Charles E1 User manual

e2006 Charles Industries Ltd.

All rights reserved. Printed in United States of America.

The availability of features and technical specifications herein

subject to change without notice.

Section 360-386-801 Equipment Issue 1

Second Printing, December 2006

Telecommunications Group

E1 Controller Unit

(3603-86)

Installation Guide

GENERAL DESCRIPTION

Document Purpose

This document provides installation information

for the for the E1 with SNMP (E1-S). This docu-

ment covers model number 3603-86.

Equipment Function

The E1-S is part of the 360-80 Intelligent Chan-

nel Bank (ICB). It allows direct connections to

public E1 networks.

Equipment Location/Mounting

Mount the E1-S in the primary slot of the

360-80. One controller unit must be installed in

the primary slot for proper system operation.

Performance History

This unit stores performance history for the last

30 days and over the last 24 hours in 15-minute

intervals. This performance history includes bit

error rate (BER), errored seconds (ES) and se-

verely errored seconds (SES).

Control Interface

This unit is managed through the Network Man-

agement Interface (NMI), which controls the pro-

visioning of the unit and obtains status informa-

tion from the unit. Provisioning and status infor-

mation is described in the Installation section of

this document. For operation of this interface,

see the Network Management Interface docu-

mentation.

This unit will maintain its default provisioning

until that provisioning is altered through the NMI.

If this unit’s provisioning is changed, it will main-

tain the new provisioning even if power is lost.

INSPECTION

Inspect for Damages

Inspect the equipment thoroughly upon delivery.

If the equipment has been damaged in transit,

immediately report the extent of damage to the

transportation company.

Equipment Identification

Charles Industries’ equipment is identified by a

model and issue number imprinted on the front

panel or located elsewhere on the equipment.

Each time a major engineering design change is

made on the equipment, the issue number is

advanced by 1 and imprinted on subsequent

units manufactured. Therefore, be sure to in-

clude both the model number and its issue num-

ber when making inquiries about the equipment.

STATIC-SENSITIVE

To prevent electrostatic charges from damaging

static-sensitive units:

Use approved static-preventive measures (such as

static-conductive wrist straps and static-dissipative

mats) at all times whenever touching units outside

of their original, shipped, protective packaging.

Do not ship or store units near strong electrostatic,

electromagnetic, or magnetic fields.

Always use the original static-protective packaging

for shipping or storage.

INSTALLATION

Attaching the Rear Panel

The rear panel of the unit should be installed

before all units are installed in the shelf, and be-

fore wiring begins.

Installing a New Unit

Step Action

1. If not already installed, install the rear panel,

screwing it to the appropriate mounting locations

on the shelf using the provided hardware.

2. Insert the unit into the shelf, making sure that the

unit is aligned with the card guides inside the

shelf.

CAUTION

Due to mechanical differences, the E1-S card

can only be installed in an Issue 3 or greater

ICB shelf.

3. Slide the unit fully in to the shelf.

CAUTION

If there is already a rear panel installed on the

shelf, check for interference. The rear panel

may need to be removed and replaced with

the rear panel shipped w/the new unit.

Step Action

4. Once the unit is fully inserted, tighten the secur-

ing screw on the front panel.

5. The unit will perform a self-test to ensure that it is

compatible with the network management soft-

ware on the system.

6. Wire the unit per the wiring section.

7. After the self-test is performed, check the soft-

ware provisioning of the card using the craft inter-

face on the front of the controller unit .

Installing a Replacement Unit

If you are replacing a unit that is already in ser-

vice, insure that the unit is the same as the unit

being replaced.

Step Action

1. Remove the wiring connectors from the front and

rear of the unit.

2. Unscrew the front panel securing screw to re-

lease the unit from the shelf.

3. Using the card ejector, remove the unit from the

shelf.

4. Follow the procedure for installing a new unit.

Wiring the Unit

Use the following steps to wire the unit.

Step Action

1. Connect E1 to the rear panel RJ48 jack (J1). If a

coaxial connection is needed, install Balun adap-

tor 97−001811.

