Simpro MegaDumper User manual

User Manual // Simpro MegaDumper®

Original Instructions // English // v86.0 // February 2022

USER MANUAL

Copyright © 2022 Simpro Handling Equipment Ltd.

No part of this document may be reproduced or transmitted in any form or by any means,

electronic, mechanical, photocopying, recording, or otherwise, without the written

permission of Simpro Handling Equipment Ltd.

For the purposes of standards compliance and international conformity, this document uses

Système International (SI) units. These may be converted to Imperial units as follows:

1 kilogram (kg) = 2.2 pounds (lb)

1 metre (m) = 1000 millimetres (mm) = 39.37 inches (in) = 3.28 feet (ft) = 1.09 yards (yd)

The following stylistic conventions are used throughout this document:

Point of interest

Point of warning

§Internal cross-reference (hyperlink in PDF edition)

Simpro partcode (hyperlink in PDF edition)

Errors in this document should be reported to info@simpro.world

User Manual // Simpro MegaDumper®

Original Instructions // English // v86.0 // February 2022 // Page 2

Contents

1. Product Overview ......................................................................................................................... 5

1.1 Key features ......................................................................................................................................... 5

1.2 Construction ........................................................................................................................................ 6

1.3 Mechanism .......................................................................................................................................... 6

1.4 Safe Lifting Capacity .......................................................................................................................... 6

1.5 Duty cycle ............................................................................................................................................ 6

1.6 Service life ............................................................................................................................................ 7

1.7 Noise emissions .................................................................................................................................... 7

1.8 Environmental restrictions ................................................................................................................... 7

1.9 Ingress protection................................................................................................................................ 7

1.10 Notes..................................................................................................................................................... 8

2. Operating Instructions .................................................................................................................. 9

2.1 Before use ............................................................................................................................................ 9

2.2 Emplacing and removing bins........................................................................................................... 9

Cradle identification........................................................................................................................................9

Type-S and Type-E Cradles............................................................................................................................ 11

Type-C Cradle ................................................................................................................................................ 11

Type-M and Type-N Cradles.......................................................................................................................... 12

Type-X (Custom) Cradle ................................................................................................................................12

2.3 Operating the controls ..................................................................................................................... 13

Control Panel identification...........................................................................................................................13

Standard Control Panel ................................................................................................................................. 14

Autocycle Control Panel ...............................................................................................................................14

VSD Control Panel.......................................................................................................................................... 15

Safety-Monitored Control Panel ................................................................................................................... 15

3. Safety Information.......................................................................................................................17

3.1 Safety features................................................................................................................................... 17

3.2 Reasonably foreseeable misuse ...................................................................................................... 17

3.3 ISO12100 Hazard and Risk Assessment Guide ................................................................................ 17

3.4 ISO13849 Conformance Guide........................................................................................................ 23

3.5 Safety Norms...................................................................................................................................... 25

4. Care and Maintenance.............................................................................................................27

4.1 Quick Troubleshooting Guide .......................................................................................................... 27

4.2 Cleaning............................................................................................................................................. 28

4.3 Cradle adjustment ............................................................................................................................ 28

4.4 Cradle jams........................................................................................................................................ 31

4.5 Electrical System (battery)................................................................................................................ 33

User Manual // Simpro MegaDumper®

Original Instructions // English // v86.0 // February 2022 // Page 4

International conformance...........................................................................................................................33

Voltmeter ........................................................................................................................................................33

Batteries ..........................................................................................................................................................34

Battery charger .............................................................................................................................................. 34

Battery box ..................................................................................................................................................... 34

Appliance inlet ............................................................................................................................................... 35

Isolator switch ................................................................................................................................................. 35

Circuit breaker................................................................................................................................................ 35

Solar panel kit ................................................................................................................................................. 35

4.6 Electrical System (3-phase mains) ................................................................................................... 36

International conformance...........................................................................................................................36

Appliance inlet ............................................................................................................................................... 37

Isolator switch ................................................................................................................................................. 37

Power supply unit ........................................................................................................................................... 37

4.7 Electrical System (1-phase mains) ................................................................................................... 37

International conformance...........................................................................................................................37

Appliance inlet ............................................................................................................................................... 37

Isolator switch ................................................................................................................................................. 38

Transformer .....................................................................................................................................................38

Variable Speed Drive..................................................................................................................................... 38

4.8 Hydraulic System ............................................................................................................................... 38

Powerpack .....................................................................................................................................................38

Control valves................................................................................................................................................. 38

Lift rams ...........................................................................................................................................................39

Hydraulic fluid................................................................................................................................................. 39

Maintenance.................................................................................................................................................. 39

Hydraulic system schematic.......................................................................................................................... 39

4.9 Safety Door and Interlock System.................................................................................................... 40

4.10 Safety-Monitoring System (CAT3/CAT4 only).................................................................................. 43

