Bulletin #: V113018-04

Issue Date: November 30, 2018

Orion Packaging Systems * A division of Pro Mach

4750 County Road 13 NE Alexandria, MN 56308

(800) 333-6556

http://www.orionpackaging.com/parts-and-service/manuals/

Page 7of 12

Sentry HP/LP

Quick Start Guide

Set Up Load

Carefully place the load to be wrapped on the turntable. Be sure the load is centered and stable.

Load the Film

The film roll can be loaded on the carriage mandrel from either end of the roll. When using tacky film,

please verify that the tacky surface of the film is inward on the load.

Press in the E-stop.

Loosen the knob on the top mandrel spool and remove the mandrel.

Put the roll of film on the bottom mandrel.

Install the top mandrel on top of the roll to prevent upward movement.

Tighten the hand knob.

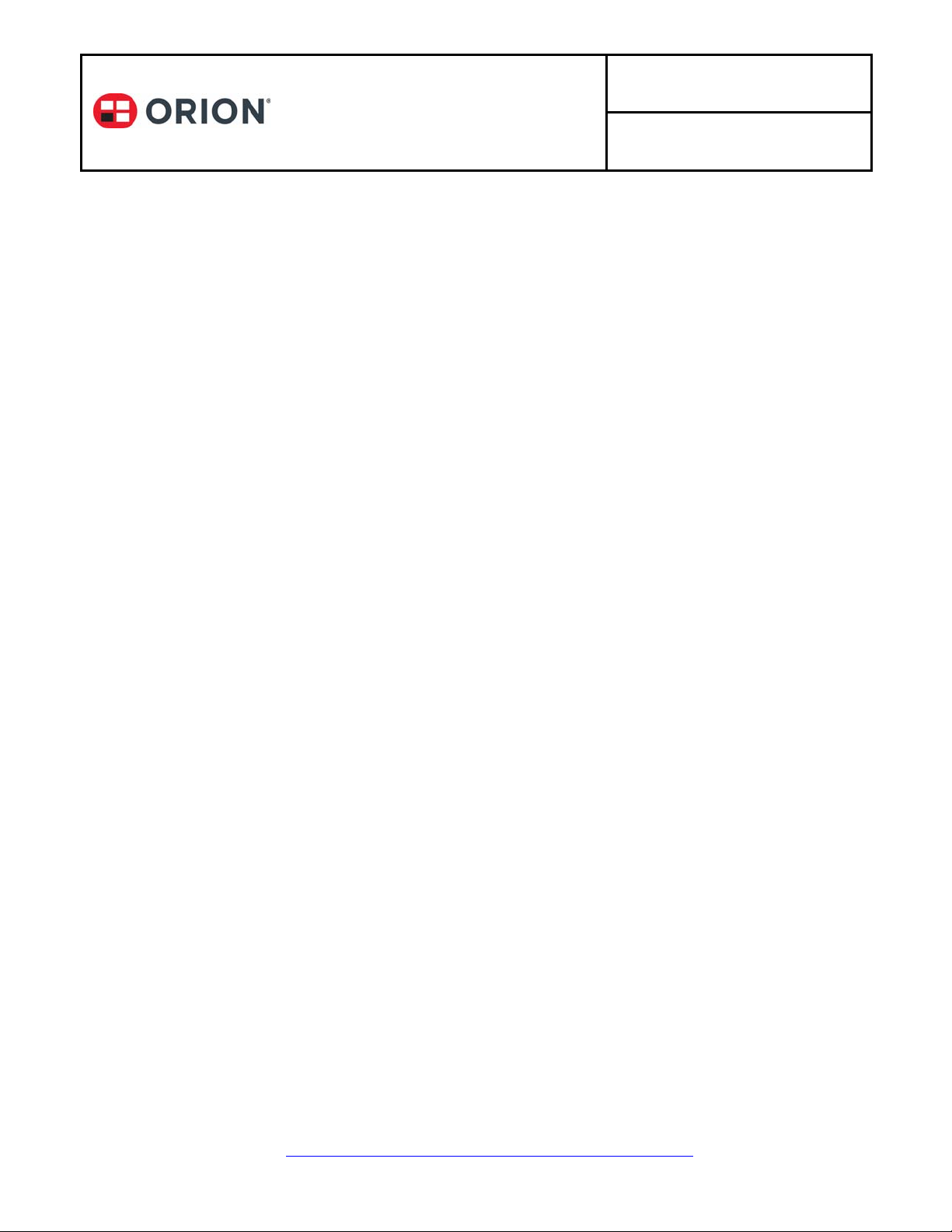

Press the latch down and pull out on the carriage door to open the carriage. The film carriage is

equipped with a switch that detects when the carriage threading door is open. When opened, it will set

off an alarm on the HMI and prevent the carriage from moving.

Illustration 7 – Threading the Film

Pass the roped tail of the film through opening.

Pass the film rope around the outside of the first

aluminum roller and through the inside of the

second roller.

Attach the film to the load.

To close the carriage door, hold the latch handle

down and press the door closed. Ensure the latch

clicks shut properly. The pins on the carriage door

will latch into the top of the carriage.

When the film feeding is completed, release the E-

stop.

Press the Start button once to reset control power.

The system is now ready to begin the first

wrapping cycle.