Chore-Time 52410-6 User manual

Introduction

The Chore-Time Water Regulator is designed to regulate water

pressure for Chore-Time Layer and Brood Grow Nipple

Watering Systems. There is a model for manual adjustment of

the regulator and one for PDS™ controller adjustment.

Installation Guidelines

Each water pressure regulator is capable of suppling one tier

(twolines)upto600’[182.8 m]. Systemsover600’[182.8m]

require two regulators per tier (one per line).

In Modular Manure Belt Brood Grow installations using air

drying tubes; two regulators per tier must be used no matter

what the cage row length. The air tube prevents water line

connection from one side of the cage row to the other.

The regulator assemblies should be mounted on one side of the

cage row. This location should be easily reachable from the

aisle for adjustment purposes and should not interfere with

other equipment (DBS system, manure belts, egg belts, belt

take ups, feeding system etc.). The regulator assemblies

should also be located so they are protected from damage.

Installation of the regulator assemblies should not be

attempted until the location of all other equipment is

established.

Theheight of the standtube/airbreathersmustalso be takeninto

consideration when positioning the regulator assemblies. It is

important to be able to maintain this height so the full

operating range of the regulator can be utilized.

It is important to install the regulator in a way that will allow the

assembly to be turned off the nipple pipe line. If removal is

necessary the stand tube/air breather will need to be removed

before turning the regulator off the nipple pipe line.

It is recommended to install the regulator assembly equal to or

slightly higher than the nipple water line. Installing the

regulator with this recommendation will aid in removal of

unwanted air in the system.

Single regulator installations (feeding two lines per tier) should

be plumbed so the output from the regulator flows through the

same number of restrictions (ells) to feed both lines. The same

number of restrictions will assure equal volume of water to

both lines. Equal volume of water is especially important in

brood grow installations so the flush times (from one line to

another) are close to the same.

In layer systems the connection between the regulator and the water supply inlet is made with a 3/4" [1.91 cm]

flexible hose assembly. This hose connects between the regulator and the water supply. The hose and connectors

must be of high quality and rated for the incoming water pressure.

In brood grow systems use the provided 5/8" x 36" [1.59 x 91.4 cm] regulator inlet supply hose. This hose connects

between the regulator and the water supply.

