ChlorKing NEXGEN60 User manual

NEXGEN60 InstallationRev1 Page 1of 42

04/11/2022

NEXGEN60 and 60R

Installation, Operation, and

Maintenance Manual

NEXGEN60 InstallationRev1 Page 2of 42 04/11/2022

TABLE OF CONTENTS

1.0DESCRIPTION 3

1.1 General Information 3

1.2 Principals of Operation 4

1.3 Specifications, Certifications, and Sizing Guidelines 5

2.0INSTALLATION 8

2.1 Unpacking 8

2.2Storage 8

2.3 Safety Considerations 8

2.4 Plan Ahead 10

2.5 Additional Parts Required for Installation 10

2.6 Power Supply Electrical Connections 11

2.7 Bonding 12

2.8 Plumbing Connections 13

2.9 Saturated Salt Feeder Installation 16

2.10 Plumbing the Overflow 17

2.11 Preparing the pH Neutral System 18

2.12 Plumbing the Hydrogen Vent 18

3.0OPERATION 19

3.1 Start-up Procedures and Checks 19

3.2 Adjusting Chlorine Output 19

3.3 Touch-screen Icon Explanations 20

3.4 Using the Touchscreen 21

4.0MAINTENANCE 28

4.1 Routine Maintenance 28

4.2 Cell Cleaning Procedure 28

5.0 WARRANTY INFORMATION 42

Note: This manual is subject to change at any time based on system improvements,

design changes, authorized modifications, or new information. Please consult

ChlorKing for the latest revision.

Manufacturer:

ChlorKing Inc

2935 Northeast Parkway

Atlanta, GA 30360

1-800-536-8180

NEXGEN60 InstallationRev1 Page 3of 42 04/11/2022

SECTION 1

DESCRIPTION

1.1 GENERAL INFORMATION

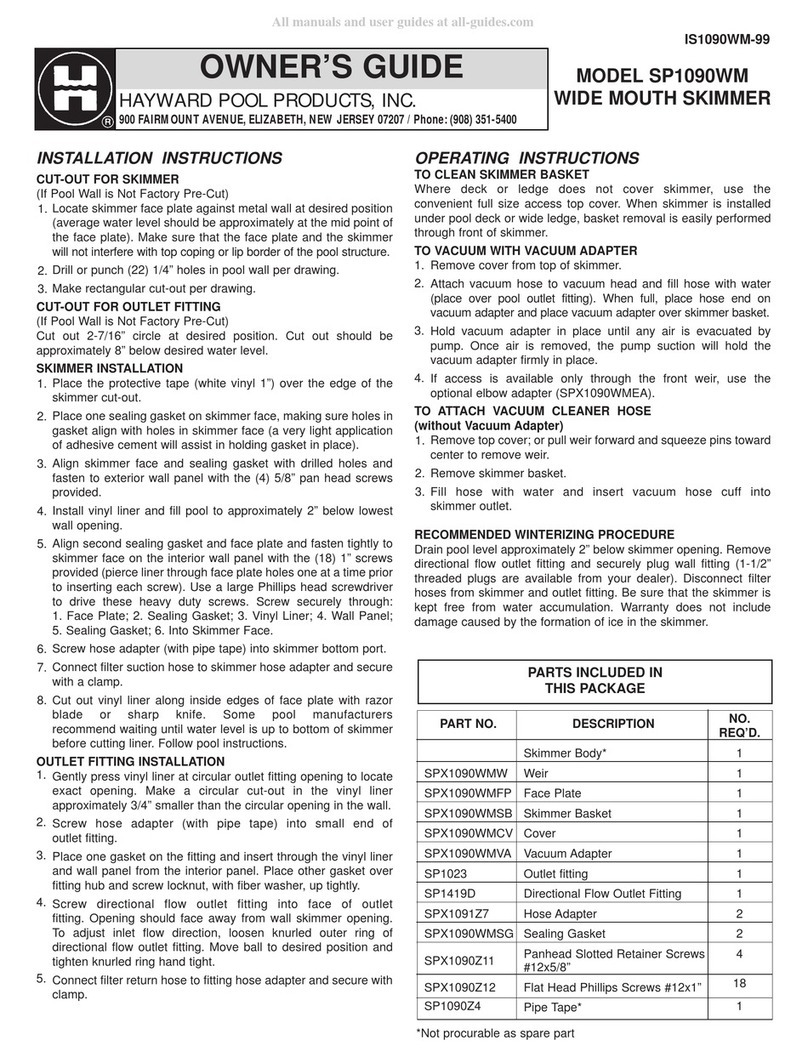

The NEXGEN system is an on-site sodium hypochlorite generator designed for

commercial swimming pool applications. The NEXGEN can produce up to 72 pounds of

equivalent chlorine per day. The system manufactures bleach continuously from a salt

concentration of 5000ppm to 7000ppm and uses the water from the pool as a raw

material. This unique feature eliminates issues with high TDS levels and requires less

salt as raw material than traditional methods. The NEXGEN is designed for commercial

service and can be run 24 hours a day or controlled by any pool controller. “R” models

