Chauvin Arnox C.A 6165 User manual

C.A 6165

Appliance multitester

GB - Quick start guide

2

Contents

1General description....................................................................................................................................... 3

1.1 Warnings and notes ................................................................................................................................... 3

1.1.1 Safety warnings.....................................................................................................................................3

1.1.2 Warnings related to safety of measurement functions...........................................................................3

1.1.3 Markings on the instrument ...................................................................................................................4

2Instrument description ................................................................................................................................. 5

2.1 Front panel.................................................................................................................................................5

3Instrument operation .................................................................................................................................... 7

3.1 General meaning of keys ...........................................................................................................................7

3.2 General meaning of touch gestures: ..........................................................................................................7

3.3 Symbols and messages .............................................................................................................................8

4Single tests.................................................................................................................................................. 11

4.1 Single test measurements........................................................................................................................11

4.1.1 Visual inspections................................................................................................................................11

4.1.2 Continuity............................................................................................................................................. 12

4.1.3 HV AC ................................................................................................................................................. 15

4.1.4 HV DC ................................................................................................................................................. 16

4.1.5 HV AC programmable ......................................................................................................................... 18

4.1.6 HV DC programmable .........................................................................................................................19

4.1.7 Insulation resistance (Riso, Riso-S).....................................................................................................21

4.1.8 Sub-leakage (Isub, Isub-S).................................................................................................................. 23

4.1.9 Differential Leakage.............................................................................................................................25

4.1.10 Ipe Leakage.................................................................................................................................... 27

4.1.11 Touch Leakage............................................................................................................................... 29

4.1.12 Power.............................................................................................................................................. 30

4.1.13 Leak's & Power............................................................................................................................... 32

4.1.14 Discharging Time............................................................................................................................ 34

4.1.15 Functional inspections ....................................................................................................................37

5Maintenance ................................................................................................................................................ 39

5.1 Fuses ....................................................................................................................................................... 39

5.2 Warranty................................................................................................................................................... 39

3

1 General description

1.1 Warnings and notes

Read before use

1.1.1 Safety warnings

In order to reach high level of operator safety while carrying out various measurements using the C.A 6165 instrument,

as well as to keep the test equipment undamaged, it is necessary to consider the following general warnings:

Read this Instruction manual carefully, otherwise use of the instrument may be dangerous for the operator,

for the instrument or for the equipment under test!

Consider warning markings on the instrument!

If the test equipment is used in manner not specified in this Instruction manual the protection provided by the

equipment may be impaired!

Do not use the instrument and accessories if any damage is noticed!

Regularly check the instrument and accessories for correct functioning to avoid hazard that could occur from

misleading results.

Consider all generally known precautions in order to avoid risk of electric shock while dealing with hazardous

voltages!

Use only standard or optional test accessories supplied by your distributor!

Only test adapters provided or approved by Chauvin Arnoux should be connected to TC1 (test and

communication) connectors.

Use only earthed mains outlets to supply the instrument!

In case a fuse has blown refer to chapter 5.1 Fuses in this Instruction manual to replace it!

Instrument servicing and calibration is allowed to be carried out only by a competent authorized person!

Chauvin Arnoux is not responsible for the content of the user-programmed Auto Sequences®!

1.1.2 Warnings related to safety of measurement functions

1.1.2.1 HV AC, HV DC, HV AC programmable, HV DC programmable

A dangerous voltage up to 5 kVAC or 6 kVDC is applied to the HV instrument outputs during the test. Therefore

special safety consideration must be taken when performing this test!

Only a skilled person familiar with hazardous voltages can perform this measurement!

DO NOT perform this test if any damage or abnormality (test leads, instrument) is noted!

Never touch exposed probe tip, connections equipment under test or any other energized part during the

measurements. Make sure that NOBODY can contact them either!

4

DO NOT touch any part of test probe in front of the barrier (keep your fingers behind the finger guards on the

probe) – possible danger of electric shock!

It is a good practice to use lowest possible trip-out current.

1.1.2.2 Diff. Leakage, Ipe Leakage, Touch Leakage, Power, Leak’s & Power

Load currents higher than 10 A can result in high temperatures of fuse holders and On/Off switch! It is advisable

not to run tested devices with load currents above 10 A for more than 15 minutes. Recovery period for cooling is

required before proceeding with tests! Maximum intermittent duty cycle for measurements with load currents higher

than 10 A is 50 %.

1.1.2.3 Insulation resistance

Do not touch the test object during the measurement or before it is fully discharged! Risk of electric shock!

1.1.3 Markings on the instrument

Read the Instruction manual with special care to safety operation«. The symbol requires an action!

Dangerous high voltage is present on terminals during the test. Consider all precautions in order to

avoid risk of electric shock.

Mark on your equipment certifies that it meets European Union requirements for EMC, LVD, and

ROHS regulations.

This equipment should be recycled as electronic waste.

5

2 Instrument description

2.1 Front panel

Figure 2.1: Front panel

1

Mains supply connector

2

F1, F2 fuses (F 5 A / 250 V)

3

F3, F4 fuses (T 16 A / 250 V)

4

On / Off switch

5

Test connections TC1 for external test adapters

6

Mains test socket

7

P/S (probe) connector

8

Keypad

9

HV output connectors

10

HV output warning lamp

11

Continuity connectors

12

Insulation / Subleakage connectors

13

Discharging time connectors

14

Colour TFT display with touch screen

15

Control outputs

16

Control inputs

17

Multipurpose RS232-1 port

18

Multipurpose RS232-2 port

19

Ethernet connector

C.A 6165

6

20

USB connector

21

MicroSD card slot

7

3 Instrument operation

The C.A 6165 can be manipulated via a keypad or touch screen.

