARNING: KEEP BYSTANDERS CLEAR FOR BLOWING DEBRIS.

WARNING: WEAR A DUST MASK IF BLOWING CREATES DUST

THAT MIGHT BE INHALED.

INSTALLING AND CLEANING FOAM CLOTHFILTER

Installing Reusable Cloth Filter

1. Verify that the power cord is disconnected from the outlet

2. Remove power head and place in upside down position. Follow instructions to

10

3.

4. Replace the power head on to the container.

Cleaning Foam Sleeve Filter

1. With the removed power head in the upside down position, carefully remove

2.

3.

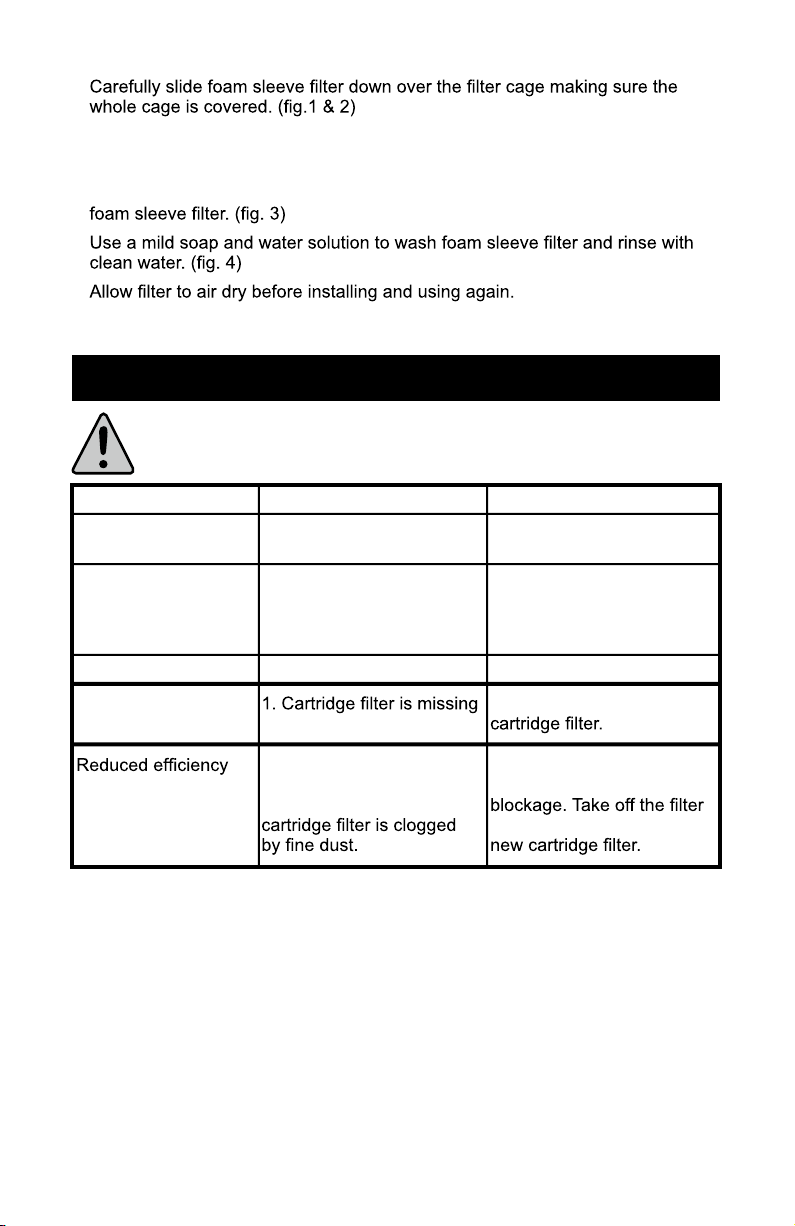

TROUBLESHOOTING

WARNING! TO REDUCE THE RISK OF ELECTRICAL SHOCK -

ALWAYS DISCONNECT THE PLUG FROM THE POWER OUTLET

BEFORE TROUBLESHOOTING.

SYMPTOM

Vacuum will not

operate.

POSSIBLE CAUSES

1. No power supply.

2. Faulty power cord.

3. Container full.

CORRECTIVE ACTION

1. Check power supply -

cord, breakers, fuses.

2. Unplug and check the

power cord. If damaged,

have it repaired by a

professional.

3. Empty Container.

Dust comes out of

motor cover. or damaged.

1. Attach or replace

and motor/speed

vibration.

