CHIOSSI E CAVAZZUTI Speedy T 2005 User manual

INSTRUCTION MANUAL

via Costituzione 50/D 4201 5 Correggio (RE) Italy - Tel. +39 0522 637224 Fax. +39 0522 631180 cc@chiossiecavazzuti.com

Speedy T - Automatic Folding Machine

TRANSLAT ON OF OR G NAL NSTRUCT ON

Version Nr 002

Date 01 /07/201 6

3

via Costituzione 50/D 4201 5 Correggio (RE) Italy - Tel. +39 0522 637224 Fax. +39 0522 631180 cc@chiossiecavazzuti.com

SUMMARY

4 NTRODUCT ON

5 SAFETY

6 CE CERT F CAT ON

7 WARRANTY

8 FEATURES

9 PARTS DESCR PT ON

1 1 D MENS ONS AND HANDL NG

1 2 NSTALLAT ON

1 4 START UP AND ADJUSTMENTS

1 6 PROGRAMS

21 USAGE

24 MA NTENANCE

26 ELECTR C SCHEMAT C

28 PNEUMAT C SCHEMAT C

4

via Costituzione 50/D 4201 5 Correggio (RE) Italy - Tel. +39 0522 637224 Fax. +39 0522 631180 cc@chiossiecavazzuti.com

INTRODUCTION

Dear client,

Congratulations on your choice. Selecting this product you join the large number of users of

Chiossi e Cavazzuti products. With this equipment you can achieve excellent quality results. To that

end, we ask that you read carefully this instruction manual before using the machine.

Chiossi e Cavazzuti s.r.l boasts over ten years of experience in the manufacturing of automated

machinery. The technological expertise that the company has built up over years of research,

closely tied to its international manufacturing and distribution activities, is the best guarantee of

quality that Chiossi e Cavazzuti s.r.l can provide.

WARNINGS:

The manufacturer does not provide warranties of any kind with regard to this manual.

The company will not be responsible for errors in this manual, or for accidental or consequential

damages resulting from providing this manual and from its use.

This document contains proprietary information.

This manual cannot be photocopied o reproduced without prior authorization in writing by the

manufacturer.

The information in this manual is subject to change without notice.

All rights reserved.

5

via Costituzione 50/D 4201 5 Correggio (RE) Italy - Tel. +39 0522 637224 Fax. +39 0522 631180 cc@chiossiecavazzuti.com

GENERAL NOTICES

The Operator must read carefully and understand fully all the information given in this Manual and

especially all the safety precautions given in this section.

Keep the machine and its work area clean and tidy.

Do not remove or alter the plates and stickers attached to the machine by Manufacturer.

DO NOT REMOVE OR BY-PASS THE SAFETY SYSTEMS NSTALLED ON THE MACH NE.

SCHED LED SE

The machine has been designed and built to facilitate the folding of garments such as T-shirts.

t can be adapted to fold other kinds of garments provided Manufacturer checks the adaptation in

advance.

OPERATOR

The personnel required to operate the machine must possess (or achieve the required competence

through adequate training programmes) the ability detailed below and have read and understood

the content of this Manual and all the information on safety matters.

General and technical education at a level sufficient to understand the content of this manual and

interpret the Figures, diagrams and schematics correctly.

Knowledge of safety, industrial accident prevention and technical regulations.

Know how to act in an emergency, where to find individual protection equipment and how to use it

correctly.

Maintenance Engineers, in addition to the abilities detailed above, must also possess adequate

technical training.

IMPROPER SE

The machine must not be:

Used for purposes other than those detailed.

Exposed to the weather.

Used to fold material not suitable for its characteristics such as paper or other stiff materials.

Operated by children or untrained personnel.

SAFETY DEVICES

The machine cannot be completely protected since in this condition its operation would be

impeded.

Therefore, pay special attention to prevent hands from being crushed.

The low level pressure used reduces the risk of serious personal injury to a considerable extent.

SAFETY

6

via Costituzione 50/D 4201 5 Correggio (RE) Italy - Tel. +39 0522 637224 Fax. +39 0522 631180 cc@chiossiecavazzuti.com

The manufacturer:

Chiossi e Cavazzuti s.r.l

Via Costituzione 50/D

4201 5 Correggio (RE)

TALY

DECLARES THAT THE MACHINE:

Serial Number ......................................................

Manufacturing year: ......................................................

Trade name: "Speedy-T 2005"

Description: Automatic folding machine

ntended use: Folding and bagging garmints made from fabric.

Complies with the applicable directives:

European Parliament and Council Directive 2004/1 08/CE of December 1 5, 2004 concerning the

alignment of member nations laws in regard to electromagnetic compatibility.

European Parliament and Council Directive 2006/95/CE of December 1 2, 2006 concerning the

alignment of member nations laws in regard to electrical materials intended for use within certain

voltage limits.

Legislative Decree No. 81 of 4/09/2008, consolidation on healthcare and safety in the workplace.