2. If using the Ethernet network management inter-

face on the rear of the unit, connect the system

to the other units using J2 and J3.

3. If you are using composite clock, remove the

connector and wire the signal to the connector

CCLK IN.

4. Reinstall the connector with the composite clock

signal wires.

5. Power and alarm should already be wired. If not,

see the documentation for the ICB shelf.

Front Panel Switch and LED Definitions

The Audible Alarm Cut Off (ACO) switch is a

pushbutton used to open the audible alarm con-

tacts from the 360-80 system. This switch will only

mask audible indications of present alarm condi-

tions—it will NOT clear the alarm. If a new alarm

occurs, the alarm will re-enable.

The Address ID switch on the front panel is a mul-

ti-section switch for setting the system address on

the system management bus. This switch is used

if the system is connected together with other

360-80 systems into a central management con-

trol center. This switch allows the control center to

‘address’ the individual systems. See section on

network management for more information.

Table 1. LED Definitions

Label Color Status Indicates that...

POWER Green ON Unit is receiving power.

OFF The unit is not powered.

AR Red ON The unit is detecting a red

alarm on the E1 interface

caused by a loss of signal

(LOS) or a loss of framing

(LOF) or out of frame

(OOF) condition.

OFF Normal operation.

AY Yellow ON The unit is receiving a

YELLOW alarm condition

on the E1. This indicates

that a problem is up-

stream at some other de-

vice or network node.

OFF Normal operation.

TP Yellow ON The system is processing

the trunk signaling data

based on detected alarm

conditions.

OFF Normal operation.

LP Green ON The unit is in loopback.

This indication only oc-

curs during testing.

OFF Normal operation.

OPTIONING

Hardware Optioning

Option Type Choices Description

Compos-

ite clock

input ter-

mination

3-pin

connec-

tor

Termina-

tion

Place the Berg con-

nector between the

middle and bottom

pins to terminate

the composite clock

wired to the ICB.

Use for a single

ICB, or on the last

ICB in a daisy-

chained series.

No ter-

mination

Place the Berg con-

nector between the

top and middle pins

to remove termina-

tion from the com-

posite clock input.

This is done when

the clock will be

connected to addi-

tional equioment.

ICB Ad-

dress

(ad-

dress= 1

+ switch

setting)

Switch

settings

00

through

15

The default is 00.

Software Optioning

This unit comes from the factory with default provi-

sioning, which can be changed through Network

Management or the craft terminal interface. Each

unit has its own provisioning options. The provi-

sioning options are as follows with the default op-

tioning noted:

Option Choices Default

E1 Frame format Conventional CAS,

CRC4-CAS

CRC4-

CAS

Transmit E1 Timing

Source

External, Internal,

Looped

Internal

Test Generator (per

channel)

Tone Test, 1 KHz 0

dBm0, None

None

E1 Loopback Selec-

tion

Loopback, Release Release

CGA Process Mode Normal, CM2, CM3 Normal

Remote Control

Method

None, Occupy one

channel, facility

data link

facility

data link

ALARMS

This unit provides for alarm contacts for audible

and visual alarms. Access to the alarm contacts is

provided on the 360-80 shelf. Pressing the audible

alarm cut-off (ACO) switch clears the alarm indica-

tion for the audible alarm contacts (pressing this

switch does not clear the alarm). See the shelf

documentation for information on wiring. The unit

generates alarm indications based on the configu-

ration of the alarm registers. See section on net-

work management for more information.

NETWORK MANAGEMENT

Default Unit Configurations

The ICB stores all configuration settings in the

E1-S. The E1-S is shipped from the factory with

the default settings, which may be changed

through the network management interfaces.

Changing Unit Configuration Locally

The ICB can be configured through the front panel

craft terminal (MGMT) jack. See the craft terminal

interface documentation for procedures.

Network Management

The 360−80 channel bank can be managed via

two different interfaces over the Ethernet connec-

tion on the rear of the E1−S card. The Network

Management System (NMS) interface is GUI

based and requires proprietary software operating

on the managing PC. The Network Node Manager

(NNM) interface is SNMP based and requires

SNMP network manager software operating on

the managing PC. See NMS and NNM documen-

tation for more information.

