tatsuno EUROPE Instruction manual

Document:CNGdispensersTATSUNOEUROPE;QuickUserGuide

File:UP044‐EN_CngDispensersUserRev01.docx

Revision&Date:revision01,March2022

Numberofpages:40(includingcover)

Createdby:Ing.MilanBerka

TATSUNOEUROPEa.s.,Pražská2325/68,67801Blansko,CzechRepublic,tel.+420516428411,http://www.tatsuno‐europe.com

CNGDISPENSERS

TATSUNOEUROPE

QuickUserGuide

TATSUNOEUROPEa.s.

Pražská2325/68•67801Blansko

CzechRepublic

Tel.:+420516428411•Fax:+420516428410

e‐mail:info@tatsuno‐europe.com,http://www.tatsuno‐europe.com

©Copyright

Neitherthemanualnoranypartofitmaybereproducedwithouttheexplicit

approvalof

TATSUNOEUROPEa.s.

CNGdispensersTATSUNOEUROPE‐QuickUserGuide,revision01,March2022

3

CONTENTS

CONTENTS.........................................................................................................................................................3

INTRODUCTION..................................................................................................................................................4

1.INTRODUCTORYINFORMATION......................................................................................................................4

1.1.PERMITTEDUSE........................................................................................................................................................5

1.2.HEALTHANDSAFETY.................................................................................................................................................5

2.TATSUNOEUROPEDISPENSERS......................................................................................................................8

2.1.DESCRIPTIONOFDISPENSERS......................................................................................................................................8

2.2.BASICTECHNICALPARAMETERS...................................................................................................................................9

2.3.DISPENSERMODELIDENTIFICATION..............................................................................................................................9

2.4.STANDARDMODELSOFDISPENSERS............................................................................................................................11

2.5.TERMINOLOGYOFBASICPARTSOFTHEDISPENSER.........................................................................................................14

2.6.NAMEPLATES.........................................................................................................................................................15

3.INSTALLATION.........................................................................................................................................16

3.1.INSTRUCTIONSFOROCCUPATIONALSAFETY..................................................................................................................16

3.2.RECEIPT,TRANSPORT,UNPACKING.............................................................................................................................16

3.3.DISPENSERLOCATION..............................................................................................................................................17

3.4.MECHANICALATTACHMENTOFTHEDISPENSER.............................................................................................................19

3.5.ELECTRICALCONNECTIONOFTHEDISPENSER................................................................................................................20

4.DISPENSERSETTINGANDBASICFUNCTIONS............................................................................................21

4.1.TBELTMCOUNTER................................................................................................................................................21

5.OPERATION.............................................................................................................................................27

5.1.INSTRUCTIONSFORSAFEOPERATION..........................................................................................................................27

5.2.DISPENSERCOMMISSIONING.....................................................................................................................................28

5.3.DISPENSEROPERATION............................................................................................................................................30

6.MAINTENANCEANDSERVICE..................................................................................................................34

6.1.MAINPRINCIPLESOFDISPENSERMAINTENANCE............................................................................................................34

6.2.TROUBLESHOOTINGANDSOLVINGDISPENSERDEFECTS...................................................................................................36

6.3.SERVICEOFDISPENSERS...........................................................................................................................................38

TATSUNOEUROPEa.s.,www.tatsuno‐europe.com

4

INTRODUCTION

ThisQuickUserGuideisintendedfortheusersofTATSUNOEUROPEelectronicCNGdispensersandownersofservice

stationwheredispensersareinstalledandoperated.TATSUNOEUROPEa.s.recommendsthoroughreadingofthismanual.

Themanualmustbeavailabletothedispenserattendantduringoperationandregularmaintenanceofdispensers.

Makeitavailabletootherownersandusers.

Performupdatesofregulationsandmanuals.ThisQuickUserGuidetogetherwithInstallationandUserGuideis

possibletoviewanddownloadhere:http://www.tatsuno‐europe.com/_en/download/

Thecontentsofthemanualatthetimeofitsreleasecorrespondstoreality.Themanufacturerreservestherighttoalterthe

technicalspecificationsofthedeviceoritspropertieswithoutawrittennotice,duetoitsdevelopmentandcontinuous

improvement.Allrightsarereserved.Nopartofthismanualmaybereproducedortransferredwithoutawrittenapproval

ofTATSUNOEUROPEa.s.

Documentrevisions

RevisionNo./DateChangesMadeby

Revision00/5.9.2018 BasicversionofthedocumentMilanBerka

Revision01/31.3.2022Updateoftechnicaldata,errormessages,dispensersettings(PDEX5),OceanTowerCNG MilanBerka

1. INTRODUCTORYINFORMATION

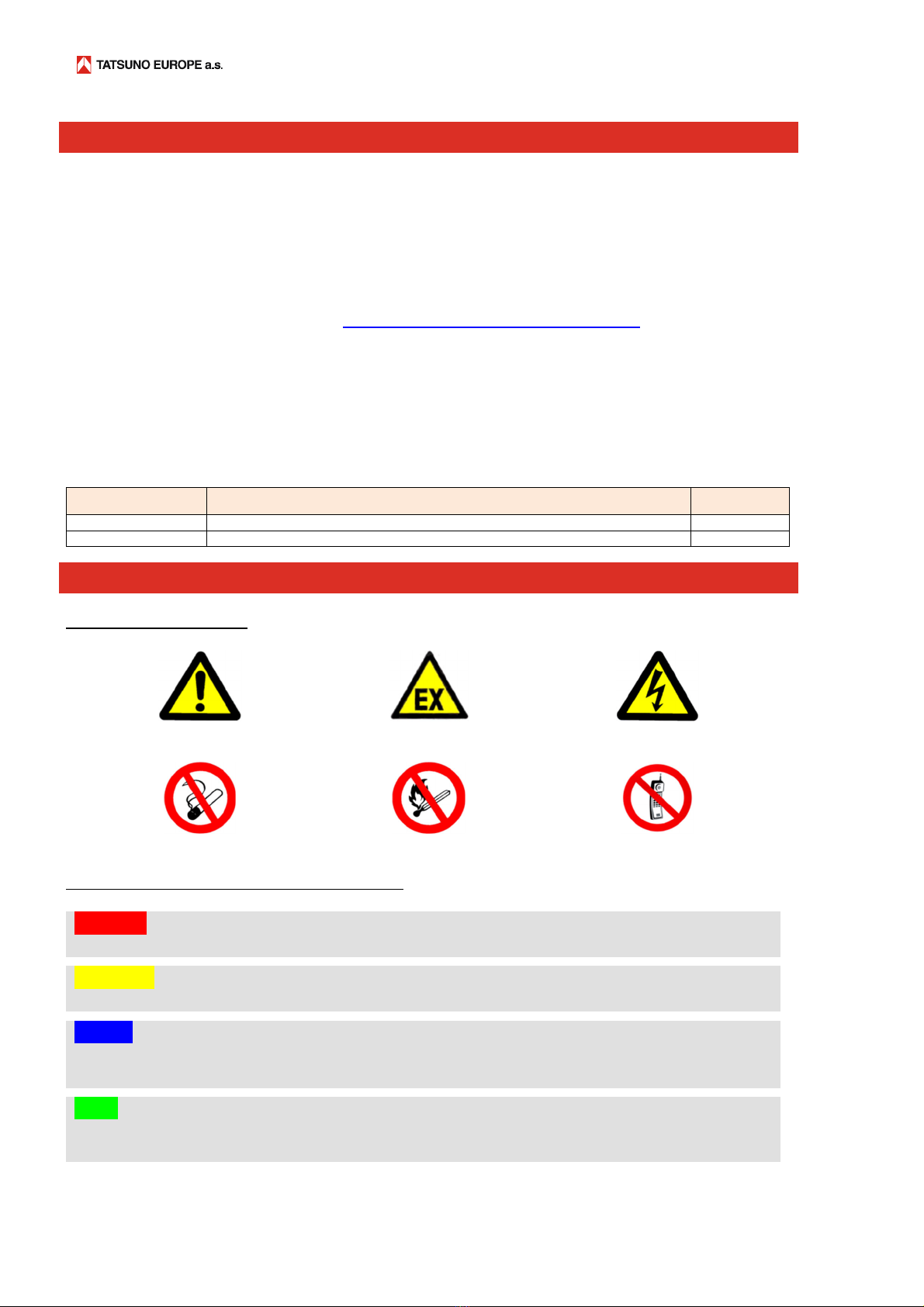

Symbolsusedinthismanual:

WarningExplosionhazardAttention!Electricaldevice

SmokingforbiddenOpenflameuseforbiddenUseofmobilephonesforbidden

Termsusedinthismanualrequiringspecialattention:

CAUTION

Failuretomeettherequirementsstatedtogetherwiththistermmaycreateconditionsleadingtoapersonal

injuryordeathortoextensivelossofproperty.

WARNING

Failuretomeettherequirementsstatedtogetherwiththistermmayleadtoapersonalinjuryand/ormay

causedispenserdamage.

NOTICE

Itemsstatedtogetherwiththistermdrawreader’sattentiontolegaland/orstatutoryrequirementsthatregulate

theassemblyanduseofdispensers.Failuretomeettheserequirementsmaycreateadangeroussituationand/orresultin

dispenserdamage

.

