Chocolate World Scirocco User manual

Lange Elzenstraat 123 • 2018 Antwerpen • Belgium • Tel. +32 (0)3 216 44 27

HOT CHOCOLATE DISPENSER

OPERATOR’S MANUAL

CARNET D’INSTRUCTIONS

MANUAL DE INSTRUCCIONES

3

4

SCIROCCO UL

ENGLISH

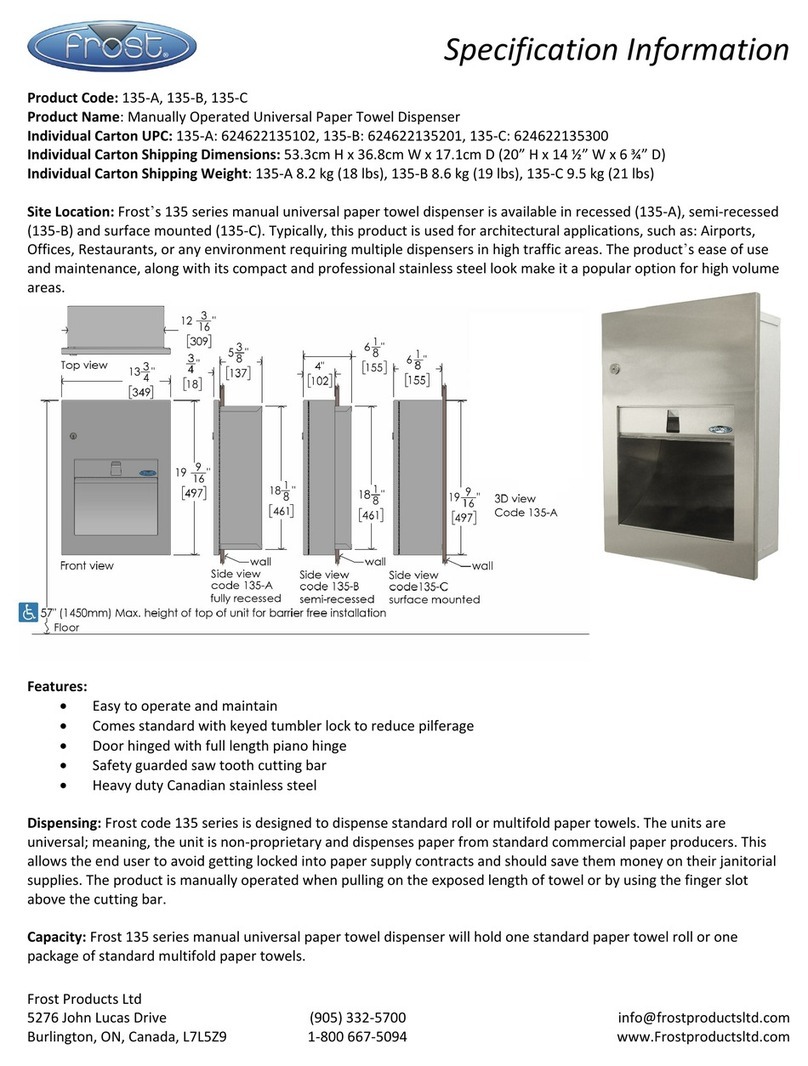

1 TECHNICAL CHARACTERISTICS

The manufacturer reserves the right to make

changes without any prior notification.

2 INTRODUCTION

Read this instruction manual carefully to know the

specifications of the dispenser. As all mechanical

products, this unit requires cleaning and

maintenance. Its working order can be

compromised by possible errors made by the

operator during disassembly and cleaning. For

this reason it is important that the staff in charge

of the dispenser is qualified to carry out the day to

day operations, which are dismantling, cleaning,

sterilisation and reassembly.

3 INSTALLATION

1Remove the dispenser from the packaging.

(This should be kept for any future requirement)

2Check the dispenser has not been damaged

during transport. The forwarding agent must be

notified immediately of any claim.

3Install the dispenser on a counter top that will

support its weight, even with a full load.

4Before connecting the dispenser electrically

check that the voltage (in the network) is as

shown on the data plate. Plug the unit into a

grounded, protected single phase electrical

supply according to the applicable electrical

codes and the specifications of your machine. If

you want to make a fixed connection to the

network, connect the cord to a bipolar wall

breaker with a contact gap of at least 3mm. not

use extension cords to co nnect the unit

electrically.

