1

Franklin Electric Co., Inc.

P. O. Box 12010

Oklahoma City, OK 73157-2010

405.947.2511 • Fax: 405.947.8720

www.LittleGiantPump.com

WATER WIZARD

AUTOMATIC

SUMP PUMP

5-ASP-FS

INTRODUCTION

This instruction sheet provides you with the information required to safely own

and operate your product. Retain these instructions for future reference.

The product you have purchased is of the highest quality workmanship and

material, and has been engineered to give you long and reliable service. This

product has been carefully tested, inspected, and packaged to ensure safe

delivery and operation. Please examine your item(s) carefully to ensure that no

damage occurred during shipment. If damage has occurred, please contact the

place of purchase. They will assist you in replacement or repair, if required.

READ THESE INSTRUCTIONS CAREFULLY BEFORE ATTEMPTING TO

INSTALL, OPERATE, OR SERVICE YOUR PRODUCT. KNOW THE PRODUCT’S

APPLICATION, LIMITATIONS, AND POTENTIAL HAZARDS. PROTECT

YOURSELF AND OTHERS BY OBSERVING ALL SAFETY INFORMATION.

FAILURE TO COMPLY WITH THESE INSTRUCTIONS COULD RESULT IN

PERSONAL INJURY AND/OR PROPERTY DAMAGE!

SAFETY GUIDELINES

1. CAUTION: To reduce risk of electric shock, pull plug before servicing this

pump.

2. This pump is designed to pump water. DO NOT PUMP strong chemicals,

solvents, brines, or thick liquids such as oils or grease.

3. Do not pump flammable liquids such as gasoline or fuel oil.

4. During operation the area around the pump may be covered with water. Take

care when handling the pump. Do not pull pump out of water when running

by the power cord.

5. Do not stand in water when changing fuse.

6. Make sure outlet is grounded.

7. The National Electric Code requires a Ground Fault Circuit Interrupter (GFCI)

be installed in the branch circuit supplying fountain equipment, ponds, etc.

See your local electrical supply dealer for various brands of GFCI devices.

8. This pump’s motor housing is filled with a dielectric lubricant at the factory for

optimum motor heat transfer and lifetime lubrication of the bearings. Use of

any other lubricant could cause damage and void the warranty. This lubricant

is non-toxic; however, if it escapes the motor housing, it should be removed

from the surface quickly by placing newspapers or other absorbent material

on the water surface to soak it up, so aquatic life is undisturbed.

ELECTRICAL CONNECTIONS

Your pump is supplied with a 3-prong electrical plug. The third prong is to ground

the pump to prevent possible electrical shock hazard. Do not remove the third

prong from the plug.

A separate branch circuit is recommended. Do not use an extension cord.

INSTALLATION

1. Clean any debris from the sump pit and set the pump in the center of the pit.

A solid bottom will prevent sand and dirt from clogging the pump.

2. Connect the discharge piping and run it to the nearest sewer or surface outlet.

Use pipe joint compound at all connections. Sump pumps can be piped to

discharge into the house drainage system, to a dry well, splash block, or to a a

storm drain, depending on local plumbing codes. The discharge pipe should

be as short as possible and contain as few elbows as possible. The discharge

pipe should be the same diameter as the discharge size to reduce pipe friction

losses. Smaller pipe will restrict capacity and reduce pump performance. The

sump pump comes with 1” female pipe thread discharge.

3. Always install a union in the discharge line, just above the sump pit, to allow

for easy removal of the pump for cleaning or repair.