NOTE

Itemsstatedtogetherwiththistermaretodrawreader’sattentiontoassemblyprocedures,techniques,and

operatingmethodsetc.thatareimportanttoensurecorrectassemblyandproperoperationofdispensersandwhich,ifnot

observed,mayresultindamage,failureorpoorperformanceofdispensers.

CNGdispensersTATSUNOEUROPE‐QuickUserGuide,revision01,March2022

5

1.1. PERMITTEDUSE

TATSUNOEUROPEdispensers,OCEANCNGtypeseries,aredesignedforstationaryormobileplacementfor

refuellingmotorvehicleswithcompressednaturalgas(CNG)inagivenamountfromagasstoragetoatankofa

motorvehicles.

CAUTIONDispensersarecomplexdevicesthatmustsecureawholerangeofdifficultfunctions.Therefore,tanksand

pipelinesmustbecleanedandfuelmustbecheckedforcleanlinessbeforecommissioning(Filterclogginginadispenser

cannotbeconsideredareasonforwarrantyrepair!).Aninspectionofwiringandacheckofconnectioncorrectnessmust

beperformedbeforecommissioningtopreventanyelectricshockinjuriesandtoensuresafetyagainstexplosion(fuels

arecombustiblesofclassI).

NOTICEAnymodificationofthedispensermayinvalidatethedevicecertification.Refertocertificationdocumentsand

manufacturerinstructionmanualsifanymodificationofthewiringand/ordeviceisconsidered.

Eachdispenserisproperlytestedinthefactoryintermsofitsfunction,safety,andmetrology.Thedeliveryofeachdispenser

alsocontainscertificationdocumentsthatmustbesubmittedbytheoperatorondemand.

1.2. HEALTHANDSAFETY

1.1.1. LISTOFSAFETYFACTORS

AnyodourofCNG(methane)mustbeimmediatelyreported.

Itisnecessarythatallworkatthefuelstation,especiallyconstructionandrepairs,isperformedfillyin

compliancewiththislist.

Itistheobligationoftheconstructorthatallhisemployeescomplywithalllaws,directives,andother

regulations.

Gas(CNG)mayonlybestoredintanksandcontainerscompatiblewith.

Locationsrequiringhighercarefulness

Pressurecontainers,supplypressurepipesanddispensers.

Anyplacesneardispensersandpressuretanksduringfilling,especiallyinstillair.

1metercircuitaroundthegaspipes.

Thefilters.

1.1.2. OBLIGATIONSOFEMPLOYEES

Toensureoptimumpreventionofinjuries,inadditiontogeneralrulesforemployeeprotectionitisnecessary

toconsideralsonationallegislationaboutemployeeprotectionandactivelysupportallmeasuresimproving

safetystandards.

Anemployeeisobligedtoobserveallcompanyguidelinesaboutaccidentpreventionexceptforthecaseswhen

theseguidelinesareassessedasillegitimate.

Employeesmustnotactaccordingtoanyinstructionthatviolatesafetyrules.

Employeesmayusedesignedtoolsonlyfortheiroriginalpurposesthataredefinedbythecompanyitself.

Ifanemployeedetectsatoolunsuitableintermsofsafety,he/shemustimmediatelyremovethedefect.Ifthe

defectremovalisnotwithintheemployee`sjobcontentorifanemployeedoesnothaveenoughknowledge

foritsremoval,he/shemustimmediatelyinformhis/hersuperordinate.

Thesameappliesalsotothefollowing:

Workingmaterialsthatarenotproperlypackedorcorrectlydescribedsothattheycorrespondtosafety

requirements.

TATSUNOEUROPEa.s.,www.tatsuno‐europe.com

6

Workingmethodsandprocessesthatarenotcorrectlycoordinatedorcheckedsothattheycorrespondto

safetyrequirements.

Ifdangerousproceduresareperformedbyseveralpersons,permanentflawlesscommunicationbetweenthem

isnecessarytopreventhazardoussituations.Insuchacaseapersonmustbeappointedandauthorizedto

performoverallsupervision.

1.1.3. DANGER

Beforestartingwork,thedispensermustbeinsulated(i.e.,completelydisconnectedfromthepowersupply)and

themainswitchmustbeswitchedoff.Thesubmersiblepump(ifused)andthecontrolsignalsfromthedispenser

mustalsobeinsulated.Thisensurestechniciansafety.Asafurtherprecaution,turnoffthemainpowersupplyin

thefuelstationboothandplacethereaclearwarningtopreventitfrombeingaccidentallyswitchedon.Itisnot

allowedtoturnonthedispenserbeforeitischeckedandapprovedbyanauthorizedtechnician.Thisauthorization

issubjecttotherelevantnationallegislation.Removedpackagingandfacingmaterialmustbestoredinsuchaway

astopreventdamagetopartsandpersonalinjury.Coversthatcanbeopened,suchasthecounterbox,shouldbe

handledwithcare.Ensurethatthefuseisinthecorrectpositiontopreventthelidfromfallingoffontheheadof

theservicetechnicianoranotherperson.Forunmannedfuelstations,theInstallationandUserManualmustbe

availabletoallend‐users.Itshouldbeplacedvisiblyonthenoticeboardandilluminatedenoughtobereadableat

night.Forunmannedfuelstations,breakawaycouplingsmustalsobeusedtoreducetheriskinthecaseofdeparture

afterthedeliverynozzlehasbeenforgotteninthevehicletank.

WARNINGOnlyqualifiedpersonnelauthorizedtodosomayperformconnectinganddisconnectingto/fromtheelectrical

system.Workinhazardousareasmustbeensuredbycomplyingwithallapplicablelegalstandards.

1.1.4. PERSONALPROTECTIVEEQUIPMENT

Protectiveclothing

Thefollowingclothingmustalwaysbewornduringdispenserinstallationandmaintenance:

Protectivehelmet.

Protectivefootwear(conductive).

Protectiveleathergloves.

Anti‐staticclothing.

Eyeprotection.

Protectiveequipmentforworkinahazardousenvironment

Thefollowingsafetyequipmentisrequiredtoworkinahazardousenvironment:

Onlyspark‐freetoolsarepermittedwhenworkingonthedispenser.

Itisstrictlyforbiddentouseelectrictools.

Onlyexplosion‐protectedworkinglightsarepermitted.

Itisstrictlyforbiddentousetelecommunicationtoolsinhazardousareas.

Safetyinstructions

Thefollowingsafetyinstructionsmustbeobservedduringinstallationandmaintenance:

Wearsuitableprotectiveclothingandgloves.

Smokingandopenfireareforbidden.

Longhairandtiescanbetrappedinmovingparts.Hairmustbereasonablycovered.

Whilerefillingmotorvehicleswithcompressednaturalgas(CNG)isifforbiddentosmokeanduseopenflamewithin

aradiusof10m–appliesalsotopassengersinsidethevehicle.Thisbanmustbelocatedinavisibleplace.Safety

labelsandsymbolsareusedaccordingtoČSN018013.Avisiblenoticeaboutswitchingofftheengineoftherefilled

vehicleanditsauxiliaryheatingwithacombustionchambermustbelocatedatthedispenser.Thevehiclemustbe

CNGdispensersTATSUNOEUROPE‐QuickUserGuide,revision01,March2022

7

securedagainstspontaneoussettinginmotion.Acarbon‐dioxideextinguisherordry‐powderextinguisherwitha

fillingofatleast6kgmustbelocatedateachdevice.Thedevicethatisoutofordermustbesecuredagainstits

misusebyanunauthorizedperson.

Devicedesignsafety

DEVICEDESIGNSAFETYISGUARANTEEDBYTHEMANUFACTURER

ThedispenserdesignmeetstherequirementsofENISO80079‐36andENIEC60079‐0standardsandisdesignedfor

operationinenvironmentsdesignatedbysymbolsII2GIIAT3statedonthetypelabelofthedispenser.Withregardto

theoperationsafetyinthepotentiallyexplosiveenvironment,dispensercomplianceassessmentwasperformedand

documentationarchivingwascarriedoutaccordingtoarticle10,par.1b(2)oftheGovernmentDecreeNo.116/2016Coll.

(article13,par.1b(ii)oftheEuropeanParliamentandCouncilDirectiveNo.2014/34/EU)inaPhysical‐TechnicalTesting

InstituteinOstrava–Radvanice,notifiedbodyNo.1026withthearchivenumberA484‐16.Intermsofpressuresafety,EU

verificationoftheunit(ProcedureG)wasperformedattheCNGdispenseraccordingtotheAppendixNo.3,point11ofthe

GovernmentDecreeNo.26/2003Coll.asamended(AppendixNo.III,point10oftheEuropeanParliamentandCouncil

DirectiveNo.2014/68/EU)bythenotifiedbodyNo.1017TÜVSUDCzechs.r.o.,Novodvorská994,14221Prague4.

Operatingsafety

Theoperatorisresponsibleforthefuelstationoperationandisobligedtoentrustitsoperationonlytotrainedemployees

havingrelevantauthorization.Thetaskoftheattendantis,whileobservingallsafetyregulations,competentlyrefillCNG

pressurestoragetanksofrefilledmotorvehiclesandchecktheconditionofdispensers,reservoirs,machineryoperation,

gaspressureandkeepprescribedoperatingrecordsinregularintervals.

Attendant’sresponsibilities

Keeptheoperateddevicesinasafeandpropercondition.