5. Assembly, Handling, Transport & Storage ................................................................................ 43

6. Preventative Maintenance Inspections ................................................................................... 45

6.1 Pre-inspection checklist .................................................................................................................... 45

6.2 Weekly inspection ............................................................................................................................. 45

6.3 Monthly inspection............................................................................................................................ 49

6.4 Annual inspection ............................................................................................................................. 51

7. Spare Parts ................................................................................................................................... 53

8. Warranty....................................................................................................................................... 55

9. EC Declaration of Conformity ................................................................................................... 57

10. Notes............................................................................................................................................. 58

1. Product Overview

Congratulations on your purchase of a Simpro

MegaDumper® bin-tipping machine. Since its

introduction in 1998, the MegaDumper has

established a reputation as the safest and most

reliable high-throughput bin lifter available.

With a modular design, the MegaDumper is

suitable for many different

applications from emptying

rubbish into compactors, to

pouring ingredients into mixers.

No matter how it is used, the

MegaDumper has proven to be

safe, economical, and easy to

operate, year after year.

1.1 Key features

Key features of the MegaDumper include:

1. A unique tipping action whereby bins are

lifted straight up, and then gently rolled

forward around the lip of the receptacle

being emptied into. Benefits of this design

and a wide range of tipping heights, from

900mm to more than six metres.

2. A standard lifting capacity of 600kg.

3. A reliable electro-hydraulic mechanism

which requires very little maintenance.

4. A hot-dip galvanised frame and cradle.

5. A versatile cradle system which lifts many

common waste bins without modification,

clamping or retaining. The standard Type-E

cradle lifts EN840 wheelie bins from the

base, avoiding damage to the

combing and extending bin life.

6. A modular design which can be easily

adapted to unique requirements, including

non-standard bins, tipping heights and

power supplies.

User Manual // Simpro MegaDumper®

Original Instructions // English // v86.0 // February 2022 // Page 6

1.2 Construction

The MegaDumper consists of a steel frame with two vertical masts and stabilizing legs, a bin

cradle, two hydraulic rams, lifting chains, guarding, powerpack cover, control panel, castor

wheels, power lead or batteries, hydraulic powerpack and electronic control systems.

1.3 Mechanism

When the RAISE button is pressed, two hydraulic rams are extended, which pull on an

arrangement of chains, causing the bin cradle to travel vertically in the masts. The cradle is

inverted at the appropriate height by an arrangement of arms, rollers, and curved tracks.

The rams are supplied by a hydraulic pump, which may be driven by a 3-phase, 1-phase,

battery, or compressed-air motor. Electrical, hydraulic, and mechanical control systems allow

the operator to lift and lower the bin in a controlled manner.

1.4 Safe Lifting Capacity

The Safe Lifting Capacity of the standard MegaDumper is 600kg (550lb).

Some machines may be specified with different capacities. Refer to the rating plate to verify

the Safe Lifting Capacity on any given machine.

Safe Lifting Capacity is a gross figure, referring to the weight of the bin, its contents, and

any other external objects which have been placed on the cradle.

Never attempt to lift bins heavier than the Safe Lifting Capacity.

1.5 Duty cycle

The duty cycle of the MegaDumper depends on the type of power supply and powerpack

that is fitted to the machine, as well as various environmental factors and the manner in

which the machine is used. The figures given below are estimates only.

Power supply

Duty Cycle (tipping ~300kg bins at 1800mm)

Net throughput

Number of bins

Units

24V/40Ah Gel Battery*

15,000kg

300 bins

Per charge

24V/40Ah Gel Battery with

continuous charge

3,000kg

10 bins

Per hour

24V/40Ah Gel Battery with solar

panel kit**

6,000kg

20 bins

Per day

Mains, 3-Phase ~415VAC

12,000kg

40 bins

Per hour

Mains, 1-Phase ~230VAC***

9,000kg

30 bins

Per hour

*4x 12V/20Ah batteries in series; default from 2015 **Subject to weather, latitude, and panel orientation; see §4.5.9 ***Deprecated since 2019

Powerpack specifications ca

1.6 Service life

The nominal service life of the MegaDumper is as follows:

Average Gross Bin Weight

Intended operational life

< 200kg

100,000 cycles

200kg 300kg

75,000 cycles

300kg 500kg

50,000 cycles

500kg 600kg

25,000 cycles

> 600kg

10,000 cycles

1.7 Noise emissions

The noise emissions of the MegaDumper do not usually

ear. Hearing protection is recommended if operating the machine for extended periods.

ISO standards specify that machinery noise emissions be measured in A-weighted

decibels, or dB(A). This is a unit of volume adjusted to reflect the sensitivity of human

hearing. Measurements for a dB(A) assessment are taken at a point 1.6 metres above the

1.8 Environmental restrictions

The MegaDumper may be used indoors or outdoors. However the following restrictions apply:

1. Minimum floor area 4 square metres, with a clear passage to exits;

2. Height above sea level not more than 1000m;

3. Ambient temperature not higher than +40℃and not lower than -10℃;

4. At ambient temperatures above 35℃, the relative humidity should not exceed 50%; at

lower temperatures, higher relative humidity is permitted;

Never operate the MegaDumper in explosive, corrosive, acidic or alkaline environments.

