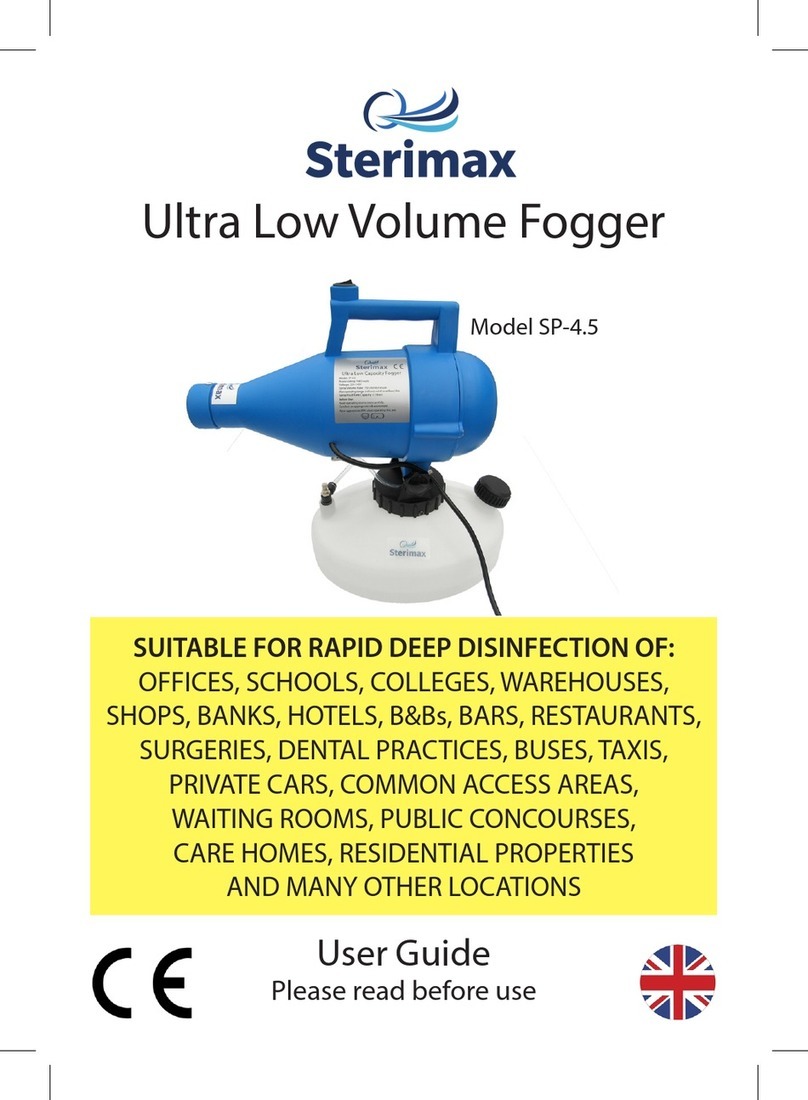

Chemtex ULV FOGGER User manual

Fogger is used to saturate air with a disinfectant such that the product spreads throughout the target area & coats surfaces

with thin, even layers.Use as a sprayer for direct application on contaminated surfaces is NOT RECOMMENDED.

ULV Fogging, works by compressing pesticides or disinfectants through a specially designed nozzle, producing a fine cold

mist or aerosol. Electric portable versions are particularly ideal for indoor applications as they don’t produce exhaust gases

ULV FOGGER

ULTRA LOW VOLUME FOGGING

MACHINE

Page 1 of 3

Operations and

Maintenance Manual

Industry Specific

Pharmaceuticals

& Biotechnology

Medical Devices, Bulk Drug

Manufacturing,Microbiology Lab, R&D

Center, Clinical Drug Trial Center,

Tissue Culture Laboratories.

Hospitals

Operation Theatres, Intensive Care

Units, AKD units, Post Operative

Wards, Pathology Labs & Blood Banks

Agriculture and

Horticulture

Greenhouses, Poly houses, Poultry

sheds, Apiaries, Cut flowers and

Vegetable Storage Areas etc.