5The dispenser does not leave the factory

presanitized and sanitized. Prior to use it must be

disassembled, cleaned and sanitized according

to the instructions in chapter 5.3 CLEANING.

4 TO OPERATE SAFELY

1Read the instruction booklet before using the

dispenser.

2Use the dispenser only if it is grounded

correctly.

3Do not use extension cords to connect the

dispenser electrically.

4Do not operate the dispenser if it is not

closed and blocked with screws.

5Do not place fingers or objects in the cooling

fissures and faucet outlet panels louvers.

6Do not remove the container when the unit is

in operation.

7This unit is not meant to be used outside.

8This unit is not to be installed in areas

subject to water-spouts.

9Do not use water-jets to clean the unit.

10 This unit can work in a room temperature

Scirocco

Transparent removable bowls n 1

Capacity of each bowl, approx. l 5

Dimensions:

width cm 24

depth cm 32

height cm 49

Net weight, approx. kg 7

Gross weight, approx. kg 8

Adjustable thermostats n 2

Noise level lower than 70 dB (A)

IMPORTANT

Electric specifications: read the informa-

tion on the data plate of each single dispen-

ser, situated on the underside. The serial

number of the units is preceded by #

ATTENTION

Ensure that the unit is grounded correctly;

if not it may cause electric shock to per-

sons or damage the dispenser.

4

5

range between +5° and +50°C.

5 OPERATING PROCEDURES

1Clean and sanitized the dispenser prior to

use following the instructions in chapter 5.3

CLEANING.

2Fill the bowl with the product, prepared

according to the instructions of the manufacturer.

3Install the cover above the container making

sure that it is placed correctly.

4Set the control switch (see charter 5.1.

COMMAND DESCRIPTIONS)

5The dispenser should always operate with

the cover installed in order to prevent possible

contamination of the product.

6The dispenser must run uninterruptedly;

heating will stop automatically when the product

is ready for dispensing. The mixing device will

continue to operate.

7The dispenser is supplied with a container

with a closed removable bottom to facilitate

cleaning and sterilisation.

5. 1 DESCRIPTION OF CONTROLS

The dispenser is equipped with a general switch

whose functions are:

The dispenser is equipped with a thermostat, on

the right side, to adjust the temperature of the

product.

Comment: the dispenser is also equipped with a

second thermostat on the underside to regulate

the temperature of the hot plate. This is calibrated

in the factory. If necessary, it is possible to act on

the thermostat reducing the temperature of the

hot plate to prevent possible burns. This will

lengthen the heating time of the product and it will

never be possible to obtain a product at a higher

temperature to that set for the hot plate.

5. 2 OPERATION HELPFUL HINTS

hot chocolate: preparation following the

traditional artisan method, mix the cocoa with milk

or water well in a pan before pouring it into the

bowl. Follow the instructions of the manufacturer

if using packaged instantaneous products. It is

possible to mix these directly in the container.

Activate the dispenser turning the switch to

position 1. Turn the thermostat knob to 90°C to

obtain the cooking temperature of the product.

When the hot chocolate is ready lower the

temperature to the value required for dispensing

turning the thermostat knob.

5. 3 CLEANING AND SANITIZING

PROCEDURES

Cleaning and sanitizing are essential to maintain

perfect taste and maximum efficiency from your

dispenser. The procedures described below are

general and can vary due to the sanitary

regulations of the local health authorized.

The product must be taken out of the dispenser

before it is disassembled for cleaning.

ATTENTION

Do not remove the container until the hot

plate is cold.

ATTENTION

Do not remove the container from the

dispenser when it contains hot products.

IMPORTANT

Place the unit on an horizontal surface.

ATTENTION

In case of damages, the power cord must

be replaced by qualified personnel only in

order to prevent any shock hazard.