Reference to harmonized standards:

EN 1 21 00-1 ; EN 1 21 00-2; EN 60204-1

And authorizes

Ugo Chiossi

Via Costituzione 50/D

4201 5 Correggio

taly

To set up a representative technical file

Correggio on ___/___/______

For the manufacturer Ugo Chiossi

Legal representative

CE CERTIFICATION

7

via Costituzione 50/D 4201 5 Correggio (RE) Italy - Tel. +39 0522 637224 Fax. +39 0522 631180 cc@chiossiecavazzuti.com

WARRANTY

The warranty of this material is one year from the date of purchase.

The warranty covers replacement of parts acknowledged as defective, with the exception of parts

subject to normal wearing (fuses, lamps, reflecting dishes, casters, power cord, etc.).

All replaced parts must be returned within fifteen days, if not returned by then we will need to

invoice them.

All service is done at our facilities.

No compensation can be claimed in case of machine downtime, regardless of the cause.

n case of dispute, the only court having jurisdiction is the Court of Reggio Emilia ( ).

WARRANTY CERTIFICATE

This must be sent for all service requests.

This product was tested and packaged with the outmost care.

n case of malfunction we ask that you quickly send this certificate with a detailed description of the

problem.

MACH NE MODEL ............................................................................................................

SER AL NUMBER ............................................................................................................

PURCHASE DATE ............................................................................................................

SOLD FROM: ............................................................................................................

CUSTOMER ADDRESS:

COMPANY ............................................................................................................

ADDRESS ............................................................................................................

TEL. ............................................................................................................

Address where the Warranty Certificate is to be sent:

Chiossi e Cavazzuti s.r.l.

Via Costituzione 50/D

4201 5 Correggio (RE)

TALY

Tel: +39 0522 637224

Fax: +39 0522 631 1 80

Email cc@chiossiecavazzuti.com

web www.chiossiecavazzuti.com

8

via Costituzione 50/D 4201 5 Correggio (RE) Italy - Tel. +39 0522 637224 Fax. +39 0522 631180 cc@chiossiecavazzuti.com

FEATURES

TECHN CAL DATA VALUES

POWER SUPPLY 230/115 V + PE

RE UIRED INPUT (max) 230 W

RE UIRED AIR PRESSURE 6 bar

AIR CONSUMPTION (max) 50 l/min

TOTAL WIDTH 71 0 mm

LENGTH WITH/WITHOUT STACKED LIFTED (min / max) 1150 / 1500 mm

ndispensable for fast and uniform folding of the T-shirts.

Can be adapted to suit all shapes and sizes available on the market.

The blades, which can be easily adjusted and are interchangeable, make it possible to suit the fold

to the required size in a few seconds, so that it is possible to fold baby t-shirts as well as extra large

sizes. Speedy T 2005 can operate in two ways:

– with stacker: the folded T-shirt is placed neatly on a stacker which descends thanks to a

photocell making it possible to form a stack;

– packing upside down : when the selected work cycle ends, the t-shirt is folded on the last blade

on which it can be easily packed in a bag.

The electronic control device allows the following functions:

– choice of 1 0 folding programs

– customization of folding programs which can be saved in memory;

– self-diagnostics of anomalies and/or faults;

– count of t shirts produced, indicating when the preset number of pieces is reached;

– hourly production programming, with acoustic signal for productions below minimum threshold

setting;

– language selection ( talian, French, English, Spanish, German);

– programming protected by means of access code;

– reset function which restores default programs.

T-SHIRT FOLDER WIDTH (min / max) 150 / 350 mm

T-SHIRT FOLDER LENGTH (min / max) 180 / 400 mm

WEIGHT 90 kg

PRODUCTION WITH STACKER (max) 500 pieces/h

PRODUCTION WITH PACKAGING (max) 350 pieces/h

NUMBER OF PROGRAMS 10

9

via Costituzione 50/D 4201 5 Correggio (RE) Italy - Tel. +39 0522 637224 Fax. +39 0522 631180 cc@chiossiecavazzuti.com