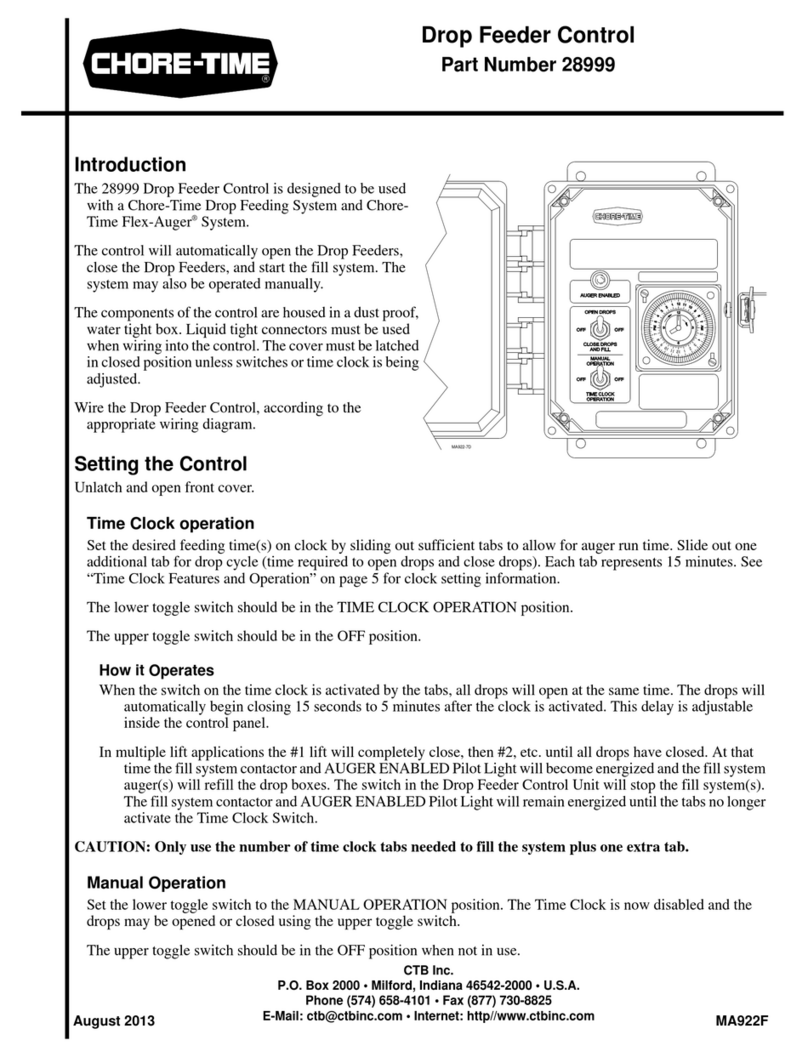

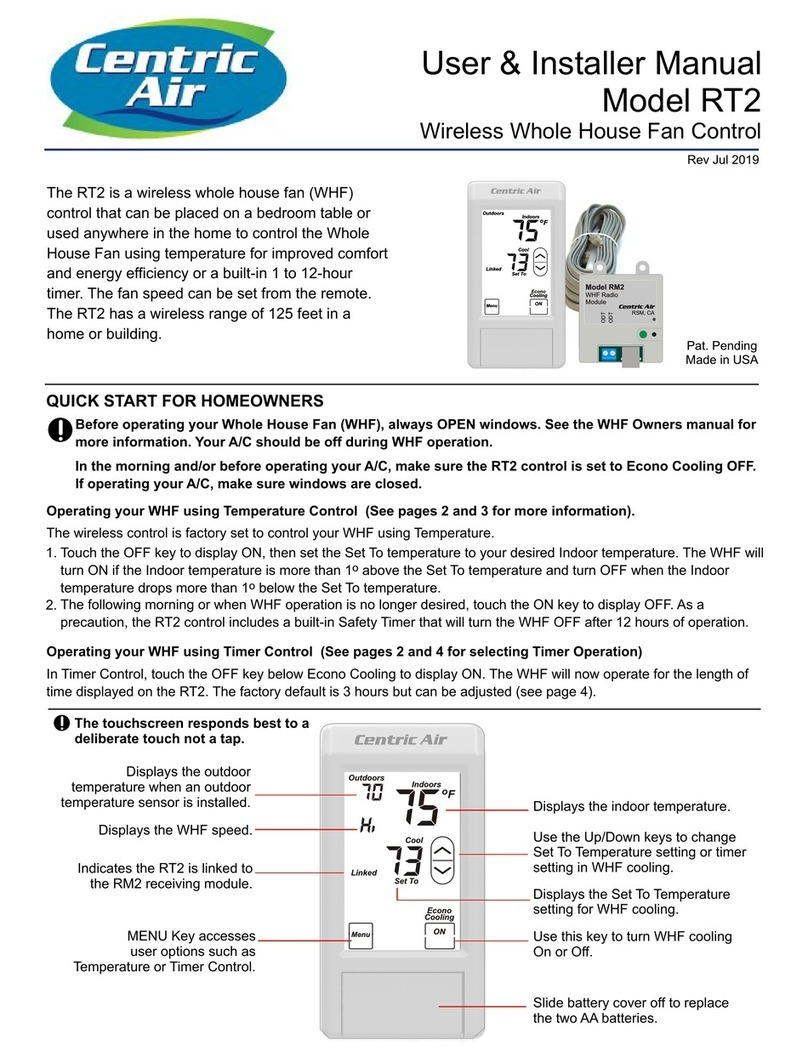

Under 600 Ft (182.9 M)

One Regulator Per Tier

Cage Row

Over 600 Ft (182.9 M)

Two Regulators Per Tier

Cage Row

WATER SUPPLY INLET

WATER SUPPLY INLET

Modular manure Belt (MMB)

One Regulator Per Tier

Cage Row

WATER SUPPLY INLET

Additional ells will be needed for routing

around and thru the manure belt framing.