Position 0 : power is turned off

Position I : mixer and heating device in

working order

IMPORTANT

Before switching off the dispenser comple-

tely (switch at position 0), bring the thermo-

stat to the lowest temperature and wait for

the product to cool down. This stops the

product (if not agitated) from sticking to the

hot plate

5

6

SCIROCCO UL

ENGLISH

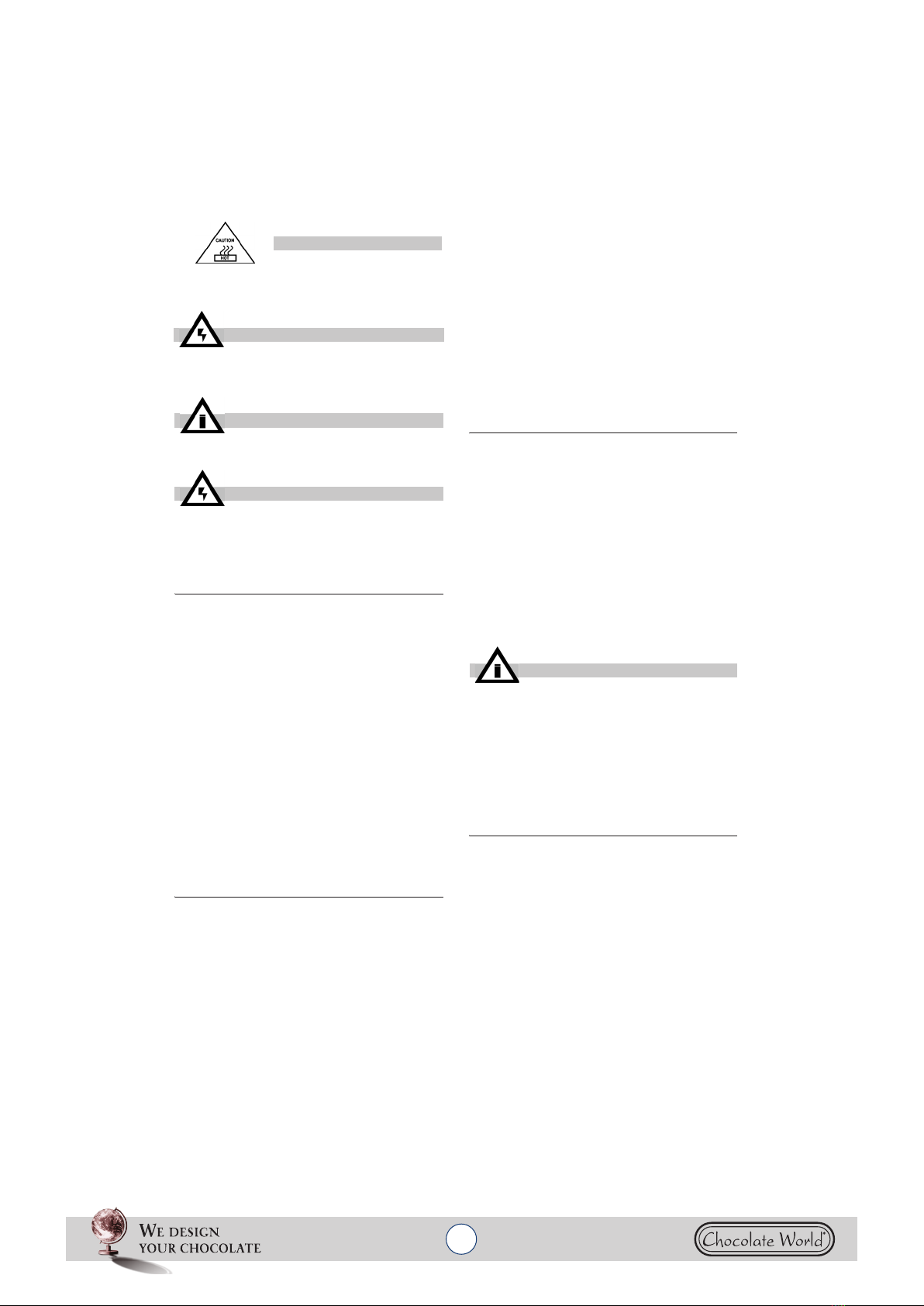

5. 3. 1 DISASSEMBLY

1Empty the bowl and remove the lid

2Remove the mixer from the central shaft

3Dismantle the faucet following the sequence

shown (see fig. 1)

figure 1

4Remove the container, lifting it upwards.

5Remove the drip-tray and empty it.

5. 3. 2 CLEANING

1Prepare approx. four litres (2 gallons) of hot

water (45-60° C) and specific detergent in a bowl

according to the instructions of the manufacturer;

a solution, which is too concentrated, may cause

damage to the parts to be washed, one that is

too diluted will not clean adequately. Do not use

abrasive detergents.

2Use a suitable brush and carefully clean all

the parts in contact with the drink

3Rinse all the washed parts in running water.

