3

Thanks for buying our Electric Bike Pump!

You’re now the proud owner of the Saris Infrastructure Electric Bike Pump, a modular ramp system designed for users

to easily transport their bikes up and down stairs.

The Electric Bike Pump is made in the USA, and features an aluminum ramp channel. The stock length of channel is 8

feet. The channel is easily cut to length. For installations up to 16 linear feet, two sections of the channel are used. The

second channel is cut to size and attached to an uncut 8’ section of ramp using the joining biscuit assembly.

High strength aluminum end cap modules are provided with the system. They bolt on to the ends of the ramp and pro-

vide a smooth transition on and off the Electric Bike Pump.

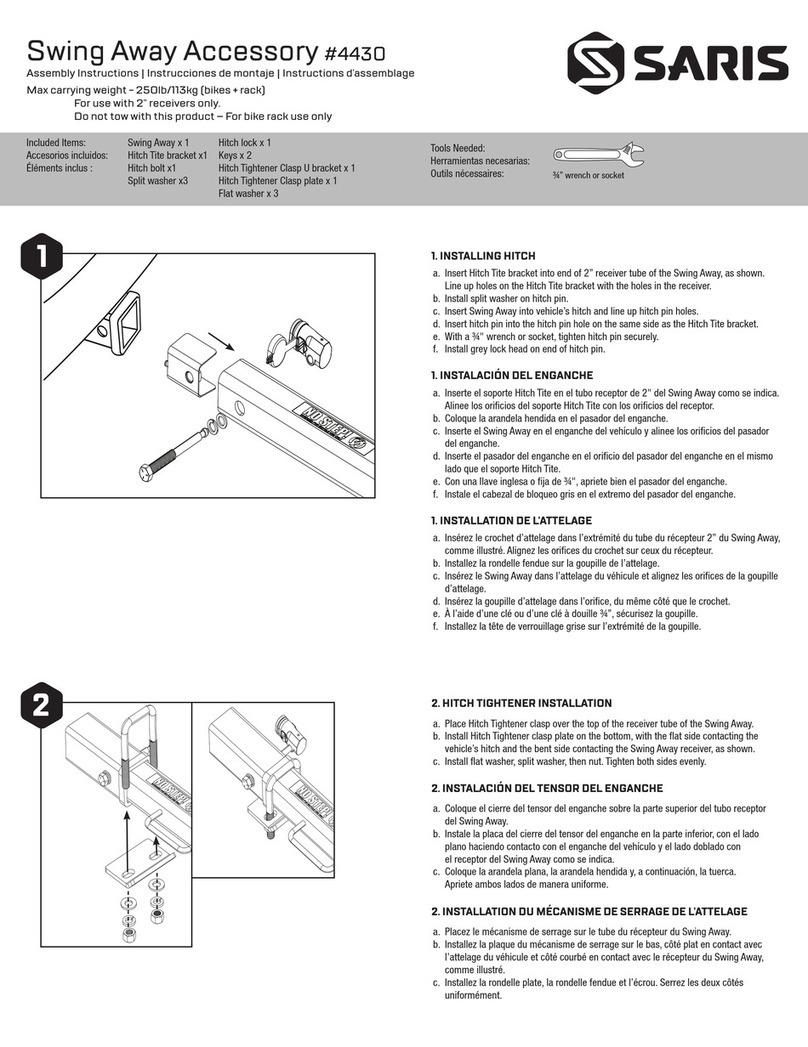

The Electric Bike Pump is attached to the stairs using a mounting bracket system. The mounting brackets pivot, allow-

ing a wide range of stair pitches to be accommodated. Brackets are bolted onto the stairs. Concrete anchors are pro-

vided with the system. If mounting to materials other than concrete, use an appropriate fastener for the base material.

Brackets are sized to accept ¼” fasteners.

Please read and understand these instructions before beginning installation.

Everyone

here

a

t

Saris

Infrastructure

want

you

to

be

happy

with

this

product.

Please

contact

us

(

[email protected],

608-

729-6243) should you need anything.

Now, let’s get started.