Charles 360-80 Reference guide

Section 360-080-102

Equipment Issue 2

First Printing, August 2006Telecommunications Group

2006 Charles Industries Ltd.

All rights reserved. Printed in United States of America.

The availability of features and technical specifications herein subject to change without notice.

Page 1 of 9

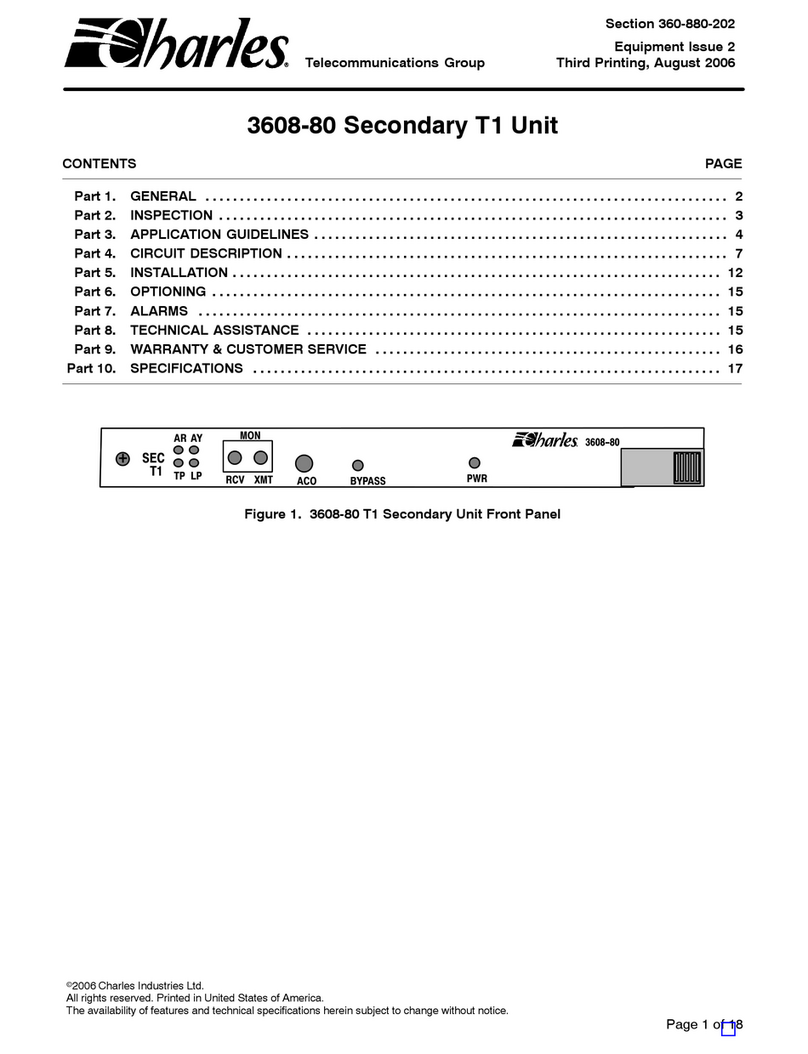

360-80 Intelligent Channel Bank Turn-Up and

Acceptance Test Procedure

CONTENTS PAGE

Part 1. GENERAL 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part 2. VERIFYING ELECTRICAL CONNECTIONS 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part 3. SYSTEM TURN-UP 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part 4. CONTROL VERIFICATION 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part 5. VERIFYING SYSTEM ALARMS 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part 6. VOICE CARD ACCEPTANCE TESTS 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part 7. DATA CARD ACCEPTANCE TESTS 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part 8. TECHNICAL ASSISTANCE 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 360-080-102

2

1. GENERAL

1.1 Document Purpose

This document provides turn up and acceptance test procedures for the 360-80 Intelligent Channel Bank (ICB).

2. VERIFYING ELECTRICAL CONNECTIONS

2.1 Initial Installation Notes

Step Action

1. Shelf must already be mounted per documentation.

2. Unit must already be wired for power from a fuse panel. Power should not be applied at this time.

2.2 19-inch and 23-inch Bays

If modules are already installed in the ICB, remove them before testing.

Step Action

1. Connect the audio and visual alarm leads to the removeable connector on the back of the ICB shelf.

Reference the Shelf documentation for the proper procedure. Figure 1 displays the shelf rear panel.