5. 3. 3 SANITIZING

The dispenser must be sanitized prior to starting

the machine. Do not allow the unit to sit for

extended periods of the time after sanitization

1Before starting the procedure described

below wash hands with an anti-bacterial soap.

2Prepare at least. four litres of hot water (45-

60°C) and sterilising product legally approved in

your Country, following the instructions of the

manufacturer. If there is no specific sterilising

product prepare a solution of water and bleach in

ATTENTION

Before proceeding to disassemble any com-

ponent always disconnect the unit from the

electricity removing the plug or switching

off the 2 pole wall breaker.

IMPORTANT

Before cleaning disconnect the dispenser

from the electricity taking out the plug or

turning off the outside switch on the wall.

ATTENTION

Do not wash any component of the

machine in the dishwasher.

IMPORTANT

Use detergents compatible with the plastic

parts to avoid damaging the dispenser.

ATTENTION

Do not use excessive amounts of water

near the electric components of the dispen-

ser when washing it as this can cause

electric shock or damage the dispenser.

6

7

the following ratio: 1 tbsp: 2 litres of water.

3Immerse all the parts to be sterilised in the

solution for time indicated by the manufacturer.

4Allow the sterilised parts to air dry on a clean

surface.

5Use non-abrasive cloths to dry the external

parts.

