5

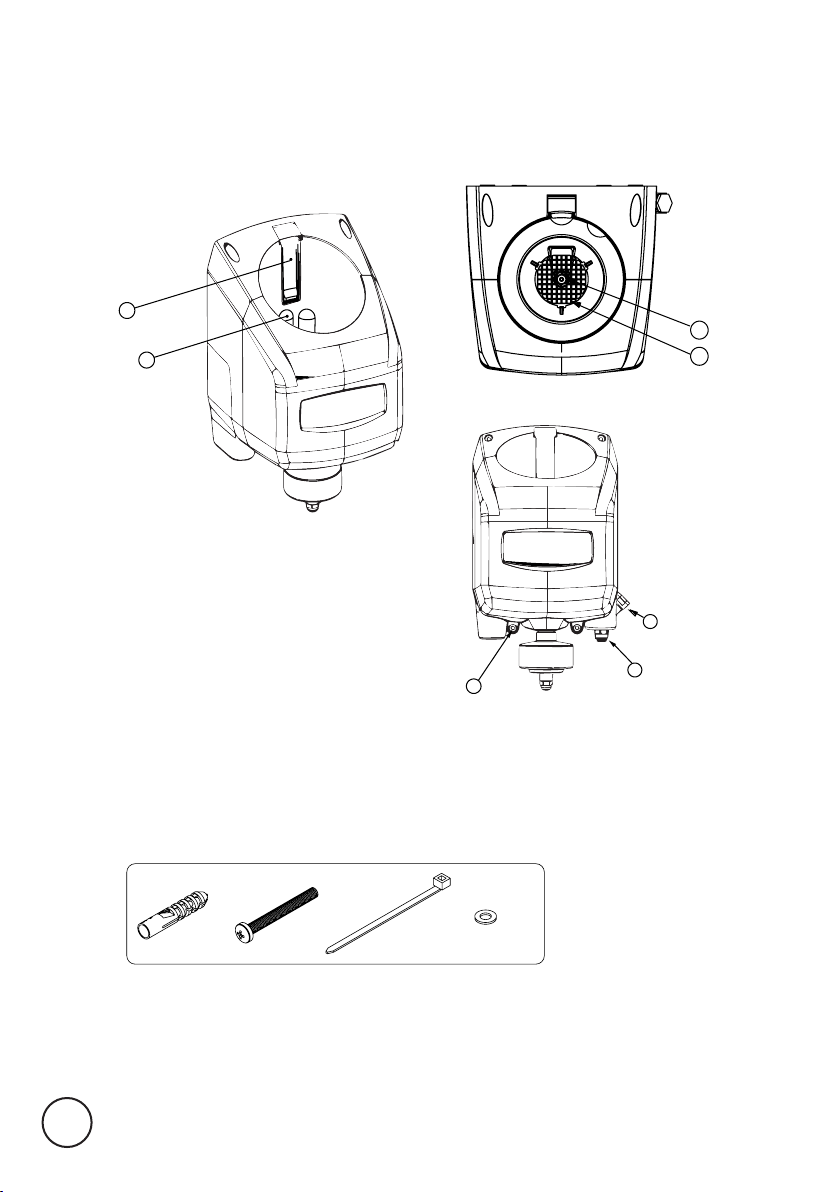

2. Installation

CAUTION Before an installation takes place it is

advisable to complete a site survey to ensure

the EvoRinse can be installed in a position that

meets all the requirements below.

CAUTION Do not install unit in an ATEX environment

WARNING Electrical installation should be completed

by a qualified electrician. All local and

national electrical regulations are to be

observed.

2.1 Site Survey & Installation Requirements

• Unit is to be installed by a trained technician; all local and

national water regulations are to be observed.

• Unit must be installed indoors, in an area that does not

suffer excess temperature changes, direct sunlight, frost or

precipitation of any kind.

• The area must be free of high levels of EMC disturbance.

• Ensue the unit is mounted in an accessible location, above

the height of the dishwasher detergent and rinse inlet

connections.

• Installer to ensure the suitability of the wall or mounting

substrate, which should be flat and perpendicular to the

floor.

• Unit location should be well lit for any maintenance, and

should be free of high levels of dust particulates.

• Scheduled maintenance should be carried out on the unit

at least once per year.

• It is a legal requirement that all water supply hose sets must

be compliant with IEC 61770.

• Ensure that the chemicals being used are compatible with

the tubing supplied. If you are unsure, please contact your

local distributor.