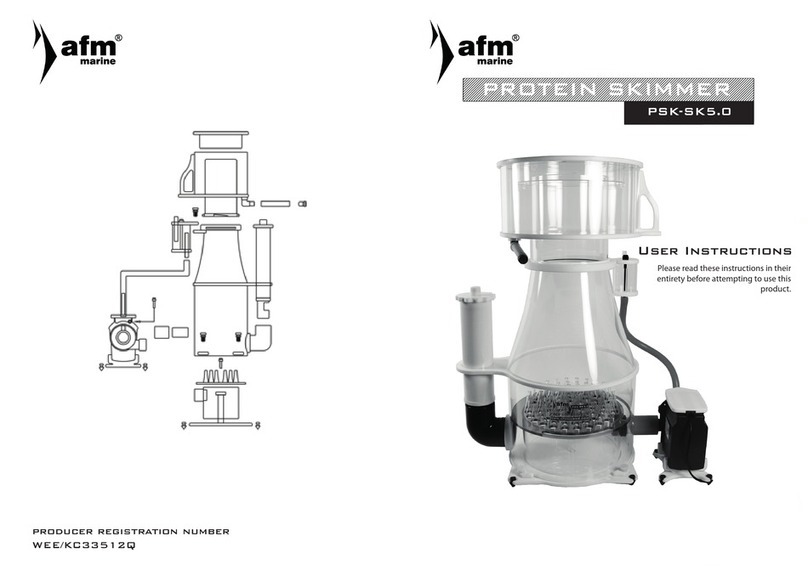

are reverse polarity for reduced maintenance. The basic components of the NEX-GEN

are outlined below.

Production

Tank

Dilution

Fan

Chemical

Metering

Power

Supply and

Control Box

NEXGEN60 InstallationRev1 Page 4of 42 04/11/2022

1.2 PRINCIPALS OF OPERATION

Production Tank Assembly

The production tank assembly consists of a polyethylene tank, four external electrolytic

cells, a circulation pump and heat exchanger. Pool water from the pool return line is fed

into the production tank. The circulation pump circulates water through the electrolytic

cells and heat exchanger. The water in the tank is maintained between 5000-ppm and

7000-ppm salt concentration. The electrolytic cells produce a 1666-ppm to 2500-ppm

sodium hypochlorite solution. The sodium hypochlorite flows to the pool at a flow rate of

3.3-gpm. The flow rate through the tank dictates the amount of sodium hypochlorite

produced. Sodium hypochlorite can be produced up to 72-gpd of equivalent chlorine.

The sodium hypochlorite flows to the pool for use in disinfection. The heat exchanger

has fresh pool water pumped through the coils to maintain tank temperatures of no more

than 10 degrees F above the pool water.

Dilution Fan

Electrochemical production of sodium hypochlorite produces hydrogen as a byproduct.

The dilution fan pumps fresh air into the production tank to dilute the hydrogen and force

it out the vent. The vent must be vented to outside atmosphere.

Saturated Salt Feeder

The saturated salt feeder supplies the production tank with a constant supply of salt to

produce sodium hypochlorite. Salt is used at the rate of 2 pounds per pound of equivalent

chlorine produced or 3 pounds per pound of equivalent chlorine produced depending on

production quantity selected. The saturated salt feeder is filled manually. Salt is pumped

using standard peristaltic chemical feed pumps.

Chemical Metering

Chemical metering is accomplished using a venturi. The flow through the venturi is

adjusted to provide the flow rate necessary to deliver the rated production of chlorine to

the pool.

Power Supply and Control Box

The power supply provides the current to the electrolytic cells to produce the rated amount

of sodium hypochlorite. The power supply houses all the safety features to prevent

system operation in the event of a malfunction.

NEXGEN60 InstallationRev1 Page 5of 42 04/11/2022

1.3 SPECIFICATIONS, CERTIFICATIONS, AND SIZING GUIDELINES

Sodium hypochlorite production:

NEXGEN60 - Up to 72 pounds per day at 7000ppm

NEXGEN60R – Up to 72 pounds per day at 7000ppm

Maximum pool return line pressure:

25 PSI including plumbing to and from the venturi injector

Electrical requirements:

NEXGEN60 and 60R

Rated 240 VAC, 87.12 A, 60 Hz.

Requires:

A 240 volt single phase connection @ 100 amps minimum and 60Hz

120 volt connection to a chemical feed controller or 120 volt outlet @1 amp

Internal System Fusing

Power Supply NEXGEN60 and 60R – 2 x 60 amp RK5 class fuse

Circulation Pump – 10 amp internal circuit breaker

Chemical Metering / Control – 12 amp internal circuit breaker

Certifications

NEXGEN60 and NEXGEN60R are certified for indoor installation.