8141 Ell 3/4" PVC SXS

8141 Ell 3/4" PVC SXS

8083 3/4" PVC Pipe

Supply Hose

Supply Hose

8083 3/4" PVC Pipe

Supply Hose

7558 Ell SxT

(Top or

Bottom Tier)

7558 Ell SxT

(Top or

Bottom Tier)

7558 Ell SxT

(Top or

Bottom Tier)

7538 Tee

SxSxT

7538 Tee

SxSxT

7538 Tee

SxSxT

7187 Hose

Clamp

50401 Hose

Adapter

7543 Nylon

Adapter

7543 Nylon

Adapter

7187 Hose

Clamp

50401 Hose

Adapter

7187 Hose

Clamp

50401 Hose

Adapter

7543 Nylon

Adapter

7538 Tee 3/4" PVC SXSXS

Figure 1. Layout Guidelines

Watering Regulator for Cage Systems

Manual Adjustment Part Number 52410-6

PDS™ Adjustment Part Number 52410-7

Chore-Time Poultry Production Systems, a Division of CTB, Inc.

P.O. Box 2000 • Milford, Indiana 46542-2000 • U.S.A.

Phone (574) 658-4101 • Fax (877) 730-8825

E-Mail: poultry@choretime.com • Internet: www.choretimepoultry.com MW1642DJune 2010