1.9 Ingress protection

Item

IP Rating

Push buttons, switches, and lamps

IP66

Door interlock

IP66

Coded magnetic switch

IP66

Motor

IP54 (additional protection is provided by covers)

Overall

IP56 (optionally upgraded to IP66 or IP69)

User Manual // Simpro MegaDumper®

Original Instructions // English // v86.0 // February 2022 // Page 8

1.10 Notes

1. This User Manual describes approved procedures for the operation, maintenance,

and routine inspection of the Simpro MegaDumper hydraulic bin-tipping machine.

2.

the purposes of EU Machinery Directive 2006/42/EC.

3. Operator(s) must read and understand this manual before using the machine.

4. If the machine is to be leased, sold, or otherwise transferred, then this manual shall

accompany the machine.

5. This is a generic manual. Simpro reserves the right to change the design of our

products at any time. In cases where a discrepancy exists between the manual and

the actual product, the manual is to be used as a reference only.

6. Contact your authorized Simpro agent if any problems or faults are encountered with

the machine.

7. Errors in this manual should be reported by email to [email protected]orld.

2.Ope rating Instruct ions

Before the MegaDumper is used for the first time, a Hazard and Risk Assessment should be

completed as per §3.3. The cradle may also need to be adjusted as per §4.3.

2.1 Before use

Before operating a MegaDumper, check the following points to ensure that the machine is

stable and safe to use:

1. The machine is on firm ground, with a slope ratio less than 1:12.

2. All covers and safety guards are in place.

3. The wheel brakes are applied, and/or the feet are wound down onto the ground.

4. All personnel other than the operator are well clear of the machine.

5. The cradle is fully lowered.

6. The key is inserted and turned to the ON position.

7. The battery indicator (if fitted) shows an acceptable level of charge.

2.2 Emplacing and removing bins

The MegaDumper cradle is designed to allow bins to be emplaced and removed easily,

while also holding them securely throughout the tipping cycle.