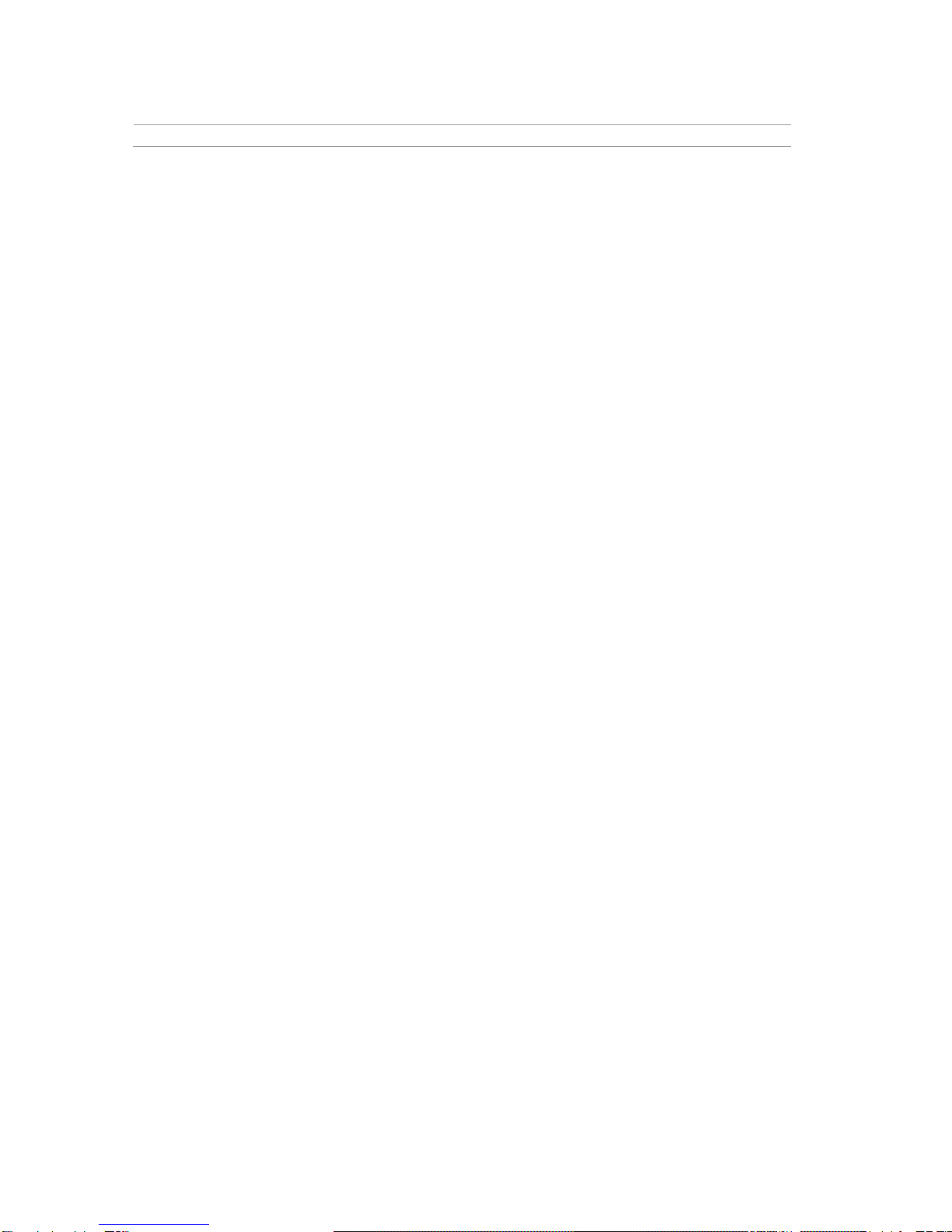

3.1 General meaning of keys

Cursor keys are used to:

- select appropriate option

Enter key is used to:

- confirm selected option

- start and stop measurements

Escape key is used to:

- return to previous menu without changes

- abort measurements

Option key is used to:

- expand column in control panel

- show detailed view of options

HV Test key is used to:

- start and stop HV tests

3.2 General meaning of touch gestures:

Tap (briefly touch surface with fingertip) is used to:

- select appropriate option

- confirm selected option

- start and stop measurements

Swipe (press, move, lift) up/ down is used to:

- scroll content in same level

- navigate between views in same level

long

Long press (touch surface with fingertip for at least 1 s) is used to:

- select additional keys (virtual keyboard)

- enter cross selector from single test screens

Tap Escape icon is used to:

- return to previous menu without changes

- abort measurements

8

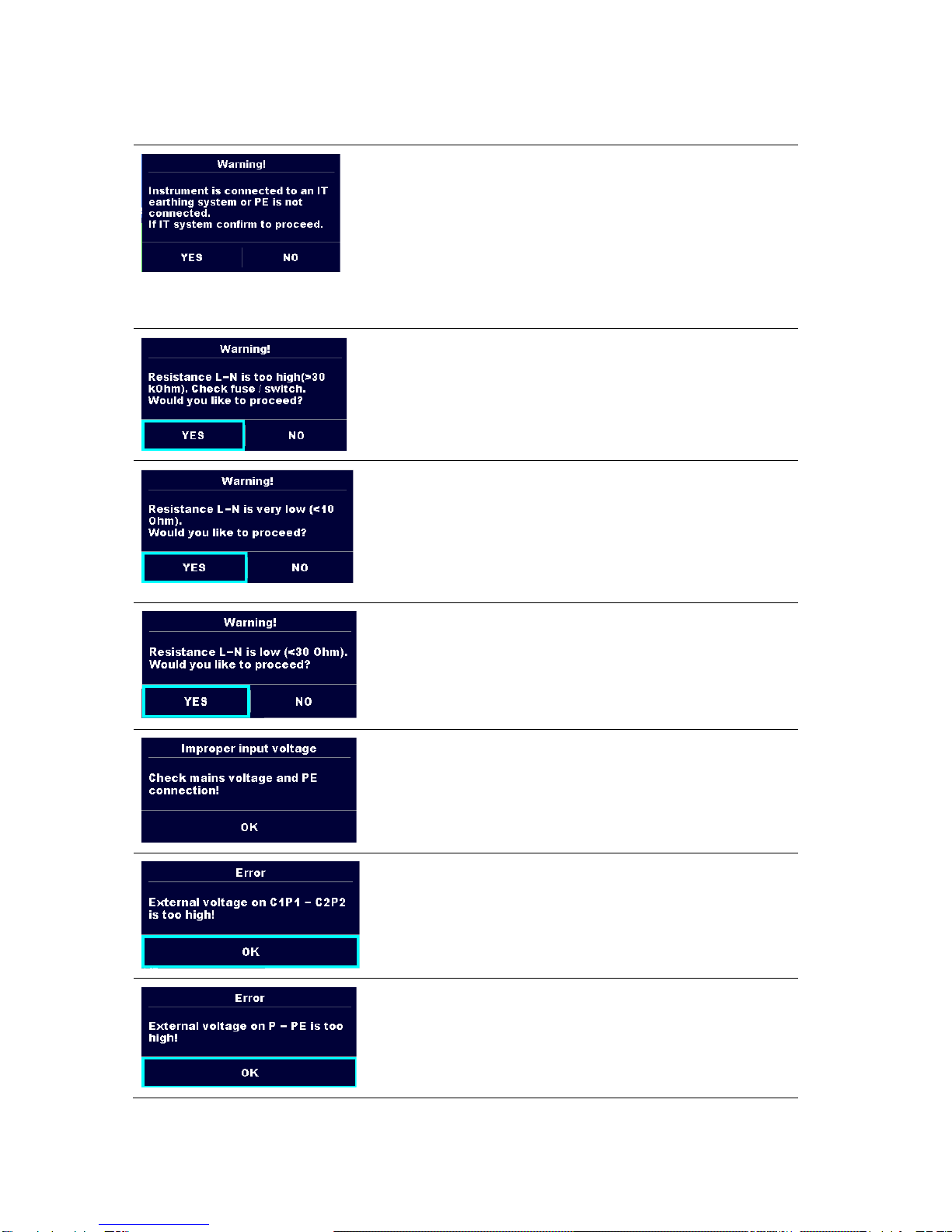

3.3 Symbols and messages

Supply voltage warning

Possible causes:

No earth connection.

Instrument is connected to an IT earthing system. Press

YES to continue normally or NO to continue in a limited

mode (measurements are disabled).

Warning:

The instrument must be earthed properly to work safely!

Resistance L-N > 30 kΩ

In pre-test a high input resistance was measured. Possible causes:

Device under test is not connected or switched on

Input fuse of device under test is blown.

Select YES to proceed with or NO to cancel measurement.

Resistance L-N < 10 Ω

In pre-test a very low resistance of the device under test supply input

was measured. This can result in a high current after applying power

to the device under test. If the too high current is only of short

duration (caused by a short inrush current) the test can be performed

otherwise not.

Select YES to proceed with or NO to cancel measurement

Resistance L-N < 30 Ω

In pre-test a low input resistance of the device under test was

measured. This can result in a high current after applying power to

the device. If the high current is only of short duration (caused by a

short inrush current) the test can be performed, otherwise not.

Select YES to proceed with or NO to cancel measurement.

Warning for improper supply voltage condition. If pressing OK

instrument will continue to work in a limited mode (measurements

are disabled).

In pre-test an external voltage between C1/P1 and C2/P2 terminals

was detected. The measurement was cancelled. Press OK to

continue.

In pre-test a too high external voltage was detected between P and

PE terminals. The measurement was cancelled. Press OK to

continue.

9

In pre-test a too high external voltage was detected between

ISO/SUB and PE terminals. The measurement was cancelled. Press

OK to continue.

In pre-test a possible high leakage current was detected. It is likely

that a dangerous leakage current (higher than 3.5 mA) will flow after

applying power to the device under test.

Select YES to proceed with or NO to cancel measurement.

The measured leakage (Idiff, Ipe, Itouch) current was higher than 20

mA. Measurement was aborted. Press OK to continue.

The load current exceeded the highest upper limit of 10 A for the

Discharging time test. Measurement was aborted. Press OK to

continue.

The load current continuously exceeded 10 A for more than 4 min

(moving average) in Power and Leakage tests. Measurement was

stopped for safety. Press OK to continue.

The load current exceeded the highest upper limit of 16 A for the

Power and Leakage tests. Measurement was aborted. Press OK to

continue.

Warning for restart of the instrument to set new Ethernet settings.

This message appears on exit from Settings menu after changing

Ethernet settings. Press OK to continue.

The instrument is overheated. The measurement can’t be carried out

until the icon disappears. Press OK to continue.

The device under test should be switched on (to ensure that the

complete circuit is tested).

Test voltage in Insulation resistance measurement is too low.

Measurement result is scaled to 110 V.