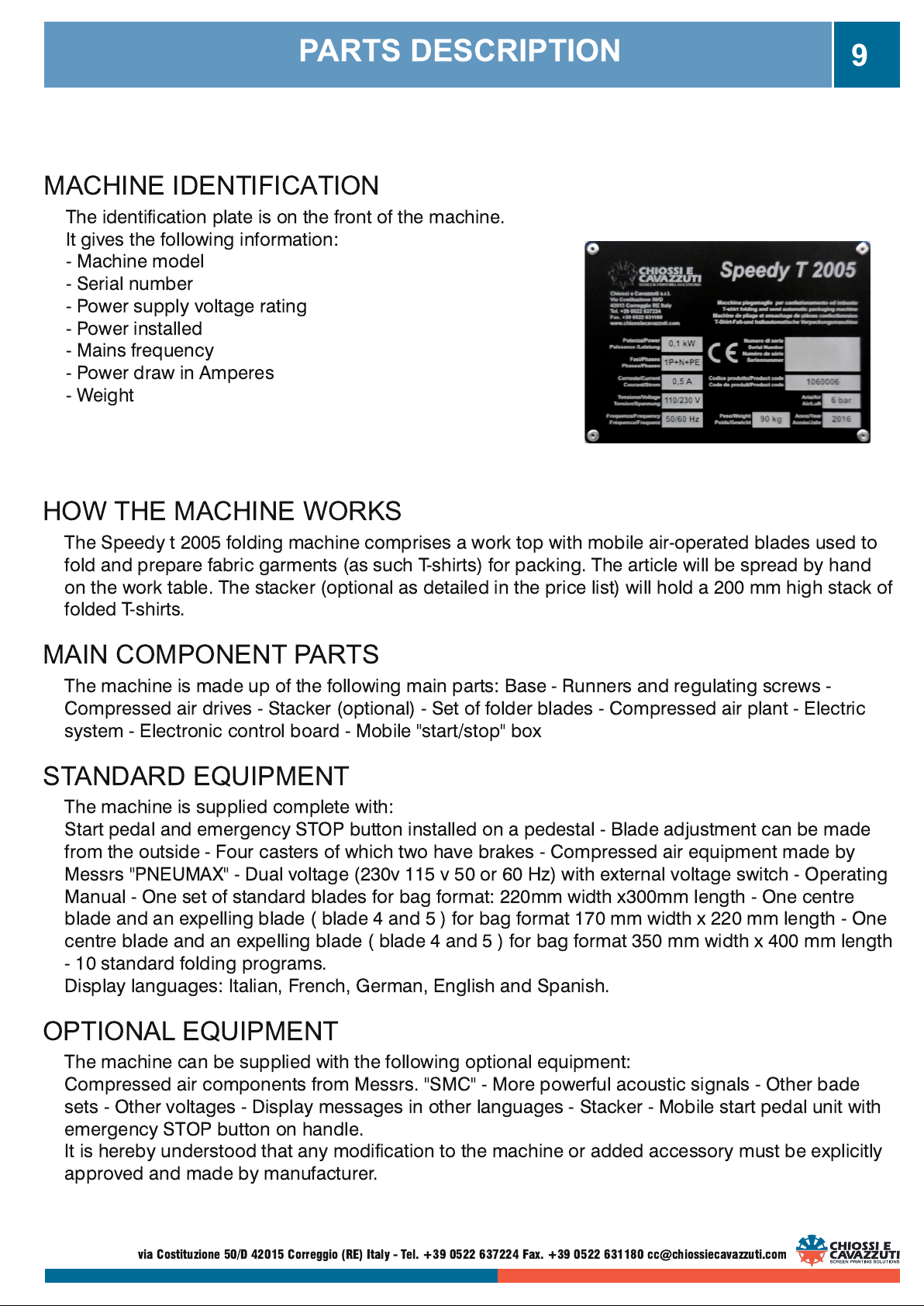

MACHINE IDENTIFICATION

The identification plate is on the front of the machine.

t gives the following information:

- Machine model

- Serial number

- Power supply voltage rating

- Power installed

- Mains frequency

- Power draw in Amperes

- Weight

PARTS DESCRIPTION

HOW THE MACHINE WORKS

The Speedy t 2005 folding machine comprises a work top with mobile air-operated blades used to

fold and prepare fabric garments (as such T-shirts) for packing. The article will be spread by hand

on the work table. The stacker (optional as detailed in the price list) will hold a 200 mm high stack of

folded T-shirts.

MAIN COMPONENT PARTS

The machine is made up of the following main parts: Base - Runners and regulating screws -

Compressed air drives - Stacker (optional) - Set of folder blades - Compressed air plant - Electric

system - Electronic control board - Mobile "start/stop" box

STANDARD EQ IPMENT

The machine is supplied complete with:

Start pedal and emergency STOP button installed on a pedestal - Blade adjustment can be made

from the outside - Four casters of which two have brakes - Compressed air equipment made by

Messrs "PNEUMAX" - Dual voltage (230v 1 1 5 v 50 or 60 Hz) with external voltage switch - Operating

Manual - One set of standard blades for bag format: 220mm width x300mm length - One centre

blade and an expelling blade ( blade 4 and 5 ) for bag format 1 70 mm width x 220 mm length - One

centre blade and an expelling blade ( blade 4 and 5 ) for bag format 350 mm width x 400 mm length

- 1 0 standard folding programs.

Display languages: talian, French, German, English and Spanish.

OPTIONAL EQ IPMENT

The machine can be supplied with the following optional equipment:

Compressed air components from Messrs. "SMC" - More powerful acoustic signals - Other bade

sets - Other voltages - Display messages in other languages - Stacker - Mobile start pedal unit with

emergency STOP button on handle.

t is hereby understood that any modification to the machine or added accessory must be explicitly

approved and made by manufacturer.