To use either interface from outside the E1 control-

ler’s LAN, a “gateway” address must be defined.

The gateway address should be the same as the

IP address of the LAN’s router.

Front Panel RJ11 Jack

The RJ-11 jack on the front of the unit is the local

craft/control port. The default interface is an

RS-232 connection that defaults to 9600 baud, 8

bits, 1 stop and no parity. The interface through

the control port is VT-100. VT-100 operation on a

PC requires VT-100 emulation software. An IP

address and IP subnet mask must be configured

through the craft interface before the unit will com-

municate with the NMS/GUI or SNMP. To commu-

nicate with SNMP, the SNMP community table

must also be configured. See the network man-

agement section or the network management in-

terface documentation for more information.

A cable (03-200542-0) is available to connect be-

tween the front panel RJ11 jack and a DB-9 con-

nector.

E1 Jack

The RJ48 connector on the rear of the E1-S is for

the primary E1.

Rear Panel RJ45 Jack

The J2 RJ45 jack on the rear of the unit is for in-

terfacing to a network management control center

using SNMP or proprietary NMS/GUI software

over Ethernet.

Table 2. Front Panel RJ11 Jack Pinouts

Pin # Use DB9

1 NC

1 2 3 4 5 6 2 GND 5

1

2

3

4

5

6

3RCV (ICB in-

put)

3

4XMIT (ICB

output)

2

5Enable PC

(ICB input)

7

6 NC

Table 3. RJ-48C E1 Jack Pinouts (J1)

Pin # Use

1R (RCV from network)

1 2 3 4 5 6 7 8 2T (RCV from network

1

2

3

4

5

6

7

8

3

4R1 (XMIT to network)

5T1 (XMIT to network)

6

7

8

Table 4. RJ45 Ethernet Jack Pinouts (J2)

Pin # Use

1XMT (TD+)

1 2 3 4 5 6 7 8 2XMT (TD−)

1

2

3

4

5

6

7

8

3RCV (RD+)

4 NC

5 NC

6RCV (RD−)

7 NC

8 NC

TECHNICAL ASSISTANCE

If technical assistance is required, contact

Charles Technical Service Center at:

847–806–8500

800–607–8500

847–806–8556 (FAX)

[email protected] (e-mail)

