Chauvin Arnox C.A 6418 User manual

2

Thank you for purchasing this C.A 6418 oblong ground tester clamp.

For best results from your instrument:

read these operating instructions carefully,

comply with the precautions for use.

WARNING, risk of DANGER! The operator must refer to these instructions whenever this danger symbol appears.

Equipment protected throughout by double insulation.

Battery.

Application or withdrawal authorized on uninsulated or bare conductors at dangerous. Type A current sensor per IEC

61010 2 032.

Information or useful tip.

The product has been declared recyclable after analysis of its life cycle in accordance with the ISO 14040 standard.

Chauvin Arnoux has adopted an Eco-Design approach in order to design this appliance. Analysis of the complete

exceeds regulation requirements with respect to recycling and reuse.

The CE marking indicates conformity with European directives, in particular LVD and EMC.

The rubbish bin with a line through it indicates that, in the European Union, the product must undergo selective disposal

in compliance with Directive WEEE 2002/96/EC. This equipment must not be treated as household waste.

Denition of measurement categories

Measurement category IV corresponds to measurements taken at the source of low-voltage installations.

Example: power feeders, counters and protection devices.

Measurement category III corresponds to measurements on building installations.

Measurement category II corresponds to measurements taken on circuits directly connected to low-voltage installations.

Example: power supply to domestic electrical appliances and portable tools.

PRECAUTIONS FOR USE

This instrument is compliant with safety standard IEC 61010-2-032, for voltages up to 100V in category IV or 150V in category III.

installations.

The operator and/or the responsible authority must carefully read and clearly understand the various precautions to be taken in

use. The operator and/or the responsible authority must carefully read and clearly understand the various precautions to be taken

in use. Sound knowledge and a keen awareness of electrical hazards are essential when using this instrument.

The safety of any system in which this instrument might be incorporated is the responsibility of the integrator of the system.

Do not use the clamp above its rated frequency, since this might cause it to overheat dangerously.

Do not use the instrument on networks of which the voltage or category exceeds those mentioned.

Observe the environmental conditions of use.

Do not use the instrument if it seems to be damaged, incomplete, or poorly closed.

3

Before each use, check the condition of the insulation on the housing. Any item of which the insulation is deteriorated (even

partially) must be set aside for repair or scrapping.

Before using your instrument, check that it is perfectly dry. If it is wet, it must be thoroughly dried before it can be connected or used.

Avoid impacts on the measurement head, in particular the air gap.

Keep the surfaces of the air gap clean; even a little dirt can cause the clamp to malfunction.

Use personal protection equipment systematically.

All troubleshooting and metrological checks must be done by competent accredited personnel.

CONTENTS

1. PRESENTATION ..................................................................................................................................................................... 4

1.1. Unpacking....................................................................................................................................................................... 4

1.2. Description of the device ................................................................................................................................................ 4

1.3. Function keys ................................................................................................................................................................. 6

1.4. Display............................................................................................................................................................................ 6

1.5. Inserting the batteries ..................................................................................................................................................... 7

1.6. Setting the date and time................................................................................................................................................ 7

2. USE........................................................................................................................................................................................... 8

2.1. General........................................................................................................................................................................... 8

2.2. Impedance and current measurement............................................................................................................................ 8

2.3. Current measurement................................................................................................................................................... 10

..............................................................................................................................11

2.5. Adjustment.................................................................................................................................................................... 12

2.6. Errors............................................................................................................................................................................ 14

2.7. Automatic stop .............................................................................................................................................................. 14

2.8. Storage ......................................................................................................................................................................... 15

3. TECHNICAL CHARACTERISTICS ..................................................................................................................................... 17

3.1. General reference conditions ....................................................................................................................................... 17

3.2. Electrical characteristics ............................................................................................................................................... 17

3.3. Variation in the domain of use ...................................................................................................................................... 18

3.4. Power supply ................................................................................................................................................................ 19

3.5. Environmental conditions ............................................................................................................................................. 19

3.6. Mechanical characteristics .......................................................................................................................................... 20

3.7. Compliance with international standards...................................................................................................................... 20

3.8. Electromagnetic compatibility (EMC)............................................................................................................................ 20

4. MAINTENANCE..................................................................................................................................................................... 21

4.1. Cleaning ....................................................................................................................................................................... 21

4.2. Replacement of the batteries........................................................................................................................................ 21

5. WARRANTY .......................................................................................................................................................................... 23

4

1. PRESENTATION

1.1. UNPACKING

1.1.1. DELIVERY CONDITION

The instrument is delivered in a carrying case containing:

4 LR6 or AA batteries.

A wrist strap

One multilingual safety data sheet.

One multilingual quick start guide.

1.1.2. ACCESSORIES

CL1 calibration loop.

1.1.3. REPLACEMENT PARTS

Carrying case MLT110.

Set of 12 LR6 or AA batteries.