Watering Regulator for Cage Systems

2MW1642D

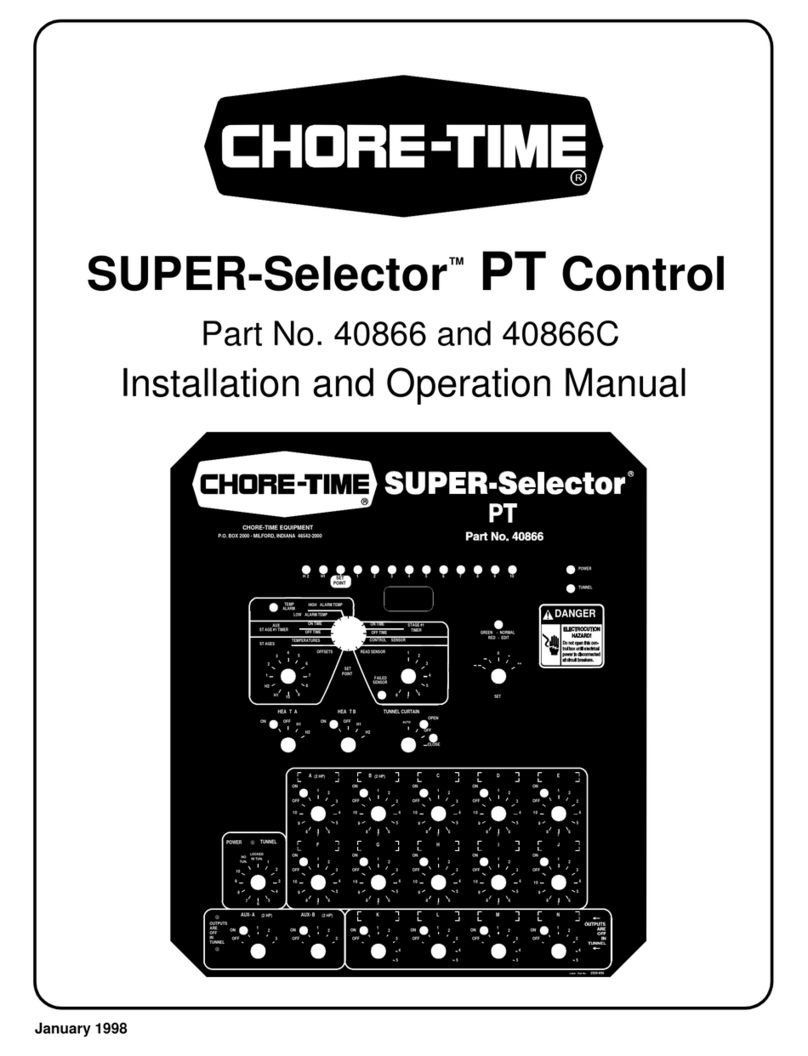

Dome Air Riser Installation

Layer and brood grow systems require one (1) dome air riser for every four (4) regulators installed per supply line.

Install the dome air riser between the high pressure water supply and regulator closest to the high pressure water

supply.

Multiple dome air risers if required: Install the second dome air riser close to the middle of the cage bank.

High Pressure Supply

To Regulators

High Pressure Supply

Can Be mounted Vertically or Horizontally

7719 Dome Air Riser

8061 Tee S x S x T

Figure 2. Dome Air Riser Installation Guidelines

Watering Regulator for Cage Systems

MW1642D 3

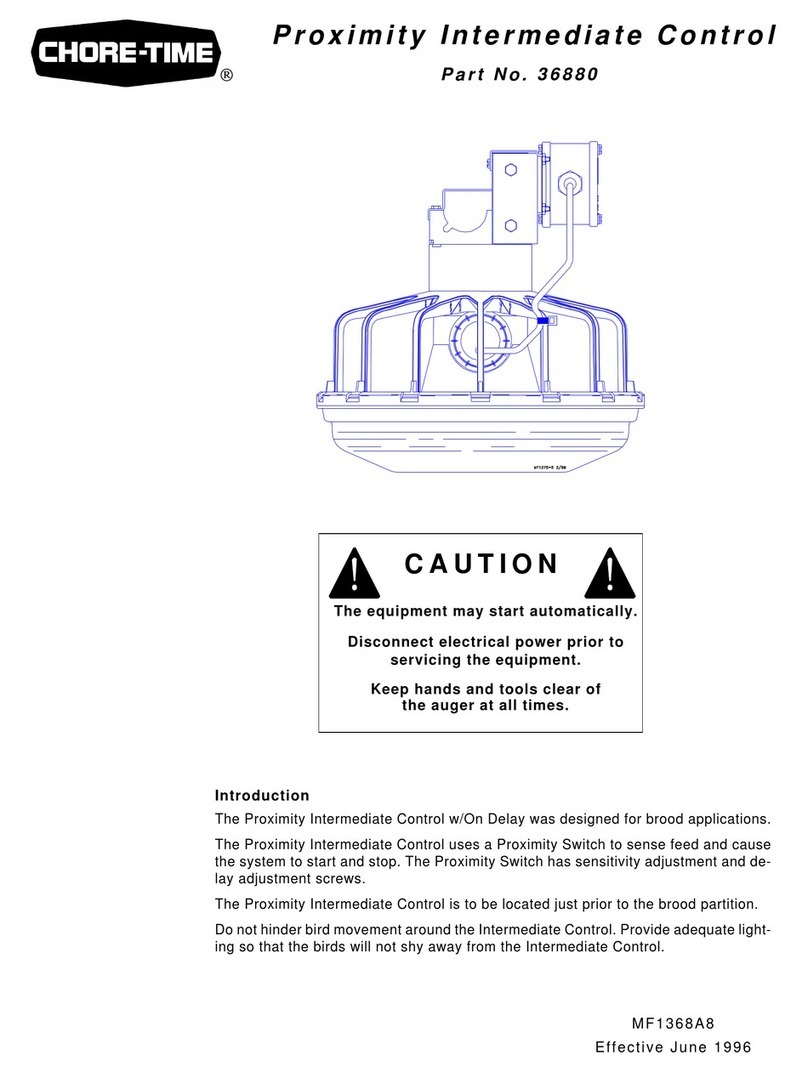

Regulator Assembly

•Do not overtighten fittings when assembling threaded connections!