Observeoperatingrulesandregulationsandoperatinginstructionsofgasdevices.

Immediatelyinformtheoperatorabouteachfailure,defectorabnormalityduringthegasdeviceoperationand

immediatelydecommissionthedeviceincaseofdangerofdelay.

Permanentlykeepthegasdevicetidyandcleanandensurethatnounauthorizedpersonsarenearbythedevice.

Immediatelyinformtheoperatoraboutcircumstancesthatimpedethedeviceoperationfortheattendant(in

caseofsuddenindisposition).

Writedowntherecordsintotheoperationlogbookabouttheshiftstartandfinish,inspectionsperformedby

theattendantandmaintenancework,repairs,inspections,andaudits.

ThefuelstationandCNGdispenserattendantmustnotperformanyrepairsofthemachineryandmodifythe

settingsofsafetyfittingsonhis/herown.

Aspecialcaseisperformingserviceinterventions

Aserviceworkermustnotviolatetheoperatingsafetyduringrepairsandotheractivities.He/shemust

payspecialattentiontoremovingthecoversofthedispensernottocauseanyinjuryofhimnoracasual

customer.

Whilehandlingofelectricalcomponents,he/shemustensuresafedisconnectingofelectricalenergy

supply.

Onlyapprovedcomponentsmaybeusedforpartreplacements.Allpartssubjecttoapprovalmustbe

alwaysputintoconditionwhichisprescribedbytechnicaldocumentation(airtightness,grounding,

electrostaticallyconductivedeliveryhoses,etc.).

Environmentalsafety

TheCNGdispenserandthefillingunitmaybefittedwithsensorsofthegasleakdetector(theyarenotastandardpart

ofthedispenserdelivery)whichcanbeconnectedtotheevaluationunit.Incaseofgasleak(lowconcentration)theunit

TATSUNOEUROPEa.s.,www.tatsuno‐europe.com

8

shallautomaticallysignaltheleakandincaseofdanger(higherconcentration)itshallimmediatelydecommissionthe

wholesystem.Incaseofasmallgasleaktheattendantofthefuelstationshallcheckthesystemandifhe/shedoesnot

findanydefect,leakedgasshallbeventilatedandthesystemshallbeputagainintooperation(smallleakwhile

connectinganddisconnectingthedeliveryhose,influenceofexhaustfumes).Incaseofhigherconcentrationsofleaked

gas,theevaluationunitshalldisconnecttheelectricalsystemfromoperation.Thefuelstationattendantshall

decommissionthefuelstationandannouncethedefecttoaspecializedcompanythatshallperformtherepair.

2. TATSUNOEUROPEDISPENSERS

2.1. DESCRIPTIONOFDISPENSERS

AllTATSUNOEUROPEdispensersareequippedwithhighqualityhydraulicsandapowerfulreliableelectroniccounter.All

dispensersworkinthemanualmode–independently,offline–aswellastheautomatedmode,whentheyarecontrolled

remotelyfromthekioskofafuelstationandconnectedtothecashregister(POS)viaadataline.Alldispensershavebody

parts(covers,doors,lids,etc.)madeofsteelpaintedsheetmetalorstainless‐steelsheetmetal.Supportingpartsofdispenser

framesaremadeofsteelpaintedsheetmetalofathickness0.8to2.5mm,orstainless‐steelsheetmetal.Eachdispenseris

equippedwithanelectroniccounterwithitsowndiagnosticsanddisplaysshowingthedeliveredamountofmoneyinthe

currencyofthecountryofinstallation,theamountoffuelinkilogramsandthefuelunitprice.Displaysofthefueldispensers

specifiedforprivateusedisplayonlythedispensedfuelquantityinkilograms.

NOTICEStandardpaintedversionsofTATSUNOEUROPEdispensersarenotintendedforuseinhighhumidity,chemical

andsaltwaterareas.ForsuchapplicationsTATSUNOEUROPEsuppliesoptionsusingstainlesssteelmaterials.

Thecompressednaturalgas(CNG)dispensingmodulehasapressurepartfittedwithcertifiedcomponentsmade

ofstainlesssteelorgalvanizedsteel.TheaccesstotheCNGpressuresystemisfittedwithalever‐closableballvalve,

then25µminputparticlefilterstoprotectpressurecomponentandequipment.Gasfillingisregulatedbyvalvesand

securedwithcheckvalves.Theamountofgasflownthroughismeasuredwithamassmetertheinputofwhichis

fittedwithanelectronicpressuresensorandmechanicalpressuregauge(manometer).Allsuchpressure

connectionsareperformedbyusingstainlessorgalvanizedsteelpipeswithahigh‐qualityconnectionsystem(two

rings).Allfixturesandbracketsinthepressuresectionaremadeofgalvanizedsheetmetal.Theoutputofthe

pressuremoduleandfixtureofdeliveryhosesissecuredwithafixedconnectiontowhichadeliveryhoseis

connectedwhichisfittedwithasafetybreakawaycouplingthatshutsthegasflowthroughthedeliveryhoseon

bothsidesinforcibletensionstresswithfollowingdisconnection.Thedeliveryhoseendswithadeliverynozzle.The

pressuresectionoftheCNGdispensermaybefurtherequippedwithaheatsensorformeasuringtheambient

temperature.Installationoftheheatsensorallowsactivationofthefillingtemperaturecompensationfunction

Fillingwithtemperaturecompensationensuresthatthevehiclestoragetankisalwaysfilledwithamaximumamount

ofgaswhileobservingtheconditionofmaximumpressureinthetankof20MPaat15°C.

CNGdispensersTATSUNOEUROPE‐QuickUserGuide,revision01,March2022

9

2.2. BASICTECHNICALPARAMETERS

Table1‐CNG(compressednaturalgas)dispensersandmodules

MassmeterCNG050CNGmass

MaximumflowrateQmax[kg/min]30/7030/70

MinimumflowrateQmin[kg/min]20.8

LowestmeteringMMQ[kg]22

Fluidtemperaturerange[°C]‐25to+55‐50to+80

Ambienttemperaturerange[°C]‐40to+55‐40to+60

MaximumtankpressurePst[MPa]30.0

MaximumgaspressurePmax[MPa]30.0

MinimumgaspressurePmin[MPa]2.0

MaximumdeliveringgaspressurePv[MPa]20.0@15°C/26.5

Maximumunitprice(numberofdigits)9999(4)or99999(5)*

Maximumamounttopay(numberofdigits)999999(6)or9999999(7)*

Maximumquantity(numberofdigits)999999(6)or1999999(6.5)*

Scaleinterval[kg]0.01or0.001

DisplaytypeElectronic

TypeofmediumCompressednaturalgas

FiltrationofmechanicalparticlesInputfilter>25µm

Accuracyclass1.0(1.5OIMLcertificate)

MechanicalclassM2

ElectromagneticclassE1

HumidityCondensing

LocationOpen

MeasuredunitMass[kg]

ElectroniccounterTBELTM

Programversion(W&Mchecksum)1.01(4092),1.02(24AD)

Calculatorpowering 230V±10%;50Hz;max.300VA

Electro‐magneticvalvesTwo‐state;+24VDC/max.1A

*Datatransmissionoftheentirecontentsofthedisplaywiththenumberofdigits7/6.5/5isonlypossibleusingtheextendedcommunicationprotocol(8/8/6)