1. There is a blockage

in the nozzle, hose, or

the container inlet. The

1. Check nozzle, hose

and container inlets for

and clean it, or install a

11

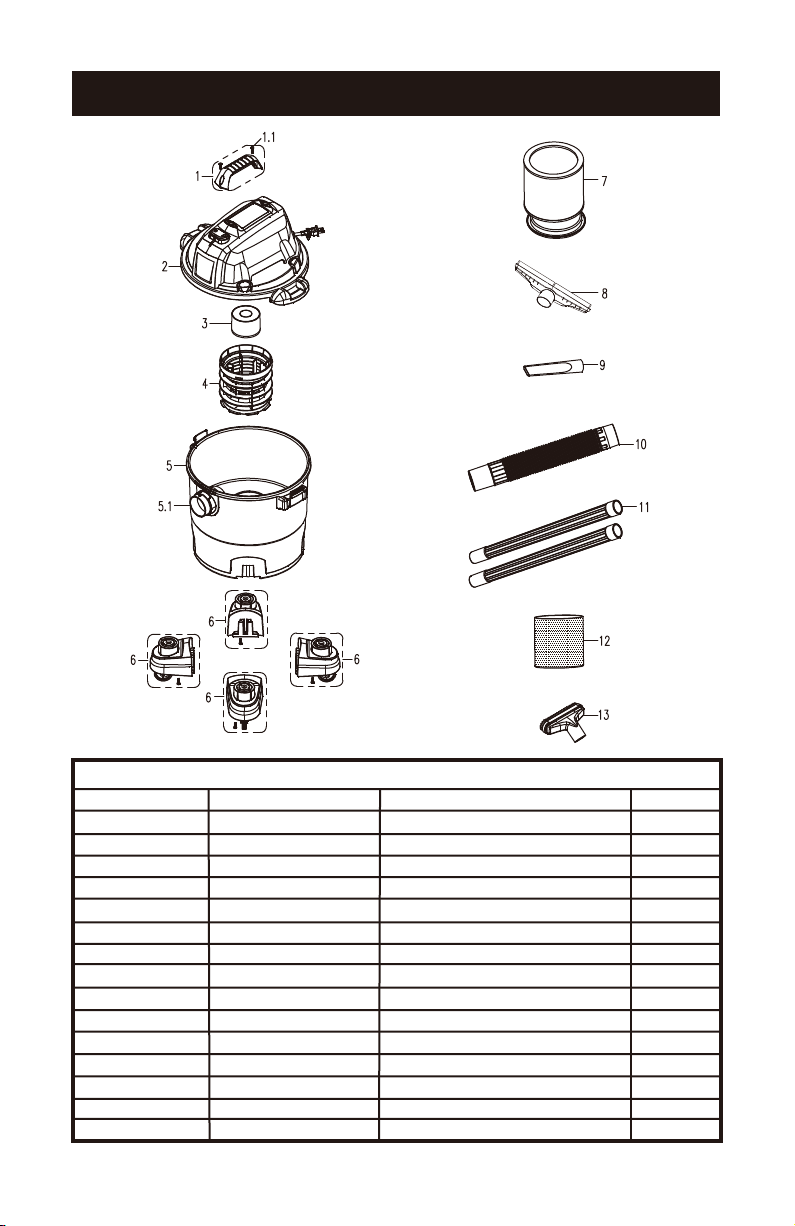

EXPLODED VIEW AND PARTS

KEY NUMBER DRAWING NUMBER DESCRIPTION QUANTITY

1 551049101 Handle Assembly 1

1.1 551017125 Screw ST3.9*16 2

2 Power Head Assembly 1

3 551005103 Water Seal Cup Assembly 1

4 551005104 Filter Basket 1

5 Tank Assembly 1

5.1 551011106 Suction Seat 1

6 551069105 Caster Foot Assembly 4

7 353879 WET/DRY Cartridge Filter 1

8 300443 10" Floor Squeegee 1

9 300442 9" Crevice Tool 1

10 365303 6' Hose 1

11 365300 19" Extension Wand 2

12

13

353780

300447

Foam Filter 1

2-IN-1 Utility Nozzle 1

300440 MANUAL PARTS LIST

12

CHANNELLOCK and CHANNELLOCK BLUE are registered trademarks of Channellock, Inc.

www.channellockproducts.com

Manufactured in China for Do it Best Corp. A Licensee of Channellock, Inc.

Fort Wayne, Indiana 46801 www.doitbestcorp.com

WARRANTY

We take pride in producing a high quality, durable product. This Channellock®

product carries a limited two (2) year warranty against defects in workmanship

and materials from date of purchase under normal household use. If product

is to be used for commercial, industrial or rental use, a 90 day limited warranty

will apply. Warranty does not apply to defects due to direct or indirect abuse,

negligence, misuse, accidents, repairs or alterations and lack of maintenance.

legal rights, and you may have other rights, which vary form state to state. For

product service call Customer Service at (866) 384-8432.

Table of contents

Other Channel Lock Vacuum Cleaner manuals