Chris King GripNut User manual

GripNut™

Congratulations! You have just pur-

chased what many people regard as the

finest headset in the world. Since 1976

Chris King has been supplying serious

cyclists with the best made, most reliable

headsets you can buy. With proper in-

stallation and maintenance you can ex-

pect to enjoy the many years of the leg-

endary quality and performance built into

each and every component we make.

Installation

Please Note: To ensure proper installa-

tion, adapter kits are recommended.

Sizes are available to fit all popular head-

set pressing and setting tools. Our press

adapters help to correctly align the cups

with the head tube and prevent damage

to the bearings by directing pressure only

and evenly over the cups. The crown race

adapters prevent damage to the base

plate by protecting the conical bearing

contact surface from the crown race set-

ting tool.

Preparation of Head

Tube and Installation

of Bearing Cups

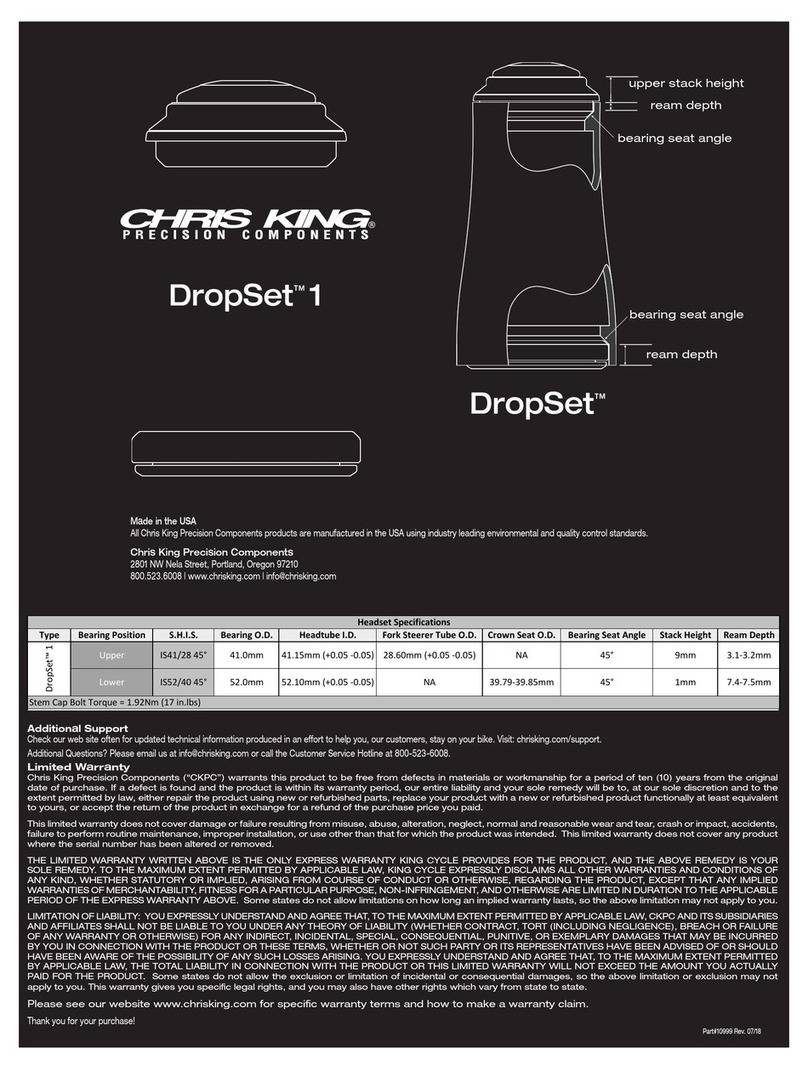

•Proper preparation of the head tube

is essential for best headset perfor-

mance. Ream and face the head

tube as necessary to ensure that the

ends are square and parallel to each

other, and the bores are the proper

dimension (see chart below).

•Using a small file or sand paper, care-

fully remove any sharp edges or

burrs and slightly round, or chamfer,

the inside edges of the head tube at

the top and bottom to prevent shear-

ing any metal from the cups during

installation.

•Clean to remove any chips, shavings,

and/or cutting oil.

•The proper press fit should be with

no more than .1mm (.004") of inter-

ference. See chart below for correct

head tube bore size. Do not file or

otherwise remove material from the

cups to make them fit.

•Press in both bearing cups using a

headset installation press fitted with

our adapters. Check to assure the

cups are seated flatly against the

ends of the head tube.

Preparation of Fork

and Installation of

Base Plate

•Proper preparation of the fork is also

important for best headset perfor-

mance. Ream and face the crown

race seat as necessary to ensure that

the face is square with the steer tube

and the press diameter is the proper

dimensions (see chart below).