2. Apply power to the shelf.

3. Locate the power terminal block on the rear (see Figure 1) of the ICB. Using a voltmeter connect the −

(common) test lead to −48VR screw terminal. With the + test lead, measure the voltage at the −48V

terminal. The voltage should be between −44 and −56 VDC. If voltages are not correct, inspect wiring

for proper polarity, and/or check power source for proper settings (or output) and correct as required.

J1 J2

IN OUT AUD VIS

CCLK

TERM

CCLK ALM

FUSE 4A

−48VR

−48V

OUT

IN

PRI

+

+

+

+

T1/E1

TERM

NETWORK

MGMT

Figure 1. 360-80 Terminal Block

3. SYSTEM TURN-UP

Use the following steps to turn up the system. Only the T1 controller unit (T1-S) should be installed as instructed.

Figure 2 displays the T1 Controller Unit Front Panel.

Section 360-080-102

3

Step Action Verification

1. Insert the T1-S into the ICB. Do NOT connect the

T1 to J1 at the rear of the T1-S.

The green LED on the T1-S should be lit, indicat-

ing that the T1-S is powered.

When first plugged in, the AR, AY, TP and LP

LEDs on the front panel of the T1-S will light and

then extinguish. Approximately 5 seconds after

power is applied, the 4 LEDs will flash simulta-

neously (LED test), indicating that the T1-S is ini-

tializing.

Since a T1 line is not connected, approximately

2.5 seconds after the flashing LEDs have extin-

guished, the red AR LED will light, followed by the

yellow TP LED, indicating that no T1 signal has

been detected and trunk processing is in progress.

T1

3603−81

AR AY

TP LP

MON

RCV XMT ACO MGMT

ADDRESS

ID PWR

+

Figure 2. T1 Controller Unit Front Panel

4. CONTROL VERIFICATION

To get the information displayed as shown, the control verification tests should be done with alarms active.

Control verification is done using the NMS or a craft terminal.

4.1 Control Verification Using a Craft Terminal

Refer to the Craft Terminal documentation while performing the following steps.

Step Action System Response

1. Connect the VT100 terminal emulator to the

MGMT jack on the front of the T1-S

2. Press <Enter> to activate the T1-S Login prompt appears.

3. Login with the user name piad and press

<Enter>

Password prompt appears.

4. Type 1234 as the password and press <Enter> The following information should be displayed in

the main menu:

Primary T1 Module Plugged

Halfsize Module Unplugged

Channel Card 1 Unplugged

Channel Card 2 Unplugged

User Administration

Card Inventory Data

SNMP Community Table

Trap IP Table

IP Address/Subnet Mask/MAC Gateway

Address Message

Logout

Section 360-080-102

4

Step System ResponseAction

5. If the Network Management System (NMS) Soft-

ware will be used, do the following. Otherwise,

skip to the next step.

a. Select the IP Address option

b. Configure the IP Address and network

for the controlling PC

c. Select the Apply Changes button.

The system is automatically restarted and control

verification is ended.

6. Use the down arrow to move to Logout and press

<Enter>.

The terminal emulator displays Please Press

ENTER to login.

4.2 Control Verification Using the Network Management System (NMS)

The procedure Control Verification Using a Craft Terminal, located in this document, must be performed in order

for the NMS software to communicate with the ICB. Refer to the NMS documentation while performing the follow-

ing steps.

Step Action System Response

1. Set all the switches for the Address ID to the down

(zero) position. The address ID switches are lo-

cated on the front panel of the T1-S.

2. Using a PC with the NMS software installed, con-

nect the ethernet from the PC to the network con-

trol terminal J2 on the rear of the T1-S.

3. Activate the NMS software on the PC. The NMS

may start with the window minimized.

4. Select Setup Supervisor Login.

5. Login as a Supervisor using the password 123.

6. Select Database Equipment Management.

7. Enter the information for the fields as follows:

Address = 1

Description = To indicate bank identifier

IP Address = Same as the T1 Controller

IP address

8. Select the Close button. The equipment description will appear on the NMS

screen on both the left and right sides of the win-

dow.

9. Double-click on the equipment description that ap-

pears on the right-side of the window.

The IAD Management System window will appear.

10. In the ICB Management System, login using the

following:

ID = piad

Password = 1234.