This manual suits for next models

1

Other Charles Controllers manuals

Popular Controllers manuals by other brands

IMI NORGREN

IMI NORGREN B68G Installation & maintenance instructions

Mitsubishi Electric

Mitsubishi Electric QD62 user manual

Outback Power Systems

Outback Power Systems FLEXnet DC user guide

Panasonic

Panasonic S-Link FP2 Technical manual

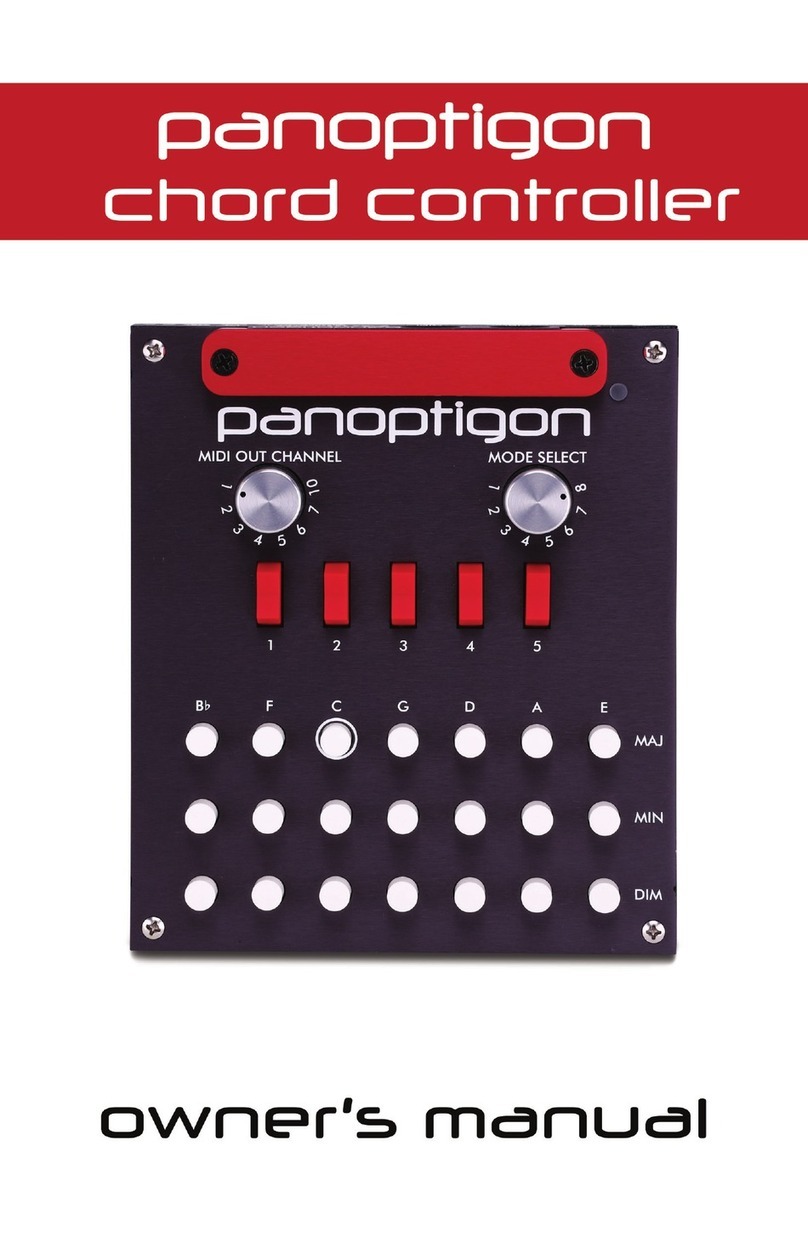

Panoptigon

Panoptigon Panochord owner's manual

EcoFlow

EcoFlow APP for Smart Home Panel user manual

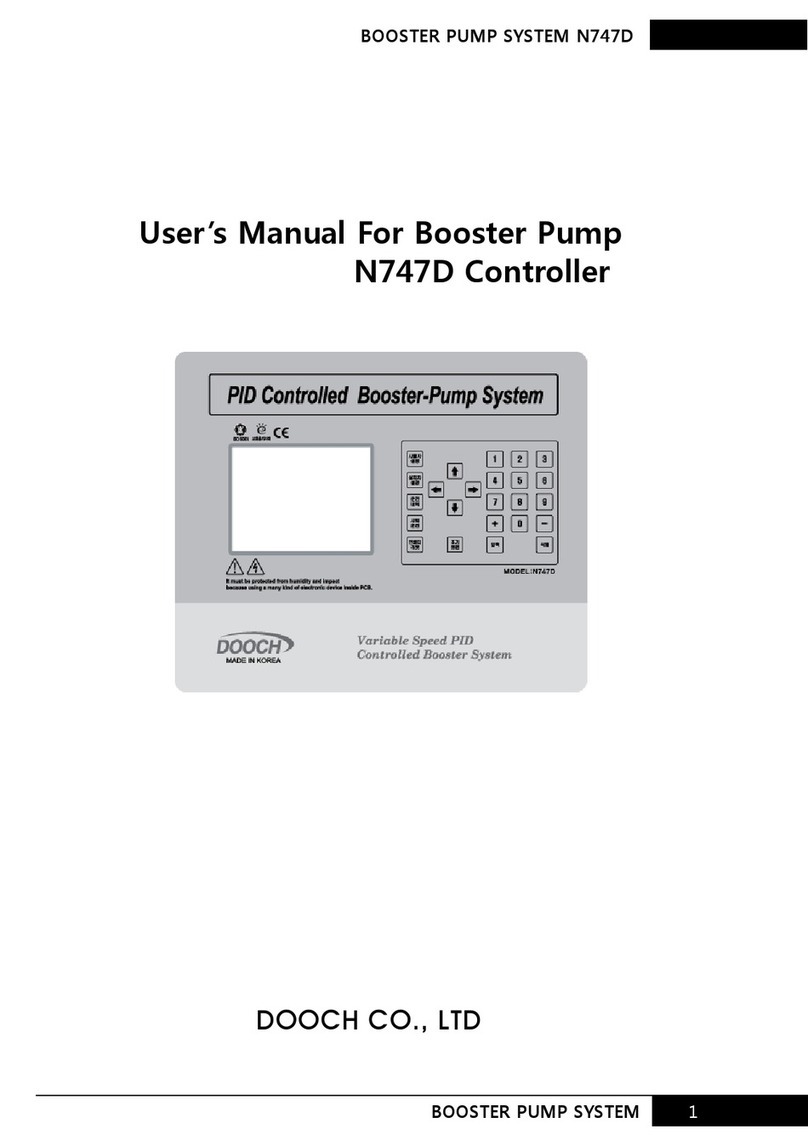