10

via Costituzione 50/D 4201 5 Correggio (RE) Italy - Tel. +39 0522 637224 Fax. +39 0522 631180 cc@chiossiecavazzuti.com

ENVIRONMENTAL CONDITIONS

The machine does not need any special environmental conditions. t should be installed in a well

lighted and ventilated factory building with a level floor designed to handle the weight of the

machine. Working area temperature range: 5°- 40° C, with humidity not above 50% at 40°C or not

above 90% at 20° C.

AREA LIGHTING

The lighting in the work area must be in compliance with the current regulations in the country

where the machine is installed and must guarantee good visibility over the entire area without

creating dangerous reflection.

VIBRATION

Under working conditions in compliance with the instructions for correct use of the machine, no

annoying levels of vibration will be encountered.

NOISE LEVEL

The machine is designed and built to reduce the noise generated as much as possible. The

machine's noise level is:

Noise level Lwa = 75 dB ( as measured )

Declared constant K = 4 dB

NOTE: The noise level mentioned above is the actual noise level measured and does not

necessarily mean a safe noise level. Though noise level and noise exposure level are related, the

measured noise level in itself cannot be used as an entirely reliable method for determining whether

or not additional ear protection devices should be used. The factors that determine the noise level

to which the workers are exposed include: exposure duration, characteristics of the work area and

other sources of noise ( number of machines, near by manufacturing processes, etc.). Furthermore,

noise exposure levels can differ from country to country. n any case, the information given in this

manual will enable the owner of the machine to make a better appraisal of the hazards and dangers

the machine generates.

ELECTROMAGNETIC ENVIRONMENT

The machine has been designed and built to work correctly in an industrial environment. t falls

within limits for Emission and mmunity required by the following Harmonised Standards:

EN 50081 -2 Electromagnetic compatibility. General emission standards, Part 2. ndustrial

Environment - ( 1 993 ).

EN 50082-2 Electromagnetic compatibility - General mmunity standards - Part 2 - ndustrial

Environment - ( 1 995 ).

11

via Costituzione 50/D 4201 5 Correggio (RE) Italy - Tel. +39 0522 637224 Fax. +39 0522 631180 cc@chiossiecavazzuti.com

DIMENSIONS AND HANDLING

PACKING AND SHIPPING

Transport must be done by professionally qualified personnel. The machine must be transported in

such a way as to prevent any damage to its parts. Depending on the type of transport vehicle, the

machine must be protected against any type of impact or strain. The machine is delivered on a

pallet and can then be moved with a forklift truck or transpallet. The machine can also be shipped in

a plywood box invoiced at cost.

Shipping dimensionson

a pallet (wheels dismantled) 1 200 x 750 x 880 (h) mm weight 1 08 Kg

normal crate (wheels dismantled) 1 220 x 770 x 900 (h) mm weight 1 30 Kg

low crate (stacker feet and cylinder dismantled) 1 220 x 770 x 630 (h) mm weight 1 25 Kg

Damage to the machine during transport are NOT covered by warranty.

Repair or replacement of such damaged parts will be charged to the customer.

STORING

f the machine is to be inactive for a long time, it must be put into storage with all the precautions

needed for the storage site and the length of time. Store the machine in a covered area.Grease all

non-painted parts. Protect the machine against bumps and strain. Protect the machine against

humidity and very high or very low temperature. Keep corrosive substances well away from the

machine.

S ITABLE WORK SITES

The folding machine must be installed in a sufficiently large area with enough space around it to

allow the operators to move easily about it. The floor must be level and sufficiently strong to hold the

weight of the machine.

PRELIMINARY CHECKS

Before running the machine, a number of checks and tests should be made to eliminate errors or

accidents during commissioning. Check to make sure the machine has not been damaged during

transport. Check to make sure that all the blades are lowered and the stacker platform (if installed) is

in its working position.

THE WORK TABLE MUST BE CLEAR OF EVERYTH NG EXCEPT THE GARMENT TO BE FOLDED.

Check if there is compressed air in the supply circuit. Check to make sure the mains voltage is the

same as that shown on the voltage change jumper sticker.

12

via Costituzione 50/D 4201 5 Correggio (RE) Italy - Tel. +39 0522 637224 Fax. +39 0522 631180 cc@chiossiecavazzuti.com

INSTALLATION

ASSEMBLY

When the volume of the transport box has considerable incidence on the cost of the transport (paid

by the customer), it can be delivered with the feet and the stacker cylinder (if ordered) disassembled

to reduce the shipping volume by about 30%. n this case, the assembly instructions will be

enclosed.

STACKER

f the machine is equipped with a "Stacker", its platform must be

raised and the support bow should be snapped into its seating.

FOOT PEDAL

1 -Remove the foot pedal and Start and Stop button from inside the

machine

2-The Start and Stop button can be attached on every side of the

machine.

3-Connect the power cord to a power socket.

REMOVING THE SIDE PANELS

The side panels snap into place. Once the retainers have been removed with a spanner, lift the

panel up to free it from the machine. The spare blades are inside this panel retained by an elastic.