Site/Treatment

Specific

Aerial & surface disinfection

treatment, closed space sanitization

Control of mold & mildew

Humidification

Odor Control

Control of flying pests

Areas of Application

Specifications

Model

Electric operate ULV Fogger

Power Supply

220V,50Hz,3.5A AC 1PH

Continuous Duty Hour

50 minutes

Compatible Chemicals

All water based disinfectants

Tank Capacity

5 liters

Droplet Size

5 ~ 10 microns

Coverage Area

30ft x 20ft, >7000cu.ft vol.

Material Dispersion Rate

50ml/min (Fix-flow system)

Optional

Timer & Rotator

Materials of Construction

Body & Parts

Chemical resistant material

Strainer

Fine SS wire mesh

Product Information

Ultra-Low Volume application (ULV) of disinfectants depends on the volume to be fumigated, strength of disinfectant solution,

time of exposure and particle size of fog produced.

Atomized liquids should be low density & non flammable. Refer to the dosage chart and MSDS for composition & compatibility,

chemical safety and accidental exposure guidelines.

Read Operating Instructions overleaf, failure to comply may lead to reduced machine life, electric shock hazard, fire & accidents.

All maintenance operations by authorized personnel only

BEFORE STARTING

ŸConnect the unit to a designated 220V,3.5A power supply

Use a grounded 3 terminal extension cord if required

ŸDO NOT reposition device by pulling on the power cord

ŸShut off ALL doors, windows, AC & ventilators in the room

ŸSwitch off & cover ALL electrical leads, digital equipments

and electro medicos etc with cloth or plastic sheet

ŸRemove any potential source of electric spark, or fire

(heating element) from the area

OPERATING INSTRUCTIONS

ŸPrepare the disinfectant solution as per instructions on the

disinfectant label and the area to be fumigated

ŸDO NOT mix chemicals in the tank; pre-mix & add to tank

ŸDO NOT add more than 5 liters liquid to tank; incase more

than 5 liter solution is need, run in successive batches

ŸNever place device directly on the floor; always elevate

with a stand or table to prevent dust & moisture clogging

ŸFor optimum results over large volumes, repeat process

from two adjacent corners of the area

ŸDO NOT operate in small enclosed areas beyond 30 minutes

DURING OPERATION

ŸAdjust the droplet size using the regulator on the tank

ŸAn ideal ULV fog is an invisible jet spray because of very

small droplet size; finer the droplets, greater the efficacy

ŸTurning the regulator by one full turn results in a visible

power mist that may deposit on nearby surfaces

ŸAdjust the head of the device at an approximate 45° angle

to the metal base cylinder and switch on the equipment

ŸLeave the area during fumigation process

AFTER FUMIGATION

ŸAdjust the droplet size using the regulator on the tank

ŸAn orifice with clean nozzle will produce uniform droplets

ŸAn ideal ULV fog is an invisible jet spray because of very

small droplet size; finer the droplets, greater the efficacy

ŸTurning the regulator by one full turn results in a visible

power mist that may deposit on nearby surfaces

ŸDO NOT switch on the device with a closed regulator

ŸAdjust the head of the device at an approximate 45° angle

to the metal base cylinder and switch on the equipment

ŸLeave the area during fumigation process

Page 2 of 3

Dosage Instructions

1.Volume of space to be fogged = Length x Width x Height

e.g. 20ft x 20ft x 10ft = 4000cu.ft

2.Recommended application rate: 400ml /1000cu.ft

3.Time required for fogging = Total Liquid to be

fogged/flow rate

Liquid (ml) = Volume (4000cu.ft) x

Application rate

(400ml/1000cu.ft)

= 1600ml

Time required = Total liquid to be

fogged/flow rate

= 1600ml/50ml/min

= 32 minutes

Quick Troubleshoot

Fumigation

volume

(cu.ft)

Amount of

Solution needed

(ml)

Time required to

Fumigate

(minutes)