10

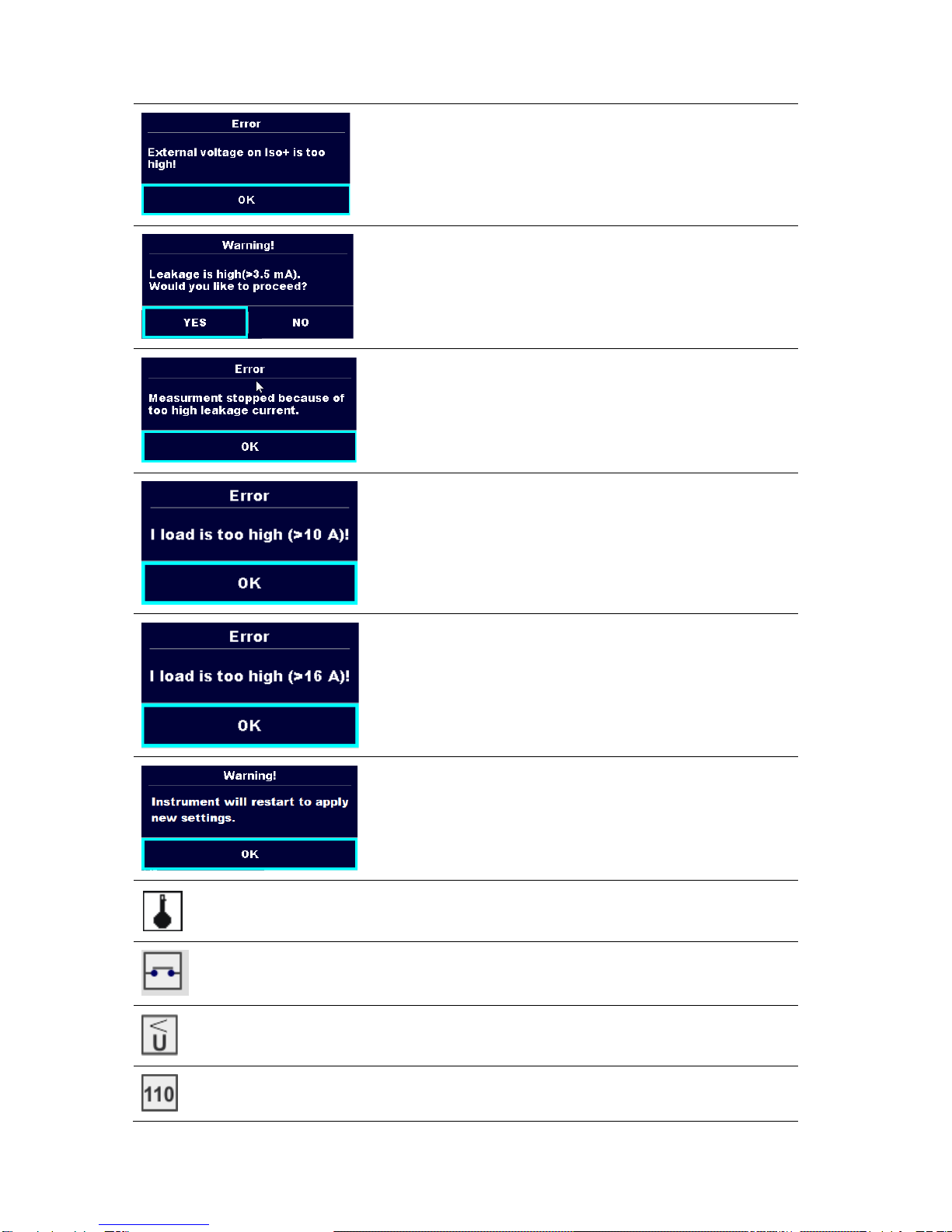

Red dot indicates phase of measurement where higher leakage was

measured. Applicable only if phase reversal is enabled during the

measurement.

Test leads resistance in Continuity P/S - PE measurement is not

compensated.

Test leads resistance in Continuity P/S - PE measurement is

compensated.

Warning!

A high voltage is / will be present on the instrument output!

(Withstanding test voltage, Insulation test voltage, or mains voltage).

Warning!

A very high and dangerous voltage is / will be present on the

instrument output! (Withstanding test voltage).

Test passed.

Test failed.

Conditions on the input terminals allow starting the measurement;

consider other displayed warnings and messages.

Conditions on the input terminals do not allow starting the

measurement, consider displayed warnings and messages.

Proceeds to next measurement step

Stop the measurement.

Expands column in control panel.

11

4 Single tests

4.1 Single test measurements

4.1.1 Visual inspections

Figure 4.1: Visual inspection menu

Test circuit

Figure 4.2: Visual inspection test circuit

Visual inspection procedure

Select the appropriate Visual inspection.

Start the inspection.

Perform the visual inspection of the appliance / equipment.

Apply appropriate ticker(s) to items of inspection.

End inspection.

Save results (optional).

12

Figure 4.3: Examples of Visual inspection results

4.1.2 Continuity

Figure 4.4: Continuity test menu

Test results / sub-results

R................... Resistance

ΔU………..Voltage drop scaled to 10 A

Test parameters

Output connections

Output [4-wire, P-PE]

Test current

I out [0.2 A, 4 A, 10 A, 25 A]

Duration

Duration [Off, 2 s ... 180 s]

ΔU test*

Enables ΔU test [On, Off]

Wire section*

Wire section for ΔU test [0.5 mm2…≥6mm2]

Test limits

H Limit (R)

H limit [Off, 0.01 Ω ... 9 Ω, Custom ]

L Limit (R)

L limit [Off, 0.01 Ω ... 9 Ω, Custom ]

H Limit (ΔU)*

H limit [1.0 V … 5.0 V ]

* Applicable only at test current 10 A.

