Emerson Leroy-Somer TAL 049 Instruction Manual

Other Emerson Industrial Electrical manuals

Emerson

Emerson PACSystems RX3i IC695CPE400 User manual

Emerson

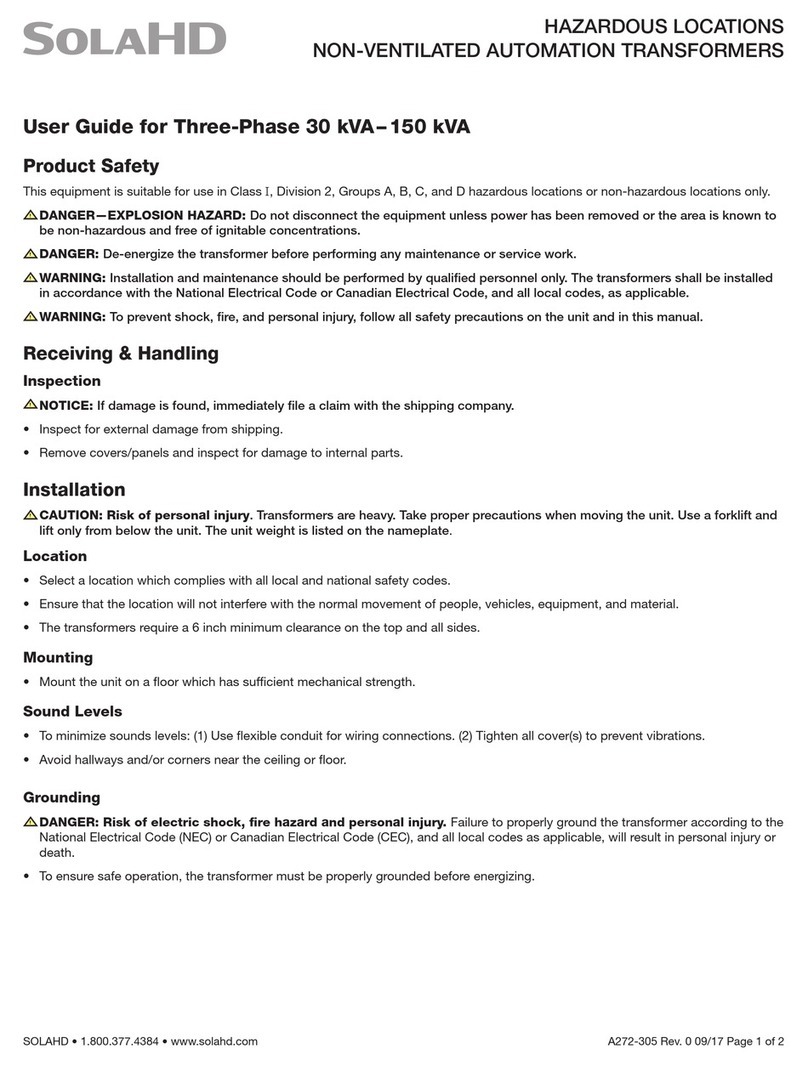

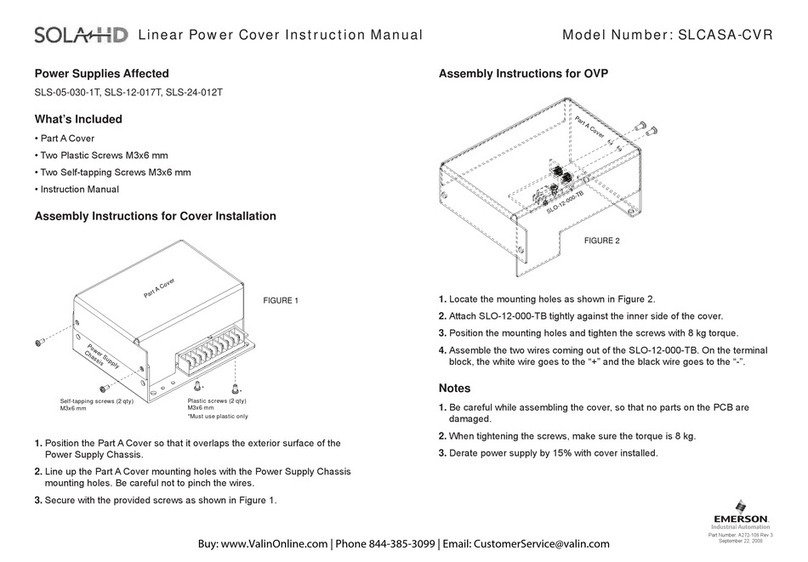

Emerson SolaHD User manual

Emerson

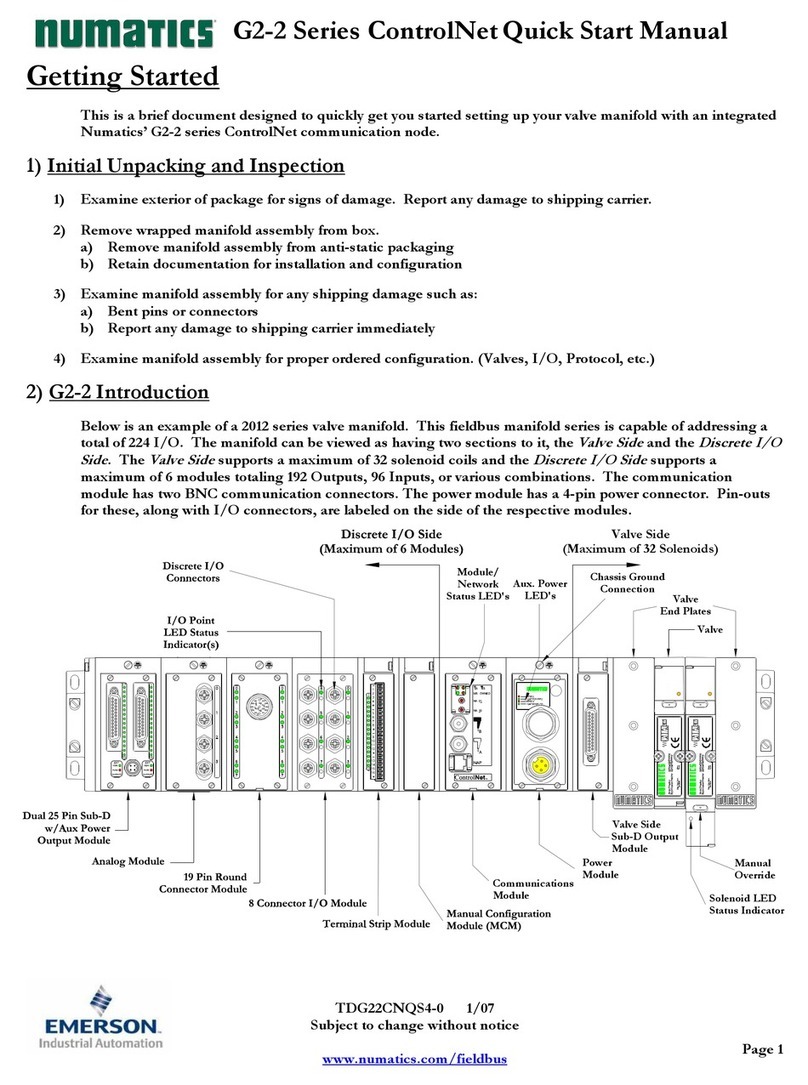

Emerson Numatics G2-2 ControlNet Series Instruction manual

Emerson

Emerson SOLA HD SLCASK-CVR User manual

Emerson

Emerson Liebert NXL User manual

Emerson

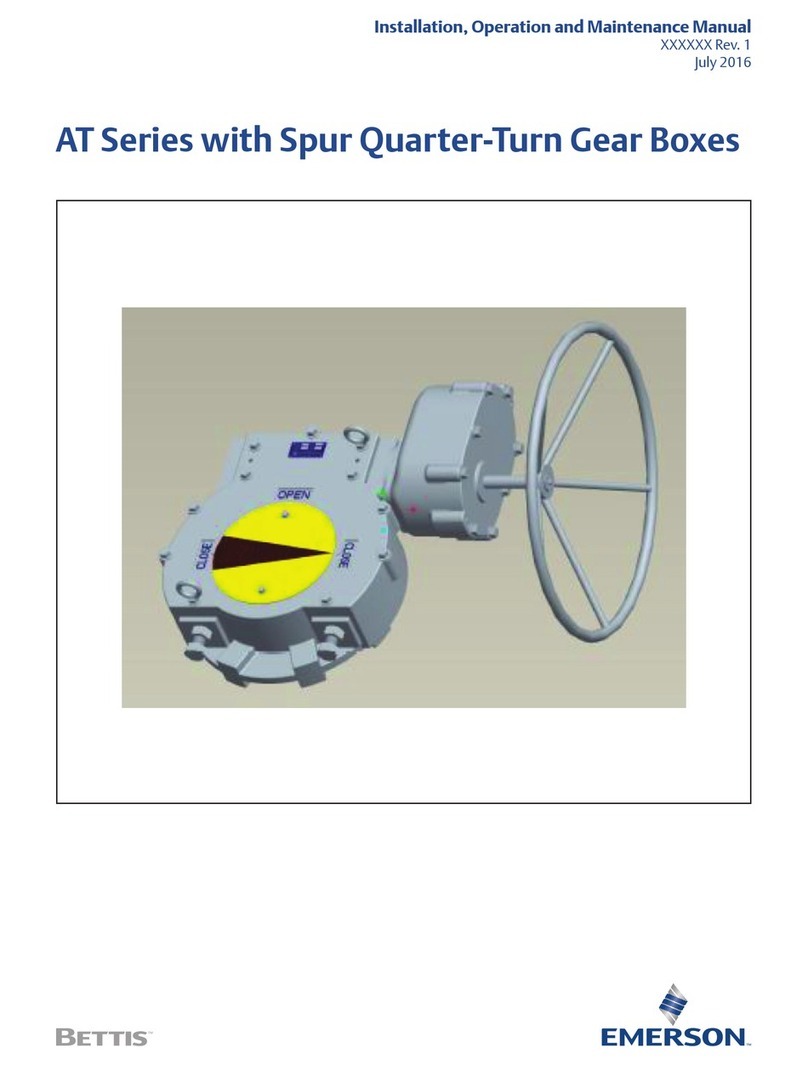

Emerson AT Series User manual

Emerson