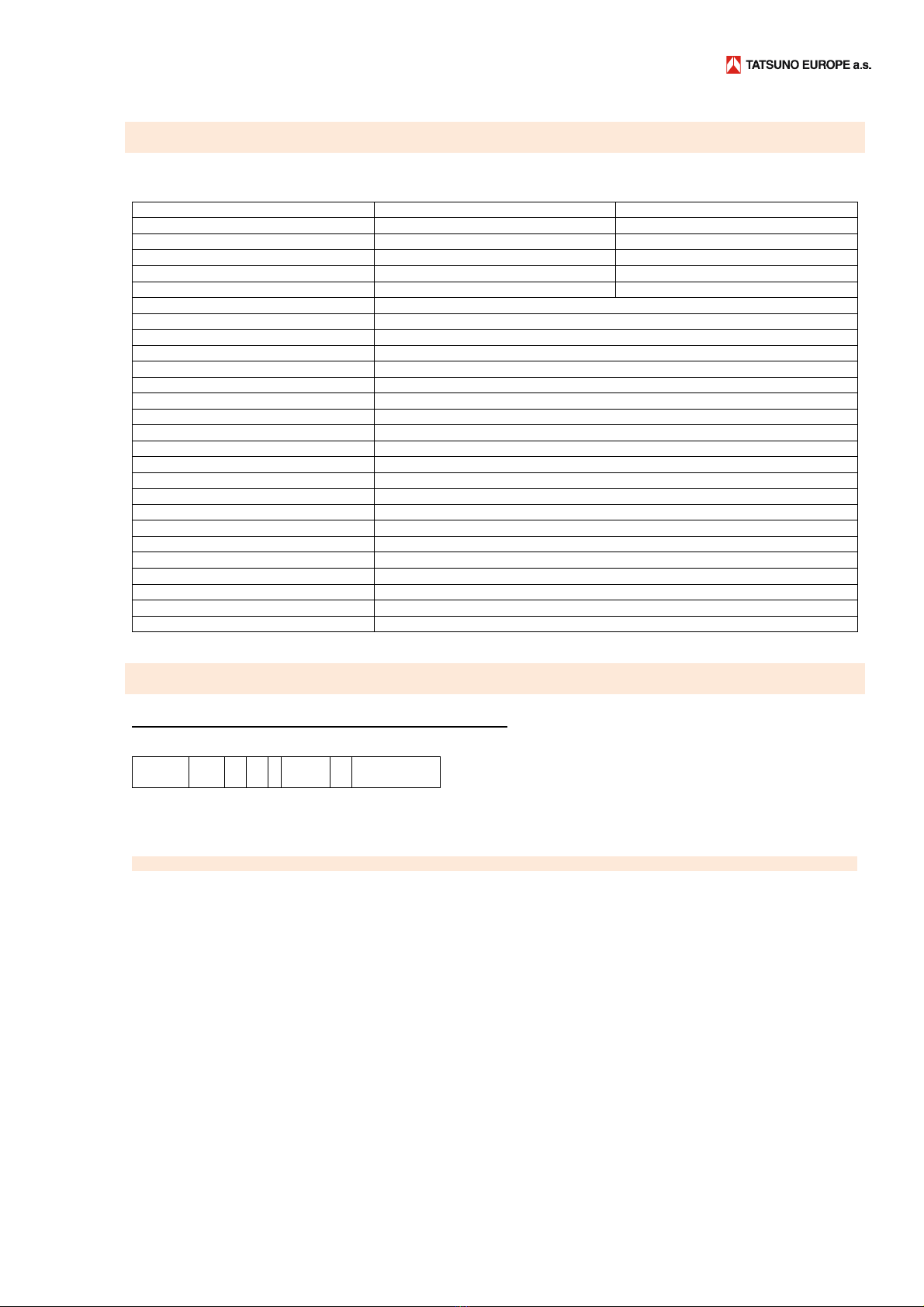

2.3. DISPENSERMODELIDENTIFICATION

ThebasicdesignoftheOCEANCNGseriesbusinessbrandingis:

1234 567

BMP4032.OWD/CNG

Astand‐alonedispenseralwaysstartswithaBMPabbreviationfollowedbyaclarificationofthedispenserconfigurationand

design.

FieldValuesDescription

1‐‐‐‐‐‐‐‐‐‐‐>Devicetype

BMPDispenser.Standalonedispenser.

2‐‐‐‐‐‐‐‐‐‐‐>Seriesofdispensers

40OCEAN.DispensersoftheOCEANEURO,OCEANSMART,OCEANTOWERseries.

31.2to3Numberofproducts.Numberofpressuregasinputs.

41,2to4Numberofdeliveryhoses.Itcorrespondstothenumberofmeasuringsystems.

5‐‐‐‐‐‐‐‐‐‐‐>Dispenserdesign.

OE*OCEANEUROdispensers

OSOCEANSMARTdispensers

OWOCEANTOWERdispensers

6‐‐‐‐‐‐‐‐‐‐‐>Dispenserorientation

DDouble‐sideddispenser.

LSingle‐sideddispenser–left.

RSingle‐sideddispenser–right.

7‐‐‐‐‐‐‐‐‐‐‐>Specifyingabbreviation

/CNGCNG(compressednaturalgas)dispenserormodule.

/HIncreasedfillingperformanceofoneCNGhose(<70kg/min).

‐2CSimultaneousdeliveryoftwodeliveryhosesononesideofthedispenser.

‐4CSimultaneousfillingoffourdeliveryhosesonadispenser.

/*Note:SerialproductionoftheOCEANEUROandOCEANTALLseriesdispenserswasterminatedinOctober2020.

TATSUNOEUROPEa.s.,www.tatsuno‐europe.com

10

2.3.1. DISPENSERPARTSMARKINGCONVENTIONS

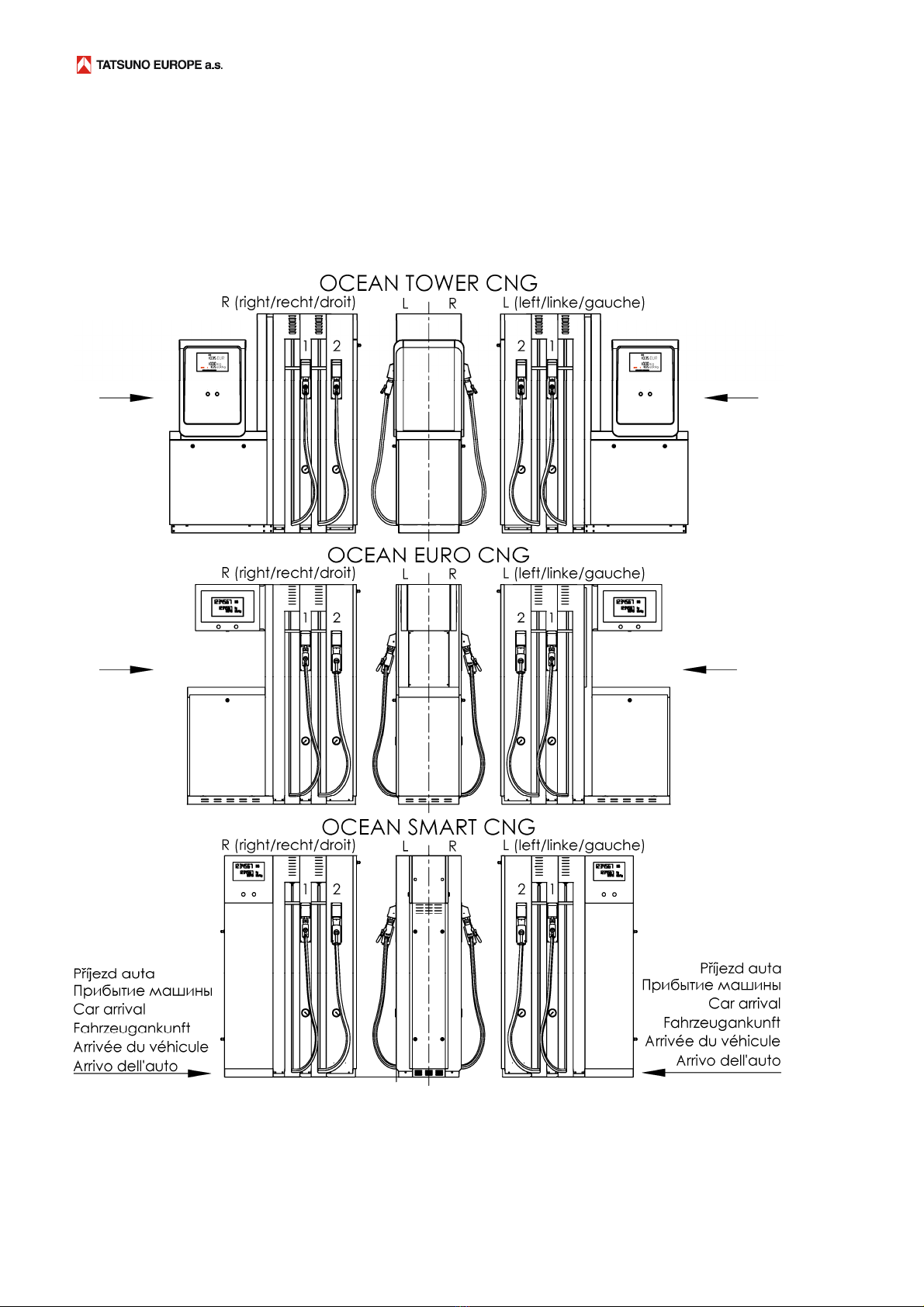

Figure1illustratestheTATSUNOEUROPEdispensermarkingandsortingsystem.Inthecaseofadouble‐sided

dispenser,therightsideofthedispenserisalsoreferredtoassideAandtheleftsideisreferredtoassideB.Fora

one‐sidedleftorone‐sidedrightdispenser,itisalwaysonlysideA.

Figure1‐Dispensermarkingsystemwiththerecommendedarrivaldirection

CNGdispensersTATSUNOEUROPE‐QuickUserGuide,revision01,March2022

11

2.4. STANDARDMODELSOFDISPENSERS

2.4.1. OCEANEUROCNGDISPENSERS

DispensersforfillingcarswithcompressednaturalgasoftheOCEANEUROCNGseriesarestandardlyproducedin

single‐sidedleft(L),single‐sidedright(R)ordouble‐sided(D)versionswithonetofourfree‐hangingpressurefilling

hoses.Themaximumfillingcapacityis30kg/min.withNGV1fillingnozzleforpassengercarsor70kg/min.with

NGV2fillingnozzleforfillingtrucks.