•Do not allow glue to enter the 3/4" threaded inlet!

•Apply thread sealant tape or thread sealing compound to all threaded connections (except hose

threads) before installation.

Use only thread sealant tape or compound approved for ABS plastic on the

regulator’s fittings.

Failure to do so could result in damage to the regulator and will void the warranty.

Line Connection Components Installation

1.Install Male PVC Adapter into the 3/4" threaded outlet.

2.Glue 1.44" threaded PCV pipe to the 3/4" slip by

thread PVC elbow. Allow time for the glue to set

before installing to the 3/4" female threaded inlet.

3.Install glued assembly to the 3/4" female threaded

inlet. Be sure the elbow is properly oriented for

connection to the water supply.

Note: The 3/4" Male adapter may be installed directly into

the 3/4" threaded inlet when PVC elbow is not required.

4.Install nylon 3/4" hose adapter to 3/4" slip by thread

PVC elbow.

Stand Tube Installation

1.Place one (1) o-ring against the shoulder of the stand tube

outlet. Lubricate the o-ring with water or soapy water.

DO NOT USE PETROLEUM BASED

LUBRICANTS!

2.Push the stand tube assembly over the lubricated o-ring

until it hits the top of the regulator. Make sure the o-ring

is properly positioned.

3.Locate clamp below the o-ring and tighten. Make sure the

stand tube is secure but to not overtighten the clamp.

Water Supply Connection

After the regulator assembly is attached to the nipple line connect the regulator assembly to the water supply.

See Figure 1. for installation layout guidelines.

•Brood grow systems use a

5/8" [1.59 cm] flexible

hose assembly to connect

to the nylon 3/4" hose

adapter.

•Layer systems use a 3/4"

[1.91 cm] flexible hose

assembly to connect to the

nylon 3/4" hose adapter.

Recommendedincomingwater

pressure to the regulator

assembly: 30 to 35 psi max

[207 to 241 kPa max].

Apply Thread Sealant

or Teflon Tape

Glue Together BEFORE

Installing to Regulator

1642-116/2010

Male PVC

Adapter

1.44" Threaded

PVC Pipe

3/4" S x T

PVC Elbow

3/4" Hose

Adapter

3/4" Threaded

Outlet

3/4" Threaded

Inlet

Figure 3.Line Connection Components

Place o-ring

as shown Install tube clamp

below o-ring

Figure 4. Stand tube installation

1.44" Threaded

PVC Pipe

3/4" S x T

PVC Elbow

3/4" Hose

Adapter

5/8" Brood Grow

Supply Hose

3/4" Layer

Supply Hose

3/4" Female

Fitting

Hose

Clamp

To Regulator

Inlet

To Water

Supply

(3/4" Threaded Connection)

