49

CONTENTS

1. PRESENTATION ............................................................................................................................ 50

1.1. The megohmmeter ............................................................................................................... 50

1.2. Accessories ......................................................................................................................... 50

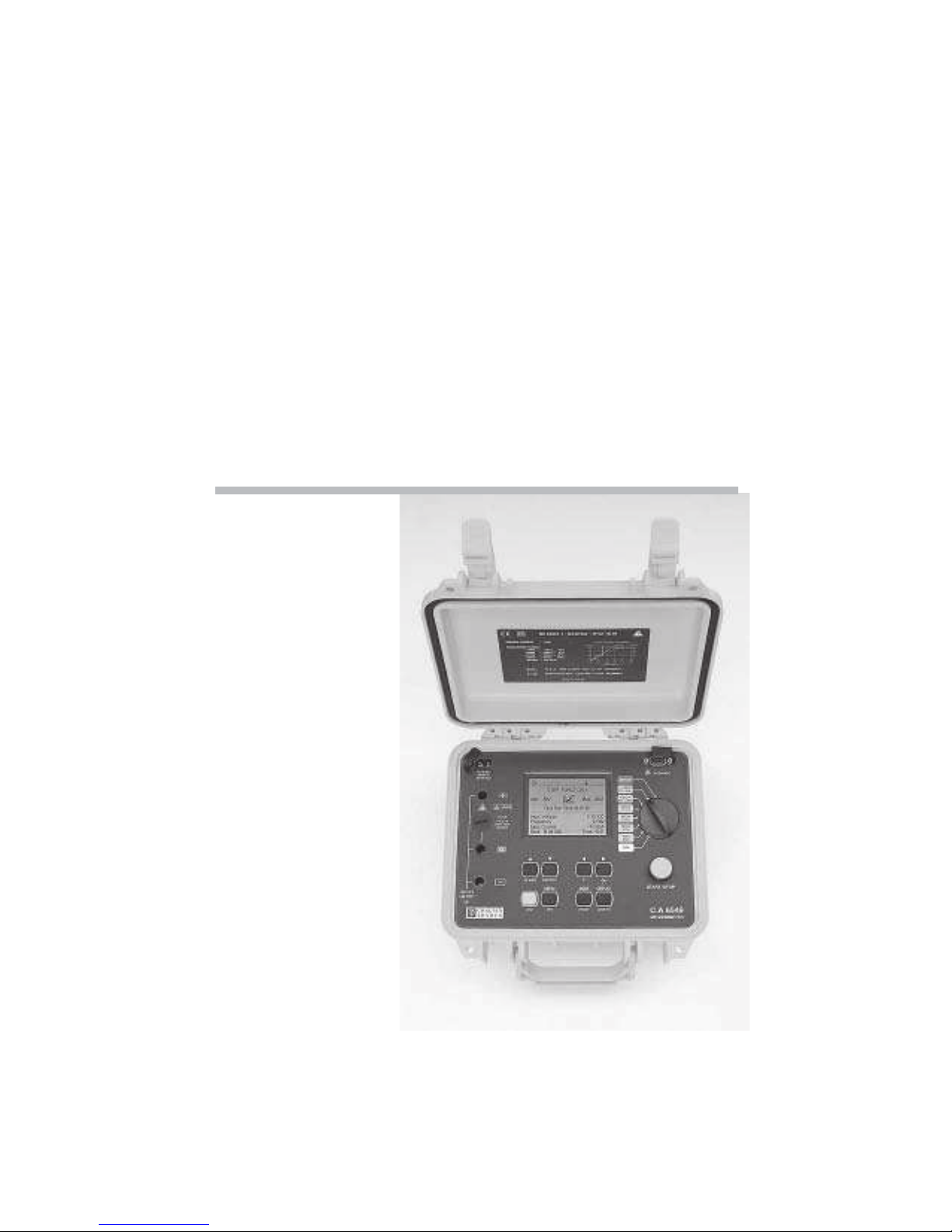

2. DESCRIPTION ............................................................................................................................... 51

2.1. Housing / Front panel / Keys ................................................................................................ 51

2.2. Display ................................................................................................................................. 53

3. MEASUREMENT FUNCTION ........................................................................................................ 54

3.1. AC / DC voltage ................................................................................................................... 54

3.2. Insulation measurement ....................................................................................................... 54

3.3. Capacitance measurement .................................................................................................. 56

3.4. Residual current measurement ............................................................................................ 56

4. SPECIAL FUNCTIONS .................................................................................................................. 56

4.1. MODE/PRINT key ................................................................................................................ 56

4.2. DISPLAY/GRAPH key ......................................................................................................... 60

4.3. 3/ T° key ............................................................................................................................ 68

4.4. 6/ SMOOTH key ................................................................................................................ 69

4.5. SET-UP function (instrument configuration) ......................................................................... 69

4.6. List of coded errors .............................................................................................................. 75

5. PROCEDURE ................................................................................................................................ 75