The graphical user interface will display a repre-

sentation of the ICB with the T1-S in the lower

right-hand slot. The LED status of the unit will be

displayed, and all the software options will be

available.

11. Perform a primary near-end line T1 loopback with

either the craft terminal or NMS interface.

12. Close the loopback screen.

Section 360-080-102

5

Step System ResponseAction

13. Once the trunk processing LED has extinguished,

select Status Retrieve T1 Parameters.

The LP LED should turn on and the following infor-

mation should be displayed:

Status of the Incoming Primary T1

Line

Card Type: T1

Operation Mode: Normal Mode

Timing Source: Internal Timing

Frame Format: ESF

Line Code: B8ZS

Automatic Detect Mode: No

LBO: 0−110

CGA Process Mode: Normal

Remote Control Method: Using Facility

Data Link

Status:Loopback (Out of Service)

14. Release the T1 loopback. Verification of the control system is complete.

5. VERIFYING SYSTEM ALARMS

Use the following steps to verify system alarms.

Step Action System Response

1. Perform a primary T1 near-end line loopback. Verify that the TP LED is extinguished and no

visual or audible alarms exist.

2. Release the T1 loopback. Verify that there are visual and audible alarms.

3. View the alarm status on the craft terminal and/or

NMS.

Display should show the correct alarm status.

4. Press the ACO switch on the T1-S. Verify that the audible alarm stops.

6. VOICE CARD ACCEPTANCE TESTS

Use the following procedures to verify voice cards AFTER all the previous acceptance testing (electrical connec-

tions, system turn-up, control verification and system alarms) has been performed. Refer to the T1 Controller with

SNMP document for T1 pinouts.

Note: All the following procedures are used for both audio and signaling.

6.1 FXS Card Acceptance Test

Step Action System Response

1. Make sure that the ICB is turned up and operating.

2. Install the FXS card per its documentation. All LEDs on the card should light, flash, and then

turn off.

3. Log in to the NMS or craft interface and verify that

the FXS card is recognized in the proper chassis

slot and the first-time boot-up configuration is FXS/

LS.

Section 360-080-102

6

Step System ResponseAction

4. For a full-size FXS, connect a test cable from a

telephone to one of the TIP/RING pairs on the rear

connector.

For a half-size FXS, connect the test cable from a

telephone to the front connector.

5. Place the telephone off-hook and verify that the

appropriate chassis slot LED lights only when the

telephone is off-hook.

6. Connect the T1 with the appropriate time slot to a

T1 signaling test set or another D4 channel bank

configured with an FXO at the far end which is

then connected to a telephone (CO) switch or tele-

phone line simulator.

Verify that a telephone call can be made through

the FXS to the telephone switch or test set.

Verify that a telephone call can be made from the

telephone switch or test set to the FXS.

6.2 FXO Card Acceptance Test

Step Action System Response

1. Make sure that the ICB is turned up and operating.

2. Install the FXO card per its documentation. All LEDs should light, flash and then turn off.

If the T1 is not in sync, the LEDs may light again.

3. Log in to the NMS or craft interface and verify that

the FXO card is recognized in the proper chassis

slot and the first-time boot-up configuration is

FXO/LS.

4. For a full-size FXO, connect a test cable from a

telephone (CO) switch or telephone line simulator

to one of the TIP/RING pairs on the rear connec-

tor.

For a half-size FXO, connect the test cable from a

telephone switch or telephone line simulator to the

front connector.

5. Connect the T1 with the appropriate time slot to a

T1 signalling test set or another D4 channel bank

configured with an FXS and telephone at the far

end.

Verify that a telephone call can be made from the

switch through the FXO to the FXS.

Verify that a telephone call can be made from the

FXS through the FXO to the Telephone switch.

6.3 E&M Card Acceptance Test

Step Action System Response

1. Make sure that the ICB is turned-up and operating.

2. Install the E&M card per its documentation. All LEDs should light, flash and then turn off.

If the T1 is not in sync, the LEDs may light again.

3. Log in to the NMS or craft interface and verify the

chassis/card configuration.

Verify the E&M card is recognized in the proper

chassis slot and the first time boot up initialization

configuration is E&M mode V.

4. Enable the tone test function under for the channel

to be tested.