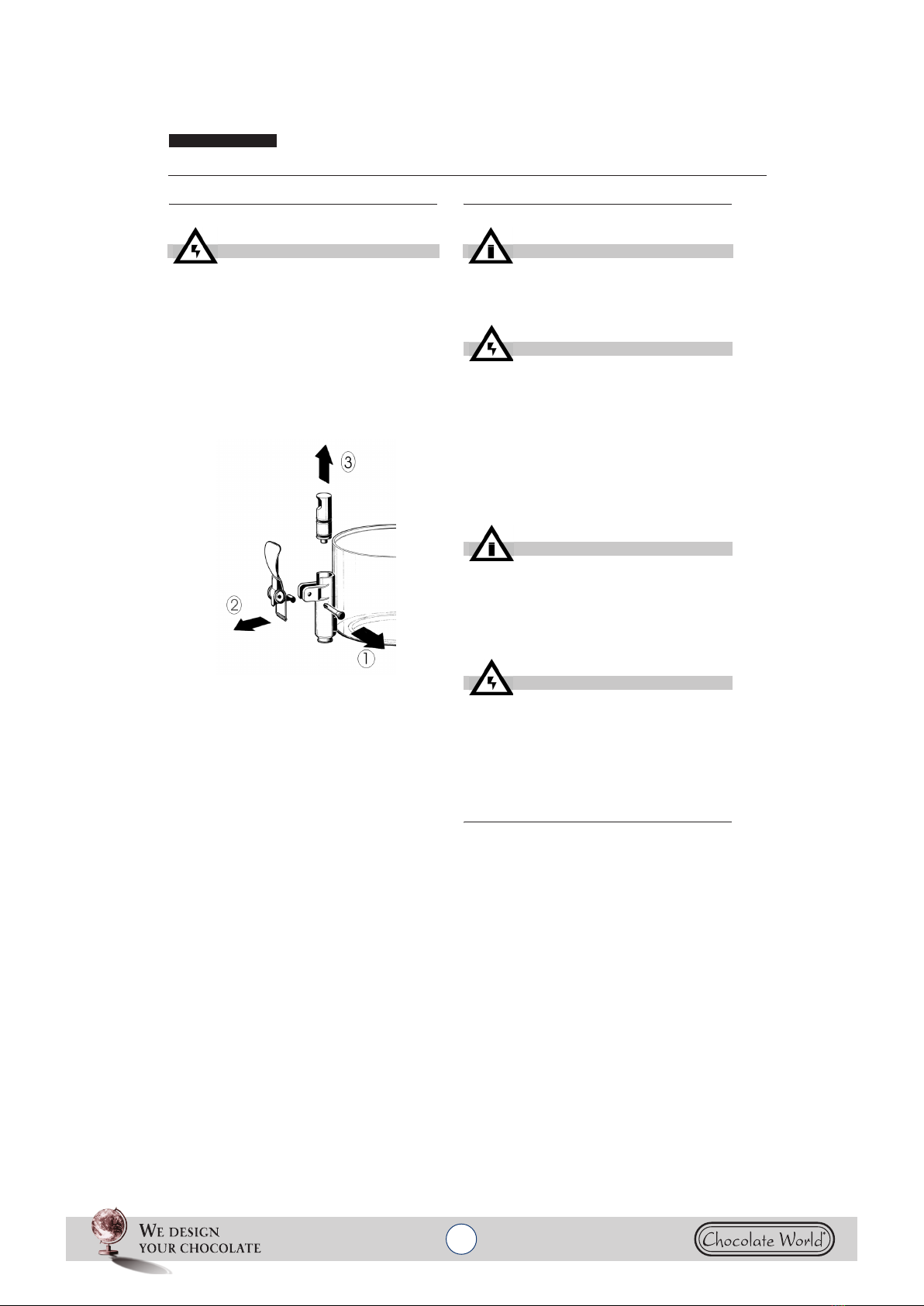

5. 3. 4 ASSEMBLY

1Put the drip-tray and grill in place

2Lubricate the faucet piston (in the area A

shown in fig. 2) using food grade approved

lubricant.

figure 2

3Reassemble the faucet assembly on the

container in the opposite way to which it was

dismantled (see fig. 1).

4Install the container putting the central shaft

in place.

5Insert the mixer in the central shaft

6Position the cover on the container.

6 MAINTENANCE

1Daily: check the dispenser for any loss of

product from the gaskets. If there is, first check

the dispenser is assembled correctly making

sure that the gaskets need no lubricating and

they are not faulty or worn. In this case they must

be replaced with original parts.

2To avoid damage to the dispenser the plastic

parts must be lubricated only with the grease

supplied by the manufacturer or other grease

compatible with polycarbonate.

7

SCIROCCO UL

8

ENGLISH

TROUBLESHOOTING

PROBLEM CAUSE SOLUTION

Mixer doesn't turn Drive shaft coupling not cor-

rect Check that it's in the cor-

rect operating position

Drive shaft coupling broken Replace mixer and/or drive

shaft

Gear motor not working See “Gear motor doesn't

turn”