ListofstandardmodelsofOCEANEUROCNGdispensers:

Modelofdispenser

Accesstodispenser

(1‐single‐sided,2‐double‐sided)

Numberofpressureinputs

Numberofmeters

(numberofmeasuringsystems)

Numberoffillinghoses

Numberofmaindisplays

(numberofsimultaneousdeliveries)

Fillingperformance

[kg/min]

BMP40x1.OEL(R)/CNG1x1111x30

BMP40x1.OEL(R)/CNG/H1x1111x70

BMP40x2.OED/CNG2x2222x30

BMP40x2.OED/CNG/H2x2221x30+1x70

BMP40x2.OED/CNG/H/H2x2222x70

BMP40x2.OEL(R)/CNG/H1x1211x30+1x70

BMP40x4.OED/CNG/H/H2x2422x30+2x70

BMP40x4.OED/CNG‐4C/HE2x4444x30

Notes:x…isthenumberofCNGinputs(CNGpressuretanks)x=1,2or3dependingonthestationtechnology.Thefillingcapacitydependsonthe

realconditionsatthefillingstation‐qualityandlengthofpiping,workingpressure,volumeandnumberofpressuretanks,compressor,length,

andcross‐sectionoffillingpipinginthevehicle,etc.Thestandardfillingcapacityis30kg/min.Thefillingcapacitycanbeincreasedto70kg/min

(/H).Inthecaseofthe/H/Hmarking,therearetwofillinghoseswithacapacityof70kg/mininthedispenser.Pictures(PNG,DWG)with

dimensionsofallmodelscanbedownloadedhere:https://www.tatsuno‐europe.com/_en/download/

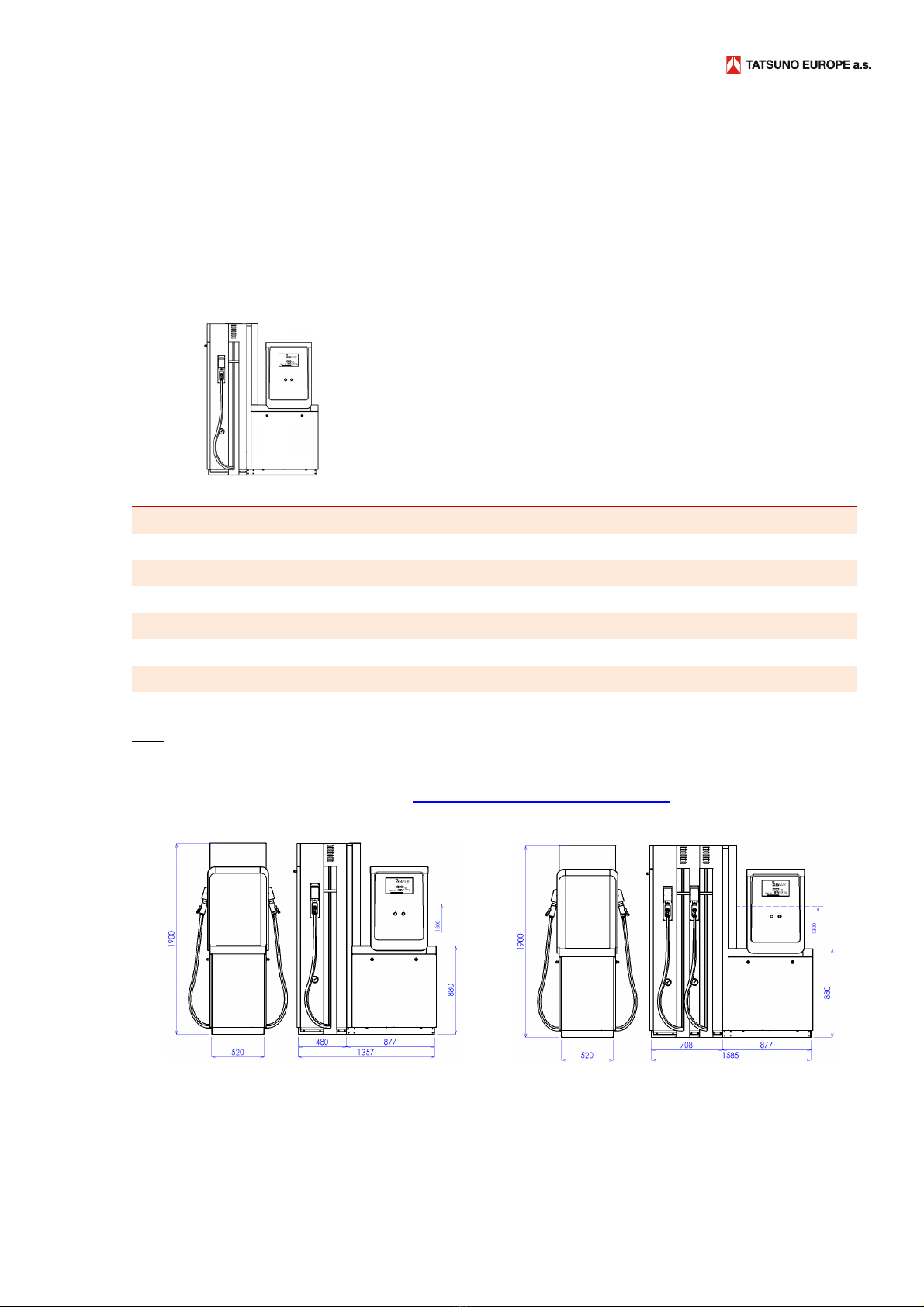

BMP40x2.OED/CNG

BMP40x4.OWD/CNG

Figure2–OverviewofstandardOCEANEUROCNGdispensers

TATSUNOEUROPEa.s.,www.tatsuno‐europe.com

12

2.4.2. OCEANSMARTCNGDISPENSERS

DispensersforfillingcarswithcompressednaturalgasoftheOCEANSMARTCNGseriesarestandardlyproducedin

single‐sidedleft(L),single‐sidedright(R)ordouble‐sided(D)versionswithonetofourfree‐hangingpressurefilling

hoses.Themaximumfillingcapacityis30kg/min.withNGV1fillingnozzleforpassengercarsor70kg/min.with

NGV2fillingnozzleforfillingtrucks.

ListofstandardOCEANSMARTCNGstandmodels:

Modelofdispenser

Accesstodispenser

(1‐single‐sided,2‐double‐sided)

Numberofpressureinputs

Numberofmeters

(numberofmeasuringsystems)

Numberoffillinghoses

Numberofmaindisplays

(numberofsimultaneousdeliveries)

Fillingperformance

[kg/min]

BMP40x1.OSL(R)/CNG1x1111x30

BMP40x1.OSL(R)/CNG/H1x1111x70

BMP40x2.OSD/CNG2x2222x30

BMP40x2.OSD/CNG/H2x2221x30+1x70

BMP40x2.OSD/CNG/H/H2x2222x70

BMP40x2.OSL(R)/CNG/H1x1211x30+1x70

BMP40x4.OSD/CNG/H/H2x2422x30+2x70

Notes:x…isthenumberofCNGinputs(CNGpressuretanks)x=1,2or3dependingonthestationtechnology.Thefillingcapacitydependsonthe

realconditionsatthefillingstation‐qualityandlengthofpiping,workingpressure,volumeandnumberofpressuretanks,compressor,length,

andcross‐sectionoffillingpipinginthevehicle,etc.Thestandardfillingcapacityis30kg/min.Thefillinghoseoutputcanbeincreasedto70

kg/min(/H).Inthecaseofthe/H/Hmarking,therearetwofillinghoseswithacapacityof70kg/mininthedispenser.Pictures(PNG,DWG)with

dimensionsofallmodelscanbedownloadedhere:https://www.tatsuno‐europe.com/_en/download/

BMP40x2.OSD/CNG BMP40x4.OSD/CNG

Figure3–OverviewofstandardOCEANSMARTCNGmodels

CNGdispensersTATSUNOEUROPE‐QuickUserGuide,revision01,March2022

13

2.4.3. OCEANTOWERCNGDISPENSERS

TheOCEANTOWERCNGseriesdispensersforfillingcarswithcompressednaturalgasarestandardlyproducedin

single‐sidedleft(L),single‐sidedright(R)ordouble‐sided(D)versionswithonetofourfree‐hangingpressurefilling

hoses.Themaximumfillingcapacityis30kg/min.withNGV1fillingnozzleforpassengercarsor70kg/min.with

NGV2fillingnozzleforfillingtrucks&buses.

ListofstandardOCEANTOWERCNGstandmodels:

Modelofdispenser

Accesstodispenser

(1‐single‐sided,2‐double‐sided)

Numberofpressureinputs

(numberofpressuretanks)

Numberofmeters

(numberofmeasuringsystems)

Numberoffillinghoses

Numberofmaindisplays

(numberofsimultaneousdeliveries)

Fillingperformance

[kg/min]

BMP40x1.OWL(R)/CNG1x1111x30

BMP40x1.OWL(R)/CNG/H1x1111x70

BMP40x2.OWD/CNG2x2222x30

BMP40x2.OWD/CNG/H2x2221x30+1x70

BMP40x2.OWD/CNG/H/H2x2222x70

BMP40x2.OWL(R)/CNG/H1x1211x30+1x70

BMP40x4.OWD/CNG/H/H2x2422x30+2x70

BMP40x4.OWD/CNG4C‐HE2x4444x30

Notes:x…isthenumberofCNGinputs(CNGpressuretanks)x=1,2or3dependingonthestationtechnology.Thefillingcapacitydependsonthe

realconditionsatthefillingstation‐qualityandlengthofpiping,workingpressure,volumeandnumberofpressuretanks,compressor,length,

andcross‐sectionoffillingpipinginthevehicle,etc.Thestandardfillingcapacityofthehoseis30kg/min.Thefillinghoseoutputcanbeincreased

to70kg/min(/H).Inthecaseofthe/H/Hmarking,therearetwofillinghoseswithacapacityof70kg/mininthedispenser.Pictures(PNG,DWG)

withdimensionsofallmodelscanbedownloadedhere:https://www.tatsuno‐europe.com/_en/download/.

