10

Skimmer WIDE

MA55-31E

ENGLISH

A

This documentanditscontentsaretheexclusive

propertyofPahlénsandmaynotbecopied,

reproduced,transmittedorcommunicatedtoathird

party,orusedforanypurposewithoutwrittenpermission.

Art.no.

Rev.no.

Scale

Designed by: Approved by:

Revised by: Date

Drawn by: Date

Drawing number

Assembly drawing no.

Surface treatment

part of ISO 2768-mK

The tolerance class in accordance with this

E

Box 728, SE-194 27 Upplands Väsby, Sweden

Phone +46 8 59411050, Fax +46 8 59086880

TK 2016-11-15

För poolstomme av thermoblock

Installationsbild bräddavlopp WM

M12627 0

A

Kakelfog

Betongstomme

Kakel/Mosaik

Fästram

Front

min 28

Klafflucka

F-F ( 1 : 4 )

G-G ( 1 : 4 )

H-H ( 1 : 4 )

GF Plugg 721961910124

1998206019982060Nylon 6/6Topptätning för PG7123

PG7-mutter19982303GenericKontramutter PG7122

Kabelförskruvning PG7

19982003Nylon 6/6

Kabelförskruvning PG7

121

1997017019970170

GenericO-ring 17,00x2,00 NBR70

120

19981600 plugg19981600PVC-UPlugg PVC G½" utv119

M1252511267Stainless SteelFront bräddavlopp WM std118

Torx A4 FM5x1219920220Steel, MildSkruv MFT A4 M5x122617

M12513112670GenericFästram116

M12523112817RubberPackning 432x132x2mm115

M125121128179RubberPackning 432x132x1,5mm114

R10639112915Stainless SteelLock Bräddavlopp -16113

DIN 7985 (H) - M5x12-H19909315A4Skruv MRX A4 M5x12 - DIN7985A212

R1110915594310

Stainless Steel

Klamma211

M1253915594405

Stainless Steel

Krage bräddavlopp WM110

R11140112620Skimvacplatta Pahlén19

R1113951245PPSilkorg komplett18

R111441128161Generic

Ändskydd

27

R11112 ihoptryckt112571Stainless SteelFjäder/bygel16

M1236415581002Flytkropp 190x100x2015

R1117115516085Stainless SteelKlafflucka -03UH14

ISO 4032 - M619930025A4Mutter M6M A4 M643

Torx A4 FM6x3019920340

GenericSkruv MFT A4 M6x30

42

M1253315594075

Stainless Steel

Bräddavlopp WM11

Drawing.no:Art_nrMaterialTitle/ NameQty.Item.

F

F

G

G

H H

This document and its contents are the exclusive

property of Pahléns and may not be copied,

reproduced, transmitted or communicated to a third

party, or used for any purpose without written permission.

Art.no.

Rev.no.

Scale

Designed by: Approved by:

Revised by: Date

Drawn by: Date

Drawing number

Assembly drawing no.

Surface treatment

part of ISO 2768-1

The tolerance class in accordance with this

E

Box 728, SE-194 27 Upplands Väsby, Sweden

Phone +46 8 59411050, Fax +46 8 59086880

1:1

112970

TK 2016-06-13

Bräddavlopp WM

M12506 P0

15

2

3

21 22 23

1920

82,5

165

64

18,5

31,63

46

46

245

33,87

58,13

230,5

232

STD vattenyta

WM vattenyta

242,5

35,5

2

5,75

120

38

Vattenyta

2,5

1,47

16,5

4

5

6

7

13

10

11

9

8

12

1

18

17

14

16

24

Art.no.

Rev.no.

Scale

Designed by: Approved by:

Revised by: Date

Drawn by: Date

Drawing number

Assembly drawing no.

Surface treatment

part of ISO 2768-mK

The tolerance class in accordance with this

E

Box 728, SE-194 27 Upplands Väsby, Sweden

Phone +46 8 59411050, Fax +46 8 59086880

TK 2016-11-15

För poolstomme av thermoblock

Installationsbild bräddavlopp WM

M12627 0

This documentanditscontentsaretheexclusive

propertyofPahlénsandmaynotbecopied,

reproduced,transmittedorcommunicatedtoathird

party,orusedforanypurposewithoutwrittenpermission.

1513 1

1

917 12 10

6

6

3

2145 6 7

8

9

10

Art.no.

Rev.no.

Scale

Designed by: Approved by:

Revised by: Date

Drawn by: Date

Drawing number

Assembly drawing no.

Surface treatment

part of ISO 2768-mK

The tolerance class in accordance with this

E

Box 728, SE-194 27 Upplands Väsby, Sweden

Phone +46 8 59411050, Fax +46 8 59086880

TK

1:4

15594075

2016-01-26Betad

Bräddavlopp WM

M12533 0

Art.no.