5.1. Course of measurements ..................................................................................................... 75

5.2. Measurement in Voltage Step mode ..................................................................................... 77

6. MEMORY / RS 232 ......................................................................................................................... 78

6.1 RS 232 characteristics ......................................................................................................... 78

6.2 Recableing / plyback of memory (MEM/MR) ........................................................................ 79

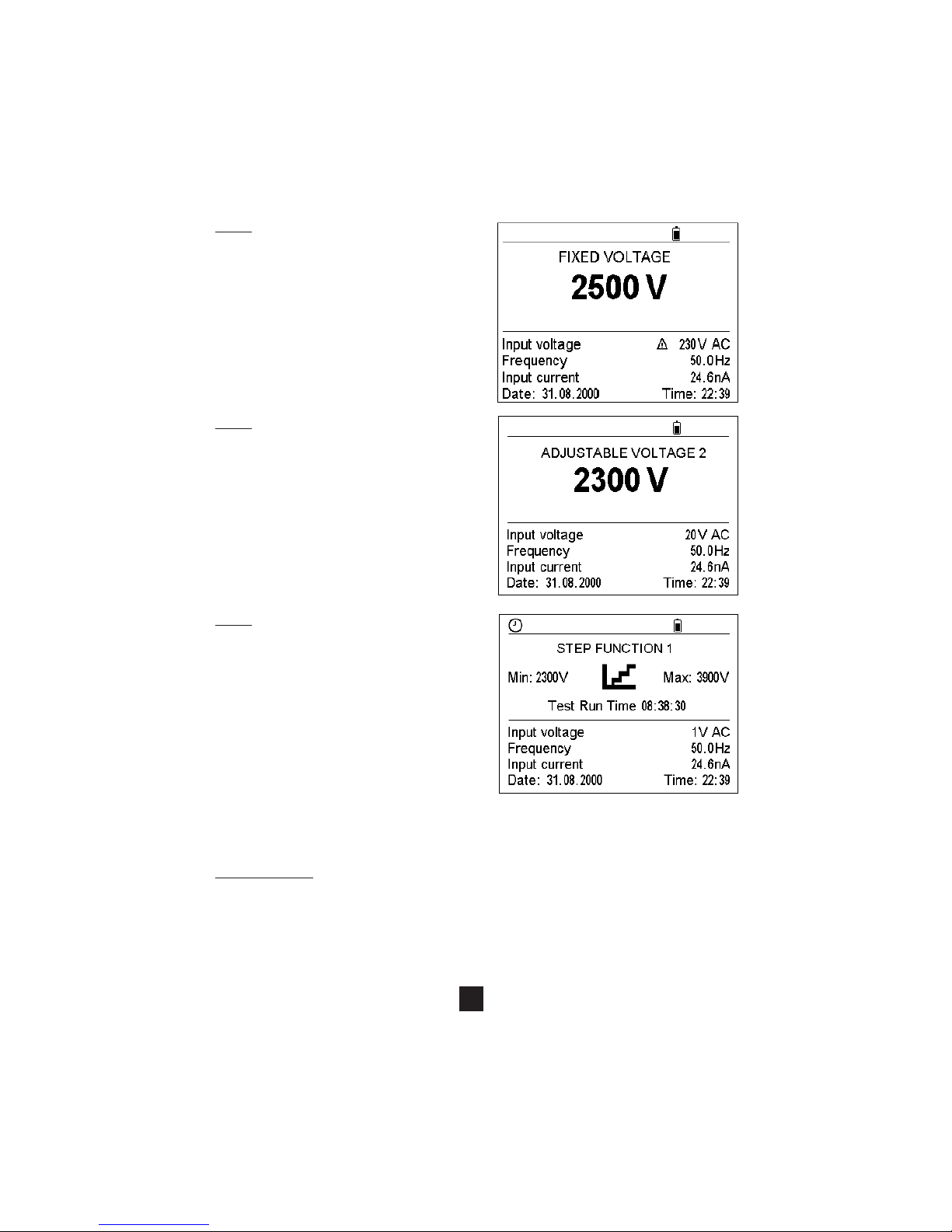

6.2 Printing measured values (PRINT key) ................................................................................ 80

7. SPECIFICATIONS .......................................................................................................................... 85

7.1 Reference conditions ........................................................................................................... 85

7.2 Characteristics per function ................................................................................................. 86

7.3 Power supply ....................................................................................................................... 89

7.4 Environmental conditions ..................................................................................................... 90

7.5 Construction specifications .................................................................................................. 90

7.6 Compliance with international standards .............................................................................. 90

7.7 Variations with in domain of use ........................................................................................... 91

8. MAINTENANCE ............................................................................................................................. 91

8.1 Servicing .............................................................................................................................. 91

8.2 Metrological verification........................................................................................................ 92

9. GUARANTEE ................................................................................................................................. 92

10.TO ORDER .................................................................................................................................... 92