12

PRECAUTIONS FOR USE

Comply with the rated maximum voltage and current and the measurement category.

Never exceed the protection limits stated in the specications.

Comply with the conditions of use, that is to say temperature, humidity, altitude, degree of pollution

and location of use.

Do not use the instrument if it is open, damaged, or incorrectly reassembled. Before each use, check

the integrity of the insulation on the coil, the leads, and the electronic unit.

The application or withdrawal of the sensor on uninsulated conductors at dangerous voltages requires

the use of suitable safety equipment.

If it is not possible to power down the installation, follow safe operating procedures and use suitable

means of protection.

All troubleshooting and metrological checks must be done by competent, accredited personnel.

CONTENTS

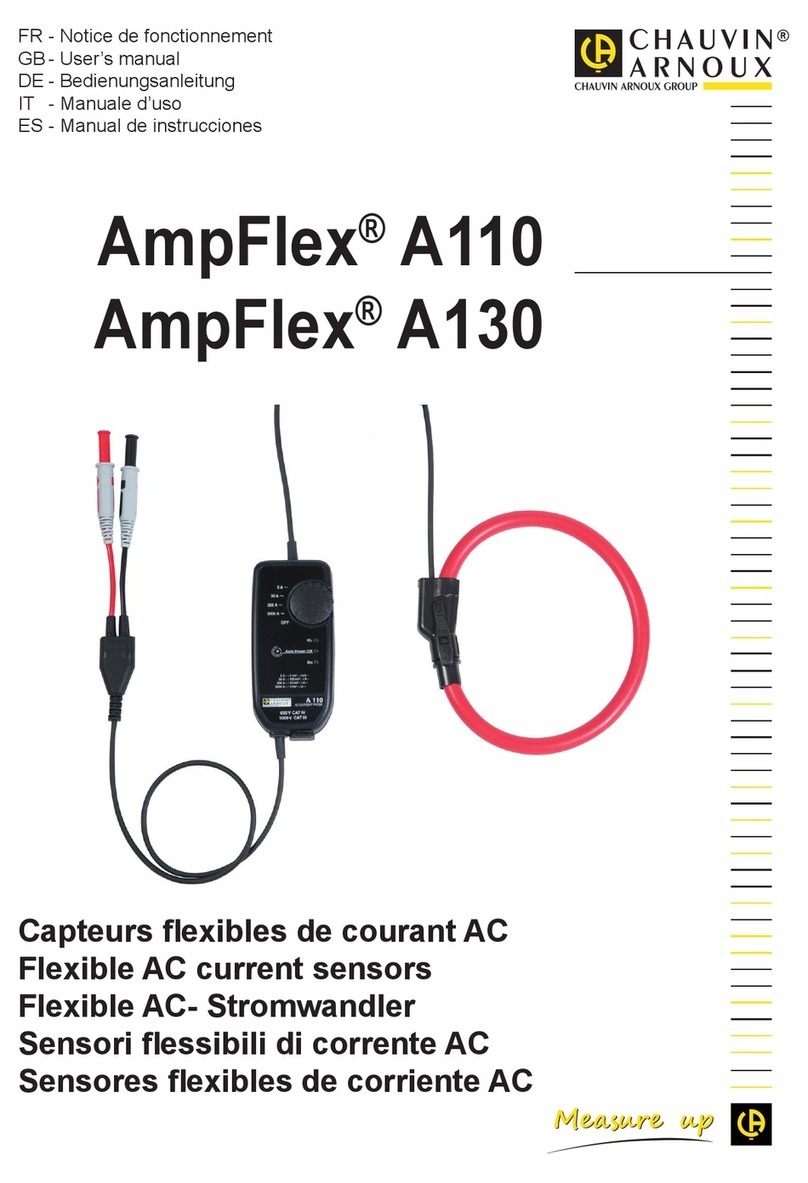

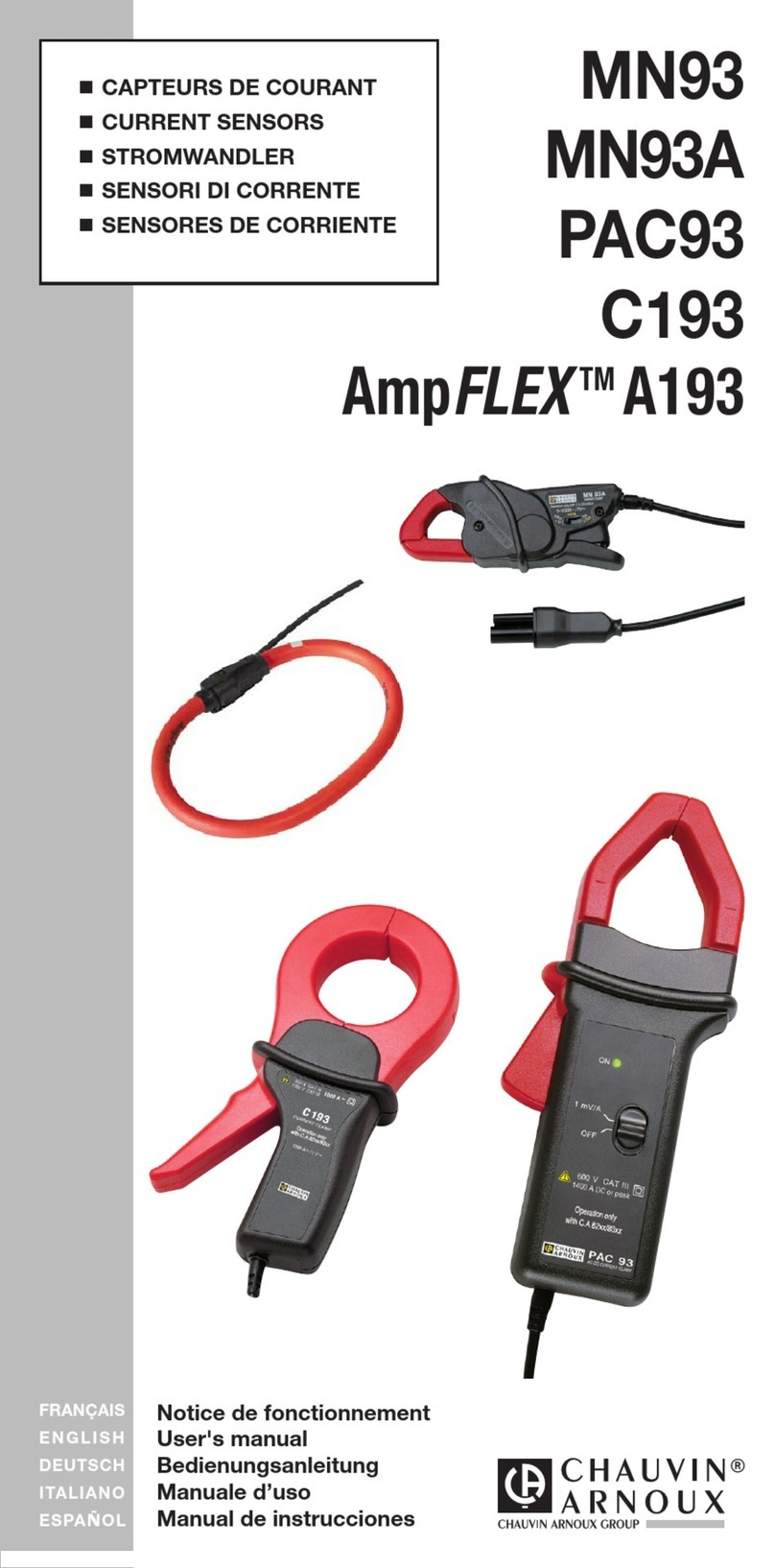

1. PRESENTATION................................................................................................................. 13

1.1. Standard models in a A100 series ........................................................................... 13

1.2. Custom models ........................................................................................................ 13

2. DESCRIPTION.................................................................................................................... 14

3. USE ................................................................................................................................. 14

4. SPECIFICATIONS............................................................................................................... 15

4.1. Reference conditions ............................................................................................... 15

4.2. Conditions of use ..................................................................................................... 15

4.3. power supply ........................................................................................................... 16

4.4. Measurement parameters ....................................................................................... 16

4.5. Compliance with electrical standards ...................................................................... 17

5. MAINTENANCE.................................................................................................................. 18

5.1. Battery replacement ................................................................................................ 18

5.2. Cleaning .................................................................................................................. 18

5.3. Calibration checking ................................................................................................ 18

5.4. Repair ...................................................................................................................... 18

6. WARRANTY ....................................................................................................................... 19

7. TO ORDER.......................................................................................................................... 19