13

via Costituzione 50/D 4201 5 Correggio (RE) Italy - Tel. +39 0522 637224 Fax. +39 0522 631180 cc@chiossiecavazzuti.com

ELECTRIC HOOK P

To eliminate problems when the machine is commissioned, follow the instruction given below:

The electric hook up is customer's responsibility.

The machine must be connected to the electric mains using the cable supplied in the installation kit.

Voltage S NGLE-PHASE 230 V.ac +/- 1 0% or 1 1 5 V.ac +/- 1 0% . n this latter case, the voltage

change jumpers will have to be moved as shown in the figure.

Nominal frequency: .50 - 60 Hz

COMPRESSED AIR HOOK P

The machine must be supplied with clean, dry compressed air delivered by a compressor capable

of providing at least 1 00 l/min of compressed air at 6 bar. The connecting point shown in the Figure

is a tapped ¼" gas fitting to which the required hose connector can be fitted. The inside diameter of

the air hose must be at least c 6 mm. Best not use a spiral hose. Best use rubberised canvas hoses

with a good thickness. The hoses should be subject to crimping or pinching.

14

via Costituzione 50/D 4201 5 Correggio (RE) Italy - Tel. +39 0522 637224 Fax. +39 0522 631180 cc@chiossiecavazzuti.com

REG LATING THE MACHINE

The machine is fully factory tested before being shipped and

therefore no regulations need be made.

When the machine is started for the first time, the compressed

air pressure should be adjusted as follows:

Pull the air pressure regulating knob up to release it.

Turn the knob until the pressure gauge needle is on 5 bar.

Push the knob back down to lock it in this position.

CONTROL AND STAT S INDICATION PANEL

The following devices are found on the control panel:

Main switch with fuse, voltage change jumper, power socket. Control and programming keyboard.

Back-lit liquid crystal display to read current settings and any fault messages.

Built in beeper.

1 ) Start key - starts work cycle (same as start pedal).

2) Stop key- stops work cycle.

3) Program key - when pressed you can select the program number on the number pad.

4) Programming key - (with the access code) is used to modify standard programs.

5) Counter - used to set the number of items to be folded.

6) Total counter - shows the number of items folded since the last reset and the number set. f

pressed twice, it will show total working time and total machine strokes.

7) Shows the hourly production set or, depending on the context, alternates upper case and lower

case.

8) Cancels the last operation executed or, depending on the context, puts a space between two

letters.

9) Number key or, depending on the context, alphanumeric key.

1 0) Confirmation key (Enter)

1 1 ) Liquid crystal display. Displays information or messages on machine operational status.

START UP AND ADJUSTMENTS

1

2

3

4

5

6

7

8

9

1 0

11

15

via Costituzione 50/D 4201 5 Correggio (RE) Italy - Tel. +39 0522 637224 Fax. +39 0522 631180 cc@chiossiecavazzuti.com

OPERATING THE MACHINE

The garment to be folded is spread on the work table with the back up and the neck towards the

stacker. Press the pedal (or key 1 ) and the machine will execute the active folding cycle (from now

on called program) and will then stop. This cycle will be repeated for each garment to be folded.

PROGRAMS

The different work programs are divided into 3 distinct operating modes described below. f the

machine is not equipped with a stacking device, Stacker Mode is disabled.

PACKAGING MODE

When the machine starts, blade 5 lifts to 45°. The stacker is not needed and should be unhooked

and folded over at the bottom.(fig. 5-1 ). A garment is spread on the work table. At cycle start, blade

5 will lower and the garment will be partially under it. As the cycle continues, the garment will be

folded over the blade. At the end of the cycle, the blade will lift again to 45° with the garment folded

around it. The operator or a second operator can then slip the bag on the garment and remove it

from the blade. Special notches have been made in the blade to facilitate grip.

STACKER MODE

The stacker must be installed on the machine and raised to its working position.

The garment is placed on the work table as described above. The selected folding program starts

and, at its end, blade 5 will rotate almost 1 80° and the folded garment on it will be tipped onto the

stacker platform. Stacker level will automatically adjust to garment thickness. As the work cycles

continue, a stack of garments will be made until full travel (200 mm) has been reached. The

machine will stop and the stacker will lift off completely. The display will show the message "Stacker

full". The machine can only be restarted when the stacker has been emptied.

TIPPING MODE

This an extra cycle offered by the machine. t is used particularly on machines without stackers

combined with a bagging machine. n practice, the program works exactly like stacker mode but

tipping will be onto any work table or machine taking the place of the stacker. This is not a standard

program and will have to be created specially.