If using NMS, select Loopback of the E&M Card.

If using the craft interface, select Tone Test.

Tone test success.

5. E&M card acceptance test is complete.

Section 360-080-102

7

7. DATA CARD ACCEPTANCE TESTS

Use the following procedures to verify data cards after all the previous T1 unit acceptance testing (electrical con-

nections, system turn-up, control verification and system alarms) has been completed.

7.1 ISDN Card Acceptance Test

Step Action System Response

1. Make sure that the ICB is turned up and operating.

2. Insert the ISDN card into the appropriate slot of

the ICB.

3. Enable the NMS or craft interface and verify the

chassis/card configuration with a system that has

been reset to the factory default.

Verify the ISDN card is recognized in the proper

chassis slot and the configuration is 2B+D and

LULT.

4. Perform a software near-end line T1 loop back. LOS and ALM LEDs should illuminate on the ISDN

unit.

5. Connect a test cable to the rear connector of the

full size ISDN card (front connector for a half size

ISDN card) and connect an ISDN NT1 test set (i.e.

TPI 550B) to one of the tip/ring pairs.

Verify that the LOS and ALM LEDs turn “off” and

that no bit errors occur on the test set for the chan-

nel being tested.

6. Release the T1 loopback. ISDN card acceptance test is complete.

7.2 DSU Card Acceptance Test

Step Action System Response

1. Make sure that the ICB is turned up and operating.

2. Insert the DSU card into the appropriate slot of the

ICB.

3. Enable the NMS or craft interface and verify the

chassis/card configuration with a system that has

been reset to the factory default.

Verify the DSU card is recognized in the proper

chassis slot and the configuration is V.35, and that

the data rate is 64K.

4. Under DSU settings, enable the latching loopback

option for one channel. Then under the loopback

menu (listed under T1 settings for VT100 craft ter-

minal), perform a DSU near-end latching loopback

with a 2047 test pattern enabled.

Display should show “Map 0” with zero bit errors.

5. Enter an “R” for release loopback if using a craft

terminal interface. The GUI interface will automati-

cally release loopback after 1 minute.

DSU loopback is removed.

7.3 64XN Card Acceptance Test

Step Action System Response

1. Make sure that the ICB is turned up and operating.

2. Insert the 64xN card into the appropriate slot of

the ICB.

3. Enable the NMS or craft interface and verify the

chassis/card configuration with a system that has

been reset to the factory default.

Verify the 64xN card is recognized in the proper

chassis slot and that the configuration is time slot

length of 2, V.35 and the data rate is 64K.

4. Perform a software near-end line T1 loop back. No system alarms.

Section 360-080-102

8

Step System ResponseAction

5. Connect the appropriate digital data cable to a

DTE test set or equivalent. The test set should be

capable of performing Bert tests.

Note: RTS must be enabled on the external test

set or FORCE RTS on the external DSU

unit.

DTE test set should show a pattern sync and no bit

errors should occur.

6. Release the T1 loopback. 64XN card acceptance test is complete.

7.4 OCU Card Acceptance Test

Step Action System Response

1. Make sure that the ICB is turned up and operating.

2. Insert the OCU card into the appropriate slot of the

ICB.

3. Enable the NMS or craft interface and verify the

chassis/card configuration with a system that has

been reset to the factory default.

Verify the OCU card is recognized in the proper

chassis slot and that the data rate is 64K.

4. Perform a software near-end T1 loop back and

then close/quit the loopback window.

No system alarms.

5. Under OCU settings, enable the latching loopback

option for one channel. Then under the loopback

menu (listed under T1 settings for VT100 craft ter-

minal), perform an OCU near-end latching loop-

back with 2047 test pattern enabled.

Display should show “Map 1” with zero bit errors.

Loopback LED turns on.

6. Enter an “R” to release loopback if using a craft

terminal interface.

The GUI interface will automatically release loop-

back after 1 minute. Loopback LED turns off.

7. Release the T1 loopback. OCU card acceptance test is complete.

7.5 Router Card Acceptance Test

Step Action System Response

1. Make sure that the ICB is turned-up and operating.

2. Insert the Router card into the appropriate slot of

the ICB.

3. Enable the NMS or craft interface and verify the

chassis/card configuration with a system that has

been reset to factory default.