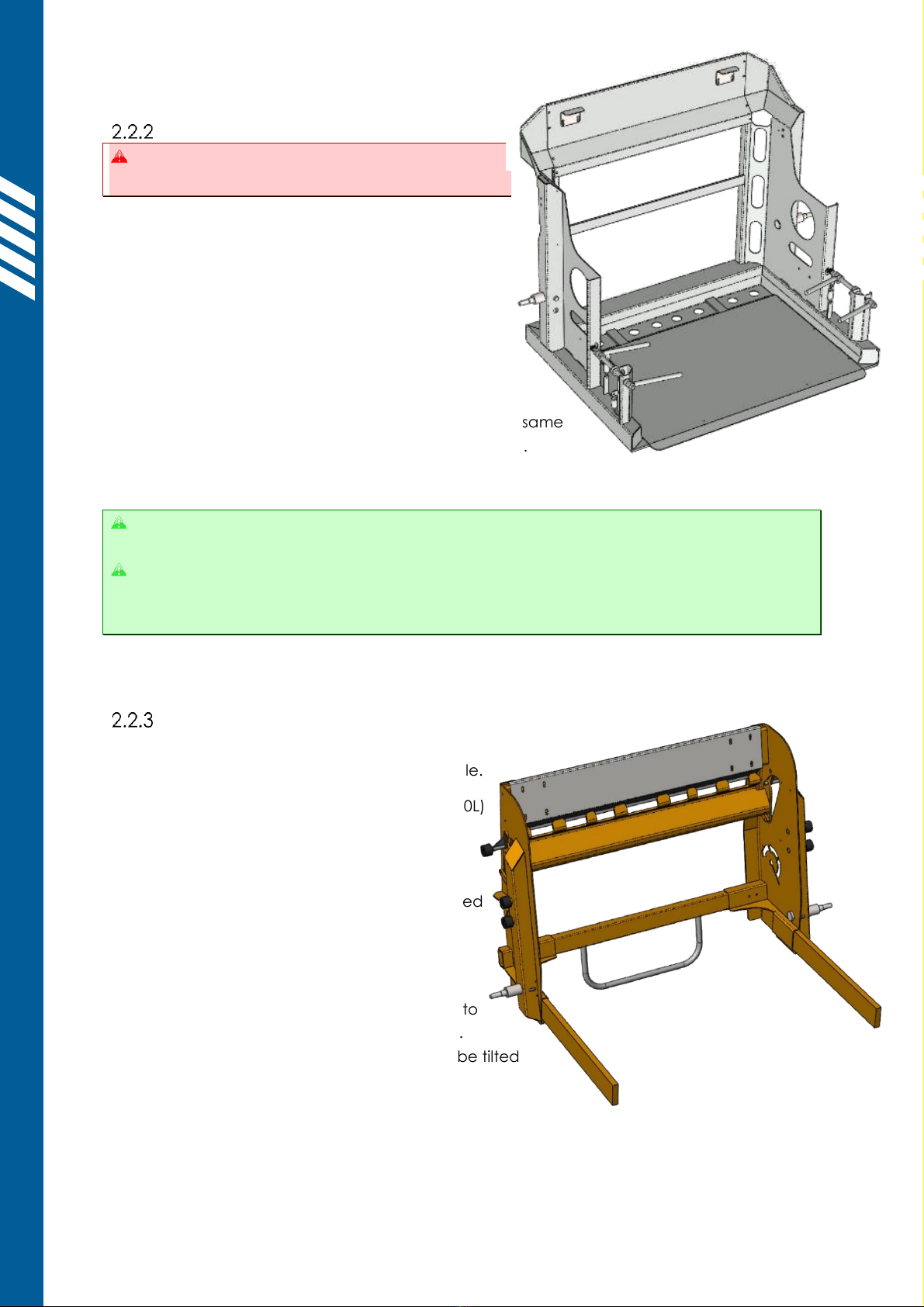

Cradle identification

A range of different cradles may be fitted to the MegaDumper, depending on the types of

bin that the machine needs to empty. Use the following table to identify the correct

instructions for your machine.

It is important to understand how to correctly emplace bins onto the cradle. Bins that are

not correctly emplaced may come loose and damage the machine while being lifted,

or fall out when inverted.

Cradle Type

Primary Use

Bin Compatibility

Cradle Image

Refer

Type-S

(Short

EN840

base-lift

cradle)

General waste

and recycling

applications

EN840 mobile

garbage bins

(wheelie

bins)

-60L

-80L

-120L

-140L

-240L

-660L

§2.2.2

User Manual // Simpro MegaDumper®

Original Instructions // English // v86.0 // February 2022 // Page 10

Cradle Type

Primary Use

Bin Compatibility

Cradle Image

Refer

Type-E

(EN840

base-lift

cradle)

-60L

-80L

-120L

-140L

-240L

-660L

-770L

-990L

-1100L

§2.2.2

Type-C

(EN840

comb-lift

cradle)

High-flow

waste and

recycling

applications

EN840 mobile

garbage bins

(wheelie

bins)

-60L

-80L

-120L

-140L

-240L

-360L

-660L

-770L

-990L

-1100L

§2.2.3

Type-M

(1200x1000

Mega bin

base-lift

cradle)

Food

processing

and logistics

applications

Bulk Bins

Nally Bins

Mega Bins

Dolav Bins

Pallet Bins

-610L

and

smaller

-Max

dims

1200W x

1000L x

1200H

§2.2.4

Type-N

(1200x1200

Nally bin

base-lift

cradle)

-780L

and

smaller

-Max

dims

1200W x

1200L x

1200H

§2.2.4

Type-X

(Custom)

Custom

applications

Custom bins

§2.2.5

Type-S and Type-E Cradles

Type-S and Type-E cradles should be adjusted

before first use, as set out in §4.3.1.

2.2.2.1 Emplacing bins

Open the door and place the bin onto the cradle:

-Large four-wheeled bins (660L/770L/1100L)

should be positioned central and firm

against the cradle backplate.

-Small two-wheeled bins (80L/120L/240L/360L)

should be positioned to one side of the cradle,

with a wheel inserted into the marked wheel

catch. Two smaller bins can be emptied at the same

time by placing one on each side of the cradle.

Once the bin is correctly emplaced, close the door.

The wheel catches are designed to work with standard EN840 wheelie bins from leading

brands such as Europlast, Sulo, ESE, Weber, Craemer, OnePlastics and Trident.

Some smaller bin manufacturers use tyres which are too wide to fit inside the wheel

catches. Should this issue occur, simply insert additional packers (flat washers) onto the

wheel catch mounting bolts, to increase the spacing as needed.

2.2.2.2 Removing bins

Open the door and, using the grab-handles provided, remove the bin from the cradle.

Type-C Cradle

2.2.3.1 Emplacing bins

Open the door and place the bin into the cradle.

-Large four-wheeled bins (660L/990L/1100L)

should be positioned central and firm

against the cradle backplate.

-Small two-wheeled bins

(80L/120L/240L/360L) should be positioned

against one side of the cradle. Two

smaller bins can be emptied

simultaneously, one on either side.

Ensure that the lifting teeth will securely hook into

the bin combing when the cradle begins to lift.

Smaller bins such as 60L and 80L may need to be tilted

Once the bin is correctly emplaced, close the door.

