Instruction Sheet 60-4702-048 Revision H, November 8, 2019

PROGRAM

CONFIGURE

VIEW LOG

SELECT DIAG: (<-->)

TEST 'RAM'

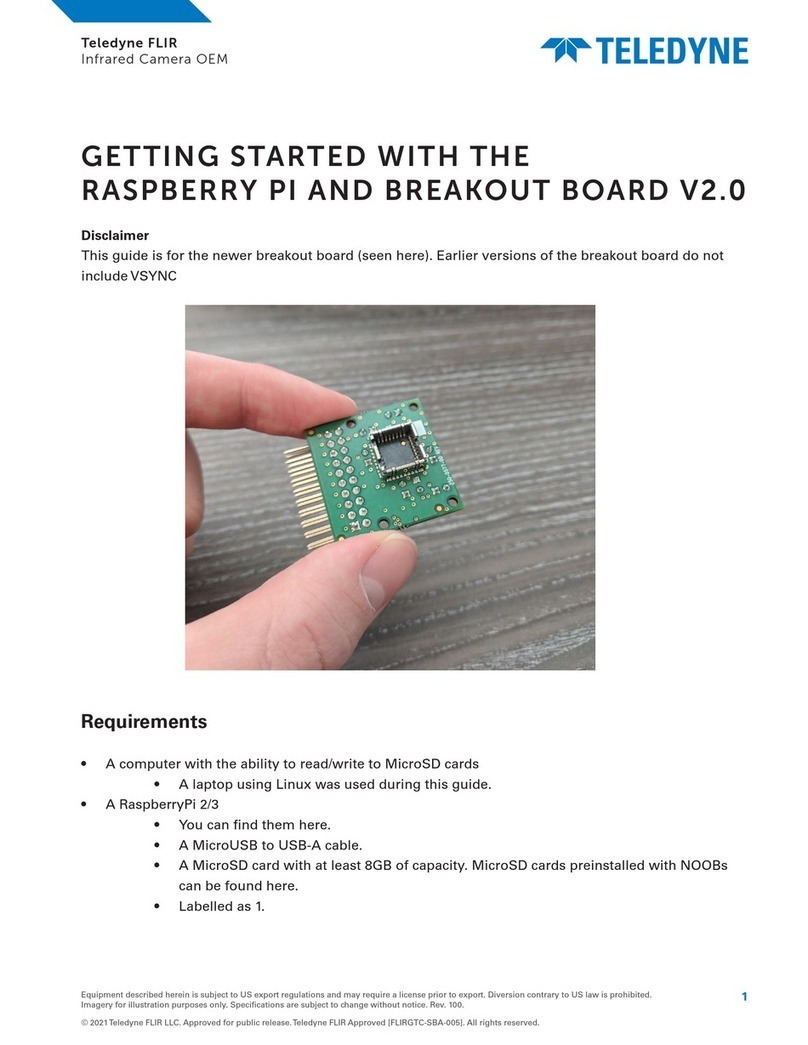

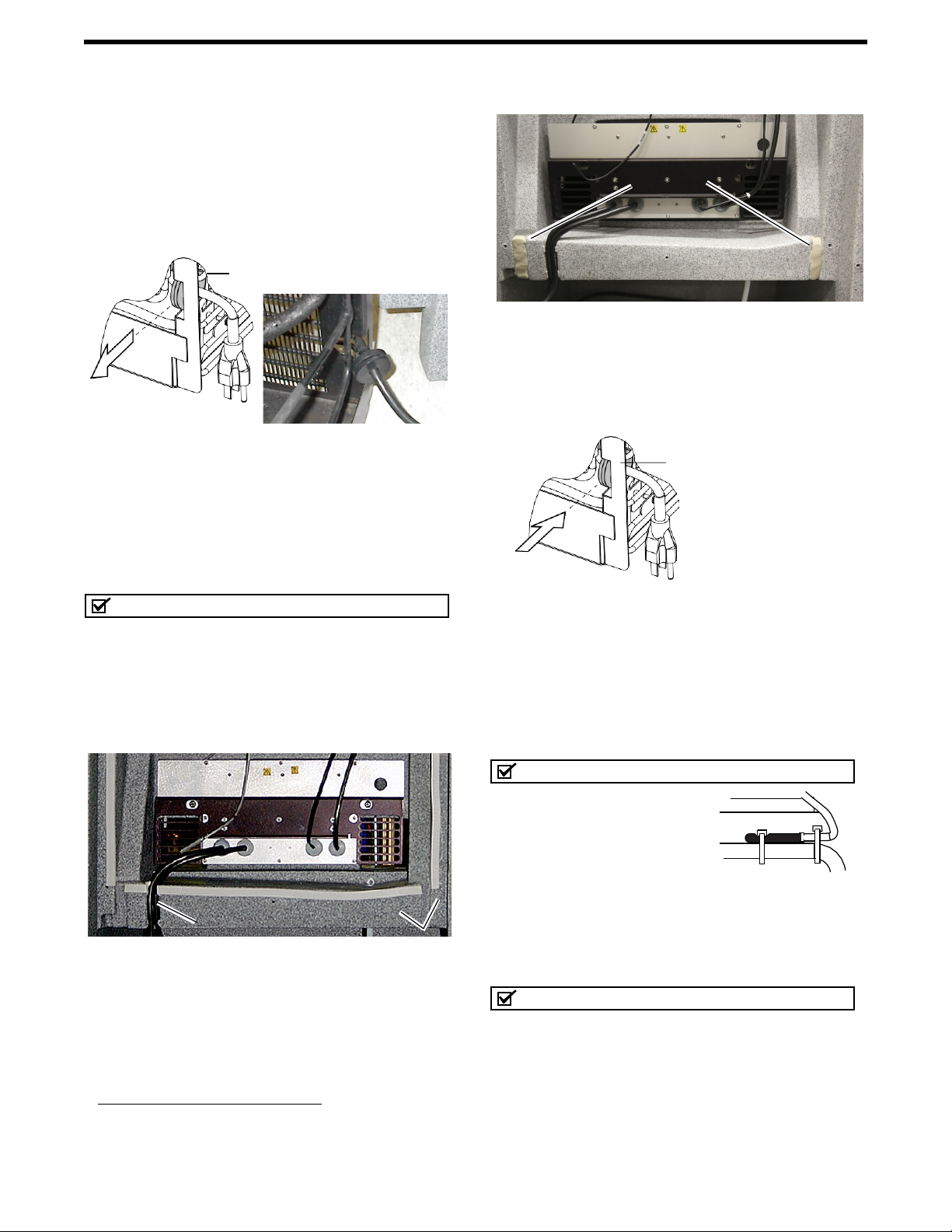

23. Install the cable tie to secure the power cord

that runs through the refrigeration assembly

(Figure 28). Ensure the slack in the power cord is

removed before securing refrigeration module

frame.