Electrical wires disconnected

or interrupted Connect or replace

electrical wires

Product too dense Dilute the product

Gear motor doesn't turn Motor overheated: “Thermal

Protection” tripped Check the voltage of the

outlet. Check the

ventilation (fins on the side

panels obstructed or lower

part of the distributor

obstructed). Check the

viscosity of the product

Stator winding burned out or

interrupted Replace the motor

Rotor shifted Check the alignment of the

rotor bearings

Gears in the reducer box

damaged or worn Replace the motor

Beverage leaks from the

container Container gasket seal broken

or worn Replace gasket seal

Tap piston o-ring broken or

worn Replace the piston o-ring

Tap piston not in closed posi-

tion Check the tap lever or

spring and replace the

worn part

8

9

Heating element not hot Heating element burned out Replace the heati ng

element

The maximum temperature

thermostat (located under the

distributor) is set too low

Regolarlo alla temperatura

opportuna

Thermal fuse burned out Adjust it to a suitable

temperature

Thermal fuse burned out Thermal fuse defective Replace with a good one

Maximum temperature

thermostat doesn't intervene Replace maximum

temperature thermostat

I'm not getting a suffi-

ciently dense product The temperature of the

service thermostat (located on

the side of the distributor) is

set too low

Adjust it to a suitable

temperature

The maximum temperature

thermostat (located under the

distributor) is set too low

Adjust it to a suitable

temperature

Product excessively diluted Increase the concentration

of the product

I'm not getting a suffi-

ciently hot product The temperature of the

service thermostat (located on

the side of the distributor) is

set too low

Adjust it to a suitable

temperature

The bottom of the tub is not

touching the heating element Position the tub on the

heating element correctly

PROBLEM CAUSE SOLUTION

21

SCIROCCO UL

22

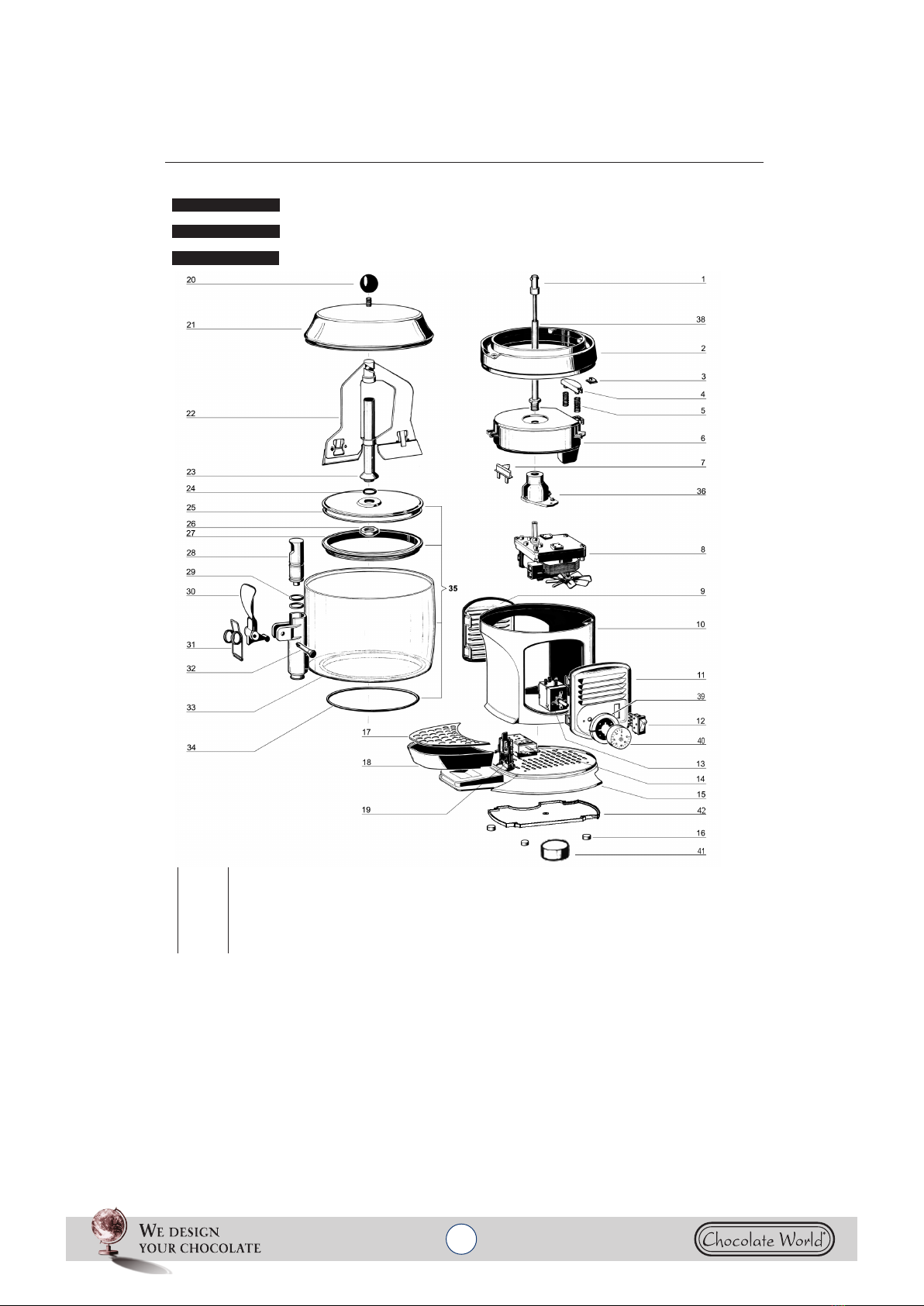

SPARE PARTS LIST

LISTE DES PIECES DE RECHANGE

DESCRIPCION PIEZAS DE REPUESTO

1 33800-09800 Driving shaft Arbre de trainement Eje transmisión

2 22800-26408 Heating plate holder Support plaque chauffante Soporte para plancha calentadora

2 22800-26427 Heating plate holder -“gold” Support plaque chauffante -“or” Soporte para plancha calentadora -”oro”

3 10554-44000 M4 Clip Clip M4 Clip M4

4 22800-26415 Thermostat bulb holder Support boule du thermostat Guia-sensor termóstato

5 22800-26420 Spring for bulb holder Ressort pour support boule Muelle para guia-sensor termóstato

6 33800-09701 Heating plate 115V 60Hz Plaque chauffante Plancha calentadora

7 22800-26426 Limit switch Thermolimiteur Fusible de seguridad

ENGLISH

FRANCAIS

ES P AÑ OL

2453_29 V 0.6 06G10

22

23

8 22092-00014 Complete gear motor 115V 60Hz Motoréducteur complet Motorreductor completo

9 22800-26478 Side panel Panneau latéral Panel lateral

9 22800-26433 Side panel -“gold” Panneau latéral -“or” Panel lateral -”oro”