Verify the router is recognized in the proper chassis

slot and the data rate is 64K for two time slots.

4. Connect the Router’s front panel RS232 to a PC

via a straight thru-9 pin RS232 cable.

5. Open a hyper-terminal window. Use the same set-

tings as the craft interface.

6. Press <Enter>.

7. For both the user and password enter, admin.

8. Enter the following:

system config restore factory

system config save

system restart

9. Once restart is complete, press <Enter>

Section 360-080-102

9

Step System ResponseAction

10. For both the user and password enter, admin.

11. Enter the following:

ip ping 192.168.0.1

Verify that the ping is returned.

8. TECHNICAL ASSISTANCE

If technical assistance is required, contact Charles Industries’ Technical Services Center at:

847-806-8500

847-806-8556 (FAX)

800-607-8500

[email protected] (e-mail)

Table of contents

Other Charles Industrial Electrical manuals

Popular Industrial Electrical manuals by other brands

ABB

ABB ACS850 series Quick start up guide

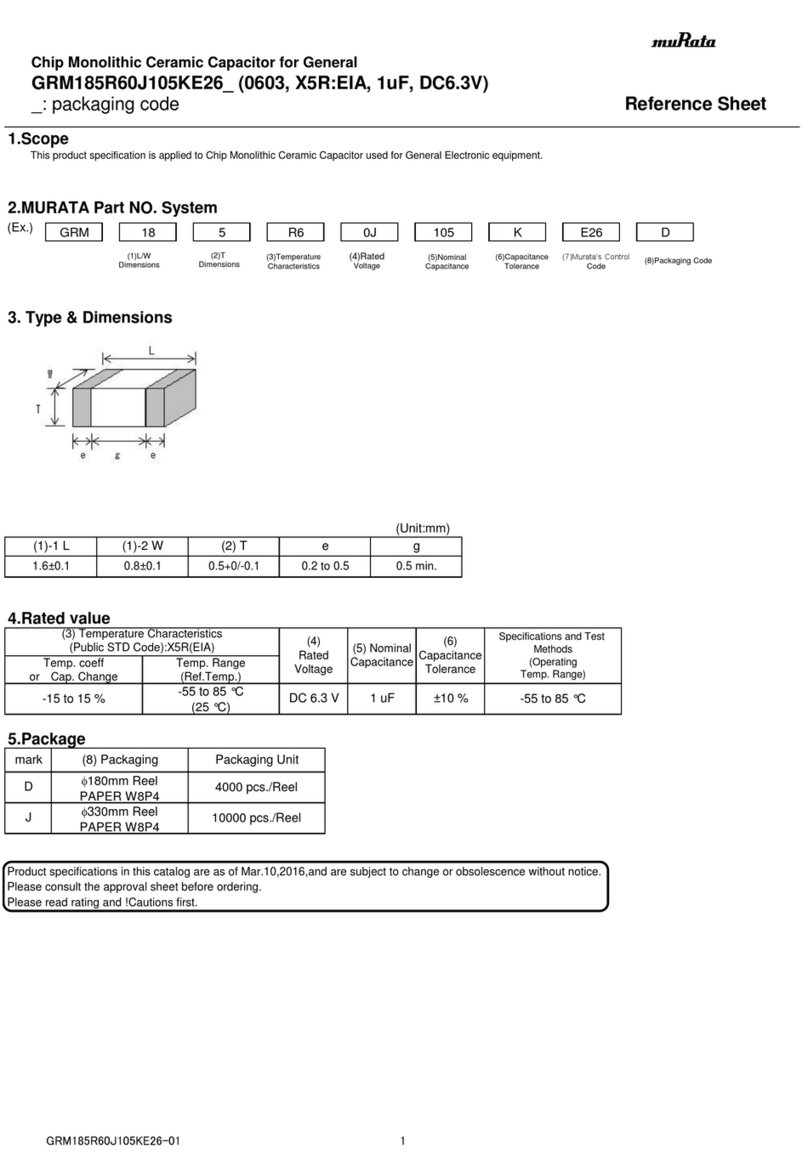

Murata

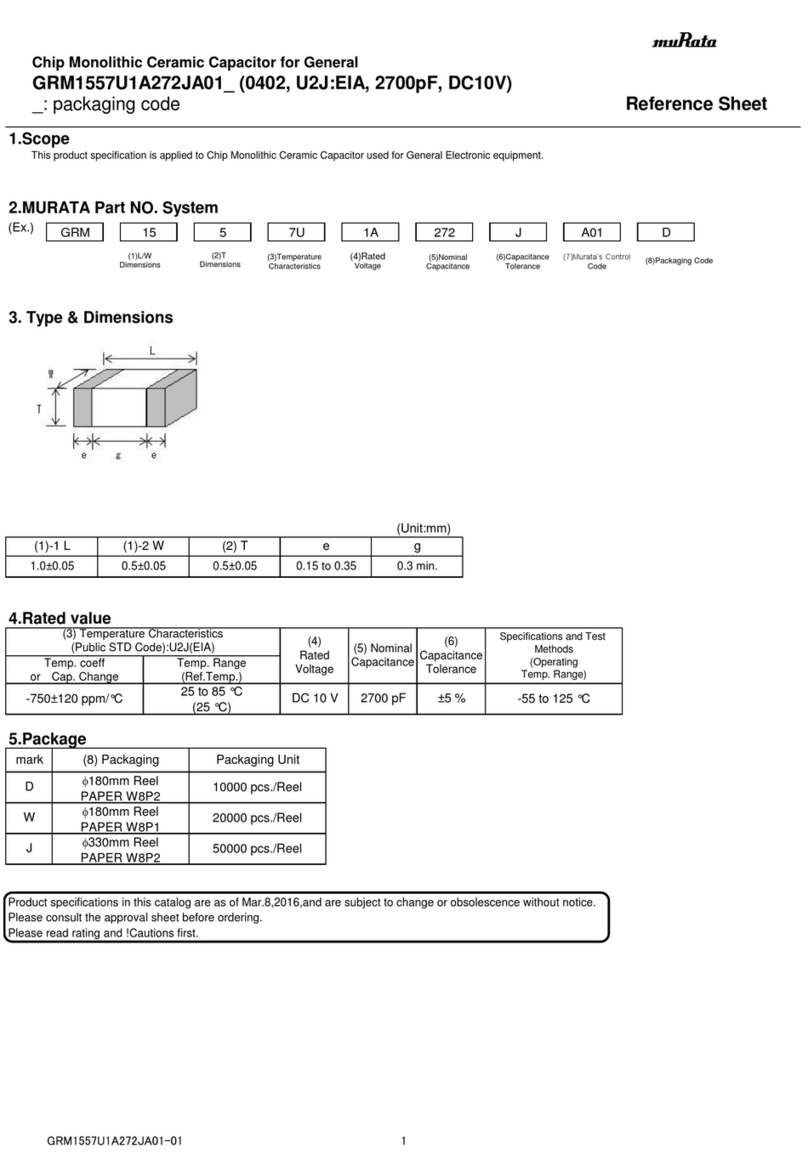

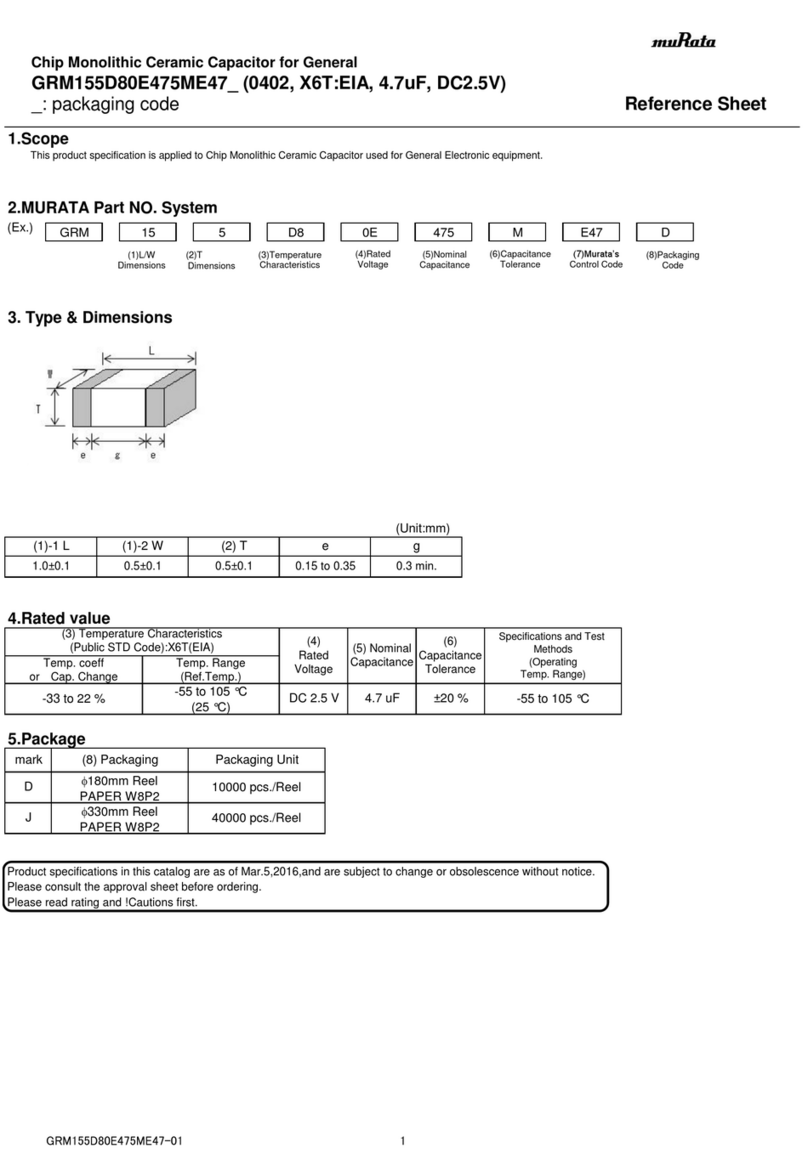

Murata GRM155D80E475ME47 Series Reference sheet

Baldor

Baldor BC145 Installation and operating manual

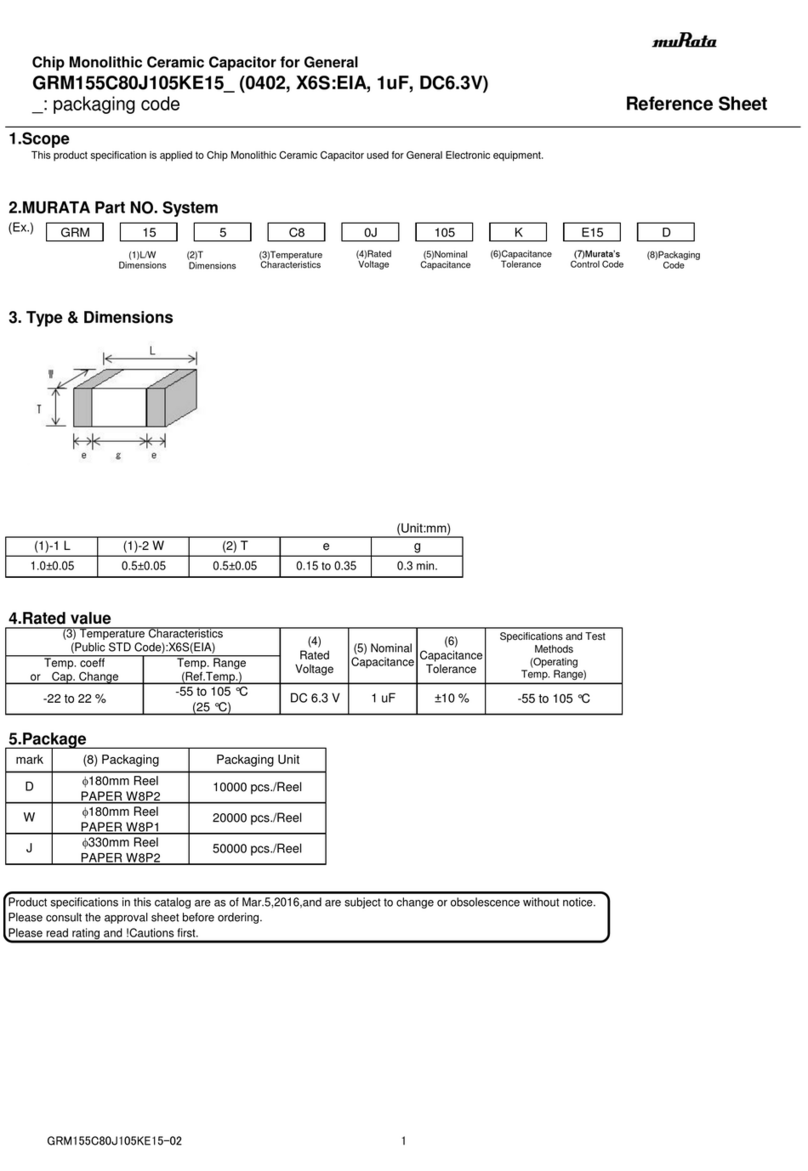

Murata

Murata GRM155C80J105KE15 Series Reference sheet

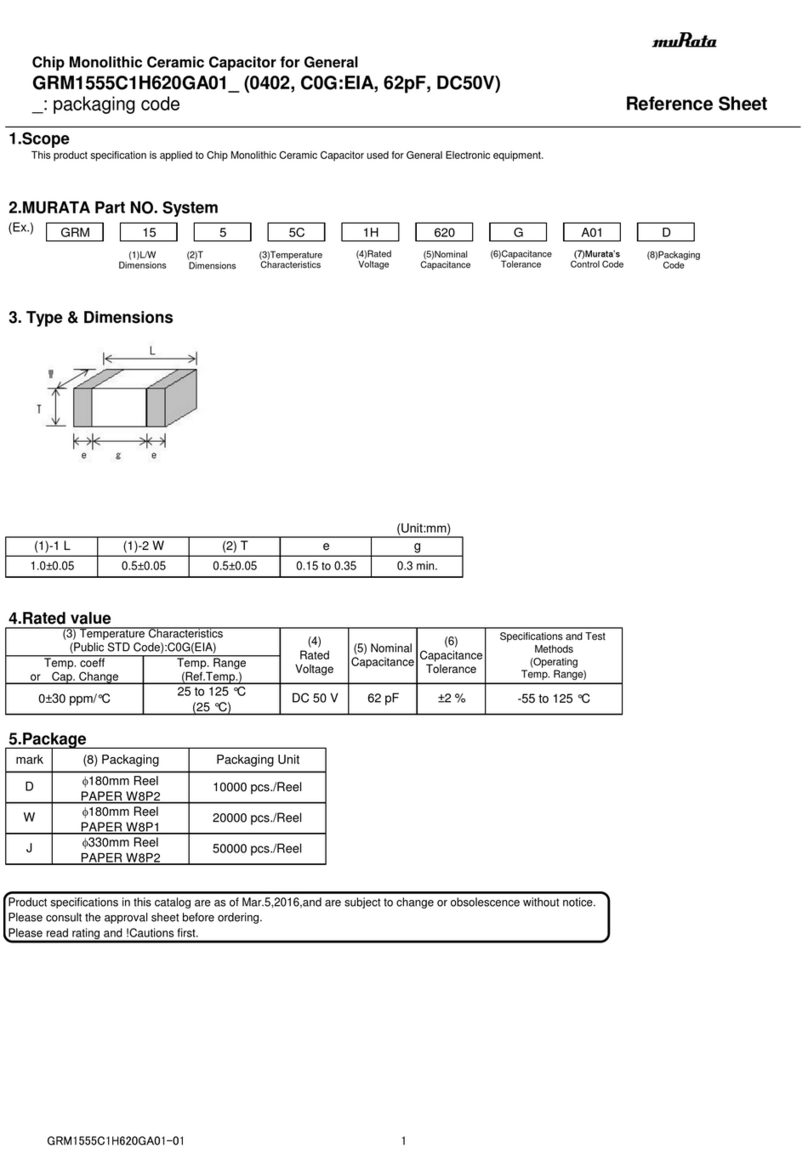

Murata

Murata GRM1555C1H620GA01 Series Reference sheet

Murata

Murata GJM0335C1E130GB01 Series Reference sheet

Murata

Murata GRT188C81C475KE13 Series Reference sheet

Murata

Murata GCM2165C1H122JA16 Series Reference sheet

KBR

KBR THYRO SWITCH operating instructions

Emerson

Emerson Leroy-Somer TAL 049 Installation and Maintenance

Murata

Murata GRM185R60J105KE26 Series Reference sheet

crosscontrol

crosscontrol CrossLink TG Getting started guide