•Clean to remove any chips, shavings,

and/or cutting oil. The proper press

fit should be with no more than .1mm

(.004") of interference. See chart be-

low for correct crown race seat size.

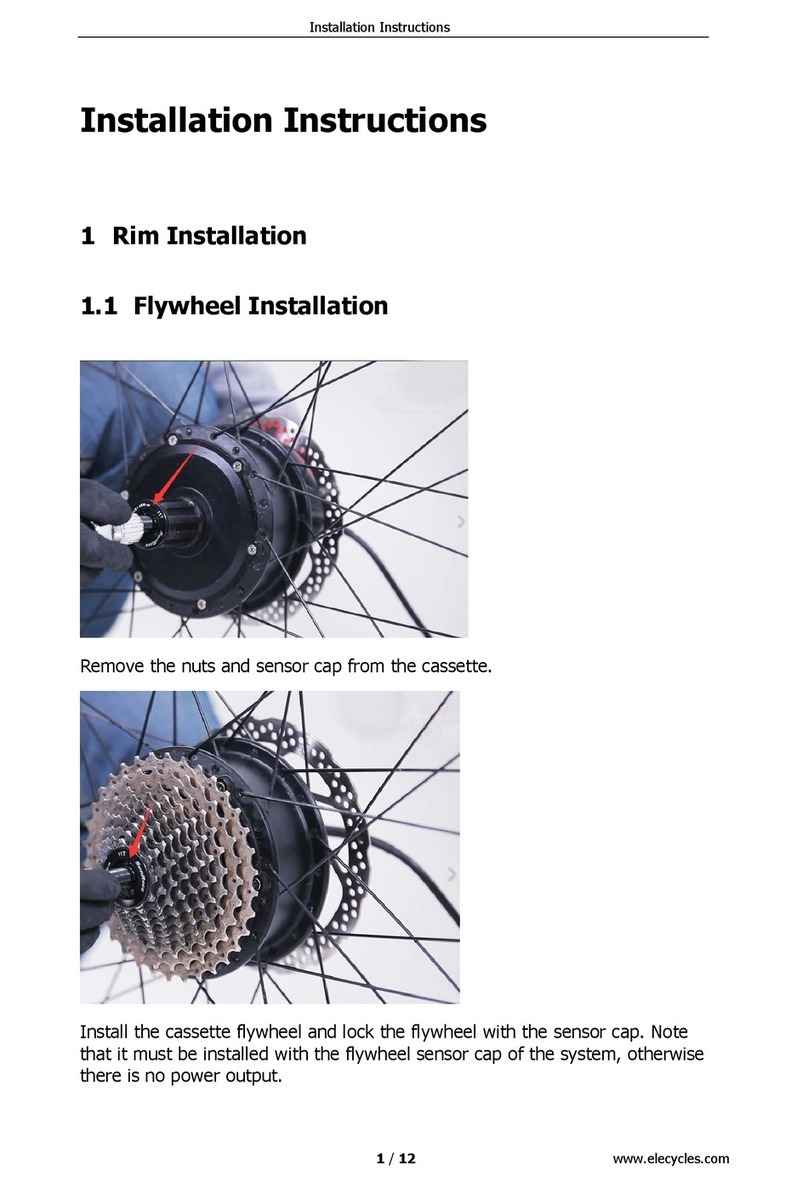

•Slide the base plate, conical side up,

onto the steerer tube. With the bev-

eled side of the base plate installa-

tion adapter against the base plate,

use a crown race setting tool to set

the base plate.

•When sizing the steerer length,

steerer tube should protrude 11-

14mm above the top of the top bear-

ing cup.

Assembly of Chris

King GripNut™

•Make sure the threads on the lock

ring and the inside thread of the ad-

justing ring are lubricated thoroughly

with an anti-seize compond or heavy

grease. Also apply grease to the ta-

pered surfaces of the threaded collet.

•Place the threaded collet into the

threaded hole of the adjusting ring,

positioning the key on the collet in

the corresponding slot.

•Screw the lock ring into the adjust-

ing ring/collet assembly until the

collet has very little float inside the

assembly.

Final Assembly and

Adjustment

•Once the GripNut™ is securely on the

steerer (about 4-5 turns and at least

1/8" prior to contacting the bearing),

tighten the lock ring into the adjust-

ing ring until it feels as though the

entire GripNut™ assembly is dragging

as it turns on the threads.

•Once you feel this drag, advance the

entire GripNut™ assembly as a unit

down to touch the bearing (using

headset wrenches on both the lock

and adjusting ring if necessary).

•Adjust the preload on the bearing and

finish tightening the GripNut™ lock

and adjusting rings together to 130-

150 in/lb.