dooch

dooch N747D user manual

Bray

Bray 71 Seires Installation, operation and maintenance manual

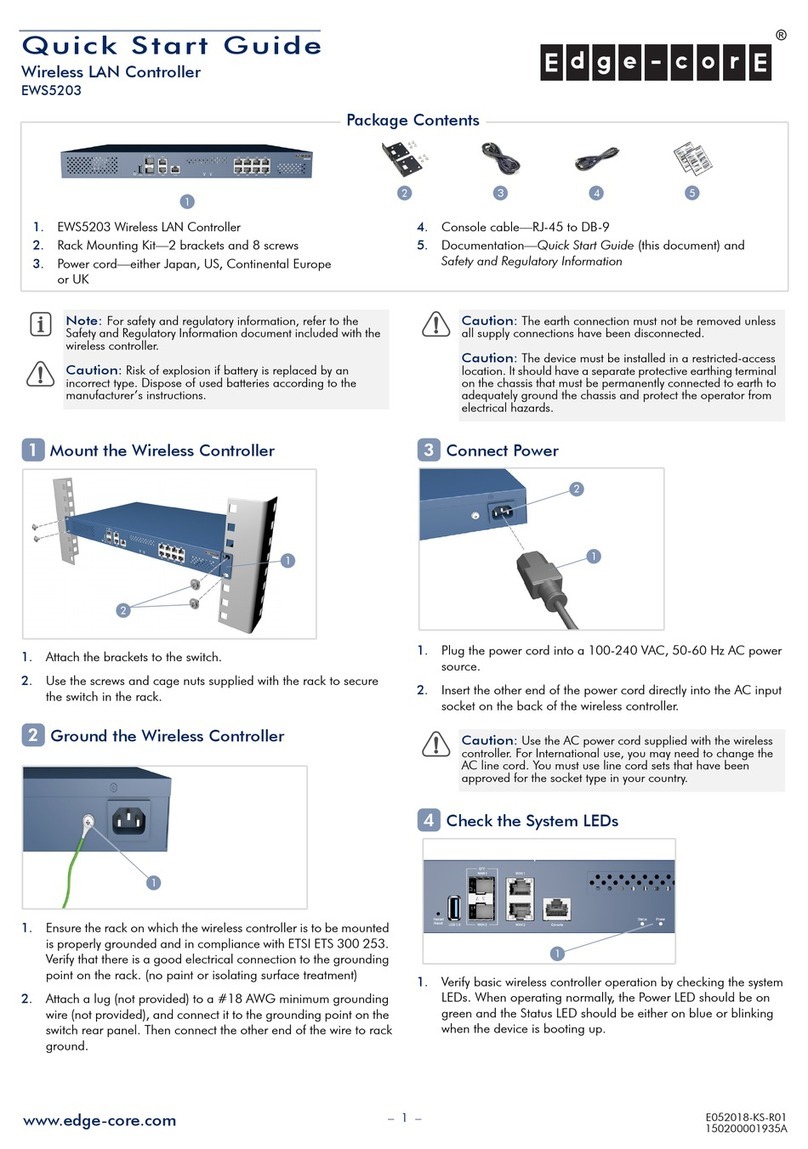

Edge-Core

Edge-Core EWS5203 quick start guide

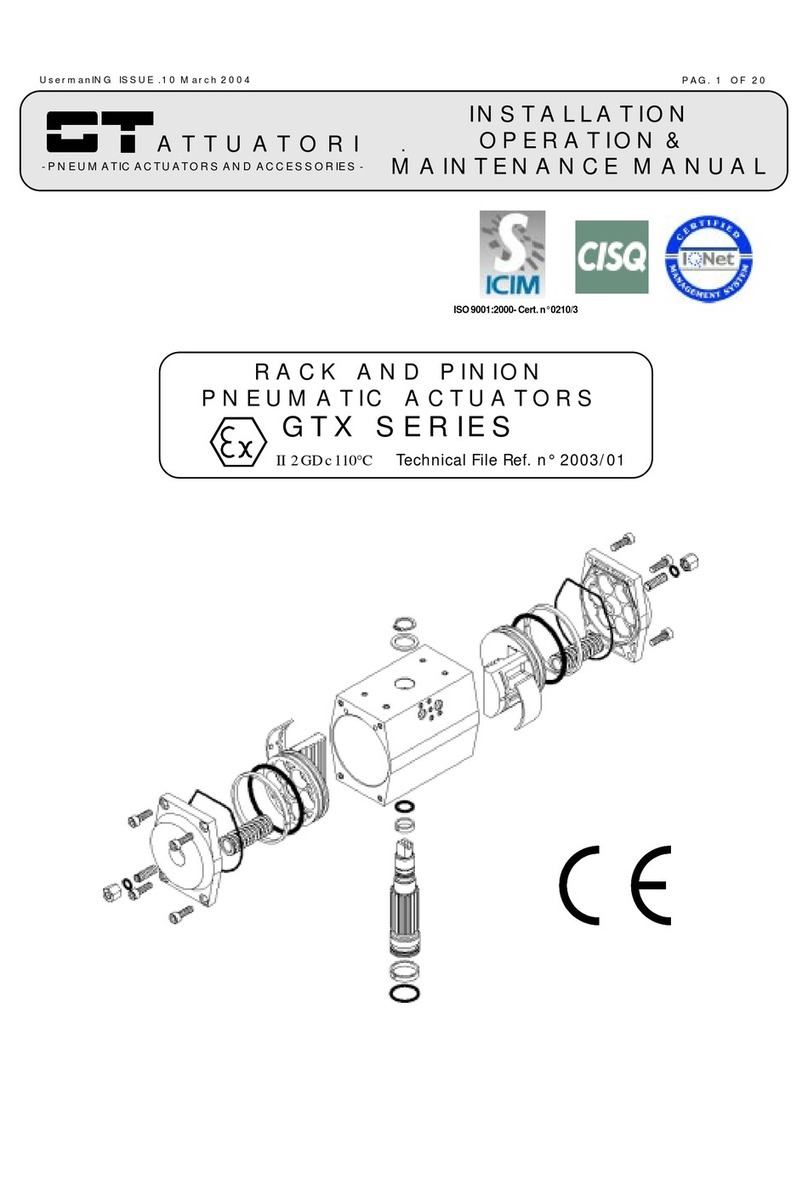

G.T. Attuatori