9 22800-26438 Side panel -”silver” Panneau latéral -”argent” Panel lateral -”plata”

10 22800-26476 Machine body Carrosserie Cuerpo maquina

10 22800-26431 Machine body -“gold” Carrosserie -“or” Cuerpo maquina -”oro”

10 22800-26436 Machine body -”silver” Carrosserie -”argent” Cuerpo maquina -”plata”

11 22800-26477 Side panel for controls Panneau latéral pour contrôles Panel lateral completo de mandos

11 22800-26432 Side panel for controls -“gold” Panneau latéral pour contrôles -“or” Panel lateral completo de mandos -”oro”

11 22800-26437 Side panel for controls -”silver” Panneau latéral pour contrôles -”argent” Panel lateral completo de mandos -”plata”

12 22800-24301 Switch Interrupteur Interruptor

13 22037-00000 0-90°C thermostat Thermostat 0-90°C Termóstato 0-90°C

14 22037-00001 0-120°C thermostat Thermostat 0-120°C Termóstato 0-120°C

15 22800-26475 Base Base Base

15 22800-26430 Base -“gold” Base -“or” Base -”oro”

15 22800-26435 Base -”silver” Base -”argent” Base -”plata”

16 22800-26417 Rubber leg Petit pied Pie de goma

17 22800-26406 Drip tray cover Couvercle tiroir égouttoir Rejilla cajón recoge-gotas

17 22800-26428 Drip tray cover -“gold” Couvercle tiroir égouttoir“or” Rejilla cajón recoge-gotas”oro”

18 22800-26464 Drip tray Tiroir égouttoir Bandeja goteo

18 22800-26434 Drip tray -“gold” Tiroir égouttoir -“or” Bandeja goteo -”oro”

18 22800-26439 Drip tray -”silver” Tiroir égouttoir -”argent” Bandeja goteo -”plata”

19 22800-05500 Cable clamp Borne Pasacable

20 22800-26416 Cover knob Pommeau du couvercle Pomo para tapa

21 22800-26409 Bowl cover Couvercle du réservoir Tapa contenedor

21 22800-26429 Bowl cover -“gold” Couvercle du réservoir -“or” Tapa contenedor -”oro”

22 22800-26414 Mixer Mélangeur Mezclador

23 22800-26412 Bowl shaft Arbre du réservoir Arbol del contenedor

24 22800-26419 Bowl shaft O-ring OR de l’arbre du réservoir OR para àrbol central

25 22800-26407 Bowl bottom plate Fond du réservoir Fondo del contenedor

26 10533-03005 Central shaft nut Ecru arbre du réservoir Dado para eje central

27 22800-26410 Bowl gasket Joint du réservoir Junta contenedor

28 22800-14801 Faucet piston Piston du robinet Pistón del grifo

29 22800-15100 Faucet piston O-ring Joint OR du robinet Junta OR del grifo

30 22700-01860 Green faucet handle Levier de débit vert Palanca grifo

30 22700-01801 Black Faucet handle Levier de débit noir Palanca grifo

31 22800-26424 Faucet spring Ressort du robinet Muelle del grifo

32 22800-22161 Green faucet handle pin Pivot vert pour levier de débit Pivote verde de la palanca

32 22800-22160 Black faucet handle pin Pivot noir pour levier de débit Pivote negro de la palanca grifo

33 22800-26405 Bowl Réservoir Contenedor

34 22800-26418 Bowl O-ring OR du réservoir OR del contenedor

35 33800-09901 Bowl assembly Réservoir complet avec fond Contenedor completo

36 22001-00001 Gear motor flange Bride pour motoréducteur Brida para motorreductor

38 22800-26413 Central shaft Arbre central Eje central

39 22800-26466 Tap ring Mancon Pomo para termostato

40 22800-26456 Thermostat knob 32-194F Pommeau du thermostat 32-194F Pomo para termostato 32-194F

41 22800-26457 Thermostat knob 32-248 F Pommeau du thermostat 32-248 F Pomo para termostato 32-248 F