BMP40x2.OWD/CNGBMP40x4.OWD/CNG

Figure4–OCEANTOWERCNGstandardmodels

TATSUNOEUROPEa.s.,www.tatsuno‐europe.com

14

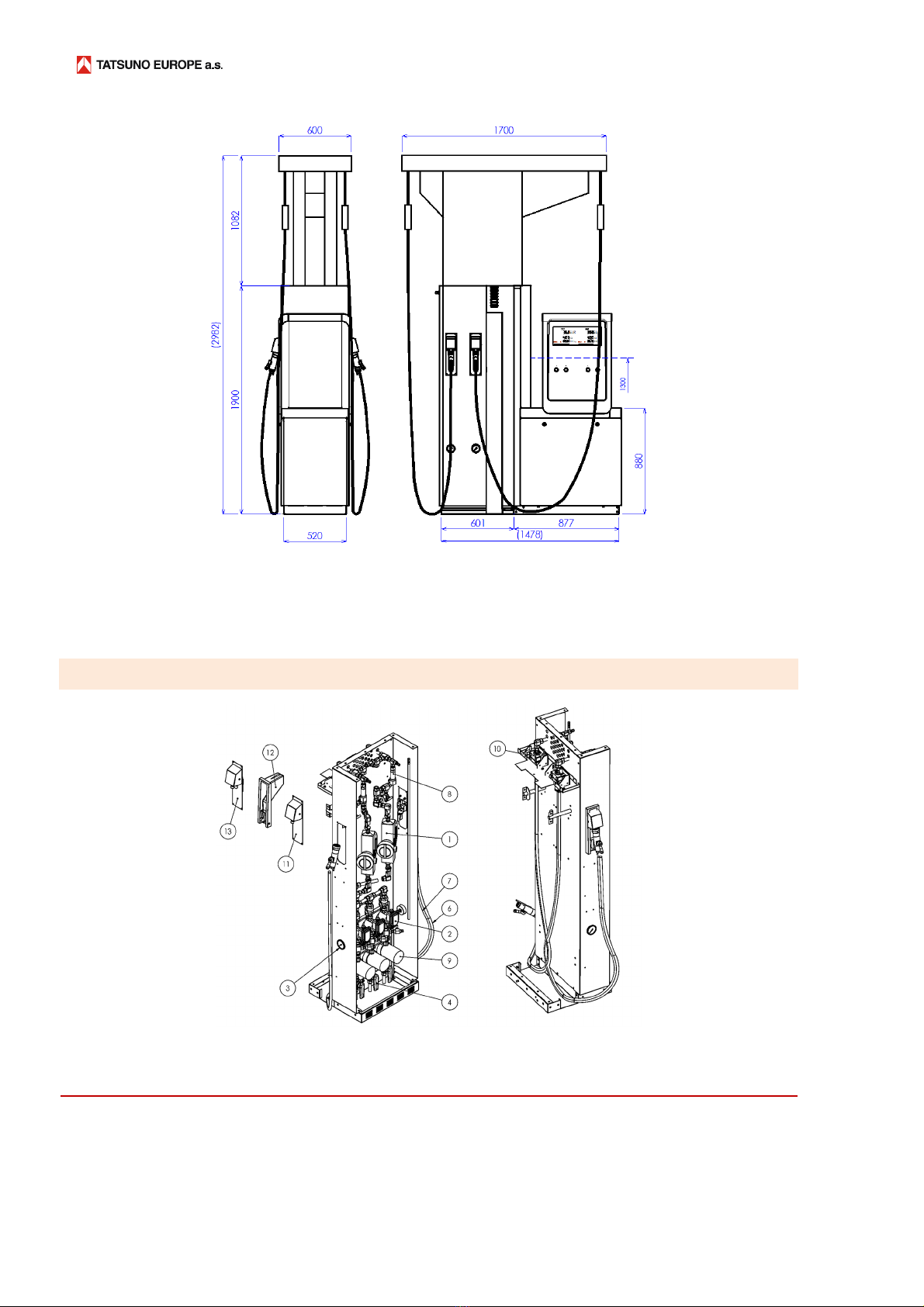

BMP4024.OWD/CNG‐4C‐‐HE

Figure5–OCEANTOWERCNGdispenserwithfourindependentdispensinghosesNGV1andhoseextender(‐HE)

2.5. TERMINOLOGYOFBASICPARTSOFTHEDISPENSER

Figure6‐BasicpartsoftheWSEdispensingmoduleanditscover

PositionDevicePositionDevicePositionDevice

1CNGmassmeter6CNGhose,filling11Nozzlecover,stainless,withoutaswitch

2CNGelectromagneticvalve 7CNGhose,ventilating12Nozzlecover,plastic,withaswitch

3Manometer400bar8Pressuresensor13Nozzlecover,stainlesswithaswitch

4Inputballvalve9CNGfilter

5CNGnozzle(fillingend)10Breakawaycoupling

CNGdispensersTATSUNOEUROPE‐QuickUserGuide,revision01,March2022

15

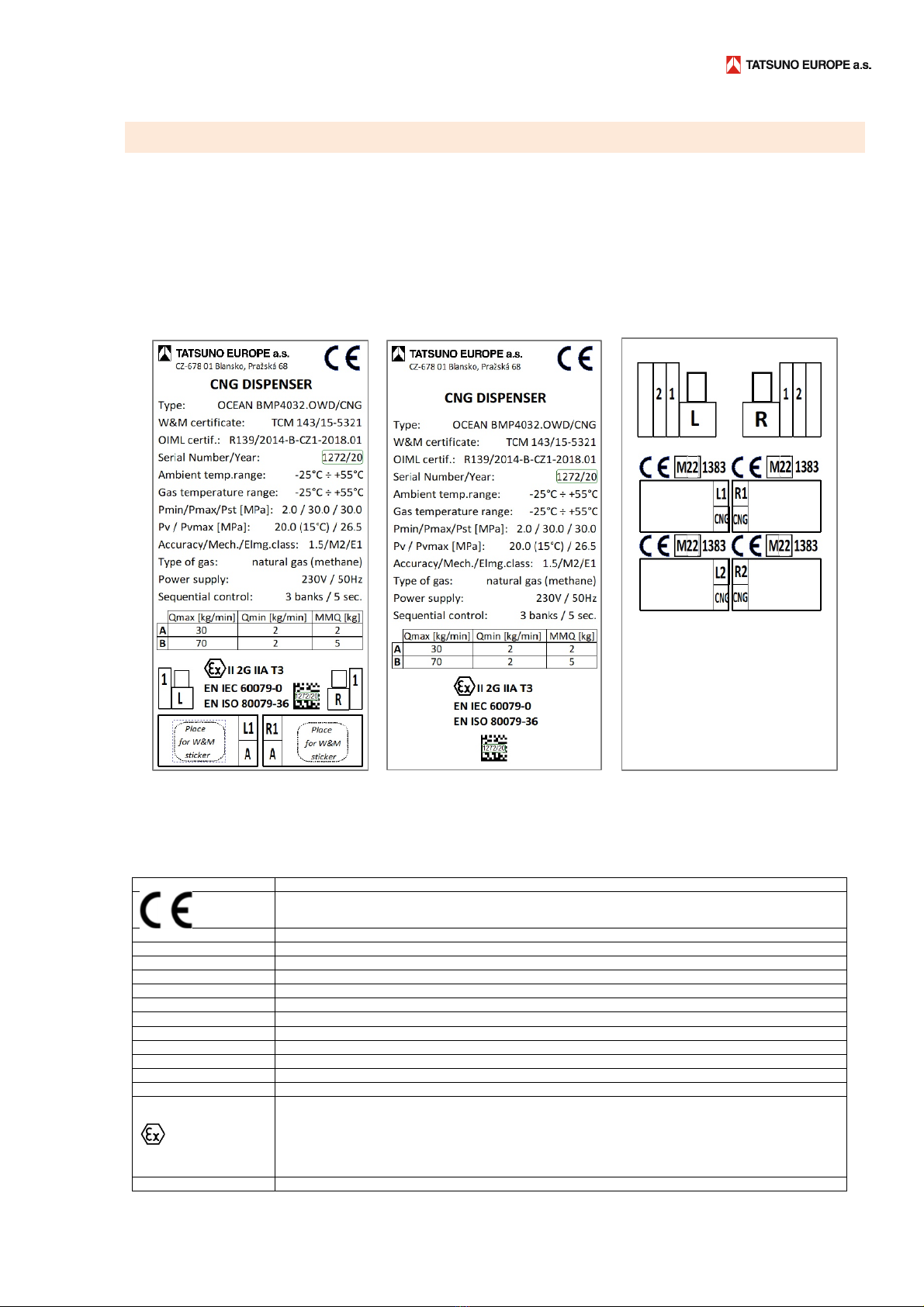

2.6. NAMEPLATES

Eachdispenserisequippedwithone,seeFigure7,orinthecaseofacombineddispenser,withseveralnameplatesfor

individualfuels,seeChyba!Nenalezenzdrojodkazů..Ifthenumberofdeliveryhosesishigherthantwothenthedispenser

issupplementedwiththeso‐calledorientationlabel,seeFigure9,whereitisschematicallyindicatedwhatkindoffuelis

pumpedandwithwhathose.AlldataonthedispenserintermsofmetrologyandsafetyaccordingtoWELMEC10.5and

Europeanstandardsforequipmentlocatedinpotentiallyexplosiveareas(EN13617‐1,EN14678‐1,ENIEC60079‐0andEN

ISO80079‐36)iscontainedinthenameplate.Atthesametime,theorientationlabelservestometrologyinspectionfor

stickingthesafetymetrologylabelsstatingtheexecutionofmeasuringsystemverification.