SELECTING A PROGRAM

The machine has 1 0 standard programs. Follow these steps to select a program:

- press the Stop key (2 Page 1 0)

- press key "0-9 program" (3 Page 1 0)

- press the number key for the program you want (0-9)

- press "Enter" (1 0 Page 1 0)

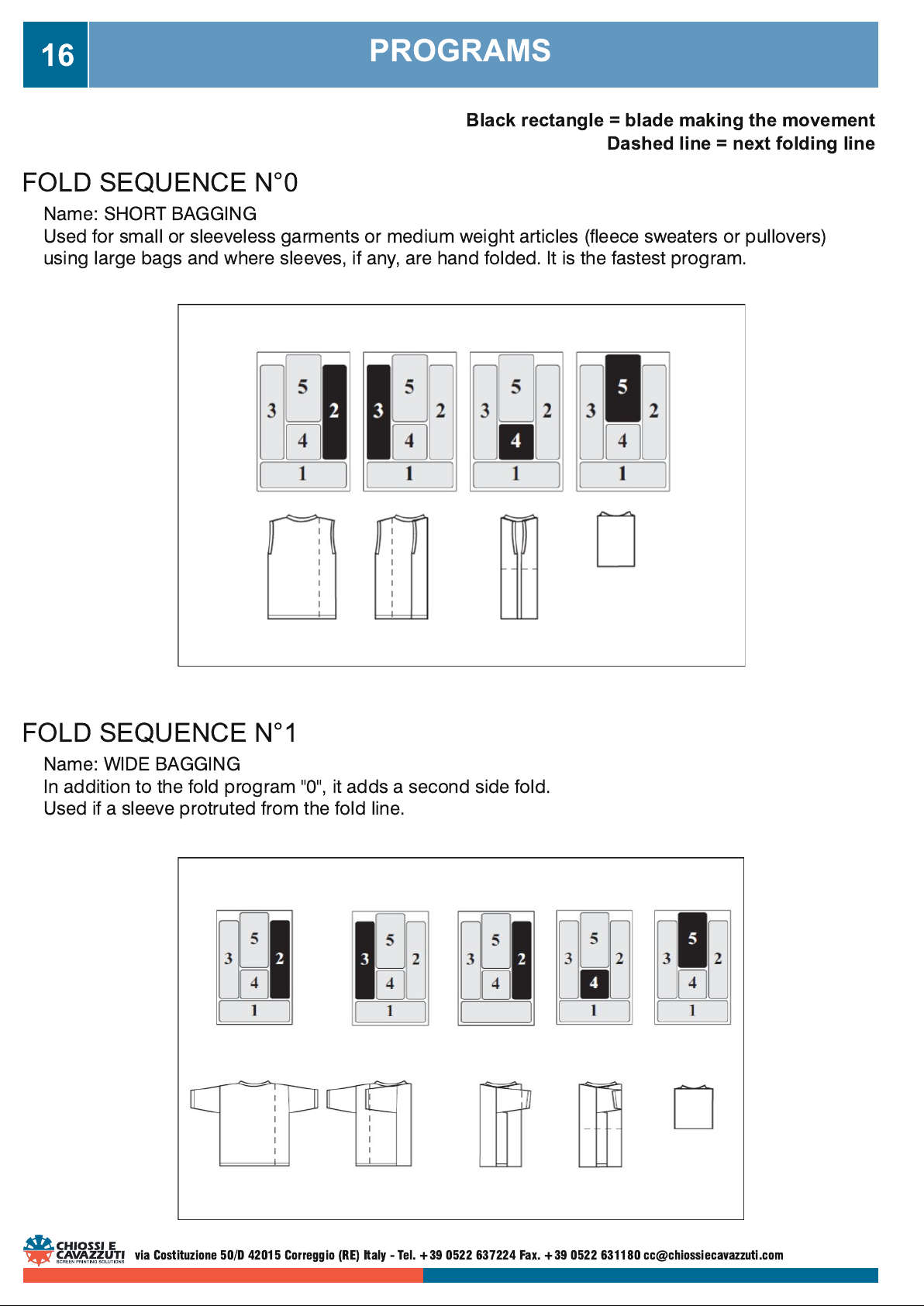

The Table below describes the 1 0 standard programs. Programs 5 to 8 require the use of the

stacker. n the Figures, the black rectangle represents the blade making the movement.

16

via Costituzione 50/D 4201 5 Correggio (RE) Italy - Tel. +39 0522 637224 Fax. +39 0522 631180 cc@chiossiecavazzuti.com

PROGRAMS

FOLD SEQ ENCE N°0

Name: SHORT BAGG NG

Used for small or sleeveless garments or medium weight articles (fleece sweaters or pullovers)

using large bags and where sleeves, if any, are hand folded. t is the fastest program.

FOLD SEQ ENCE N°1

Name: W DE BAGG NG

n addition to the fold program "0", it adds a second side fold.

Used if a sleeve protruted from the fold line.