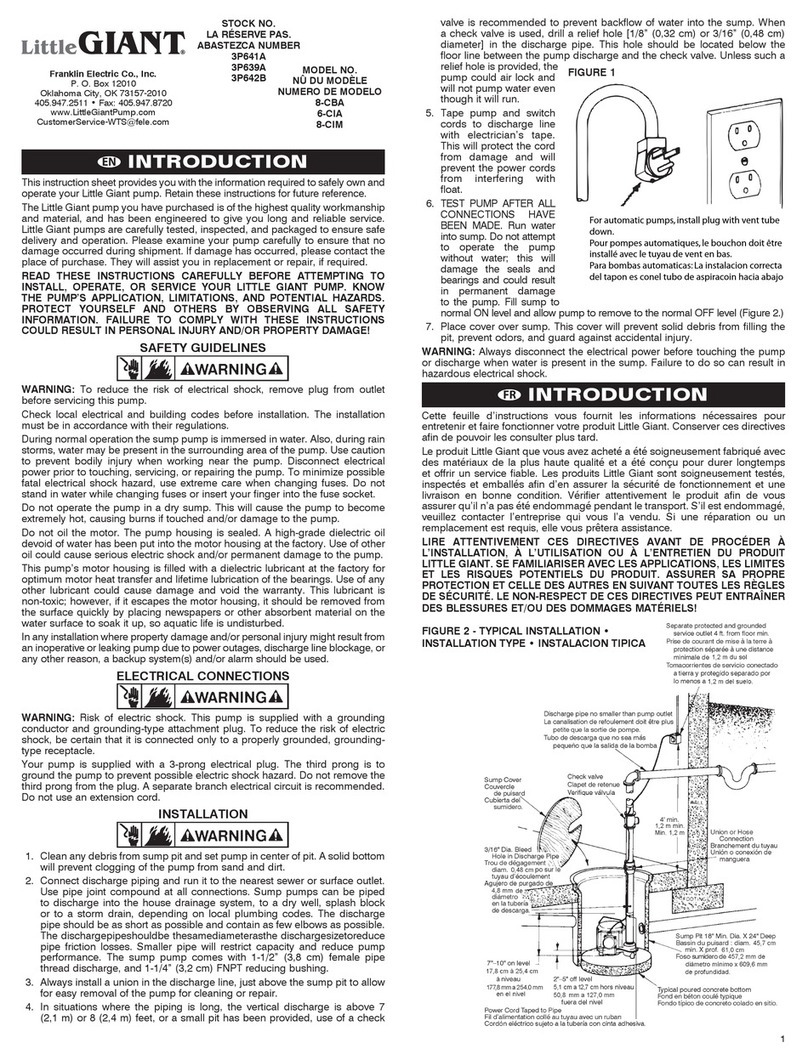

4. In situations where the piping is long, the vertical discharge is above 7 or 8

feet, or a small pit has been provided, use of a check valve is recommended

to prevent backflow of water into the sump. When a check valve is used, drill

a relief hole (1/8” or 3/16” diameter) in the discharge pipe. This hole should

be located below the floor line between the pump discharge and the check

valve. Unless such a relief hole is provided, the pump could air lock and will

not pump water even though it will run.

5. Tape the switch cord and pump cord to the discharge line with electrician’s

tape. This will protect the cords from damage and will prevent them from

interfering with the float.

6. TEST THE PUMP AFTER ALL CONNECTIONS HAVE BEEN MADE. Run

water into sump. Do not attempt to operate the pump without water; this will

damage the seals and bearings and could result in permanent damage to the

pump. Fill sump to normal “on” level and allow pump to remove water to the

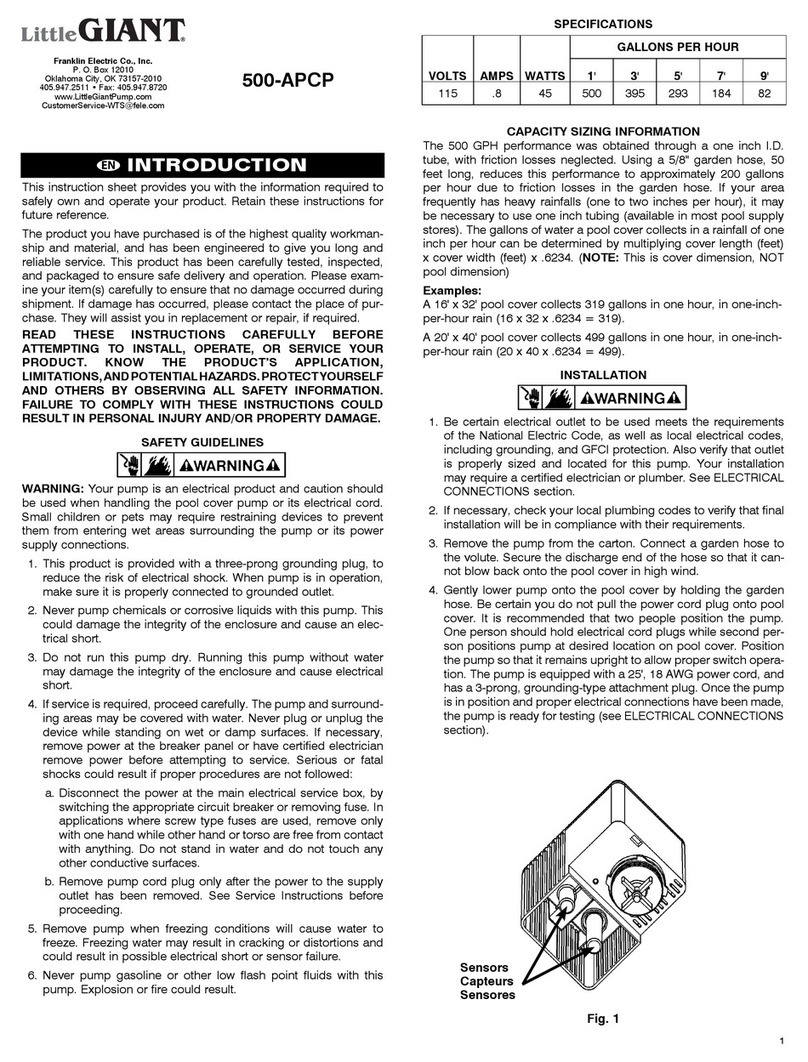

normal “off” level (Figure 1).

7. Place the cover over the sump. This cover will prevent solid debris from filling

the pit, reduce odors, and guard against accidental injury.

MAINTENANCE

The motor housing of the pump is completely sealed and requires no service.

Disassembly of the motor housing or alteration of the power cord voids all

warranty.

The motor is continuous duty type sealed in oil with an automatic thermal

overload protector device.

The pump can run against a restricted discharge (such as a fountain) without

damage to the pump.

1. If the pump becomes clogged, snap the screen off and clean out the area.

2. If necessary, remove the six screws holding the volute base to the motor

housing and clean the volute.

3. If the impeller is removed, make sure that a spacing of .050” with shaft

pushed toward housing is maintained when reassembling (Figure 2).

4. When reassembling, ensure that you install the seal ring between the volute

base and the motor housing.

PERFORMANCE DATA

Maximum pumping height = 26.3’

Maximum PSI = 11.4 PSIG

Discharge height above

pumping level

1’ 3’ 5’ 10’ 15’ 20

Gallons per minute (water) 20.4 20 19 16 13 8

NOTE: Ratings based on 1” pipe with friction loss neglected. Using 3/4” garden

hose adaptor performance will be reduced approximately 15%. This pump does

not deliver enough pressure to operate lawn sprinklers properly.

FIGURE 1

TYPICAL INSTALLATION