Install

cable tie

Figure 28: Install cable tie tosecure power cord

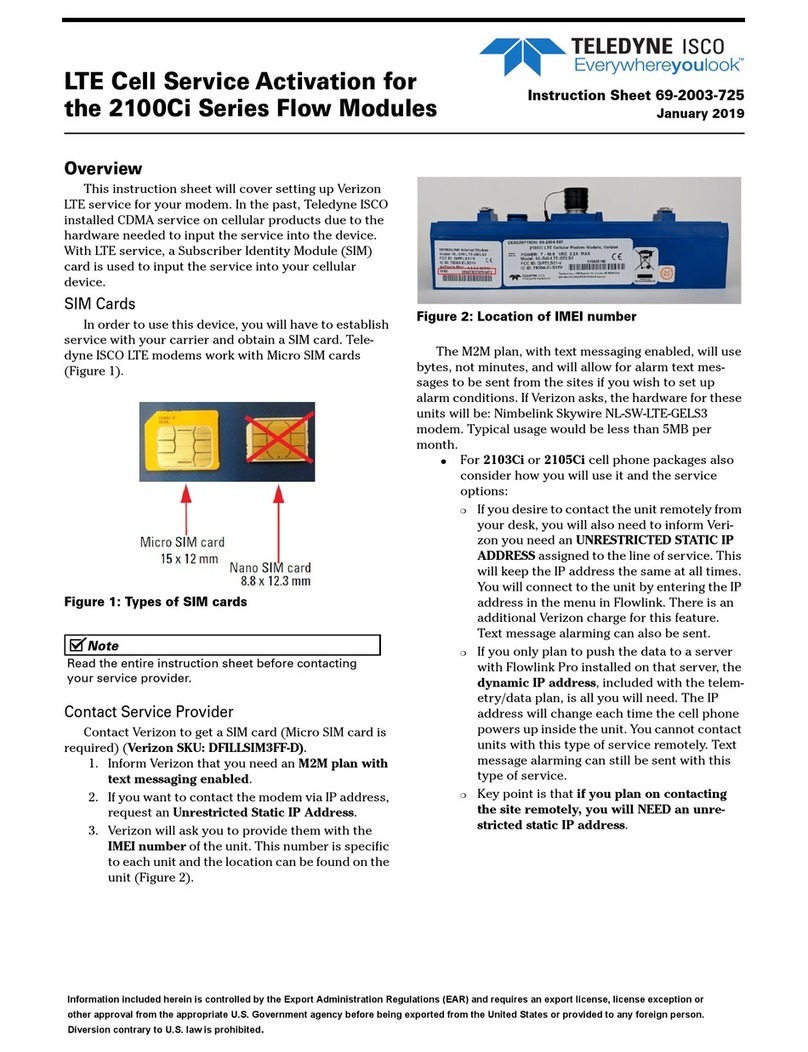

a. Mark two corners of the foam insulation with

1 1/2” x 4 1/2” lines (Figure 29).

Figure 29: Mark foam insulation

b. Cut the insulation panel as marked in the

previous step (Figure 30).

Figure 30: Cut foam insulation

c. Install foam panel on the refrigeration

module, taking precautions not to damage the

foam around the tubing (Figure 31).

Figure 31: Install the insulation panel

24. Reinstall the cover brace, back cover, and

insulation panel (Figure 14).

a. Restore AC power to the 5800 refrigerator.

25. Review the refrigerator temperature diagnostic

test, as described in the following section.