13

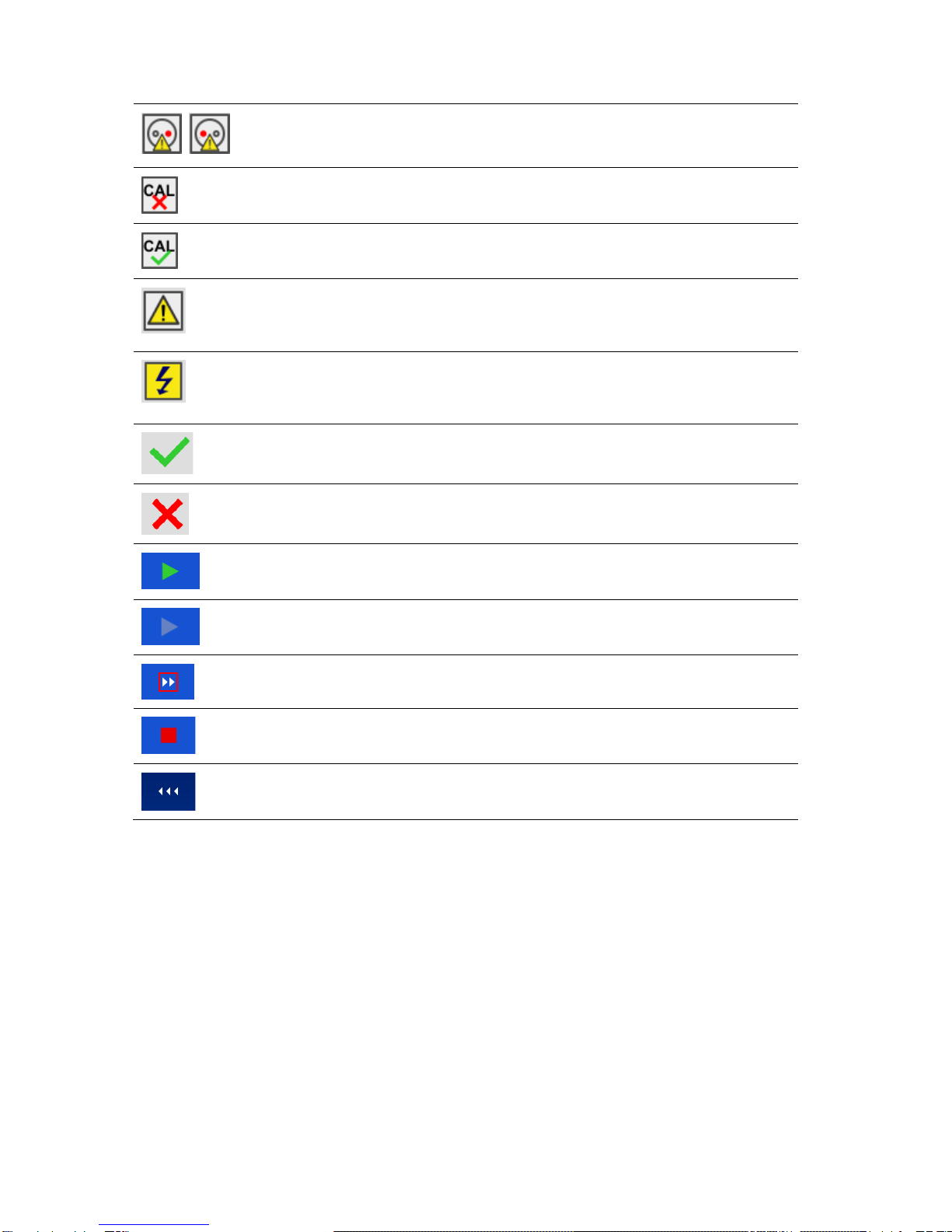

Test circuit

Figure 4.5: Measurement of continuity 4-wire

Figure 4.6: Measurement of Continuity P/S - PE

Continuity measurement procedure

Select the Continuity function.

Set test parameters / limits.

Connect test leads to C1, P1, P2 and C2 terminals on the instrument (4 wire), or connect test lead to P/S terminal

(2 wire measurement P/S – PE).

Compensate test leads resistance (optional).

Connect test leads to device under test.

Start measurement.

Measurement can be stopped manually or by timer.

Save results (optional).