NSF Standard 50

UL Standard 1081

CSA Standard C22.2 #218.1

PRMA Reg. No. 33004

Sizing guidelines

Chlorinator sizing must comply with local codes. Please contact your local health

department for specific requirements or contact your local ChlorKing representative for

assistance.

NEXGEN60 InstallationRev1 Page 6of 42 04/11/2022

MINIMUM SPACE REQUIREMENTS FOR NEXGEN60

18 24

31

NEXGEN60 InstallationRev1 Page 7of 42 04/11/2022

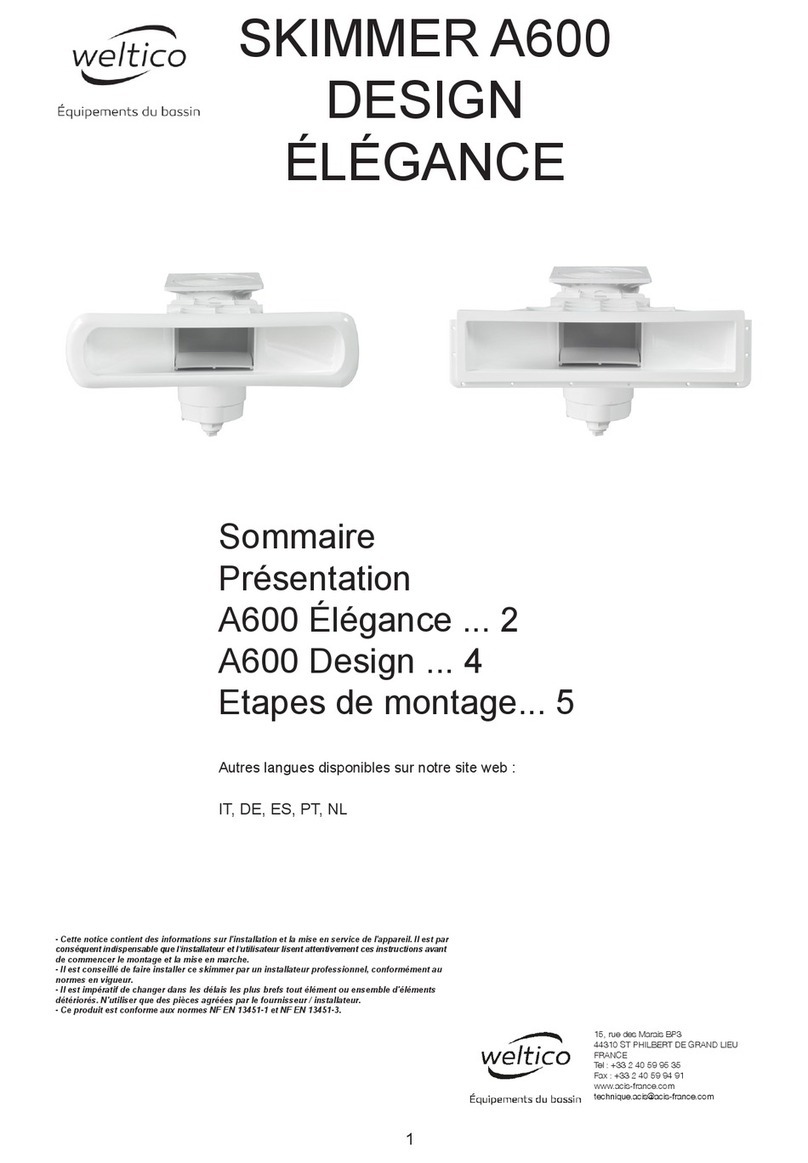

MINIMUM SPACE REQUIREMENTS FOR NEXGEN60R

NEXGEN60 InstallationRev1 Page 8of 42 04/11/2022

SECTION 2

INSTALLATION

2.1 UNPACKING

Units are shipped from the factory. In the event of damages during shipping, it is the

responsibility of the customer to notify the carrier immediately and to file a damage claim.

Open the crate carefully and examine all material inside.

2.2 STORAGE

When storing units, use the original packaging and store under a shelter to protect the

contents from weather.

2.3 SAFETY CONSIDERATIONS

IMPORTANT SAFETY INSTRUCTIONS

READ AND FOLLOW ALL INSTRUCTIONS

SAVE THESE INSTRUCTIONS

WHEN INSTALLING, OPERATING, AND MAINTAINING THIS EQUIPMENT, KEEP

SAFETY CONSIDERATIONS FOREMOST. USE PROPER TOOLS, PROTECTIVE

CLOTHING, AND EYE PROTECTION WHEN WORKING ON OR INSTALLING THE

EQUIPMENT. FOLLOW THE INSTRUCTIONS IN THIS MANUAL AND TAKE ANY

ADDITIONAL SAFETY MEASURES APPROPRIATE. BE EXTREMELY CAREFUL IN

THE PRESENCE OF HAZARDOUS SUBSTANCES.