Table2‐Labelinformationonthedispenserandmodule

TATSUNOEUROPEa.s.Nameandaddressofdispensermanufacturer

Dispenserlabellingmeansthatitisdesigned,manufacturedandlabelledinaccordancewithEuropeanCommissiondirectives.

CNGDISPENSERDeviceidentification

TypeofMarkingofthedispensertype(seesection2.3)

OIMLcertificateNumberoftheOIMLcertificate

SerialnumberSerialnumberofthedispenser(seq.number/yearofproduction)

GastemperaturerangeRangeofgastemperatureforwhichthedispenserwasdesignedandapproved

AmbienttemperaturerangeRangeofambienttemperatureforwhichthedispenserwasdesignedandapproved

Pressuremin/maxMinimumandmaximumworkingpressure

Accuracyclass/mech/elm.Accuracyclass/Mechanicalclass/Electromagneticclass

CNGTypeofgasforwhichthedispenserwasdesignedandapproved

Q

max

Maximumpumping/fillingflowrateinkg/min

Q

min

Minimumpumping/fillingflowrateinkg/min

MMQ Minimumconsumptioninkg

II2GIIAT3

Identificationoftheprotectionofanon‐explosiveelectricaldevice:

II2–deviceforenvironmentwithanexplosionhazardotherthansubsurfacemines,probabilityofexplosiveatmosphere

occurrence–zone1

G–explosiveatmosphereisformedbygases,vapoursormists

IIA–gasgroup–theleastdangerous

T3–maximumtemperatureofanelectricaldevicethatcouldcauseignitionoftheambientatmosphere(200°C)

EN60079‐0;EN80079‐36NumberoftheEuropeanstandardunderwhichthedispenserwasapproved

Figure7‐Nameplateofatwo‐hoseCNG

dispenser

Figure8‐Nameplateofthemulti‐

hoseCNGdispenser

Figure9‐Orientationlabelfor

multiplehoseCNGdispensers

TATSUNOEUROPEa.s.,www.tatsuno‐europe.com

16

3. INSTALLATION

3.1. INSTRUCTIONSFOROCCUPATIONALSAFETY

CAUTION

Theinstallationofthisappliancemustbecarriedoutbyqualifiedpersonnelaccordingtotherelevantstandards,rules

andregulationsandlocalrestrictionsandaccordingtotheseinstructions.

Itisforbiddentosmokeoruseopenfireintheimmediatevicinityofthedispenser.

Alwaysfollowthemeasuresforhandlingofgasoline,diesel,LPG,AdBlue®,WSEandCNG

Observeallleaksinthedispenser.Ifanyleakageoffuel,mediaorgasoccursduetoanyuntightens,disconnectthe

supplyvoltage,andcontactaserviceorganization.

Theelectricalinstallationmustbecarriedoutbyqualifiedspecialists.

Ensurethataproperlyfunctioningfireextinguisherisavailable.

Whenhandlingoftheappliance,usesuitableprotectiveequipment.

3.2. RECEIPT,TRANSPORT,UNPACKING

Thecustomershallcontractuallyensurethemethodofdispensershipping.IfthetransportisensuredbyTATSUNOEUROPE,

a.s.,itshalltransporttheproducttoanagreedplace.Themanufacturerhassufficientknowledgeaboutthemethodof

handlingandtransport.Ifthetransportisensuredbythecustomerinanotherway,themanufacturershallensure

professionalloading.However,themanufacturerisnotresponsibleforthemethodoftransport.Itisgenerallystatedthat

thedispensermustbetransportedproperlypacked,alwaysattachedtotheframe.Thedispensermustbesecuredonthe

meansoftransportagainstdamage(covers,paint),shiftingandoverturning.Allhandlingandtransportshallbetotally

performedinaverticalposition.Thedispensermustnotbelaidoncovers.

WARNINGOnlyforklifttrucksmaybeusedduringhandling.IncaseofuseofotherhandlingequipmentTATSUNOEUROPE,

a.s.isnotresponsiblefordamagesuffered.

Packagingofdispensersisperformeddifferently,accordingtothedestination.

NOTICE

Incaseofpackingthedispenserintoabubblewrapthemaximumstorageperiodundershelteris3months,1

monthincaseofoutdoorstorage.

Incaseofpackingthedispenserintocardboardpackagingthemaximumstorageperiodundershelteris6months.

3.2.1. DISPENSERHANDLING

Thefollowingrulesmustbeobservedwhenloading,unloadingandsettingupthedispenser.

Useaforklifttohandlethefueldispenserfirmlyattachedtothewoodenpallet.Followthesafetyrulesdescribed

bytheforkliftmanufacturer.

CNGdispensersTATSUNOEUROPE‐QuickUserGuide,revision01,March2022

17

Figure10–Usingofaforkliftduringloadingandunloading

Whenunloadingandloadingthefueldispenserfromorintothetransportvehicle,usethedirectionfromtheside

ofthevehicle.Loadingfromtherearofthevehicleisdangerousandcandamagethevehicle,thestandandinjure

people(seefigurebelow).

Figure11–Permittedandforbiddendirectionofloadingandunloadingofthedispenser

(1‐transportvehicle,2‐dispenseronapallet,3‐forklift,4‐woodenpallet,5‐permitteddirectionofloadingandunloading)

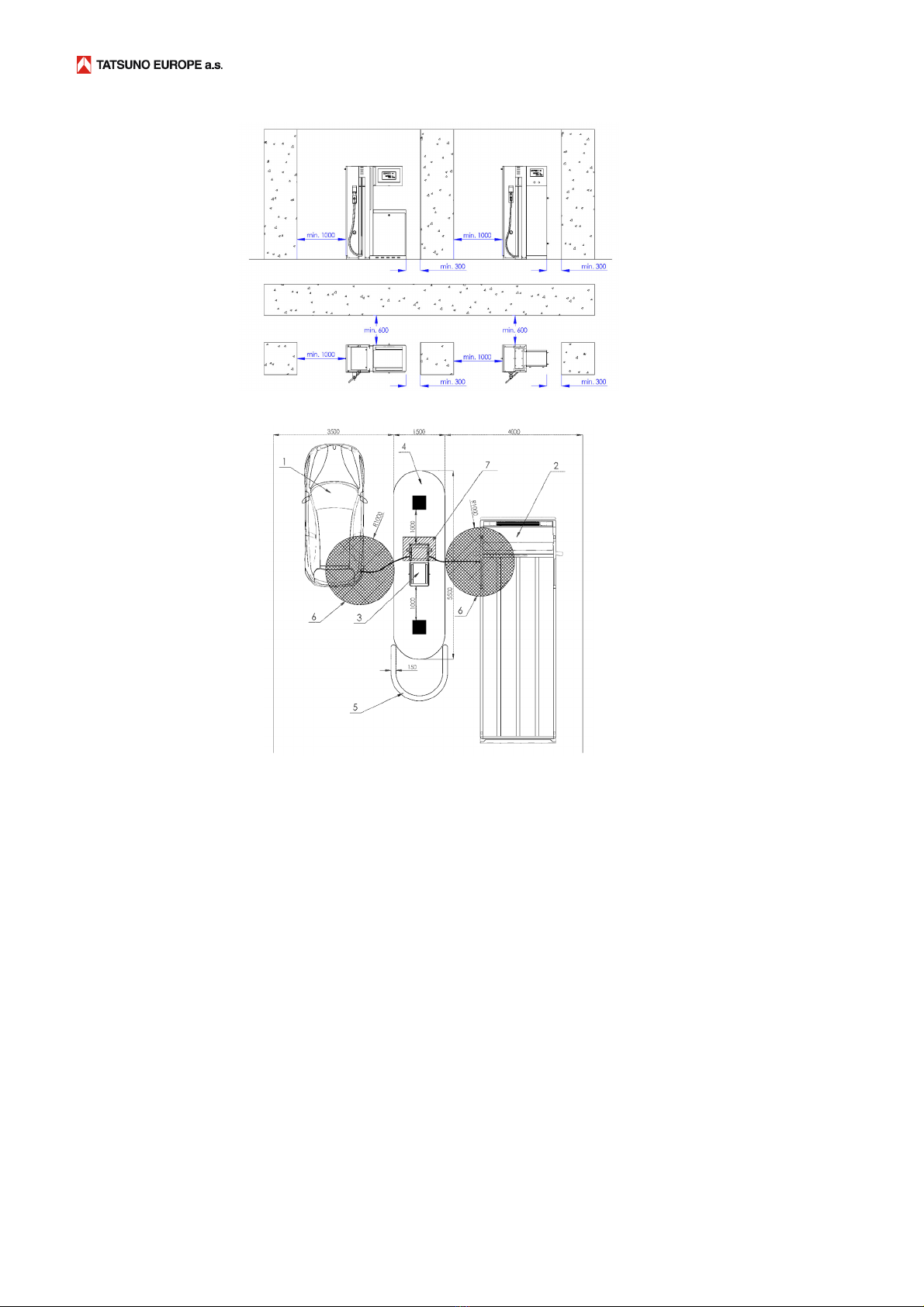

3.3. DISPENSERLOCATION

3.3.1. INGENERAL

Themanufacturerrecommendsplacingdispensersonsafetyislandsoffuelstationsinsuchawaythatthedirectionofarrival

ofthevehiclestothedispensercorrespondstotheorientationofthearrow,seeFigure1.Thesamefigureshowsthe

numberingofthedispenserproducts.Thespacefordispenserinstallationmustbestructurallysecuredsothatthe

possibilityofdispenserdamagebyanincomingcarandfollowingmediumleakageintoatmosphereisavoidedasbestas

possible.Therefore,itissuggestedto:

Securetheaccesstotherefillingpositioninstraightdirection

Installthedispenserontoanelevatedrefugewiththefollowingparameters

‐refugeelevationabovethesurroundingroadatleast150mm

‐refugewidthatleast1,500mm/refugelengthatleast4,000mm

Incaseofdispenserinstallationdirectlyontothesurfacewithoutarefugeitisnecessarytosecurethedispenser

againstcollisionwithavehiclebyusingatubeguardwiththefollowingparameters:

‐guardwidthatleast1,500mm(refugewidth)/length2,000mm

‐heightoftheupperedgeofthetubeabovetheroadatleast450mm

Exampleofthedispenserlocationatthefuelstation–seeFigure13.Ifthereisanyfixedobstacle(column,wall,etc.)nearby

thedispenser,theminimumseparationdistanceofthedispenserfromsuchobstaclesmustbeobservedduetosafe

operationandmaintenance–seeFigure12.

TATSUNOEUROPEa.s.,www.tatsuno‐europe.com

18

Figure12–Minimumrecommendedseparationdistanceofthedispenserfromafixedobstacle

Figure13–ExampleoftheCNGdispenserlocationatthefuelstation

(1‐refillingpositionforpassengercars,2‐refillingpositionfortrucksandbuses,3‐dispenserCNGdispenser,

4‐dispenserrefuge,5‐tubeguard,6‐projectionofthedangerouszoneborder(zone1)ofthefillingendpieceduringdelivery,

7‐projectionofthedangerouszoneborder(zone2)oftheCNGdispenser)

3.3.2. INSTALLATIONOFTHEDISPENSERSINTERMSOFEXTERNALINFLUENCES(DANGERZONES)

Dispensersforgaseousfuel(CNG)createdangerousareasattheinstallationsite‐zoneswhereundercertain

conditions(highsurfacetemperature,flame,electricspark…etc.)thefuelorfuelvaporcouldigniteorexplode.

Beforeinstallingthedispenseratthefillingstation,thefollowingmustbetakenintoaccountinparticular:

whatdangerzonesthedispensercreateswithitsoperation

whatdangerzonesarecreatedbythesurroundingequipment(adjacentdispenser,storagetank,etc…)

Hazardousareas(zones,areaswithariskofexplosion)aredeterminedaccordingtoEN60079‐10‐1.ForCNG

dispensersthedispenserzonesarealsoregulatedbytheENISO16923.Drawingsofthezonescreatedbythe

dispenserarepartofthemandatorydocumentationofthedispensermanufacturer,seedocumentsIN041‐ML

InstallationplansIandIN043MLInstallationplansII.Thedrawingofthezonesmustdefinethespatialdistribution

ofthehazardousareasinsideandoutsidethedispenser‐seetheexampleinthefigurebelow,wherehazardous

zone2(simplyhatched)occursuptoadistanceof20cmverticallyand5cmhorizontallyfromthecontourofthe

dispenser.Insidethedispenser,inadditiontothemeterhousing,thereiszone1orzone0(insidethevapour

CNGdispensersTATSUNOEUROPE‐QuickUserGuide,revision01,March2022

19

recoverypipes).Allelectricalandnon‐electricalequipmentlocatedinthesezonesmustbedesignedandapproved

forthishazardousenvironment(ATEXcertificate,documentationarchiving…).

OCEANTOWERCNGOCEANSMARTCNG

OCEANEUROCNG

Figure14–ExampleofdrawingthedangerzonesoftheOCEANCNGdispenseraccordingtoEN60079‐10‐1aENISO16923

(0‐zone0;1‐zone1,2‐zone2;3‐non‐explosivearea)

CAUTIONTATSUNOEUROPEliquidorgaseousfueldispensersmustnotbelocatedinthedangerzone.Theelectronic

countersusedinthesedispensersareseparatedfromotherareasbyatype1partitionaccordingtoEN13617‐1,theyareinan

uncovereddesign(IP54/IP55)andmustthereforebelocatedinanon‐explosivearea.

3.3.3. ORIENTATIONOFASINGLE‐SIDEDDISPENSER

Single‐sideddispenserstandsarelabelled"L"and"R"("L"left/left‐sidedand"R"right/right‐sided)afterthedispensertype

designation,e.g.,BMP4011.OWL/CNG,seesection2.3.Dispenserorientationisdeterminedbyaviewofthedispenserfrom

thevehiclearrivaldirection,seeFigure1.

3.4. MECHANICALATTACHMENTOFTHEDISPENSER

Dispensersareattachedtospecialfoundationframesbyusinganchorboltsuppliedwiththedispenser.The

foundationframeofthedispenserisnotapastofdispenserstandardequipmentbutmaybeorderedseparately.

TATSUNOEUROPEa.s.,www.tatsuno‐europe.com

20

Thefoundationframeisconcretedintothesafetyisland,thenthefrontandrearcoversofthedispenserare

removed,thedispenserisplacedontothefoundationframeandattachedbyanchorbolts.Thenthedispenseris

connectedtothepressurepipelinewith.DocumentIN041‐MLInstallationplansIshowsthefoundationframesand

foundationplansofalltypesofdispenserswiththeindicatedpositionofthepressurepipelineandthepipelinefor

extractinggasfromdispensernozzles.InthecaseoftheCNGdispenser/module,theinletpipelineoftheouter

diameterø12mm(standarddelivery)orø16mm(higherdelivery/H)isinsertedtotheinterconnectingthreaded

jointwithascrewringlocatedundertheballshut‐offvalveonthedispenserandthenthethreadedjointistightened.

Theinletpipelinemustbefittedwithshut‐offvalvesbeforeitsentrancetotheshaftspaceunderthedispenser

forpotentialdisassemblyofthedispenser.

CAUTIONJointdesignmustensureperfecttightnessuptothepressureof400bar.

CAUTIONTheinletpipelineofthedispensermustbesecuredbyoverpressureprotection(overpressurevalve,etc.)

againstpressurehigherthanthepermissiblemaximumoperatingpressure.

3.5. ELECTRICALCONNECTIONOFTHEDISPENSER

ForelectricalconnectionofTATSUNOEUROPEdispensers,itisnecessarytoperformprotectionagainsttouchvoltage

accordingtoaninternationalstandardHD60364‐4‐41:2017,andapplicableelectricalcablesmustbethenroutedto

eachdispenser.Itisnecessarythatalldispensersatthefuelstationareinterconnectedbyagroundingwireand

connectedtothegroundingsystem.Asagroundingwireyoucanuseayellow‐greencablewithasectionofatleast

4mm2oraspecialgroundingstrap.Thegroundingwiremustbeconnectedtoacentralgroundingterminalofthe

dispenserlocatedonthefoundation(boltM10)markedwithamarkforgrounding.

CAUTIONOnlycablescomplyingwiththerequirementsofEuropeanstandardEN13617‐1:2012maybeusedassupply

cables.Theessentialpropertiesofthesecablesincluderesistancetooils,gasoline,andgasolinevapour(accordingtoHD21

13S1).ExamplesofelectricalwiringaregiveninIN041–Connectionplans.

Intermsofusedvoltageandfunctionthecablesmaybedividedintopower(supply)andsignalcables.

Powercables:

supplyofcounters,switchingcircuits

switchingofvalveslocatedoutsidethedispenser(controlofpressuresectionvalves)

Signalcables:

communicationline

additionalserviceandsafetylines(STOPsignal,collectiveerrorsignal,etc.)

Table3–Cablecharacteristics

CabletypeFunctionNumberofwiresDAnom[mm]

H05VV5‐F3x1.5counterpowersupply37.4–9.4

H05VVC4V5‐K5x0.5dataline510.1

H05VV5‐F2X0.5collectiveerrorsignal25.9

H05VV5‐F5G1.5controlofpressuresectionvalves59.1–11.4

Legend:DAnom‐cableouterdiameter

NOTICECablebushingsM20x1.5andM25x1.5inanexplosion‐proofdesignwithprotectionExII2GExeIIandIP65are

usedinthedispenserdistributionboxes.Thesebushingshaveacablediameterrange(Danom)of7.0mmto13.0mm(M20)

and11.0mmto17.0mm(M25).Itisforbiddentousecablesthathaveadiameteroutsideofthepermittedbushingrange!

NOTICEPulseovervoltagemayoccurinanylineduetothestrikeoflightninguptothedistanceofseveralkilometresordue

toanyindustrialactivity.Thesizeofpulsesformedbylightninginductionissufficienttoatotaldamageofelectricalequipment.

Table of contents

Other tatsuno Dispenser manuals