•To test GripNut™: Using both

wrenches, try to turn the GripNut™ as

a unit in the loosening direction. It

should be extremely difficult, if not im-

possible, to turn. If it turns easily,

continue to turn the entire unit 1/4 turn

in the loosening direction and re-

torque.

PLEASE NOTE: New seals will produce

some resistance in rotation for the first

50-100 hours of use. Avoid confusing

this with rubbing or binding that may re-

sult from improper installation or stems

that are not properly faced.

Maintenance

CHRIS KING HEADSETS are designed

to provide the maximum life of any head-

set with a minimum of maintenance. Be-

sides an occasional adjustment, the only

service necessary is an occasional clean-

ing and regreasing of the bearings. Riding

conditions will dictate how often to ser-

ebutdaeH erob taesnworC DO

"1 mm1.03mm5.62

XMB"1 mm7.23mm5.62

"8/1-1 mm9.33mm1.03

"4/1-1 mm9.63mm1.33

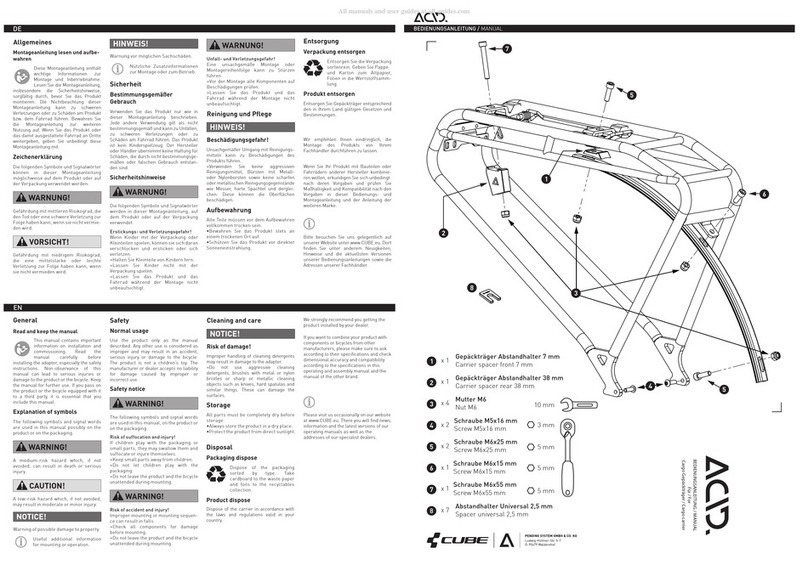

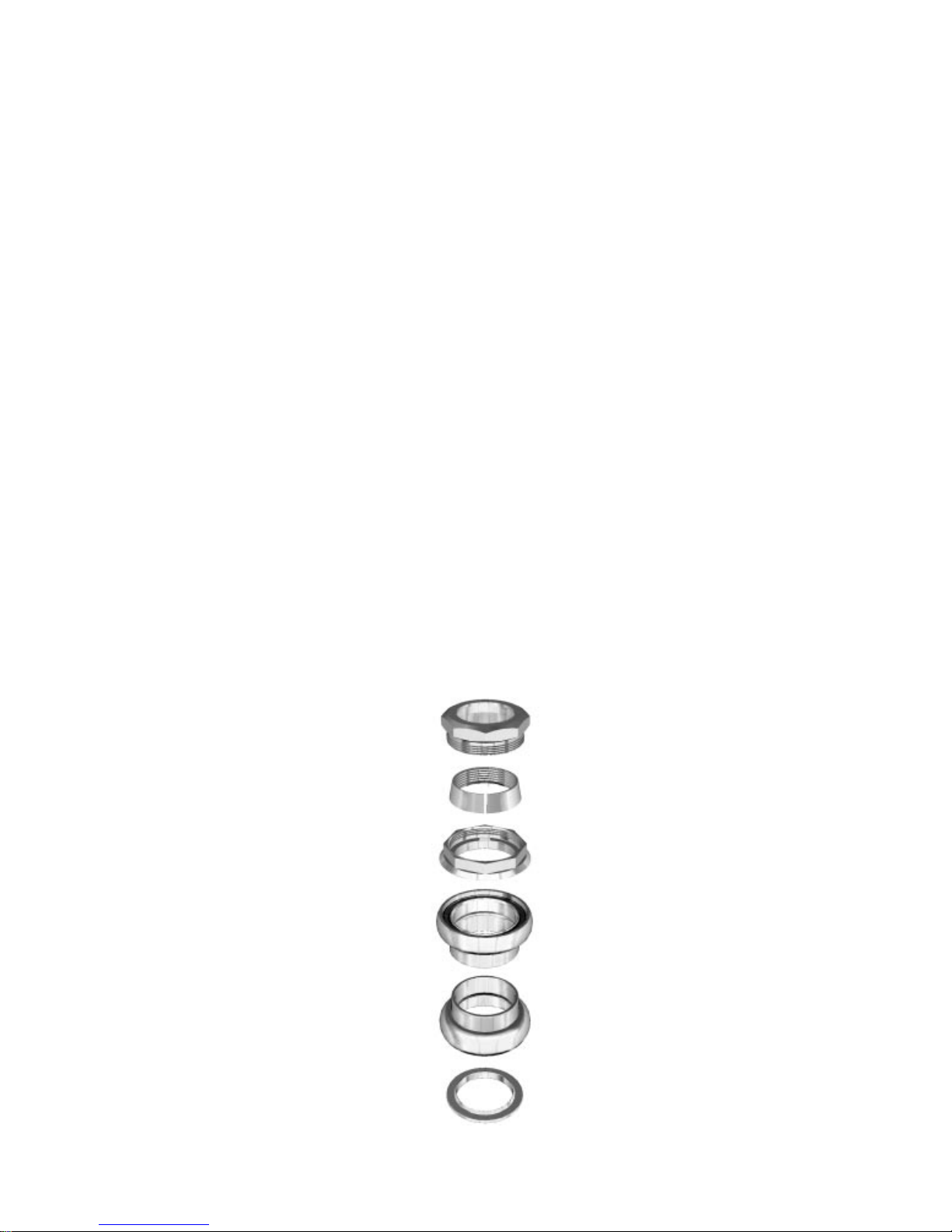

Lock

ring

Adjusting

ring

Base

plate

Bearing

cups

Thread

collet

vice your headset. In wet conditions, ser-

vice may be necessary as often as every

6 months; in dry conditions, up to every

5 years.

Service of Bearings

•Our sealed bearings have removable

snap rings holding the seals in place.

Carefully remove snap ring and then

seal to gain access to the bearings.

Flush with solvent, blow dry, then lu-

bricate with a waterproof grease and

reassemble. Reuse seals and snap

rings unless damaged.

•If necessary, seals and snap rings are

available through your dealer or di-

rectly from Chris King Precision Com-

ponents.

PLEASE NOTE: Water is the most com-

mon cause of problems with any sealed

bearing. When water enters the frame

through breather or other holes it can

eventually work its way to the head tube

and into the headset bearings. High pres-

sure spray wash, transporting or riding

the bicycle in the rain, or submersion in

water while riding can quickly lead to this

condition. Although the stainless steel

bearings will resist corrosion, the grease

will eventually deteriorate. Avoid these

situations if possible or service as if in

wet conditions.

Removal and

Reinstallation

•Remove cups from head tube with a