Rev.no.

Scale

Designed by: Approved by:

Revised by: Date

Drawn by: Date

Drawing number

Assembly drawing no.

Surface treatment

part of ISO 2768-mK

The tolerance class in accordance with this

E

Box 728, SE-194 27 Upplands Väsby, Sweden

Phone +46 8 59411050, Fax +46 8 59086880

TK

1:4

15594075

2016-01-26Betad

Bräddavlopp WM

M12533 0

28

For the pool frame of concrete - covered with tile/mosaic

Consultyourconcrete/waterproongsupplierforanywaterproongandapplicationmethod.

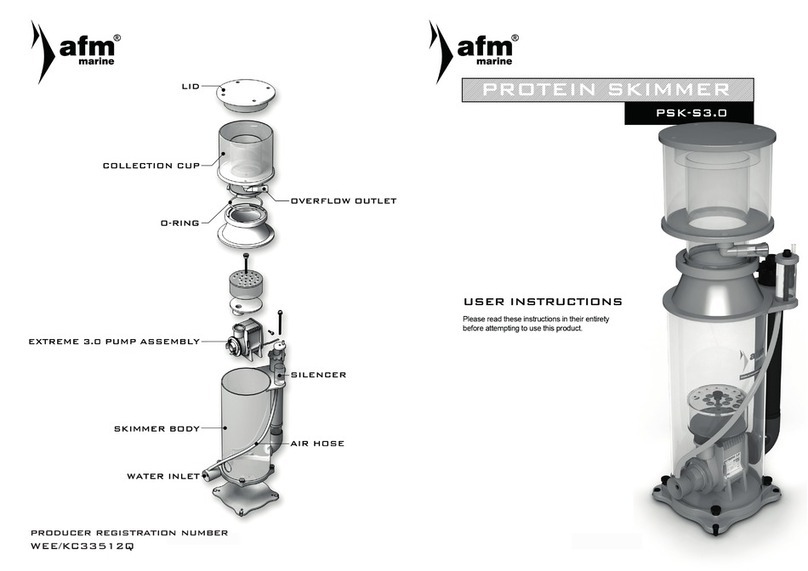

Fig9.

Fig 10.

Fig 11.

Installation as following:

NOTE! When casting/reinforcing the pool frame work, do not get closer than at

least 50 mm to the stainless materials.

1. Make a hole for the skimmer in the framework, dimensions and placement as

shown in Figure 2.

2. Applysealeratthejointbetweenthesealingangesandtheskimmerhousing

(seeFig.9).

Pahlén recommends Tec7 as a sealant from Novatech (available from Pahlén) or

AquaMaxfromGrion.

Upon application of the sealant, it is important that the joints are tight, so that no

water can penetrate.

See sealant instruction for preparation, application and hardening.

3. Fastentheskimmerinthemold,sothattheangeisincontactwiththeconcrete

wall. NOTE! Non-corrosive material (e.g. steel) may not be closer to the stainless

steel (pipe) than 50 mm.

4. Connectthecable(atleast6mm²)witharingfromtheintakeangetoearth

(seeitem3Figure8).Screw,toothedwasherandnutaresuppliedwiththeproduct.

If other components are used, it must be ensured that they are of stainless steel

quality (Min. A4).

5. Priortosealing;masktheskimmerexposedangeandopeningsinordertoavoid

unsightly stains from concrete splashes.

Theopeningsintheskimmerbackedgeoftheoatswitch,theoverowandrell

openings can be sealed with supplied plugs, see Fig.11

6. Seal the pool frame.

7. Mountthewallcladding(x,tile,mosaic,etc.).Makesurethatthemountingholes

(see Fig. 10) for fastening the frame are free, so that the mounting frame can be

installed later.

8. Checkthattheapcapisproperlyinplaceandcanmove.

9. Assembletheframeandsecureitwithscrews(4xM5x30),seeFig.8.

10. Mount the front of the frame and secure it with the supplied screws (4x M5x12)

in the second and eighth holes, see Fig. 12.

11. Connect the pipe coupling to the

pool circulation with an appropriate

thread sealant.

12. The position of the skimmer top

should be adjusted in height to the

ooringaroundthepool.Fixtothe

desired height with attached straps.

13. If the skimmer top is shortened or

processed in any other way,

tools only for stainless materials

should be used.

1. Fixing strip with a screw M5x12 (2x)

2. Skimmer top

3. Earthing point

4. Countersunk screw M6x30 (4x)

5. Mounting frame

6. Countersunk screw M5x12 (4x)

7. Front

8.Flange

9. Concrete

10. Reinforcing bar

Fig8.

Fig 12.

Screw

Front

Mountning

frame

Tail/Mosaic

Tail join

Concrete wall

Tailx

Flap cap