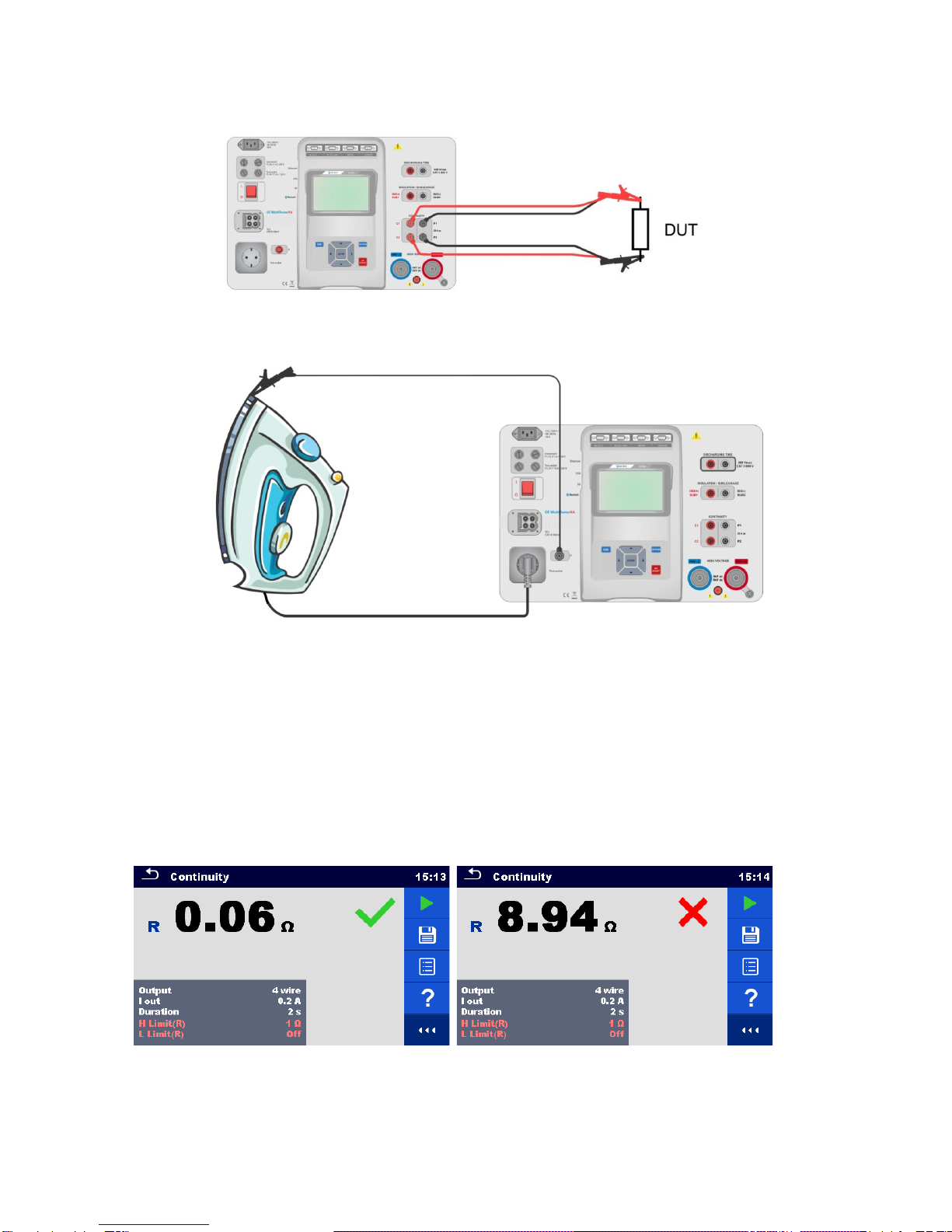

Figure 4.7: Examples of Continuity measurement results

14

4.1.2.1 Compensation of test leads resistance

This chapter describes how to compensate the test leads resistance in Continuity (Output = P/S –PE) function.

Compensation can be carried out to eliminate the influence of test leads resistance and the internal resistances of the

instrument on the measured resistance.

Connection for compensating the resistance of test leads

Figure 4.8: Shorted test leads

Compensation of test leads resistance procedure

Select the Continuity function. Parameter Output must be set to P/S - PE.

Connect test leads to the instrument and short the test leads together, see Figure 4.8.

Touch the key to compensate leads resistance.

Symbol is displayed if the compensation was carried out successfully.

Figure 4.9: Uncompensated and compensated result

Note:

The compensation of test leads is carried out with set test current (I out).

15

4.1.3 HV AC

IMPORTANT SAFETY NOTE

Refer to chapter 1.1 Warnings and notes for more information regarding safe use of the instrument.

Figure 4.10: HV AC test menu

Test results / sub-results

I.................... test current

U................... measured a.c. test voltage

Ir................... resistive portion of test current

Ic .................. capacitive portion of test current

Test parameters

AC test voltage

U test [100 V ... 5000 V in steps of 10 V]

Duration

t end [Off, 1 s ... 120 s]

Test limits

High limit (I)

H limit [0.5 mA ... 100 mA ]

Low limit (I)

L limit [Off, 0.5 mA ... 100 mA]

Test circuit

Figure 4.11: HV AC measurement

16

HV AC measurement procedure

Select the HV AC function.

Set test parameters / limits.

Connect HV test leads to HV(~,+) and HV(~,-) terminals on the instrument.

Connect HV test leads to device under test.

Start measurement.

Measurement can be stopped manually or by timer.

Save results (optional).

Figure 4.12: Examples of HV AC meaasurement results

Note:

First HV measurement after power on the instrument (if password protection is enabled) or first HV

measurement after enabling or changing password require entering password for enabling HV test.

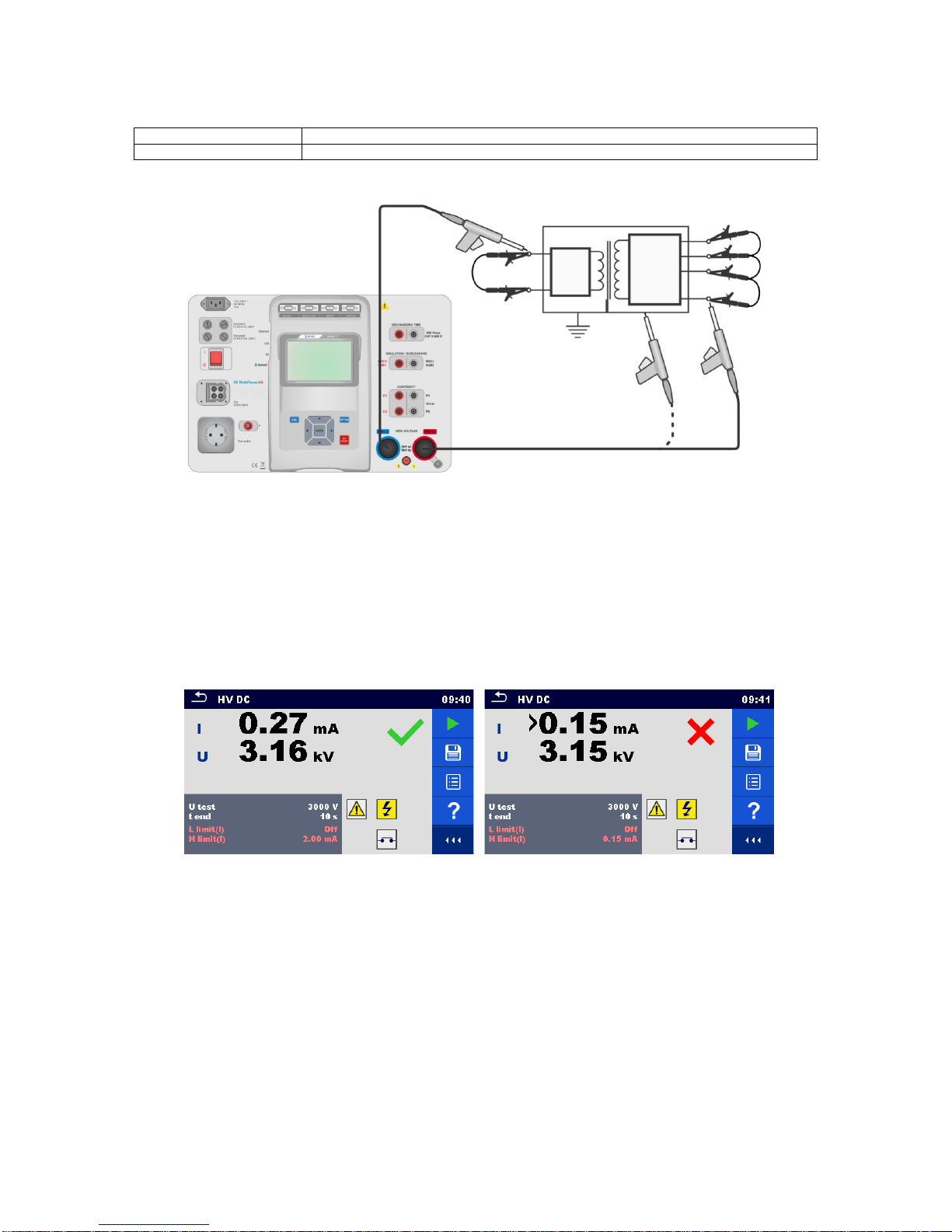

4.1.4 HV DC

IMPORTANT SAFETY NOTE

Refer to chapter 1.1 Warnings and notes for more information regarding safe use of the instrument.