User Manual // Simpro MegaDumper®

Original Instructions // English // v86.0 // February 2022 // Page 12

2.2.3.2 Removing bins

Open the door and, using the grab-handles provided, remove the bin from the cradle. Some

bins may need to be lifted or tilted slightly to disengage the combing from the lifting teeth.

Type-M and Type-N Cradles

2.2.4.1 Emplacing bins

Open the door and place the bin onto the cradle,

central and firm against the cradle backplate.

If using a forklift or powered pallet truck to load the

bin, reduce speed to avoid heavy impacts which

might damage the cradle.

Once the bin is correctly emplaced, close the door.

Most common 610L bulk bins have a

1000x1200mm oblong plan view. These bins

must be loaded in the correct orientation,

with the longer 1200mm faces at front and

rear, and the 1000mm faces at the sides.

Bulk bins are held in place when inverted by

catches These catches

should be positioned to hold the top edges of the bin,

with a maximum free travel of 25mm (1 inch). The

catches can be unbolted and repositioned to allow emptying bins of different sizes.

It is recommended to use a forklift or powered pallet truck when moving bulk bins.

2.2.4.2 Removing bins

Open the door and remove the bin from the cradle.

Type-X (Custom) Cradle

The exact procedure for emplacing bins into a custom

cradle may vary. Contact your Simpro agent for advice or

training if required.

2.2.5.1 Emplacing bins

Open the door and place the bin, drum, or container onto

the cradle, positioned centrally against the backplate.

If using a forklift or powered pallet truck to load the

bin, reduce speed to avoid heavy impacts which

might damage the cradle.

Once the bin is correctly emplaced, close the door.

2.2.5.2 Removing bins

Open the door and remove the bin, drum, or

container from the cradle.

2.3 Operating the controls

The MegaDumper controls are designed to allow safe, intuitive operation of the machine.