For the accessories and spares, consult our web site:

www.chauvin-arnoux.com

1.2. DESCRIPTION OF THE DEVICE

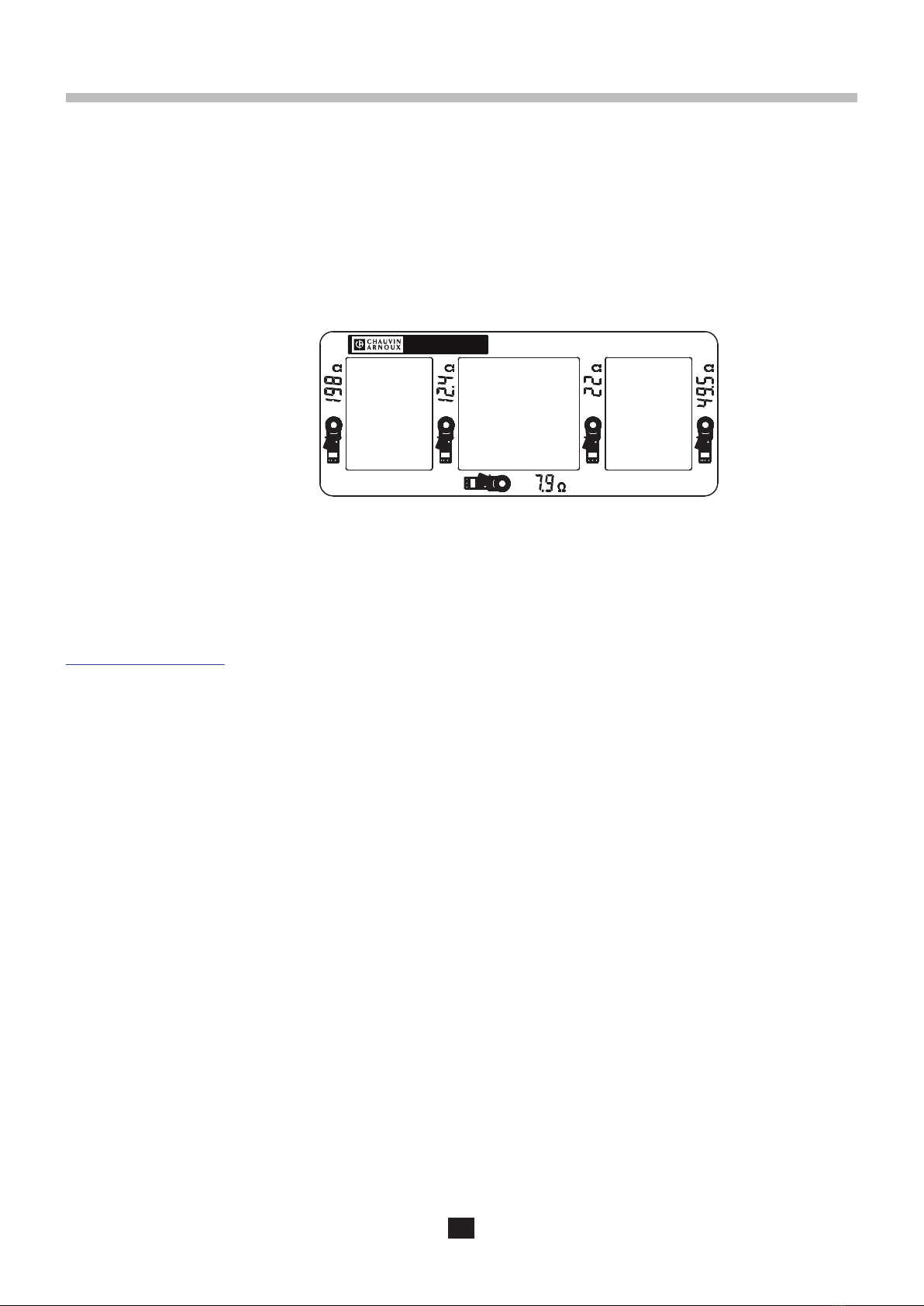

The C.A 6418 is used to make loop impedance measurements in a parallel earth network, for example for power distribution poles,

overhead contact lines, etc. These measurements are simpler to perform than the traditional measurements with two auxiliary rods.

The C.A 6418 can make loop impedances measurements with good accuracy at low values, and AC current measurements.

The C.A 6418 is simple to use. Its large measurement head can clamp bars up to 30x40mm.

Its memory function is used to record and read back the measurements.

Its OLED (Organic Light Emitting Diode) display unit is very easy to read, even in direct sunlight.