G.T. Attuatori GTX Series Installation, operation & maintenance manual

Plecter Labs

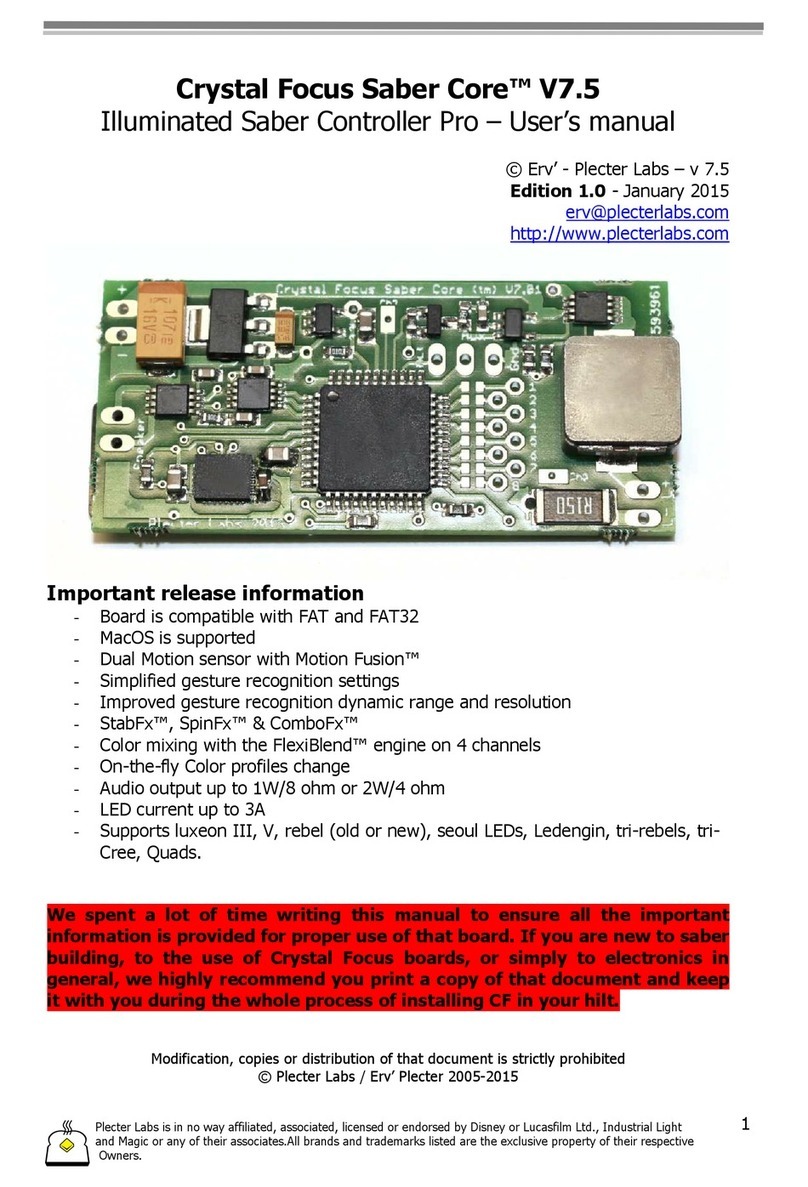

Plecter Labs Crystal Focus Saber Core V7.5 user manual

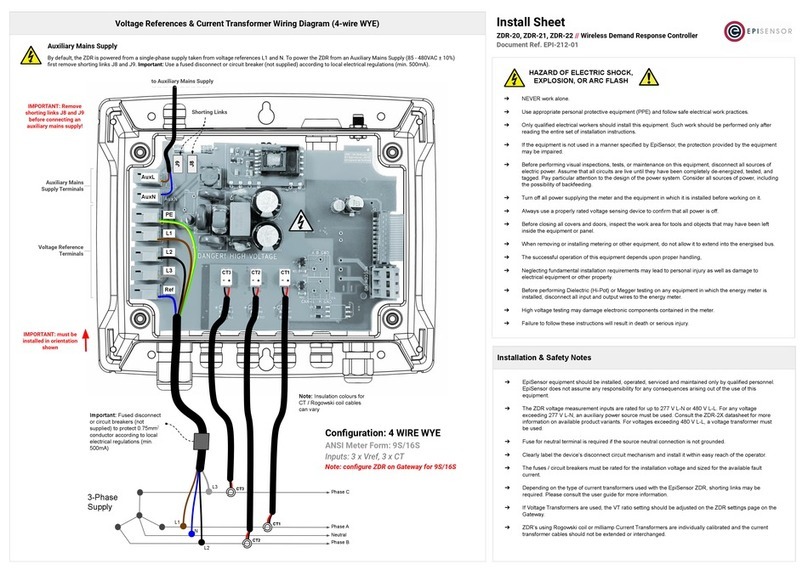

EpiSensor

EpiSensor ZDR-20 Install Sheet