THE PERSONNEL RESPONSIBLE FOR INSTALLATION, OPERATION, AND

MAINTENANCE OF THIS EQUIPMENT MUST BE FULLY FAMILIAR WITH THE

CONTENTS OF THIS MANUAL.

ANY SERVICING OF THIS EQUIPMENT MUST BE DONE WITH THE UNIT FULLY OFF

AND DISCONNECTED FROM THE POWER SOURCE AND ALL PRESSURE BLED

FROM THE LIQUID LINES.

WARNING

CHLORKING® SYSTEMS ARE INTENDED TO BE INSTALLED ACCORDING

TO ALL LOCAL AND NATIONAL REGULATIONS.

CONNECT THE EQUIPMENT ASSEMBLY TO A CIRCUIT PROTECTED BY A

GROUND-FAULT CIRCUIT-INTERRUPTER.

NEXGEN60 InstallationRev1 Page 9of 42 04/11/2022

ONLY A CERTIFIED TECHNICIAN MAY INSTALL AND SERVICE THE

CHLORKING® NEXGEN SYSTEM.

MODIFYING THE CHLORKING® NEXGEN SYSTEM IN ANY WAY MAY CAUSE

BODILY INJURY AND WILL VOID THE WARRANTY.

DO NOT ALLOW CHILDREN OR ANYONE NOT CAPABLE TO OPERATE THE

CHLORKING® NEXGEN SYSTEM.

ONLY REPLACE COMPONENTS WITH THOSE SPECIFIED BY THE

MANUFACTURER.

WHEN INSTALLING THE SYSTEM, ENSURE THAT POWER IS LINKED TO

THE MAIN PUMP POWER SOURCE FOR THE POOL TO ENSURE THAT THE

CHLORKING® NEX-GEN SYSTEM NEVER OPERATES WHEN THE PUMPS

ARE OFF.

ALL BOXES ON THE CHLORKING® NEXGEN SYSTEM CONTAIN HIGH

VOLTAGE COMPONENTS. NEVER OPEN ANY BOX WHILE THE POWER IS

ON.

THE SYSTEM HAS THE POTENTIAL TO RELEASE HIGH DOSES OF

CHORINE. USE CAUTION WHEN HANDLING, SERVICING, OR OPERATING

THE EQUIPMENT.

DO NOT ENERGIZE OR OPERATE THE SYSTEM IF THE CELL HOUSING IS

DAMAGED OR IMPROPERLY ASSEMBLED.

THE MOUNTING LOCATION OF THE UNIT MUST BE AT LEAST 1.5 METERS

FROM THE POOL.

CONSERVEZ CES INSTRUCTIONS

LORS DE L'INSTALLATION, DE FONCTIONNEMENT ET L'ENTRETIEN DE CET

ÉQUIPEMENT, GARDEZ LES CONSIDÉRATIONS SUR LA SÉCURITÉ AVANT

TOUT. UTILISER DES OUTILS APPROPRIÉS, DES VÊTEMENTS DE PROTECTION

ET LUNETTES DE PROTECTION LORSQU'ILS TRAVAILLENT SUR OU À

L'INSTALLATION. SUIVEZ LES INSTRUCTIONS DE CE MANUEL ET PREND LES

MESURES DE SÉCURITÉ SUPPLÉMENTAIRES APPROPRIÉES. SOYEZ

VIGILANTS EN PRÉSENCE DE SUBSTANCES DANGEREUSES.

LE PERSONNEL CHARGÉ DE L'INSTALLATION, DE FONCTIONNEMENT ET

D'ENTRETIEN DE CE MATÉRIEL DOIT ÊTRE PARFAITEMENT FAMILIARISÉ AVEC

LE CONTENU DE CE MANUEL.

AUCUNE OPÉRATION DE MAINTENANCE DE CET ÉQUIPEMENT DOIT ÊTRE

FAITE AVEC L'UNITÉ ENTIÈREMENT ÉTEINT ET DÉBRANCHÉE DE

L'ÉLECTRICITÉ ET TOUTE LA PRESSION SAIGNÉ À PARTIR DES LIGNES DE

LIQUIDES.

MISE EN GARDE

NEXGEN60 InstallationRev1 Page 10 of 42 04/11/2022

CHLORKING ® SYSTEMES SONT DESTINES A ETRE INSTALLES SELON TOUS

LES REGLEMENTS LOCAUX ET NATIONAUX.

CONNECTER LE MONTAGE DE L'ÉQUIPEMENT SUR UN CIRCUIT

PROTÉGÉ PAR UN DISJONCTEUR DE FUITE À LA TERRE.

SEUL UN TECHNICIEN CERTIFIE PEUT INSTALLER ET ENTRETENIR LE

SYSTEME CHLORKING ® NEXGEN.