Black rectangle = blade making the movement

Dashed line = next folding line

17

via Costituzione 50/D 4201 5 Correggio (RE) Italy - Tel. +39 0522 637224 Fax. +39 0522 631180 cc@chiossiecavazzuti.com

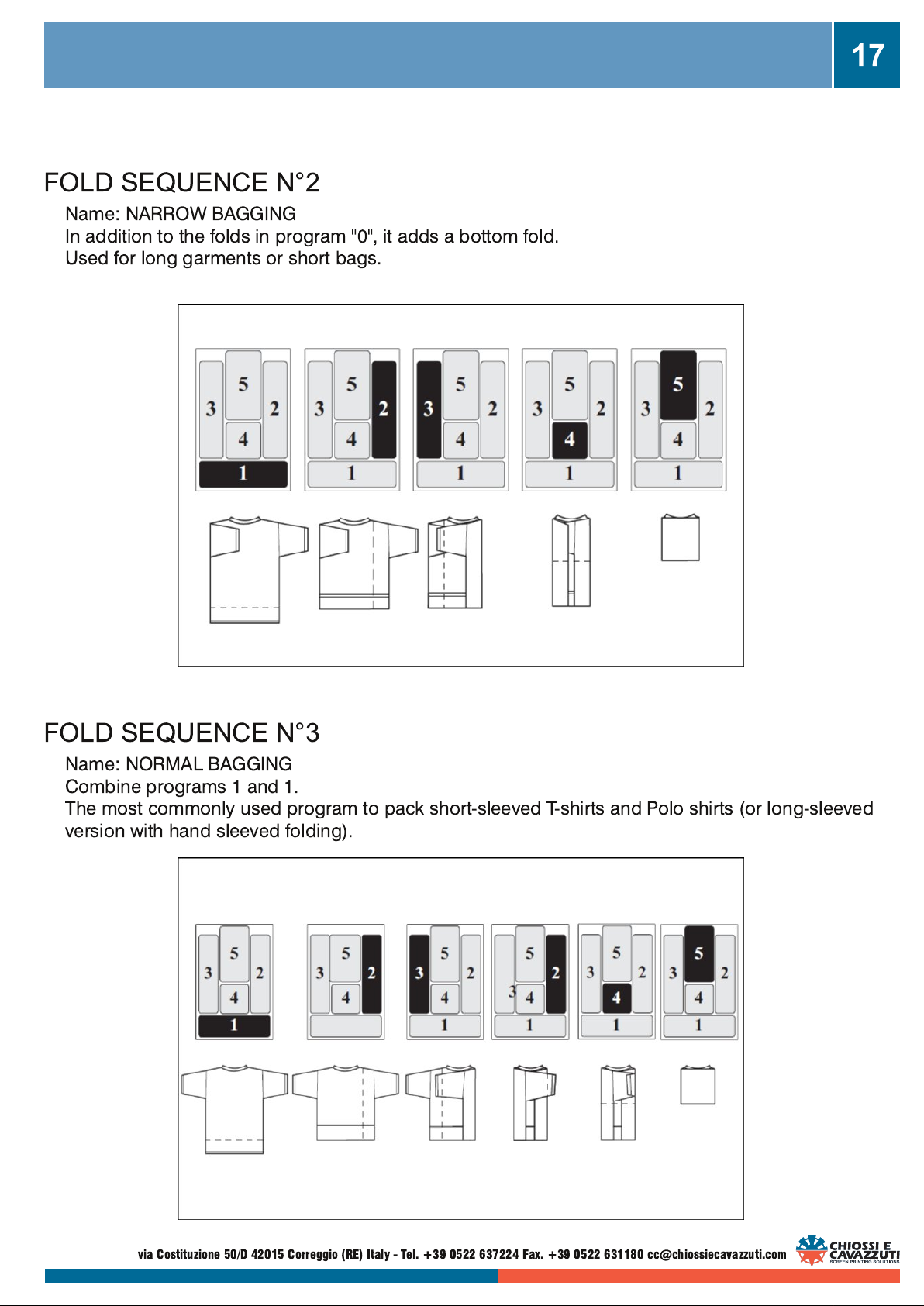

FOLD SEQ ENCE N°2

Name: NARROW BAGG NG

n addition to the folds in program "0", it adds a bottom fold.

Used for long garments or short bags.

FOLD SEQ ENCE N°3

Name: NORMAL BAGG NG

Combine programs 1 and 1 .

The most commonly used program to pack short-sleeved T-shirts and Polo shirts (or long-sleeved

version with hand sleeved folding).

18

via Costituzione 50/D 4201 5 Correggio (RE) Italy - Tel. +39 0522 637224 Fax. +39 0522 631180 cc@chiossiecavazzuti.com

