IMPORTANT

SAFETYRULES

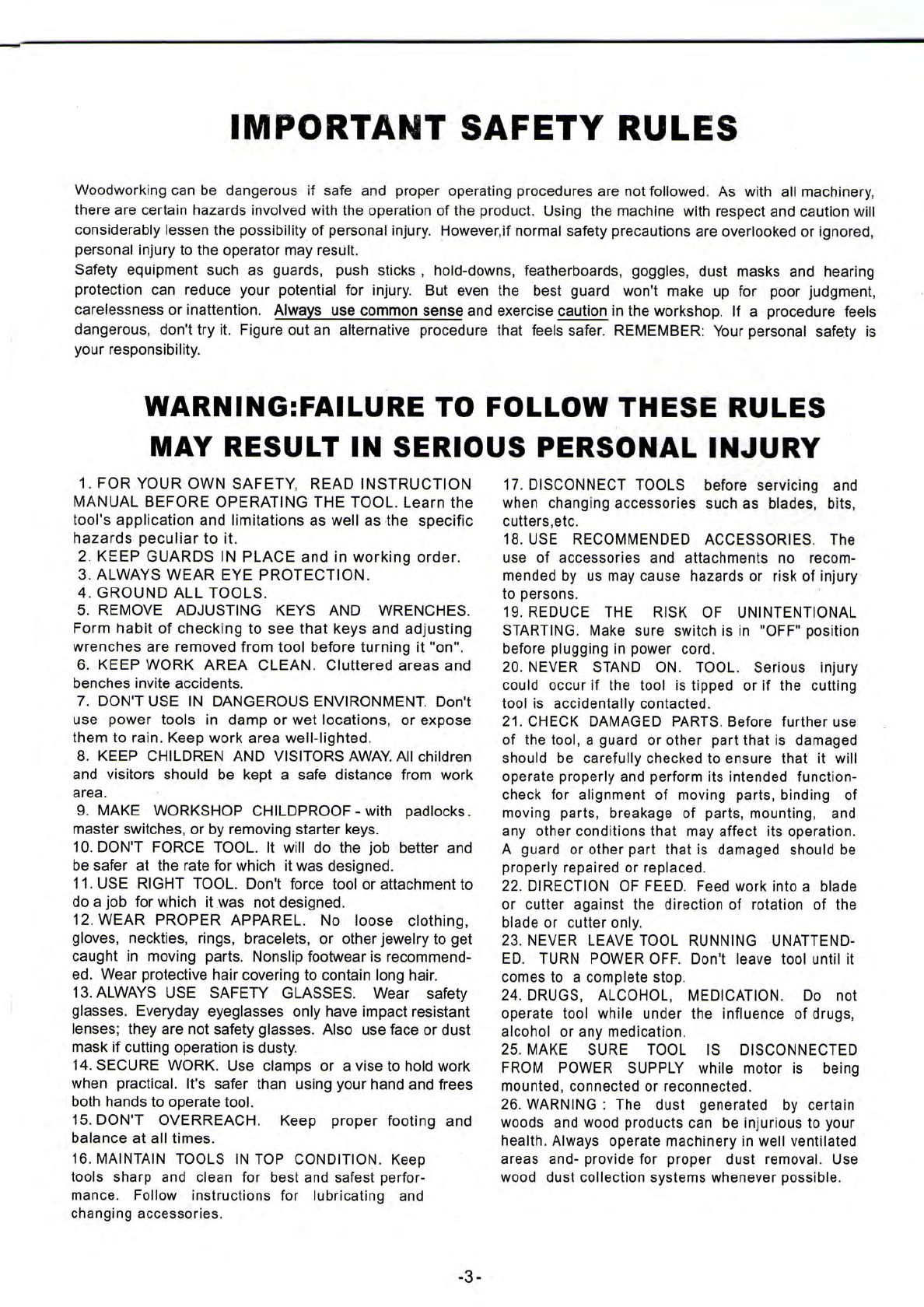

Woodworkingcanbedangerousif safeandproperoperatingproceduresarenotfollowed.Aswithallmachinery,

therearecertainhazardsinvolvedwiththeoperationoftheproduct.Usingthemachinewithrespectandcautionwill

considerablylessenthepossibilityofpersonalinjury.However.ifnormalsafetyprecautionsareoverlookedorignored,

personalinjurytotheoperatormayresult.

Safetyequipmentsuchasguards,pushsticks, hold-downs,featherboards,goggles,dustmasksandhearing

protectioncanreduceyourpotentialforinjury.Buteventhebestguardwon'tmakeupforpoorjudgment,

carelessnessorinattention.Alwaysusecommonsenseandexercisecautionintheworkshop.Ifa procedurefeels

dangerous,don'ttryit.Figureoutanalternativeprocedurethatfeelssafer.REMEMBER:Yourpersonalsafetyis

yourresponsibility.