Figure 4.13: HV DC test menu

Test results / sub-results

U................... measured test voltage

I.................... test current

Test parameters

DC test voltage

U test [500 V ... 6000 V in steps of 50 V]

Duration

t end [Off, 1 s ... 120 s]

17

Test limits

High limit (I)

H limit [0.05 mA ... 10.0 mA ]

Low limit (I)

L limit [Off, 0.05 mA ... 10.0 mA]

Test circuit

Figure 4.14: HV DC measurement

HV DC measurement procedure

Select the HV DC function.

Set test parameters / limits.

Connect HV test leads to HV(~,+) and HV(~,-) terminals on the instrument.

Connect HV test leads to device under test.

Start measurement.

Measurement can be stopped manually or by timer.

Save results (optional).

Figure 4.15: Examples of HV DC measurement results

Note:

First HV measurement after power on the instrument (if password protection is enabled) or first HV

measurement after enabling or changing password require entering password for enabling HV test.

18

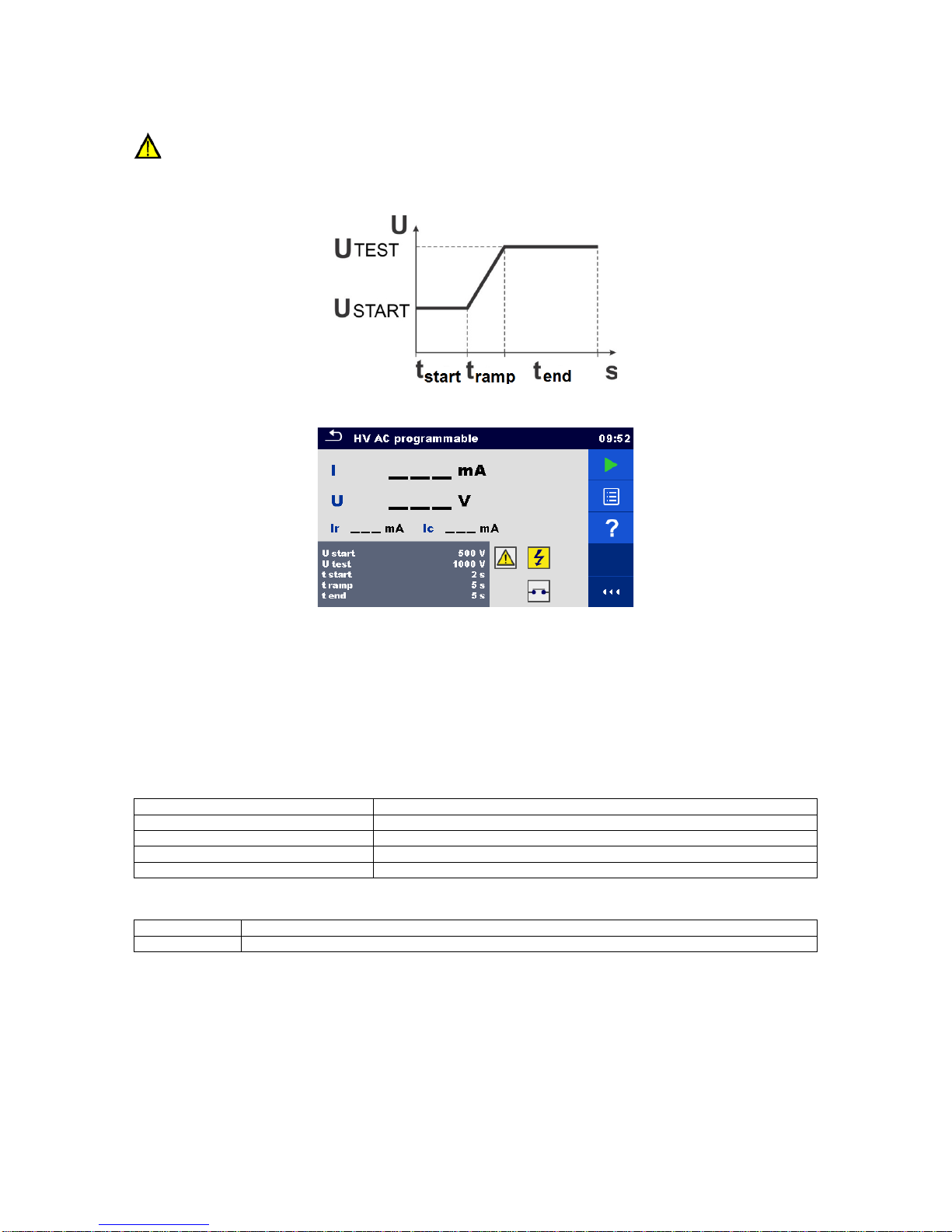

4.1.5 HV AC programmable

IMPORTANT SAFETY NOTE

Refer to chapter 1.1 Warnings and notes for more information regarding safe use of the instrument.

In the HV AC programmable test the time dependency of high voltage can be set according to diagram on Figure 4.16.