42 22800-26455 Base protection

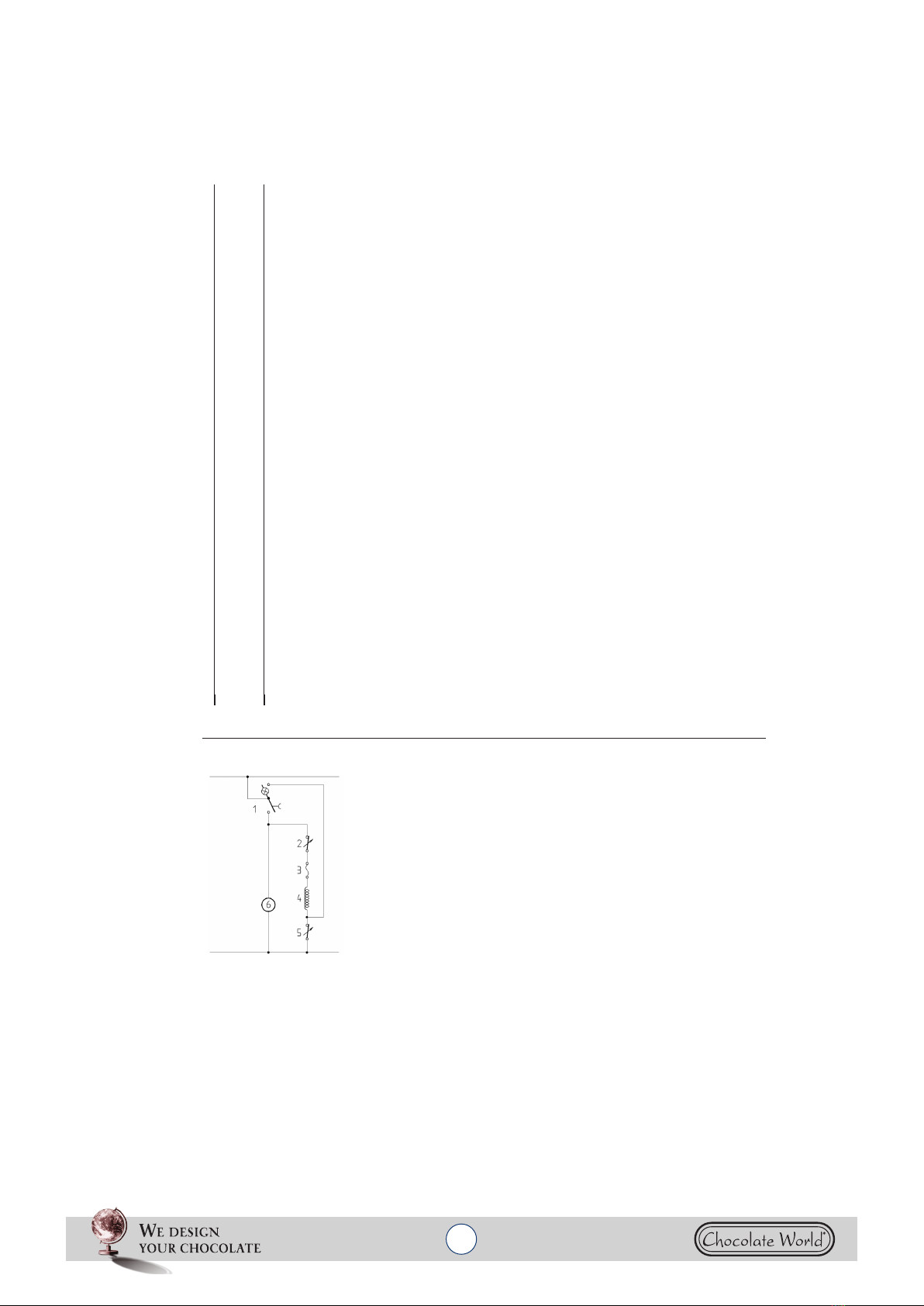

SCHEMA ELETTRICO / WIRING DIAGRAM / SCHEMA ELECTRIQUE / SCHALTSCHEMA / ESQUEMA ELECTRICO

1 Interruttore Switch Interrupteur Dreiwegeschalter Interruptor

2 Termostato 0-120°C 0-120°C Thermostat Thermostat 0-120°C Thermostat 0-120°C Termóstato 0-120°C

3 Termolimitatore 152°C Limit switch 152°C Thermolimiteur 152°C Sicherung 152°C Fusibile de seguridad

4 Resistenza Resistance Resistance Heizung Resistencia

5 Termostato 0-90°C 0-90°C Thermostat Thermostat 0-90°C Thermostat 0-90°C Termóstato 0-90°C

6 Motoriduttore agitatore Gear motor Motoréducteur Motoruntersetzung Motoreductor

This manual suits for next models

2

Table of contents