1000

400

8

2000

1150

23

3500

2300

46

5000

3450

69

7000

5000

100

Problem

Fog and power mist is weak

Solution

Re-calibrate orifice regulator

Problem

Liquid forms around the base of the

motor housing

Solution

Extended operation time resulting in

mist deposition on metal base

Problem

Fogger is operating erratically;

frequently turning on & off

Solution

Electric cord & plug may be

loose/damaged or Motor failure

Problem

Fogger becomes very warm (hot)

during normal operation

Solution

Filter and strainer systems may be

blocked and need cleaning

Use a 3/C terminal 220V

power supply

Fill tank with pre-mixed

disinfectant solution

Adjust the droplet

size using regulator

Adjust orifice at

45° angle and Fumigate

© Copyright 2004, Chemtex Speciality Limited

No freedom from any patent owned by seller or others is to be inferred. Because use conditions and applicable laws may differ from one location to another and may change with time. Customer ids responsible for determining whether products and the information in this document are

appropriate for customer’s use and for ensuring that customer’s workplace and disposal practices are in compliance with applicable laws and other government enactments. chemtex Speciality Limited or any of its reseller assume no obligation or liability what so ever for the information

in this document.

NO WARRANTIES ARE GIVEN; ALL IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE EXPRESSLY EXCLUDED

Chemtex Speciality Limited

111, Haute Street Corporate Park, 86 A, Topsia Road (S) Kolkata -700046, WB, India

Tel: +91 (33) 7111-1111 | Fax: +91 (33) 7111-1117 | Email: cnh@chemtexlimited.com

www.chemtexlimited.com

Certifications and Approvals:

ROUTINE MAINTENANCE

Clean your fogger after each use. Drain the unused chemical from the tank, rinse it with the water

after using water base product or kerosene after using oil based product. Always fog for a few

minutes with clean water to flush chemical residues from the internal lines.

Nozzle cleaning -If any deposits are formed into the nozzle parts,it requires to be cleaned. Follow

instructions from dealer to clean solid residues left in the nozzle parts. Run the machine with plain

water to flush out the residues.

Tank Cleaning -To separate tank for cleaning, unscrew the wing nuts on the tank lid and lift the

blower head. The tank is separated for cleaning. Clean strainer & tank as needed. Do not leave

fogging solution in tank for long period of time. Always empty tank after each use before storage.

Motor Brushes- Graphite motor brushes conduct electricity to the motor commentator. Brushes are

a wear part, with a life of about 400 operating hours. Contact dealer for replacing motor brushes.

Intake Air Filter- Air borne particles, dirt, dust, & chemical being fogged can cause internal

corrosion & premature wear of motor parts. Warranty does not cover damages from such causes.

Dirty & clogged filter may be washed with water, dried and used (Do not squeeze)

(Life of the intake air filter depends upon frequency of the machine used, type of chemical used.

While replacing ensure that filter gets firm grip. Filter life is 75 hours of use or maximum six months.

PRECAUTIONS

Refer to MSDS of chemical to be fogged & follow dosage instruction, restriction & safety precautions specified.

Comply with requirement of goggles, gloves, facial masks recommended by chemical label.

Do not dispense flammable liquids such as acetone, benzene, gasoline, alcohol etc. Never fog around open flame.

Do not touch the blower orifice while the unit is in operation. The cooling time is 10 to 15 minutes after switch off.

Do not use to dispense highly corrosive liquids, paint or lacquer.

Do not fog a non-approved product which can damage machine parts and accelerate motor wear.

Do not switch ON the machine in absence of intake air filter, replace it when dirty.

Do not restrict the air intake of the ULV Fogger by blocking hand, holding it quiet near to body.

Do not insert any instrument or wire into the machine from front or rear end or nozzle end.

Always use 3 wire grounded electrical system. Do not disconnect the safety ground or use extension cords to

convert this machine to 2 wire system. This defeats the purpose of safety ground and may result in electrical shock.

Extension cord current rating if used must be greater than the amperage shown on the fogger nameplate.

Do not operate Fogger without strainer at the rear end of the liquid suction tube to avoid clogging of nozzle and tubes.

Do not expose to rain or immerse the machine in water or liquid to clean it.

Do not swing Fogger in running condition as motor rotates at very high speed.

Do not start damaged, broken or partially opened machine.

Allow fog to dissipate for 15 minutes before opening windows &/or ventilators to recirculate room with fresh air