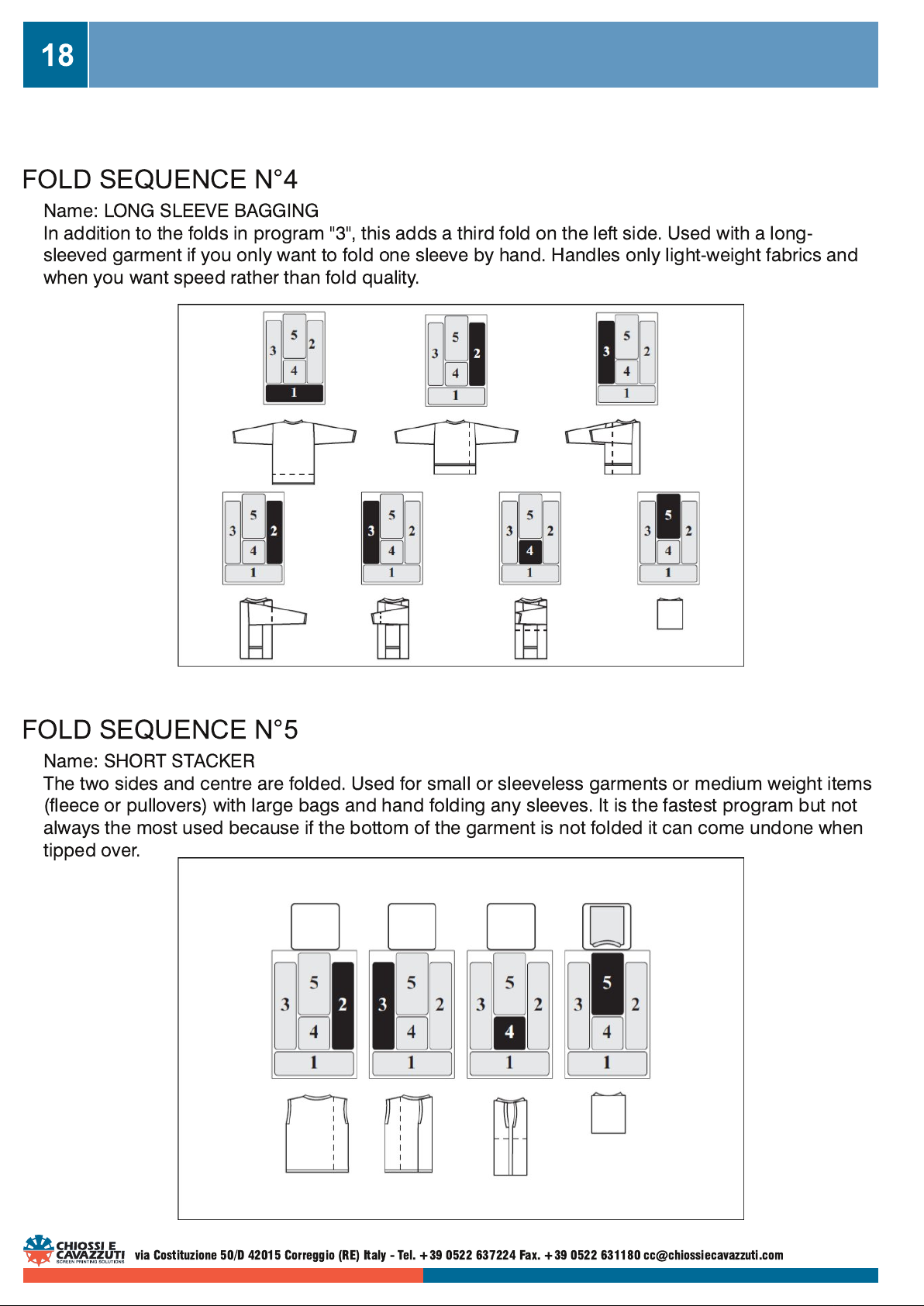

FOLD SEQ ENCE N°4

Name: LONG SLEEVE BAGG NG

n addition to the folds in program "3", this adds a third fold on the left side. Used with a long-

sleeved garment if you only want to fold one sleeve by hand. Handles only light-weight fabrics and

when you want speed rather than fold quality.

FOLD SEQ ENCE N°5

Name: SHORT STACKER

The two sides and centre are folded. Used for small or sleeveless garments or medium weight items

(fleece or pullovers) with large bags and hand folding any sleeves. t is the fastest program but not

always the most used because if the bottom of the garment is not folded it can come undone when

tipped over.

19

via Costituzione 50/D 4201 5 Correggio (RE) Italy - Tel. +39 0522 637224 Fax. +39 0522 631180 cc@chiossiecavazzuti.com

FOLD SEQ ENCE N°6

Name: W DE STACKER

n addition to the fold in program "5", this adds a second fold on the side. Used if a sleeve protudes

beyond the fold line. t cannot slways be used because, if the bottom is not folded, the garment can

come apart when tipped over.

FOLD SEQ ENCE N°7

Name: NARROW STACKER

n addition to the folds in program "5", it adds a bottom fold. Used for long garments or short bags.

20

via Costituzione 50/D 4201 5 Correggio (RE) Italy - Tel. +39 0522 637224 Fax. +39 0522 631180 cc@chiossiecavazzuti.com

FOLD SEQ ENCE N°8

Name: NORMAL STACKER

This combine programs "6 and 7".

This is the program most used to fold short-sleeved T-shirts and Polo shirts (or long-sleeved ones

with manual sleeve folding).

FOLD SEQ ENCE N°9

Contains a copy of program 8.

USE TH S PROGRAM TO CHECK OUT YOUR CUSTOM SED FOLD NG PROGRAMS

Table of contents

Other CHIOSSI E CAVAZZUTI Packaging Equipment manuals