WARNING:FAILURE

TO

FOLLOW

THESERULES

MAY

RESULT

IN

SERIOUSPERSONAL

INJURY

1.

FORYOUROWNSAFETY,READINSTRUCTION

MANUALBEFOREOPERATINGTHETOOL.Learnthe

tool'sapplicationandlimitationsaswellasthespecific

hazardspeculiartoit.

2.

KEEPGUARDSINPLACEandinworkingorder.

3.ALWAYSWEAREYEPROTECTION.

4.

GROUNDALLTOOLS.

5.REMOVEADJUSTINGKEYSANDWRENCHES.

Formhabitofcheckingtoseethatkeysandadjusting

wrenchesareremovedfromtoolbeforeturningit"on".

6.KEEPWORKAREACLEAN.Clutteredareasand

benchesinviteaccidents.

7.DON'TUSEINDANGEROUSENVIRONMENT.Don't

usepowertoolsindamporwetlocations,orexpose

themto

rain.

Keepworkareawell-lighted.

8.KEEPCHILDRENANDVISITORSAWAY.Allchildren

andvisitorsshouldbekepta safedistancefromwork

area.

9.MAKEWORKSHOPCHILDPROOF- withpadlocks,

masterswitches,orbyremovingstarterkeys.

10.

DON'TFORCETOOL.Itwilldothejobbetterand

besaferattherateforwhichitwasdesigned.

11.

USERIGHTTOOL.Don'tforcetoolorattachmentto

doa jobforwhichitwasnotdesigned.

12.

WEARPROPERAPPAREL.Nolooseclothing,

gloves,neckties,rings,bracelets,orotherjewelrytoget

caughtinmovingparts.Nonslipfootwearisrecommend-

ed.

Wearprotectivehaircoveringtocontainlonghair.

13.

ALWAYSUSESAFETYGLASSES.Wearsafety

glasses.Everydayeyeglassesonlyhaveimpactresistant

lenses;theyarenotsafetyglasses.Alsousefaceordust

maskif cuttingoperationisdusty.

14.

SECUREWORK.Useclampsora visetoholdwork

whenpractical.It'ssaferthanusingyourhandandfrees

bothhandstooperate

tool.

15.

DON'TOVERREACH.Keepproperfootingand

balanceatalltimes.

16.

MAINTAINTOOLSINTOPCONDITION.Keep

toolssharpandcleanforbestandsafestperfor-

mance.Followinstructionsforlubricatingand

changingaccessories.

17.

DISCONNECTTOOLSbeforeservicingand

whenchangingaccessoriessuchasblades,bits,

cutters,etc.

18.

USERECOMMENDEDACCESSORIES.The

useofaccessoriesandattachmentsnorecom-

mendedbyusmaycausehazardsorriskofinjury

to persons.

19.

REDUCETHERISKOFUNINTENTIONAL

STARTING.Makesureswitchisin"OFF"position

beforeplugginginpower

cord.

20.

NEVERSTANDON.TOOL.Seriousinjury

couldoccurif thetoolistippedorifthecutting

toolisaccidentallycontacted.

21.

CHECKDAMAGEDPARTS.Beforefurtheruse

ofthe

tool,

a guardorotherpartthatisdamaged

shouldbecarefullycheckedtoensurethatitwill

operateproperlyandperformitsintendedfunction-

checkforalignmentofmovingparts,bindingof

movingparts,breakageofparts,mounting,and

anyotherconditionsthatmayaffectitsoperation.

Aguardorotherpartthatisdamagedshouldbe

properlyrepairedorreplaced.

22.

DIRECTIONOFFEED.Feedworkintoa blade

orcutteragainstthedirectionofrotationofthe

bladeorcutteronly.

23.

NEVERLEAVETOOLRUNNINGUNATTEND-

ED.

TURNPOWEROFF.Don'tleavetooluntilit

comestoa completestop.

24.

DRUGS,ALCOHOL,MEDICATION.Donot

operatetoolwhileundertheinfluenceofdrugs,

alcoholoranymedication.

25.

MAKESURETOOLISDISCONNECTED

FROMPOWERSUPPLYwhilemotorisbeing

mounted,

connectedorreconnected.

26.

WARNING: Thedustgeneratedbycertain

woodsandwoodproductscanbeinjurioustoyour

health.

Alwaysoperatemachineryinwellventilated

areasand-provideforproperdustremoval.Use

wooddustcollectionsystemswheneverpossible.