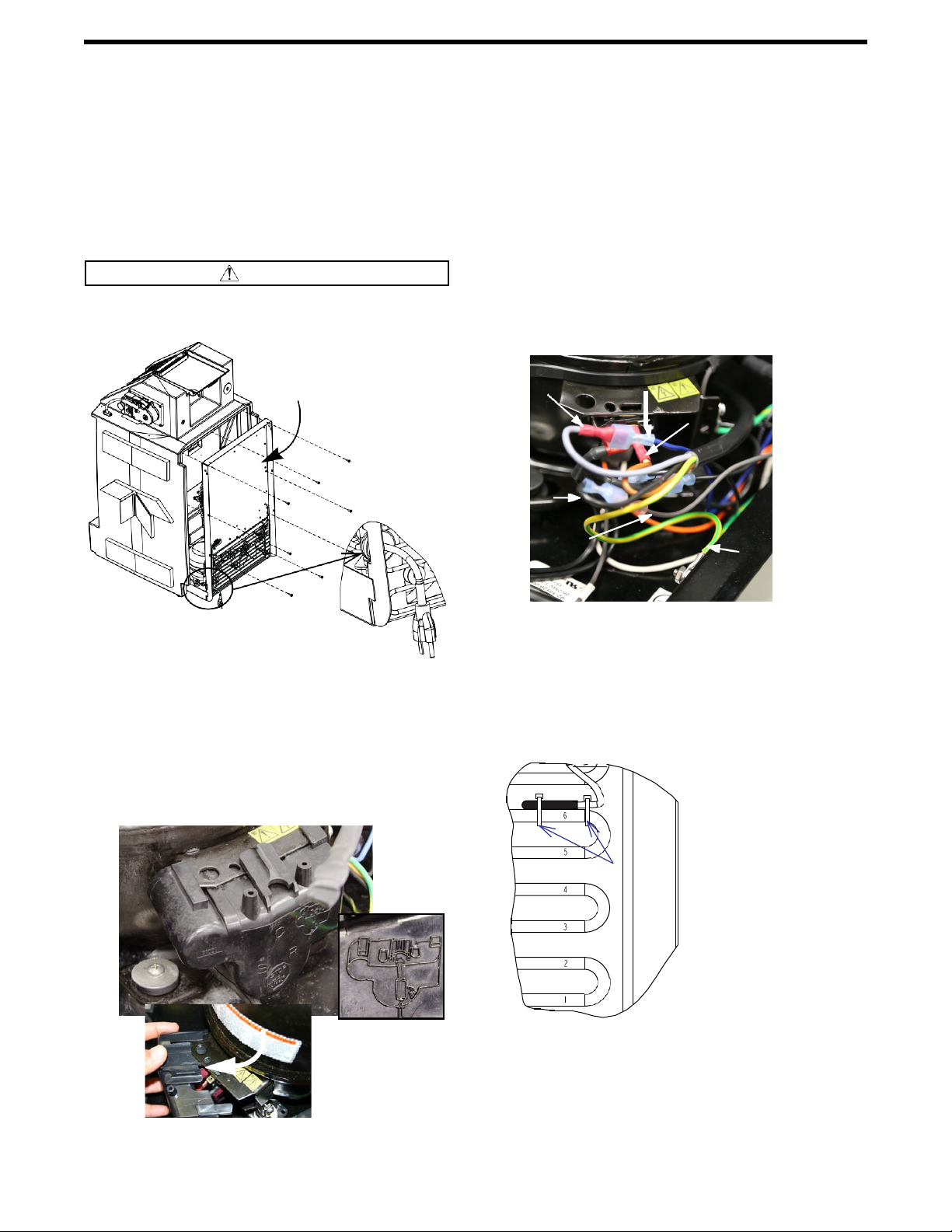

RefrigeratorTemperature Diagnostic

The REFRIG TEMPERATURE diagnostic displays the

temperature of the refrigerated compartment.

To start the diagnostics from the standby screen:

1. Select the CONFIGURE option and press Enter.

2. Press the left arrow button until the RUN

DIAGNOSTICS option is displayed. Press Enter.

3. Press the right arrow key 7 times to display

REFRIG TEMPERATURE. Press Enter to start the test.

When this test is started, the sampler should display

the temperature until you press the Stop or Enter

button. There is no pass or fail. This test simply

provides continuous temperature monitoring.

As the refrigerator cycles off and on, the reported

temperature will rise above and below the set

temperature. However, the average reported

temperature should be the same as the configured

temperature. The evaporator temperature may at times

read as low as –20° C; this is considered normal.

If the screen displays an asterisk (*) or inaccurate

temperature reading, the temperature sensor cable may

be malfunctioning.

Last modified November 8, 2019

Teledyne Isco

P.O. Box 82531, Lincoln, Nebraska, 68501 USA

Toll-free: (866) 298-6174 • Phone: (402) 464-0231 • Fax: (402) 465-3001

E-mail: IscoService@teledyne.com

Teledyne Isco is continually improving its products and reserves the right to change product

specifications, replacement parts, schematics, and instructions without notice.

REFRIG TEMPERATURE:

AIR= C EVAP= C

SELECT DIAG: (<-->)

REFRIG TEMPERATURE

SELECT OPTION: (<--

RUN DIAGNOSTICS

1 1/2 x 4 1/2 marks