MODIFIANT LA CHLORKING ® NEXGEN SYSTEME EN QUELQUE SORTE

PEUT CAUSER DES LESIONS CORPORELLES ET LA GARANTIE

ANNULATION.

N'AUTORISENT PAS LES ENFANTS OU N'IMPORTE QUI PAS CAPABLE

D'ALIMENTER LE SYSTEME CHLORKING ® NEXGEN.

REMPLACEZ UNIQUEMENT LES COMPOSANTS AVEC CELLES

SPÉCIFIÉES PAR LE FABRICANT.

LORSQUE VOUS INSTALLEZ LE SYSTEME, S'ASSURER QUE LA

PUISSANCE EST LIEE A LA SOURCE D'ALIMENTATION DE POMPE A MAIN

POUR LA PISCINE POUR VOUS ASSURER QUE LE SYSTEME DE NEX-GEN

CHLORKING ® FONCTIONNE JAMAIS QUAND LES POMPES SONT HORS

SERVICE.

TOUTES LES CASES SUR LE SYSTEME CHLORKING ® NEXGEN

CONTIENNENT DES COMPOSANTS HAUTE TENSION. NE JAMAIS OUVRIR

N'IMPORTE QUELLE BOÎTE TANDIS QUE L'APPAREIL EST ALLUMÉ.

LE SYSTÈME A LA POSSIBILITÉ DE LIBÉRER DES DOSES ÉLEVÉES DE

CHLORE. SOYEZ PRUDENT LORS DE MANIPULATION, ENTRETIEN OU

FONCTIONNEMENT DE L'ÉQUIPEMENT.

NE PAS METTRE SOUS TENSION OU FAIRE FONCTIONNER LE SYSTÈME

SI LE BOÎTIER DE LA CELLULE EST ENDOMMAGÉ OU MAL ASSEMBLÉ.

L'EMPLACEMENT DE MONTAGE DE L'UNITÉ DOIT ÊTRE D'AU MOINS 1,5

MÈTRES DE LA PISCINE.

2.4 PLAN AHEAD

The NEXGEN is intended to be installed indoors. It is imperative to have prior knowledge

of the facility in which the unit is to be installed. Evaluate space requirements, electrical

requirements, and plumbing requirements. Determine what type of tools and hardware

will be needed to make the installation as problem free as possible.

2.5 ADDITIONAL PARTS REQUIRED FOR INSTALLATION

½ inch polypropylene or polyethylene tubing

¼ inch polypropylene or polyethylene tubing and a ¼ inch valve for tubing connection

PVC tubing in 2 inch or greater, PVC pipe in 2 inch or greater

PVC 90’s, 45’s, couplings and saddles or adapters for the return line size encountered

3 inch PVC pipe, 90’s, 45’s and couplings for the hydrogen vent

Anchors and mounting hardware

Container specified for muriatic acid solutions

NEXGEN60 InstallationRev1 Page 11 of 42 04/11/2022

2.6 POWER SUPPLY ELECTRICAL CONNECTIONS

WARNING

BE SURE TO CONNECT THE EARTH TERMINALS AND THE EQUIPMENT BONDING

WIRE. THE ELECTRICAL SUPPLY MUST MATCH THE SYSTEM RATED CURRENT.

ENSURE THAT POWER IS LINKED TO THE MAIN PUMP POWER SOURCE FOR THE

POOL TO ENSURE THAT YOUR CHLORKING® NEXGEN SYSTEM NEVER

OPERATES WHEN THE POOL PUMPS ARE OFF.

For ease of service, it is recommended that a manual disconnect be installed

between the electrical service and the NEXGEN system.

Connect the electrical supply from the pool equipment room to the connections marked

240 VAC L1, L2 and ground. Ensure that the electrical service is protected by a circuit

interrupter and is rated for the model NEXGEN that is installed.

240 VAC

L1 and L2 Ground

240 VAC

L1 and L2

NEXGEN60 InstallationRev1 Page 12 of 42 04/11/2022

Connect the blue control cord to a chemical feed controller or for manual operation, into

a 120V electrical outlet protected by a ground fault circuit interrupter.

2.7 BONDING

Connect a minimum 8awg bonding wire to the bonding lug on the bottom of the electrical

enclosure.