Emerson AVTRON LOADBANK LPH400 User manual

Popular Industrial Electrical manuals by other brands

Rexroth Indramat

Rexroth Indramat DURADRIVE SYSTEM200 Project planning manual

Abtech

Abtech HVJB Series Installation, operation & maintenance instructions

Murata

Murata GRM0335C1H8R1DA01 Series Reference sheet

SAF-HOLLAND

SAF-HOLLAND CBX 5415.5 Installation and operation manual

Eaton

Eaton Ulusoy HMH24-04 user manual

Murata

Murata GJM0335C1E4R4BB01 Series Reference sheet

Newlong

Newlong NP-7H NSTRUCTION MANUAL/PARTS LIST

Stahl

Stahl 8575/12 operating instructions

SI

SI Pegasus installation instructions

Murata

Murata GRM1555C1H2R7CA01 Seies Reference sheet

Murata

Murata GRM0225C1E6R4BA03 Series Reference sheet

Cooper Power Systems

Cooper Power Systems VXE15 Installation and operation instructions

S&C

S&C Vista SD manual

Murata

Murata GRM0335C2A7R3CA01 Series Reference sheet

Siemens

Siemens 3VA9988-0BM10 operating instructions

Siemens

Siemens SITRANS LVS100 operating instructions

Murata

Murata GRM32ER60G227ME05 Series Reference sheet

Rockwell Automation

Rockwell Automation Allen-Bradley MP-Series installation instructions