Calibration Loop

5

1

0

0

V

C

A

T

I

V

2

0

A

SET-UP

MR

A

OFF

Ω+ A

C.A 6418

GROUND TESTER

MEM

HOLD

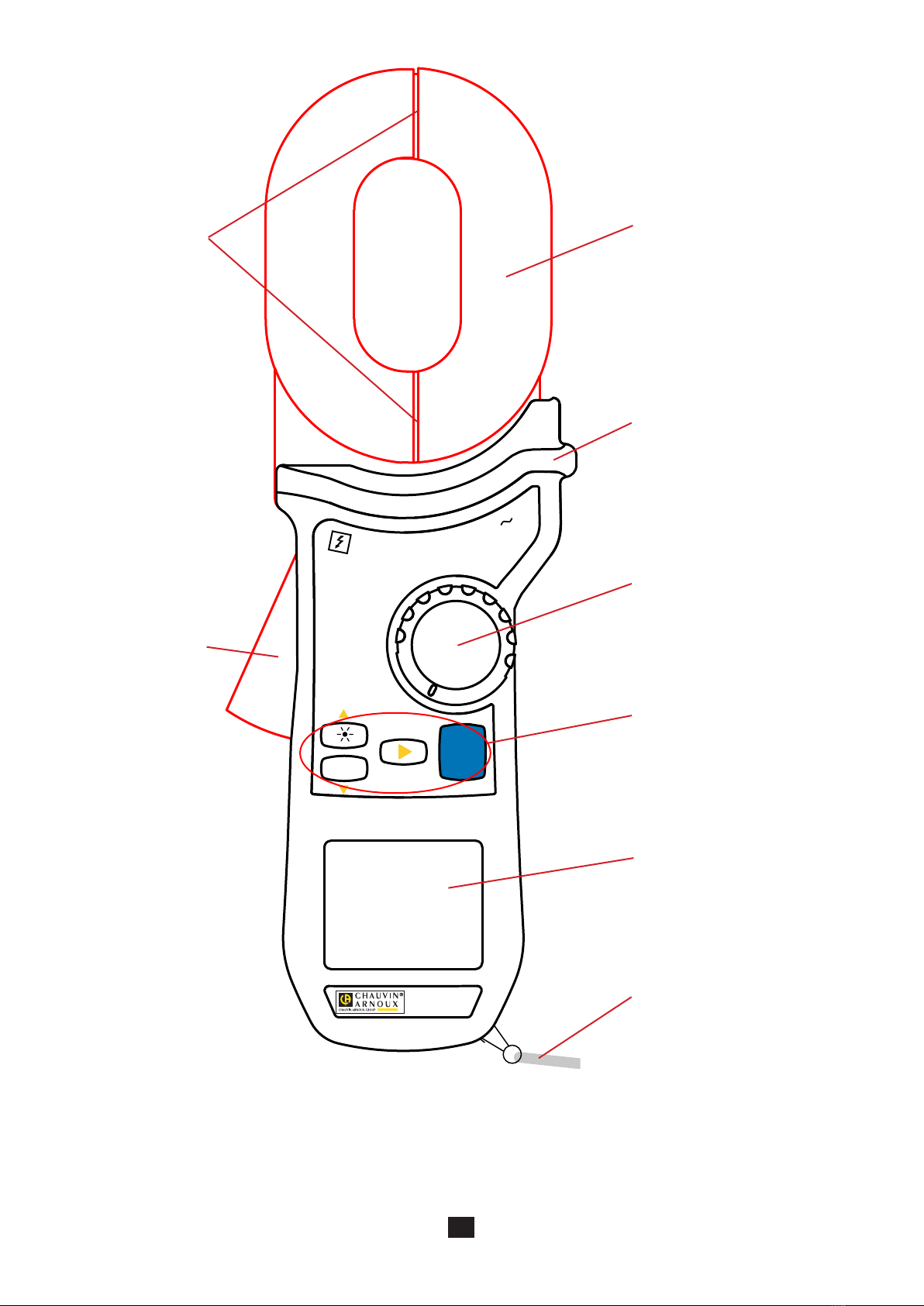

Measurement head.

Guard.

Trigger.

4 function keys.

Rotary switch to turn the instrument

on and select measurement, SET-

UP, or read memory.

OLED display unit.

Wrist strap.

Air gaps.

Table of contents

Popular Test Equipment manuals by other brands

Redtech

Redtech TRAILERteck T05 user manual

Venmar

Venmar AVS Constructo 1.0 HRV user guide

Test Instrument Solutions

Test Instrument Solutions SafetyPAT operating manual

Hanna Instruments

Hanna Instruments HI 38078 instruction manual

Kistler

Kistler 5495C Series instruction manual

Waygate Technologies

Waygate Technologies DM5E Basic quick start guide

StoneL

StoneL DeviceNet CK464002A manual

Seica

Seica RAPID 220 Site preparation guide

Kingfisher

Kingfisher KI7400 Series Training manual

Kurth Electronic

Kurth Electronic CCTS-03 operating manual

SMART

SMART KANAAD SBT XTREME 3G Series user manual

Agilent Technologies

Agilent Technologies BERT Serial Getting started