Blue

Controller

Cord

Bonding

Lugs

NEXGEN60 InstallationRev1 Page 13 of 42 04/11/2022

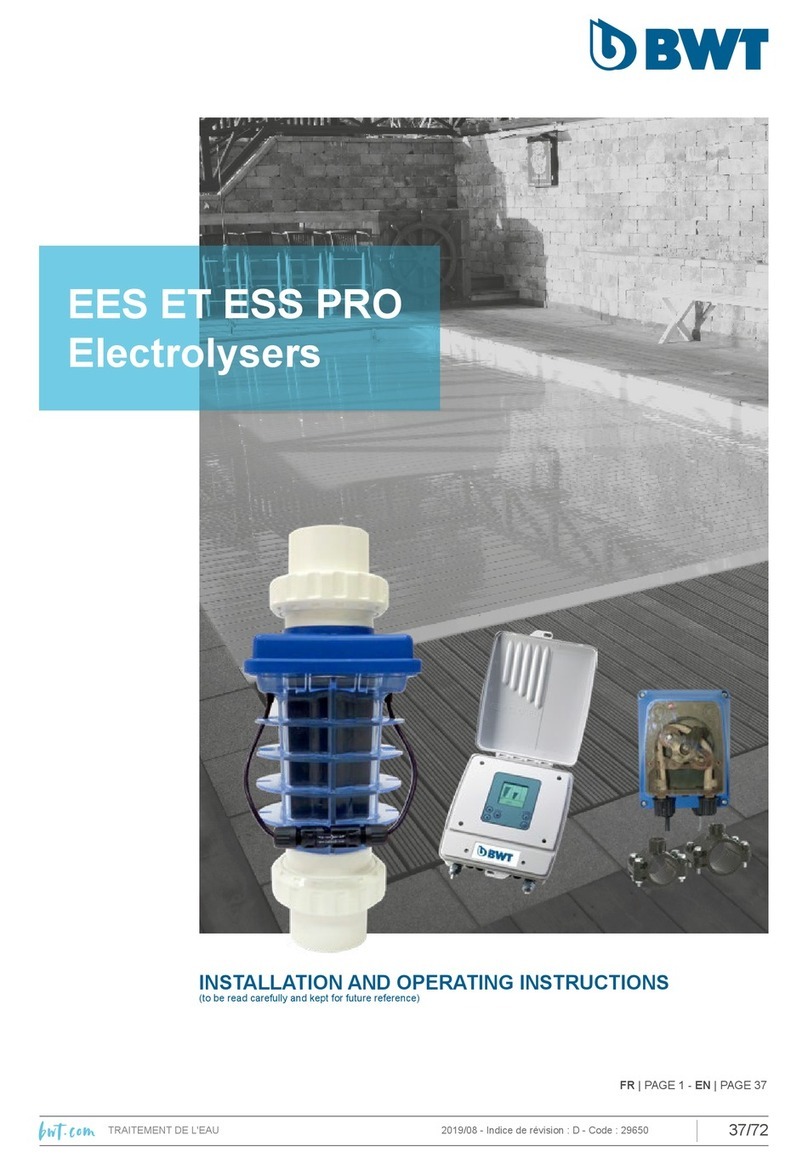

2.8 PLUMBING CONNECTIONS

PLUMBING THE CHEMICAL METERING VENTURI

It is important that the Chemical Metering Venturi is plumbed correctly, or the

system will not function properly, and the warranty will be void.

The chemical metering venturi injector requires a pressure differential across the venturi

to achieve the rated chemical flow. A booster pump is needed to ensure the required

pressure differential is achieved. The NEXGEN will provide 100% of the rated output with

a maximum of 25 PSI at the venturi outlet. Install the booster pump in the supply line to

the venturi. Consult ChlorKing for booster pump sizing.

The booster pump is powered by the NEXGEN and must be installed within 10 feet

of the NEXGEN skid to ensure the electrical connection will reach the pump. The

pump wiring is located on the bottom side of the enclosure. Wire the booster pump

to the NEXGEN with the cable provided and to the pump according to the

instructions on the pump for 208/240 VAC connections. The NEXGEN ships with a

12amp breaker for a 1HP pump. Larger pumps will require changing the breaker.

Contact ChlorKing for breaker sizing.

Booster

Pump In

Return To Pool

ChlorKing

Nex-Gen

BY

Return To Pool Return To Pool

Nex-Gen 80 and 60R

Plumbing Layout

Field Installation

Hydrogen

Vent

18"

BLUE - Water

ORANGE- Acid

GREEN - Brine

Overflow

to

Drain Pump

pressure

switch.

Plumb

to pump

discharge

Acid

Tank

Filter Heat

Exchanger

Pump

Floor

Salt

Tank

NEXGEN60 InstallationRev1 Page 14 of 42 04/11/2022

Plumb the inlet of the venturi to the booster pump which is connected to the return line of

the pool after all other pool components such as heaters etc. Use at least 2 inch PVC

pipe for this connection. It is recommended that a valve be installed at this connection

so that the system can be isolated from the pool.

Plumb the outlet of the venturi to the return line of the pool 18

inches after the inlet plumbing connection. Use at least 2 inch

PVC pipe for this connection. It is recommended that a valve

be installed at this connection so that the system can be

isolated from the pool.