1642-13 06/2010

Figure 5. Water Supply Connection

Watering Regulator for Cage Systems

4MW1642D

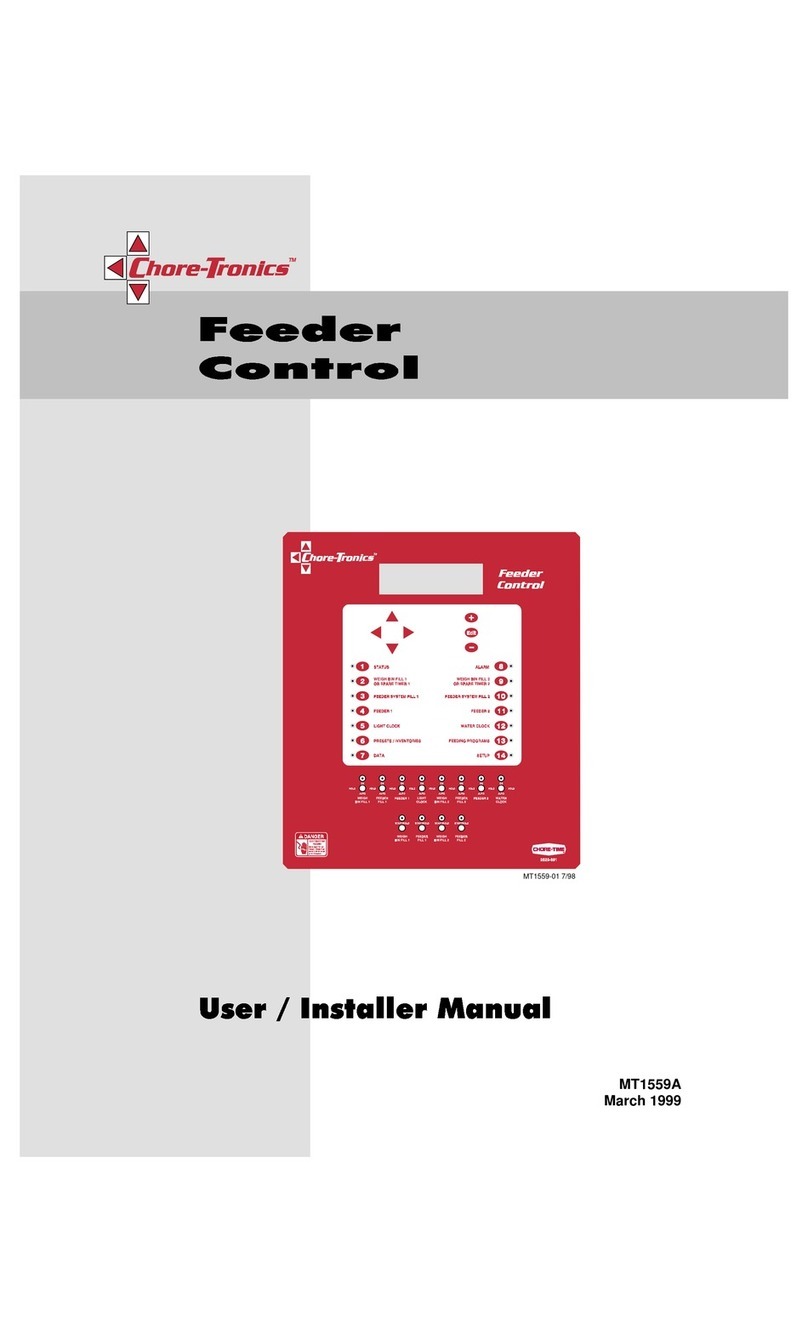

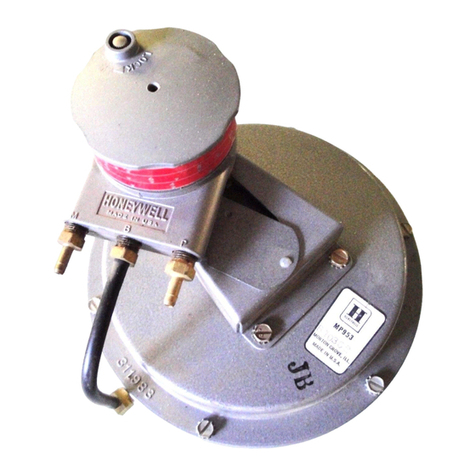

Regulator Operation

Recommended incoming water pressure to

the regulator assembly: 30 to 35 psi max

[207 to 241 kPa max].

Adjust water column by turning the knob on

the bottom of the regulator, see Figure 6.

STOP turning the

adjustment knob as soon as

resistance is noticed or damage will

occur.

Water column adjustment knob for PDS™

regulators is used to set a default water

column. This default will be the operating

water column in the event of an air pressure

loss to the PDS system.