Control Panel identification

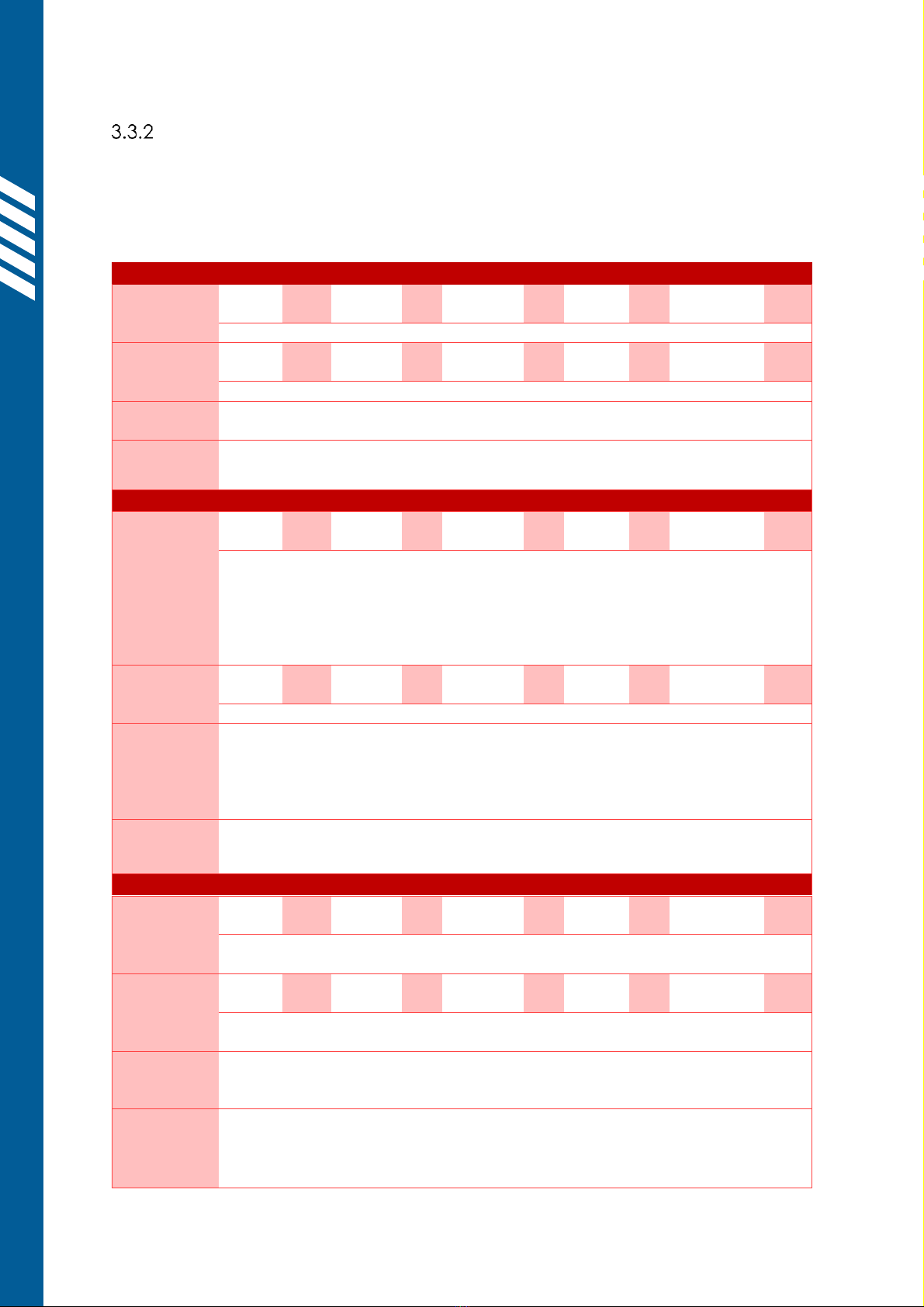

The MegaDumper may be fitted with a variety of different controls, depending on the

operational and safety requirements of the machine. Use the following table to identify the

correct instructions for your machine.

It is important to understand how to use the controls correctly, as improper operation

may result in a safety hazard or damage to the machine.

The control panel is normally atop the powerpack cover, but on some models, it is

mounted onto a separate enclosure.

Control

Panel Type

Primary Usage

Controls

Image

Refer

Standard

Standard

machines

-RAISE/LOWER

-KEY SWITCH

-VOLTMETER (battery

machines only)

§2.3.2

Autocycle

Machines with an

autocycle

controller

-RAISE/LOWER

-EMERGENCY STOP

-CONTROL MODE

(AUTO/MANUAL)

§2.3.3

VSD

Machines with a

Variable Speed

Drive controller

-JOYSTICK FOR

RAISE/LOWER

-KEY SWITCH

§2.3.4

Safety-

Monitored

Machines with

safety-monitoring

systems to comply

with 13849-1:2015

and AS/NZS4024

up to CAT3/CAT4

-RAISE/LOWER

-EMERGENCY STOP

-CONTROL MODE

(AUTO/MANUAL)

-SAFETY RESET

-Panel describing

the architecture of

the safety-

monitoring systems

(CAT3/CAT4)

Example Only

§2.3.5

User Manual // Simpro MegaDumper®

Original Instructions // English // v86.0 // February 2022 // Page 14

Standard Control Panel

How to operate the controls of a standard

machine, with no PLC or autocycle controller.

1. Before operation, check that the machine is

stable and safe to use as per §2.1.

2. Open the door and place the full bin onto the cradle,

taking care that it is properly positioned as per §2.2, then shut the door.

3. Press and hold the RAISE button until the bin reaches the inverted position, then

release. Wait for the contents of the bin to empty.

Release the RAISE/LOWER button to stop the cradle at any time.

Do not continue pressing the RAISE button after the cradle has reached the top of the

cycle, as this can overheat the hydraulic fluid and cause premature wear on the motor.

4. Press and hold the LOWER button until the cradle rests on the ground.

5. Open the door and remove the empty bin as per §2.2.

6. Repeat from step 1) as required.

Autocycle Control Panel

How to operate the controls of a machine with

an autocycle controller, allowing bins to be

emptied without continuous input.

MegaDumper models that are fitted with an

autocycle control system may be used in either MANUAL or

AUTO mode, selected using a switch on the control panel.

The operating procedure for each mode is as follows:

2.3.3.1 AUTO mode

1. Before operation, check that the machine is stable and safe to use as per §2.1.

2. Open the door and place the full bin onto the cradle, taking care that it is properly

positioned as per §2.2, then shut the door.

3. Turn the mode-selector switch to AUTO.

4. Press the RAISE button once. The cradle will automatically lift, hold the bin inverted for

a short time, and return to ground level.

Press the EMERGENCY STOP button to stop the cradle at any time.

5. Open the door and remove the empty bin as per §2.2.

6. Repeat from step 1) as required.

2.3.3.2 MANUAL mode

1. Before operation, check that the machine is stable and safe to use as per §2.1.

2. Open the door and place the full bin onto the cradle, taking care that it is properly

positioned as per §2.2, then shut the door.

3. Turn the mode-selector switch to MANUAL.

4. Press and hold the RAISE button until the bin reaches the inverted position, then

release. Wait for the contents of the bin to empty.

Release the RAISE/LOWER button or press the EMERGENCY STOP button to stop the cradle

at any time.

5. Press and hold the LOWER button until the cradle returns to the ground.

6. Open the door and remove the empty bin as per §2.2.

7. Repeat from step 1) as required.

VSD Control Panel

How to operate the controls of a VSD machine,

with a joystick to allow progressive control of

the lifting speed.

1. Before operation, check that the machine is

stable and safe to use as per §2.1.

2. Open the door and place the full bin onto the cradle, taking care that it is properly

positioned as per §2.2, then shut the door.