Size Booster Pump based on return line

pressure

Return Line Pressure Pump Horsepower

5 PS! ½ HP

7 PSI 1 HP

12 PSI 2 HP

25 PSI 3 HP

PLUMBING THE PRESSURE SWITCH

Connect the pressure switch to the return line with ¼ tubing (not supplied) and the ¼

inch valve supplied. The pressure connection should provide a minimum of 5 psi when

the pool pump is on, and pressure should be less than 3 psi when the pool pumps are

off. Contact ChlorKing for installations that do not meet these specifications.

Inlet Outlet

Pressure

Switch

Connection

NEXGEN60 InstallationRev1 Page 15 of 42 04/11/2022

2.9 SATURATED SALT FEEDER INSTALLATION

Place the Saturated Salt Feeder tank in an easy to access location. The tank will need

access for adding salt on a continuous basis.

Plumb the peristaltic pump suction lines to the salt outlets on the Saturated Salt Feeder

with 1/4 tubing supplied with the peristaltic pump. The salt outlets on the Saturated Salt

Feeder two small blue and white valves located at the bottom of the salt feeder. Plumb

the Saturated Salt Feeder water supply to the fitting on the chemical metering assembly

using ½ inch tubing.

NEXGEN60 InstallationRev1 Page 16 of 42 04/11/2022

2.10 PLUMBING THE PRODUCTION TANK OVERFLOW

Install the overflow with the T provided in the installation kit. This T will remain open on

top to prevent syphoning in case of tank overflow. The bottom of the T receives a 1.5”

FPT low pressure connection with hose directed to a floor drain, drain tube is not

provided.

NEXGEN60 InstallationRev1 Page 17 of 42 04/11/2022

2.11 PREPARING THE pH NEUTRAL SYSTEM

Before use, remove the pH probe from the top of the production tank and remove the

cover from the end of the pH probe. Re-install the probe.

Plumb the suction port of the peristaltic pump with the #1 hose to a container (not

supplied with the NEXGEN) specified for muriatic acid solutions.

Note: Sulfuric acid and dry acid (sodium bisulfate) are not recommended for pH

adjustment. Under some conditions the electrolytic cell can be damaged.

WARNING

Read all cautions and directions provided with the muriatic acid used. Always add acid

to water. Use only with adequate ventilation. If strong odor is noticed, STOP, ventilation

is inadequate. Leave area immediately. If the work area is not well ventilated, you MUST

use a properly fitted and maintained NIOSH approved respirator for acid fumes.

For best results fill the acid tank with a 1 to 1 water / muriatic acid solution.

2.12 PLUMBING THE HYDROGEN VENT

WARNING

EXOLOSION RISK. FAILURE TO PLUMB THE HYDROGEN VENT TO OUTSIDE

ATMOSPHERE MAY RESULT IN DAMAGE TO EQUIPMENT OR PERSONS.

ALWAYS VENT THE SYSTEM AWAY FROM SPARK OR FLAME

Hydrogen vent pipes must be rigid plastic (PVC) and installed in a continuous upward

gradient (1/8 inch per foot rise). The pipe must be vented to outside atmosphere. Use a

minimum of 3 inch pipe for the vent. The vent pipe should not be longer than 100 feet.

(Consult ChlorKing if longer runs are required). Keep the opening clear and protected

from water or debris with the use of a hood or bend. Do not use screens or louvres at the

vent outlet.

Hydrogen

Vent

NEXGEN60 InstallationRev1 Page 18 of 42 04/11/2022

SECTION 3

OPERATION

3.1 START-UP PROCEDURES AND CHECKS

Check that all components are mounted securely. Check that all plumbing is secure and

tight. Check that all plumbing and electrical connections are connected in the proper

place.

Ensure that all system isolation valves installed during installation are open.

Fill the Saturated Salt Feeder with pure rock or pellet salt. Do Not Use Granular Salt.

Open both Saturated Salt Feeder valves.

Fill the muriatic acid container with a 50% water to 50% muriatic acid solution.

Turn on any breakers or disconnect boxes used for circuit protection.

Ensure the blue cord is connected to a chemical feed controller and the controller is calling

for feed, or that the blue cord is plugged into a live outlet.

The NEX-GEN will go through a series of startup steps and automatically start generating

chlorine.

If the NEX-GEN does not start automatically, see Troubleshooting in section 6.

3.2 ADJUSTING CHLORINE OUTPUT

Adjust the flow through the flow meter for the following

production rates:

3.3 GPM = 72 pounds of chlorine production per day

2.6 GPM = 58 pounds of chlorine production per day

2.2 GPM = 63 pounds of chlorine production per day

1.0 GPM = 54 Pounds of chlorine production per day

NOTE

The maximum production rate of 72 pounds is

achieved at 7000 ppm salt concentration and 3.3

GPM.

Adjustments in excess of 3.3 gallons per minute will

not produce more chlorine. Adjustments in excess of

3.3 gallons per minute will consume excess salt.

