MA-037 - CB Watch 3 Operating Manual v7.0 - May 2020 Page 5 of 118

Figure 46 –Example of historical chart –reaction and operating time .................................................. 33

Figure 47 –Entry of travel distances........................................................................................................ 34

Figure 48 –Operation graphs for opening............................................................................................... 35

Figure 49 –Operation graph for closing .................................................................................................. 35

Figure 50 –Monitoring the auxiliary contacts......................................................................................... 36

Figure 51 –Alarms from monitoring the auxiliary contacts .................................................................... 36

Figure 52 –Monitoring the overtravel..................................................................................................... 37

Figure 53 –Overtravel display ................................................................................................................. 37

Figure 54 –Setting the overtravel threshold........................................................................................... 37

Figure 55 –Overtravel alarm ................................................................................................................... 38

Figure 56 –Timing compensation data entry.......................................................................................... 39

Figure 57 –Two examples of operating time temperature compensation values.................................. 40

Figure 58 –Example of closing operating time changes with voltage changes....................................... 40

Figure 59 –Thermodynamic law applied to SF6 gas................................................................................ 44

Figure 60 –Equivalent density lines and liquefaction curve ................................................................... 45

Figure 61 –Gas sensor information......................................................................................................... 45

Figure 62 –Gas sensor alarms ................................................................................................................. 46

Figure 63 –Not enough gas values to display data ................................................................................. 46

Figure 64 –Gas measurements ............................................................................................................... 47

Figure 65 –Gas thresholds min/max....................................................................................................... 48

Figure 66 –Gas pressure thresholds........................................................................................................ 49

Figure 67 –Gas pressure alarms.............................................................................................................. 49

Figure 68 –Gas liquefaction pressure...................................................................................................... 49

Figure 69 –Gas liquefaction risk alarm.................................................................................................... 50

Figure 70 –Gas moisture level................................................................................................................. 50

Figure 71 –Moisture alarm threshold..................................................................................................... 50

Figure 72 –Excessive moisture alarm...................................................................................................... 51

Figure 73 –Linear gas pressure extrapolation......................................................................................... 51

Figure 74 –Forecasted gas pressure values ............................................................................................ 52

Figure 75 –Time horizons setup.............................................................................................................. 52

Figure 76 –Extrapolated gas pressure alarms......................................................................................... 53

Figure 77 –Gas leak rates........................................................................................................................ 53

Figure 78 –Typical CB nameplate with gas info ...................................................................................... 54

Figure 79 –Nominal gas values entry...................................................................................................... 54

Figure 80 –Gas % leak rate thresholds.................................................................................................... 55

Figure 81 –Gas % leak rate alarms .......................................................................................................... 55

Figure 82 –gas graph selection................................................................................................................ 55

Figure 83 –Short-term gas graphs –gas density..................................................................................... 56

Figure 84 –Long-term gas graphs –gas pressure.................................................................................... 56

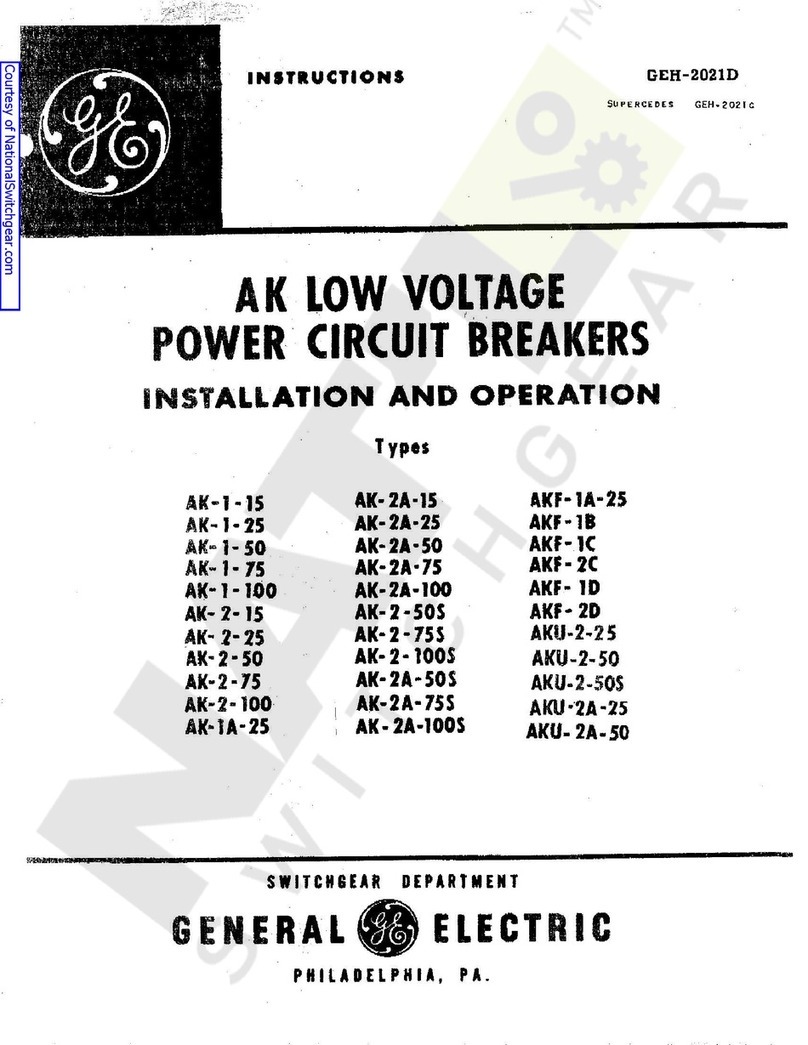

Figure 85 –Name plate data.................................................................................................................... 57

Figure 86 –Example name plate.............................................................................................................. 59

Figure 87 –Example settings ................................................................................................................... 60

Figure 88 –Setting primary current measurement ................................................................................. 61

Figure 89 –Stored interrupted current curve.......................................................................................... 62

Figure 90 –Current before and during interruption................................................................................ 62

Figure 91 –Interrupted current value ..................................................................................................... 62

Figure 92 –Separation offset input ......................................................................................................... 63

Figure 93 –Opening operation timing diagram....................................................................................... 63