3. Push the JOYSTICK FULLY FORWARD to begin lifting the bin.

4. When the bin reaches the top of the mast and starts to invert, gently move the

JOYSTICK SLIGHTLY BACK so that the material is poured from the bin in a controlled

manner, as desired. Wait for the contents of the bin to empty.

Release the JOYSTICK to stop the cradle at any time.

5. Pull the JOYSTICK FULLY BACK until the cradle rests on the ground.

6. Open the door and remove the empty bin as per §2.2.

7. Repeat from step 1) as required.

Safety-Monitored Control Panel

How to operate a machine with a safety-

rated PLC control unit and CAT3/CAT4

monitoring system.

MegaDumper models that are fitted with a

safety-monitored control system may be used in

either MANUAL or AUTO mode, selected using a

switch on the control panel.

The operating procedure for each mode is as follows:

2.3.5.1 AUTO mode

1. Before operation, check that the machine is stable and safe to use as per §2.1.

2. Open the door. If the door is locked, press the LOWER button to unlock it.

3. Place the full bin onto the cradle, taking care that it is properly positioned as per §2.2,

then shut the door.

4. Turn the mode-selector switch to AUTO.

5. Press and hold the blue RESET button for two seconds.

User Manual // Simpro MegaDumper®

Original Instructions // English // v86.0 // February 2022 // Page 16

a. The safety system will now conduct an auto-diagnostic check. If no faults are

detected, the blue light will go out and the machine will be enabled.

a. If the safety system detects a fault, the blue light will not go out and the

machine will be disabled. The fault must be found and corrected before the

machine can be used, as per §4.10.

6. Press the RAISE button once. The cradle will automatically lift, hold the bin inverted for

a short time, then return to ground level.

Press the EMERGENCY STOP button to stop the cradle at any time.

7. Open the door and remove the empty bin as per §2.2.

8. Repeat from step 1) as required.

Once the cradle has lowered, the door is automatically unlocked for about 15 seconds. If

the door re-locks, press the LOWER button to unlock it at any time.

2.3.5.2 MANUAL mode

1. Before operation, check that the machine is stable and safe to use as per §2.1.

2. Open the door. If the door is locked, press the LOWER button to unlock it.

3. Place the full bin onto the cradle, taking care that it is properly positioned as per §2.2,

then shut the door.

4. Turn the mode-selector switch to MANUAL.

5. Press and hold the blue RESET button for two seconds.

a. The safety system will now conduct an auto-diagnostic check. If no faults are

detected, the blue light will go out and the machine will be enabled.

b. If the safety system detects a fault, the blue light will not go out and the

machine will be disabled. The fault must be found and corrected before the

machine can be used, as per §4.10.

6. Press and hold the RAISE button until the bin reaches the inverted position, then

release. Wait for the contents of the bin to empty.

Release the RAISE/LOWER button or press the EMERGENCY STOP button to stop the cradle

at any time.

7. Press and hold the LOWER button until the cradle rests on the ground.

8. Open the door and remove the empty bin as per §2.2.

9. Repeat from step 1) as required.

Once the cradle has lowered, the door is automatically unlocked for about 15 seconds. If

the door re-locks, press the LOWER button to unlock it at any time.

3.Safety Information

The MegaDumper has been designed to be as safe as possible without restricting the ease-

of-use and versatility of the machine.

Before the MegaDumper is used for the first time, a Hazard and Risk Assessment should be

completed as per §3.3.

3.1 Safety features

Safety features of the standard MegaDumper design include:

1. Mesh and sheet-metal panels which prevent access to all moving parts.

2. A safety interlock system which disables the machine unless the door is shut, and

electrically locks the door as soon as the cradle leaves the ground.

3. A tipping action which maintains the weight of the bin within the machine footprint.

4. A pressure-compensating lowering valve which automatically regulates the lowering

speed regardless of the weight of the bin.

5. A control system which either:

a. stops the machine unless continuous operator input is received, or;

b. features a prominent EMERGENCY STOP button to disable the machine.

3.2 Reasonably foreseeable misuse

Reasonably foreseeable misuse considered in the standard MegaDumper design includes:

1. Attempts to use the machine by untrained operators;

2. Attempts to empty bins that the cradle is not specifically designed to hold;

3. Attempts to bypass the door interlock or other safety systems;

4. Attempts to clear spilt material from inside the guarding without proper procedures;

5. Attempts to clean the machine without following proper procedures.

3.3 ISO12100 Hazard and Risk Assessment Guide

As set out in §3.4, organisations seeking to demonstrate ISO13849 conformance must assess

the safety of their machinery in the intended conditions of use, considering all relevant

factors such as the area the machine is to be used, the training of operators, the proximity of

other persons, frequency of use, etc.

The following section uses the ISO12100:2010 risk assessment model to assist prospective

MegaDumper owners in carrying out this process. Hazards intrinsic to the MegaDumper are

pre-filled, while blank spaces are provided to assess application-specific hazards.