Flow

Control

Flow Meter

NEXGEN60 InstallationRev1 Page 19 of 42

04/11/2022

3.3 TOUCH SCREEN ICON EXPLANATIONS

This icon is displayed if the system is turned off.

This icon is displayed if the system is waiting for a signal from an external

controller.

This icon is displayed if cell cleaning mode has been selected. This icon

will be displayed until the cell cleaning process is complete.

This icon indicates a failure during the acid wash sequence for cell

maintenance.

Press this icon to clear the fault described above.

This icon indicates that acid is being pumped during the cell cleaning cycle.

Faults are accompanied by a beeping sound. If this icon is visible, pressing

it will stop the beeping sound.

NEXGEN60 InstallationRev1 Page 20 of 42 04/11/2022

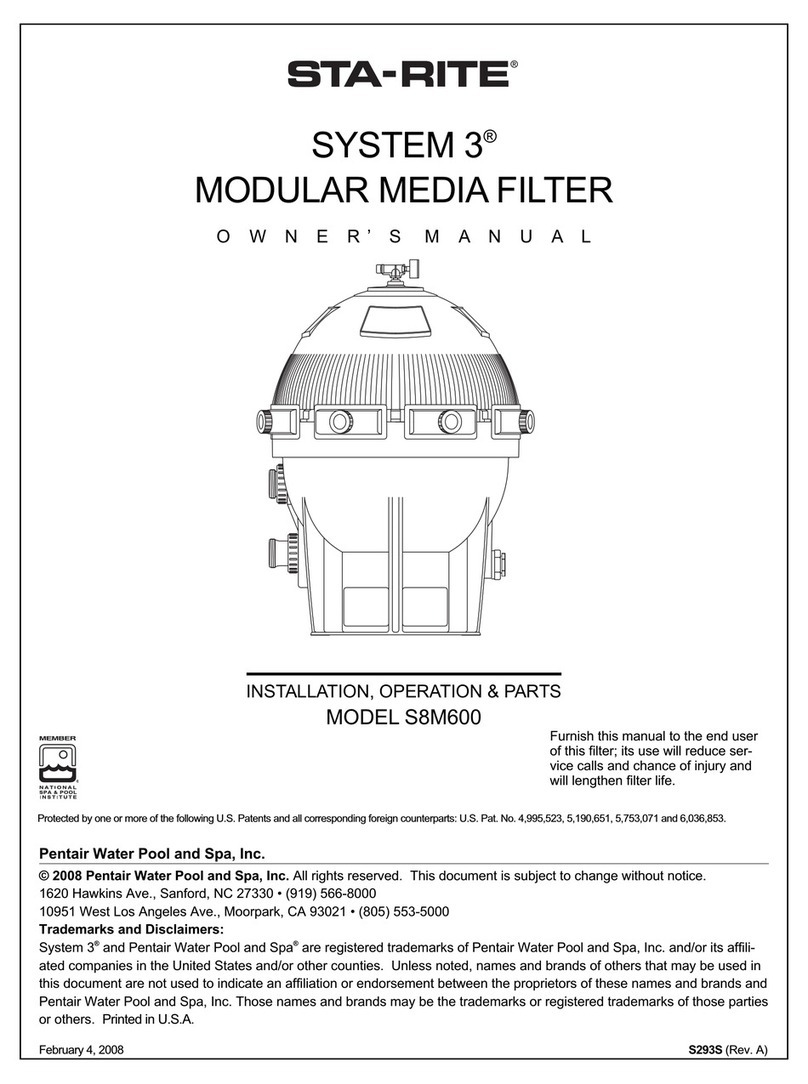

3.4 USING THE TOUCHSCREEN

Home Screen

Below is the HOME screen that will be displayed any time the NEXGEN is operating

normally.

On/Off

Indicator

Process

Tank

Temperature

On/Off

Button

Pool Feed

Indicator

Process

Tank pH

Electrolytic

Cell Volts

Menu Button Electrolytic

Cell Amps

Process

Tank Salt

Level

This manual suits for next models

1

Table of contents

Other ChlorKing Swimming Pool Filter manuals

Popular Swimming Pool Filter manuals by other brands

BLAU aquaristic

BLAU aquaristic Scuma MKB Series user guide

Hayward Pool Products

Hayward Pool Products SP1090WM owner's guide

EINHELL

EINHELL SF 1000 operating instructions

Bestway

Bestway 58498 owner's manual

Aquascape Pro

Aquascape Pro Signature Series Instructions & maintenance

Hamma

Hamma RAPID 4 Operating instruction

fluidra

fluidra ASTRALPOOL Viron CL Series Installation and operating instructions

GRE

GRE FA6100 Installation and maintenance manual

Hayward

Hayward Ntech Evac-sharkvac owner's manual

Watermaid

Watermaid WM10LED Owner's handbook

Bestway

Bestway FLOWCLEAR 58678 owner's manual

Pool Systems

Pool Systems G2flo ZEN quick start guide