9

STROPPING & POLISHING IN STAGE 2

a. Make about 4 to 5 pairs of pulls through Stage 2 (Figure 8), alternating each pull in the left

and right slots (about 3 seconds for each pull on a 5 inch [12 cm] long blade.)

b. Then make 4 pairs of fast pulls alternating through the left and right slots. (1 second for each

pull for a 5 inch [12 cm] blade.)

c. Check the blade for sharpness. For a sharper edge make a few more pairs of fast pulls as

in step b and check for sharpness.

RE-SHARPENING THE E RO/AMERICAN BLADE

Re-sharpen in Polishing Stage 2 as described above. You will be able to re-sharpen repetitively

about 5-10 times using only Stage 2 as described above. After resharpening a number of times,

you may want to hone in Stage 1 to speed the re-sharpening process. In Stage 1 make about

5 pairs of alternating slow pulls and check for a burr. When a burr exists, proceed to polish in

Stage 2 as described above.

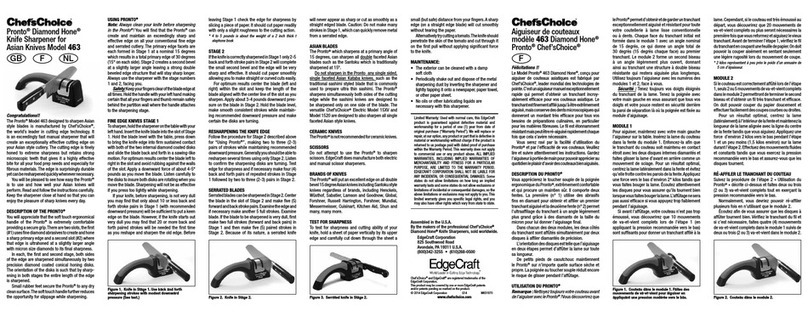

DESCRIPTION OF ASIAN AND E RO/AMERICAN BLADES

In general you will find that Euro/American blades have a sturdier cross-section than the more

delicate and thinner contemporary Asian blades. The variation among commercially available

knives of any type is great and in fact some Euro/American blades are very thin and certain

Asian knives have a thicker cross-section designed for heavier work.

2. TRADITIONAL JAPANESE KNIVES, Fig. 9b

The traditional Japanese knife is single beveled and has a wide

factory bevel A along one face of the blade above the small

edge facet. These are sold as either right handed or left handed

versions as shown in Fig. 9b. The wide factory bevel A is

ground, commonly at about 10 degrees. The most popular

example of this type blade is the sashimi knife also called

Yanagi and Takohiki, designed as shown to the right This

lengthy, slicing blade is ideal for preparing very thin slices of

raw tuna or salmon. The back of this blade is commonly slightly

hollow ground. A small single cutting edge facet of about 15° to

20° is created along the front of the edge of the sashimi blade as shown in Figures 9b and 10 in order to estab-

lish the geometry of the cutting edge. An even smaller cutting micro-facet (barely visible to the unaided eye) is

customarily created on the back face of the blade to enhance the sharpness of the finished edge. Figure 10

shows a greatly enlarged cross-section view of a typical factory edge on the traditional single-bevel Japanese

knife. The large factory bevel A serves to deflect the food slice away from the blade as it is cut.

1. CONTEMPORARY ASIAN KNIVES, Fig. 9a

The more popular Asian blades; the thin, light weight Santoku

and Nakiri are generally double faceted (sharpened on both

faces of the blade) as shown in Fig. 9a. Occasionally Santoku

knives are sold with single facets (Fig. 9b below) but these are

not readily available in the United States.

There are other but somewhat heavier double-faceted Asian

knives, the Deba and Gyutou, popular in Asia, which are used for

chopping hard vegetables, for tailing and filleting fish and for

meats. These are basically Asian chefs knives designed for

heavier duty work. The Chinese cleaver is included in this class.

Thickness

(approx. 0.25mm)

double faceted

Thickness

(approx. 0.1-0.2mm)

Back

Left handed ight handed

Factory

Bevel A

Commonly

small

10 to 11°

Factory

Bevel A

Commonly

small

10 to 11°

Front face

Front face

Each facet

about 15°

Sharpened

edge facet

about 15°

Figure 9a. Double faceted contemporary blades.

Figure 9b. Single beveled traditional blades.