Risk assessment and risk reductionard issued by the

International Standards Organisation. It describes procedures for identifying hazards and

estimating and evaluating risks during relevant phases of a machine life cycle.

User Manual // Simpro MegaDumper®

Original Instructions // English // v86.0 // February 2022 // Page 18

As with all powered industrial equipment, some hazards will remain despite any

precautions undertaken by the manufacturer or owner of the machine. It is essential that

operators are aware of these residual hazards and what they must do to prevent harm to

themselves or to others, as set out in §3.3.3.

The ISO12100 risk assessment model

In the ISO12100 risk assessment model, each identified hazard is given a Risk Factor, from

which is derived a Risk Evaluation. These parameters are assessed as follows.

3.3.1.1 Determining the Risk Factor

The Risk Factor associated with any given hazard may be calculated from the following

table, using the formula: Risk Factor = LO x FE x DPH x NP

3.3.1.2 Determining the Risk Evaluation

Once the Risk Factor has been calculated, the Risk Evaluation of the hazard can be

determined from the following table:

Risks evaluated as Very High, Extreme or Unacceptable are likely to require additional or

uprated safety functions, as set out in §3.4. These must be specified at the time of order.

LO

Likelihood of

Occurrence

FE

Frequency

of Exposure

DPH

Degree of

Possible Harm

NP

Number of

Persons at risk

0.1

Impossible, or

possible only in

extreme

circumstances

0.1

Infrequently

0.1

Scratch or

bruise

1

1 2 persons

0.5

Highly unlikely

though

conceivable

0.2

Annually

0.5

Laceration,

mild ill-health

2

3 7 persons

1

Unlikely but

could occur

1

Monthly

1

Break minor

bone or illness

(temporary)

4

8 15 persons

2

Possible but

unusual

1.5

Weekly

2

Break major

bone or illness

(permanent)

8

16 50

persons

5

Even chance

could happen

2.5

Daily

4

Loss of 1 limb or

eye/serious

illness

(temporary)

12

51 or more

persons

8

Probable not

surprised

4

Hourly

8

Loss of 2 limbs

or eyes/serious

illness

(permanent)

-

-

10

Likely, only to be

expected

5

Constantly

15

Fatality

-

-

15

Certain, no

doubt

-

-

-

-

-

-

Risk Factor

0-1

2-5

6-10

11-50

51-100

101-500

501-1000

1001 +

Evaluation

Negligible

Very

Low

Low

Significant

High

Very

High

Extreme

Unaccept

able

Identified Hazards

The following hazards have been identified that are intrinsic to the MegaDumper design. For

each hazard a full Risk Evaluation has been completed and control measures described.

Blank template spaces are also provided to identify, assess, and describe control measures

for application-specific hazards.

Entanglement or amputation of fingers or limbs in moving parts

Operator

LO:

0.5

FE:

4

DPH:

1

NP:

1

Risk

Factor:

2

Guarding prevents access to all moving parts and trapping hazards.

Other

persons

LO:

1

FE:

4

DPH:

1

NP:

1

Risk

Factor:

4

As above.

Control

measures

Operators are responsible to obey warning signs fitted to the machine and

instructions, regarding keeping himself and others clear of all moving parts.

Comments

The MegaDumper is designed so that trapping hazards are eliminated,

minimized or isolated.

Crushing by unauthorized rapid descent of cradle

Operator

LO:

0.5

FE:

4

DPH:

1

NP:

1

Risk

Factor:

2

The operator is protected from the cradle by the frame and guarding during

operation. A door safety interlock ensures that the door can only be opened

when the cradle is on the ground, and the cradle cannot be raised unless

the door is closed and locked.

Significant safety margins ensure that the probability of failure of any steel,

hydraulic, or control parts failing is very low.

Other

persons

LO:

0.5

FE:

4

DPH:

1

NP:

1

Risk

Factor:

2

As above.

Control

measures

Operators are responsible to obey all instructions and warning signs,

regarding keeping personnel away from the area beneath the cradle when

raised.

The machine must be regularly maintained, and all faults repaired

immediately.

Comments

A hydraulic speed-control valve limits the maximum speed of descent in

normal use.

Operator or others being hit by falling or flying debris

Operator

LO:

1

FE:

4

DPH:

0.5

NP:

1

Risk

Factor:

2

The operator is protected from the cradle by the frame and guarding during

operation. There is some risk if items such as broken glass are being tipped.

Other

persons

LO:

1

FE:

4

DPH:

0.5

NP:

1

Risk

Factor:

2

There is some risk to others standing close to the bin if items such as broken

glass are being tipped

Control

measures

Operators are responsible to obey all instructions and warning signs

regarding keeping personnel from the machine while in use.

If tipping product such as glass, metal or liquids, suitable PPE should be worn.

Comments

Other manuals for MegaDumper

2

Table of contents

Other Simpro Industrial Equipment manuals