Set the default water column with consideration of the bird age. Lower default water column should be used for

young birds so the nipple valves do not become hard to operate.

PDS Controllers CAN NOT adjust the operating water column below the set default water column.

Functional Modes:

There are three (3) selectable modes for operating the water regulator (OFF, REGULATE, and FLUSH). These

modes are selected by using the individual regulate and flush control knobs.

•PDS™ controlled regulators are to operate in the REGULATE mode.

•Flushing the system does not require turning off the regulate control knob.

DO NOT FLUSH DRINKER LINES WITH PDS™ CONTROL unless drinker lines are

pressurized with water! Product damage may occur if this caution is not followed.

•When flushing the system make sure the outlet line is clear of restrictions. Excessive back pressure can

damage the regulator.

Setting Functional Modes:

1.Rotate the control knob to free the latch.

2.Pull up on the control knob. Control knobs: UP position is ON and DOWN position is OFF.

3.Always lock the control knob into position by rotating knobs

into the shown positions, see Figure 8.

Water Column

Adjustment

FLUSH

Control Knob

REGULATE

Control Knob

Water Outlet

Water Inlet

Figure 6. Water Regulator

FLUSHOFF REGULATE

Figure 7. Functional Mode Settings

Figure 8. Control Knob Locked Position

Watering Regulator for Cage Systems

MW1642D 5

Parts List

*Items must be ordered separately.

**Item available in bulk lengths 47820-50 (50 Ft), 47820-100 (100 Ft), 47820-200 (200 Ft)

Manual Adjust

52410-6 PDS™ Adjust

52410-7 Manual Adjust

52410-6 PDS™ Adjust

52410-7

Item Description Part No Part No Item Description Part No Part No

1 #6 X 5/8" Screw 52025 52025 17 C-Clip 52028 52028

2 Bottom Housing 51558 52089 18 Mode Selection Knob 51560 51560

3 Adjustment Knob 51564 51564 19 Rigid Stand Tube Assy 52532-7 52532-7

4 Spring Support Plate 51563 51563 20 Hose Clamp 49529 49529

5 Spring 52031 52031 21 O-Ring 48325 48325

6 5/16-18 SS Nut 46764 46764 22 Blue Ball 37142 37142

7 Diaphragm Support 51562 51562 23 Breather Cap Assy 45703 45703

8 Diaphragm 51565 51565 24 3/4 x 1 7/16" PVC Pipe 7531-5 7531-5

9 Trigger 51561 51561 25 3/4 SxT PVC Ell 7558 7558

10 Male PVC Adapter 9229 9229 *26 3/4" Female Fitting 50401 50401

11 Top Housing 52088 52088 *27 Hose Clamp 7187 7187

12 Seat 52027 52027 28 3/4" Hose Adapter 7543 7543

13 Ball 52026 52026 *29 5/8 x 36" Supply Hose 50800-2 50800-2

14 Valve Body Gasket 51566 51566 30 1/4" PDS Tube Conn. --- 50820

15 Valve Body 51559 51559 31 O-Ring --- 52030

16 O-Ring 52029 52029 **32 3/4" ID Supply Hose 47820-0 47820-0

1

2

3

4

5

6

7

8

9

12

13

14

15

16 17

16

18

1

2

30

3

31

PDS™

REGULATOR

19

23

22

21

20

To Water Supply

Brood Grow System

Layer System

10

24

25

28

29

26

11

1642-12 6/2010

27 32

MADE TO WORK.

BUILT TO LAST.®

Contact your nearby Chore-Time distributor or representative for additional parts and information.

CTB Inc.

P.O. Box 2000 • Milford, Indiana 46542-2000 • U.S.A.

Phone (574) 658-4101 • Fax (877) 730-8825

E-mail: poultry@choretime.com • Internet: www.choretimepoultry.com

Printed in the U.S.A.

This manual suits for next models

1

Table of contents

Other Chore-Time Controllers manuals