standard cup removal tool, taking

care that tool contacts the inside

edges of the cup, not the bearing.

•To remove base plate from fork, we

recommend using a 1/4" or 3/8" drift

punch

alternating strikes

on either

side of fork crown to lessen the pos-

sibility of warping or bending.

•After removing base plate from fork,

carefully inspect for damage. Some

warpage may flatten upon reinstalla-

tion. If not, or if bearing contact sur-

face has become damaged, replace.

•Base plates and other parts are avail-

able individually through your dealer

or directly from Chris King Precision

Components.

Warranty

Chris King Precision Components war-

rants its bicycle headsets to be free from

defects in materials or workmanship for

a period of 10 years from the original date

of purchase. Any Chris King product that

is found by Chris King Precision Com-

ponents to be defective in materials or

workmanship will be repaired or replaced

at the sole discretion of Chris King Preci-

sion Components providing it is returned

to the factory freight prepaid. This war-

ranty does not cover damage or failure

resulting from misuse, abuse, alteration,

neglect, normal and reasonable wear and

tear, crash or impact, failure to perform

routine maintenance as instructed, or use

other than that for which the product was

intended.

If a defect is found, our entire liability and

your sole remedy shall be, at our option,

free repair or replacement. Chris King

Precision Components shall not be held

liable for any indirect, special, or conse-

quential damages. The warranty does

not cover any Chris King Precision Com-

ponents product where the serial num-

ber has been altered or removed. This

written express warranty is in lieu of all

other warranties, implied or expressed,

and does not cover any representation

or warranty made by dealers beyond the

provisions of this warranty. This warranty

gives you specific legal rights, and you

may also have other rights which vary

state to state.

Thank you for your purchase!

KING CYCLE GROUP

2801 NW Nela Street

Portland, Oregon 97210

800.523.6008

http://www.chrisking.com

email: [email protected]

Rev. 3/04-A

Table of contents

Other Chris King Bicycle Accessories manuals