Figure 4.16: Voltage / time diagram of the HV AC programmable test

Figure 4.17: HV AC programmable test menu

Test results / sub-results

I.................... test current

U................... measured test voltage

Ir................... resistive portion of test current

Ic .................. capacitive portion of test current

Test parameters

Starting AC test voltage

U start [100 V ... 5000 V in steps of 10 V]

AC test voltage

U test [100 V ... 5000 V in steps of 10 V]

Duration of starting voltage

t start [1 s ... 120 s ]

Duration of ramp

t ramp [2 s ... 60 s ]

Duration of test voltage

t end [Off, 1 s ... 120 s ]

Test limits

High limit (I)

H limit [0.5 mA ... 100 mA ]

Low limit (I)

L limit [Off, 0.5 mA ... 100 mA]

19

Test circuit

Figure 4.18: HV AC programmable test

HV AC programmable test procedure

Select the HV AC programmable function.

Set test parameters / limits.

Connect HV test leads to HV(~,+) and HV(~,-) terminals on the instrument.

Connect HV test leads to device under test.

Start measurement.

Measurement can be stopped manually or by timer.

Save results (optional).

Figure 4.19: Examples of HV AC programmable test results

Note:

First HV measurement after power on the instrument (if password protection is enabled) or first HV

measurement after enabling or changing password require entering password for enabling HV test.

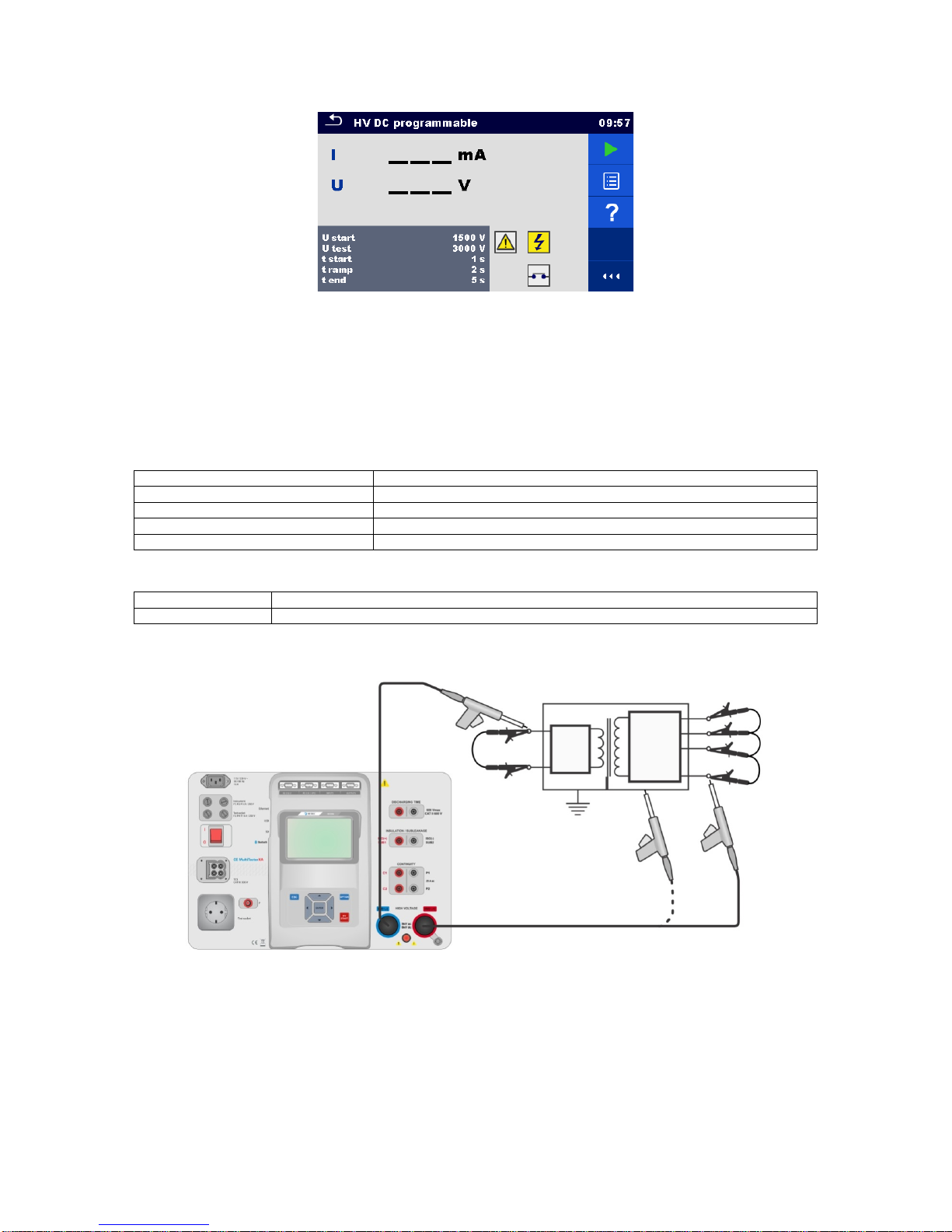

4.1.6 HV DC programmable

IMPORTANT SAFETY NOTE

Refer to chapter 1.1 Warnings and notes for more information regarding safe use of the instrument.

In the HV DC programmable test the time dependency of high voltage can be set according to diagram on Figure 4.16.

20

Figure 4.20: HV DC programmable test menu

Test results / sub-results

U................... measured test voltage

I.................... test current

Ic .................. capacitive portion of test current

Ir................... resistive portion of test current

Test parameters

Starting DC test voltage

U start [500 V ... 6000 V in steps of 50 V]

DC test voltage

U test [500 V ... 6000 V in steps of 50 V]

Duration of starting voltage

t start [1 s ... 120 s ]

Duration of ramp

t ramp [2 s ... 60 s ]

Duration of test voltage

t end [Off, 1 s ... 120 s ]

Test limits

High limit (I)

H limit [0.05 mA ... 10.0 mA ]

Low limit (I)

L limit [Off, 0.05 mA ... 10.0 mA]

Test circuit

Figure 4.21: HV DC programmable test

Table of contents

Other Chauvin Arnox Multimeter manuals