Christie Projectors 6 User manual

’Projectors 6 and 7’ Ruggedized Lens Components Installation Manual 1 of 25

020-100055-01 Rev. 1 (05/07)

‘Projectors 6 and 7’

Ruggedized Lens Components

Installation Manual

This document includes the procedures required to install the ruggedized lens components for

‘Projectors 6 & 7’ (Matrix 4000 M / 38-DSP104-09). Every effort has been made to ensure the

information in this document is accurate and reliable; however, due to constant research this

document is subject to change without notice.

This document includes:

•1 Ordering Parts

•2 Index of Parts and Modules

•3 Safety Warning and Guidelines

•4 Installation Procedures

2 of 25 ’Projectors 6 and 7’ Ruggedized Lens Components Installation Manual

020-100055-01 Rev. 1 (05/07)

1ORDERINGPARTS

When ordering replacement parts, provide the following information:

• Part Number (for each required item)

• Projector Model (see license label)

• Projector Serial Number (see license label)

• Manufacture Date (see license label)

Table 1.1 Technical Support Contact Information

* For the most up-to-date listings, refer to www.christiedigital.com

AVAILABILITY: Not all parts identified in this booklet are available separately. Some parts are

stocked as inventory and are available only until the current supply lasts.

AMERICAS

Canada

Toll Free: 1-800-221-8025

Tel: 519-744-8005

Fax: 519-749-2776

Monday to Friday

8:00am-8:00pm EST

Film Cinema: 714-503-3381

Monday to Friday

8:00am-5:00pm PST

USA

Toll Free: 1-800-221-8025

Tel: 519-744-8005

Fax: 519-749-3302

Monday to Friday

8:00am-8:00pm EST

Film Cinema: 714-503-3381

Monday to Friday

8:00am-5:00pm PST

Chile

Toll Free: 1-800-221-8025

Tel: 519-744-8005

Fax: 519-749-3302

Monday to Friday

8:00am-8:00pm EST

Film Cinema: 714-503-3381

Monday to Friday

8:00am-5:00pm PST

EUROPE, MIDDLE EAST AND AFRICA

United Kingdom

Support/Service Centre

Tel: +44 (0) 118 977 8111

Fax: +44 (0) 118 977 8112

Monday to Friday

8:30am-6:00pm CEST

Italy

eHome Italia Service

Tel: +39 (0) 2 9902 1161

Fax: +39 (0) 2 9902 2641

Monday to Friday

9:00am-6:00pm CEST

Middle East & Africa

Support/Service Centre

Tel: +44 (0) 118 977 8111

Fax: +44 (0) 118 977 8112

Monday to Friday

8:30am-5:00pm GMT

Germany

Support

Tel: +49 (0) 1749 9834 95

Fax: +49 (0) 2161 6645 46

Service Centre

Tel: +49 (0) 2161 56620 22

Fax: +49 (0) 2161 6645 46

Monday to Friday

8:30am-5:30pm CEST

Spain

Marcus Fernandez

Christie Spain c/o Esher

Tel: +34 91 633 9990

Fax: +34 91 633 9991

Mobile: +34 667 447 707

Monday to Friday

9:00am-6:00pm CEST

Eastern Europe

Support/Service Centre

Tel: +44 (0) 118 977 8111

Fax: +44 (0) 118 977 8112

Monday to Friday

8:30am-5:00pm GMT

France

Support

Tel: +33 (0) 1 47 48 28 06

Fax: +33 (0) 1 47 48 26 06

Service Centre

Tel: +33 (0) 1 47 48 28 88

Fax: +33 (0) 1 47 48 26 06

Monday to Friday

10:00am-6:00pm CEST

Hungary & Russia

Support/Service Centre

Tel: +44 (0) 118 977 8111

Fax: +44 (0) 118 977 8112

Monday to Friday

8:30am-5:00pm GMT

ASIA-PACIFIC

Singapore

Tel: +65 877 8737

Fax: +65 877 8747

Japan - Tokyo

Tel: +81 3 3599 7481

Fax: +81 3 3599 7482

China - Beijing

Tel: +86 21 6278 7708

Fax: +86 21 6278 7707

(Shanghai Office)

South Korea

Tel: +82 2 702 1601

Fax: +82 2 702 1602

China - Shanghai

Tel: +86 21 6278 7708

Fax: +86 21 6278 7707

’Projectors 6 and 7’ Ruggedized Lens Components Installation Manual 3 of 25

020-100055-01 Rev. 1 (05/07)

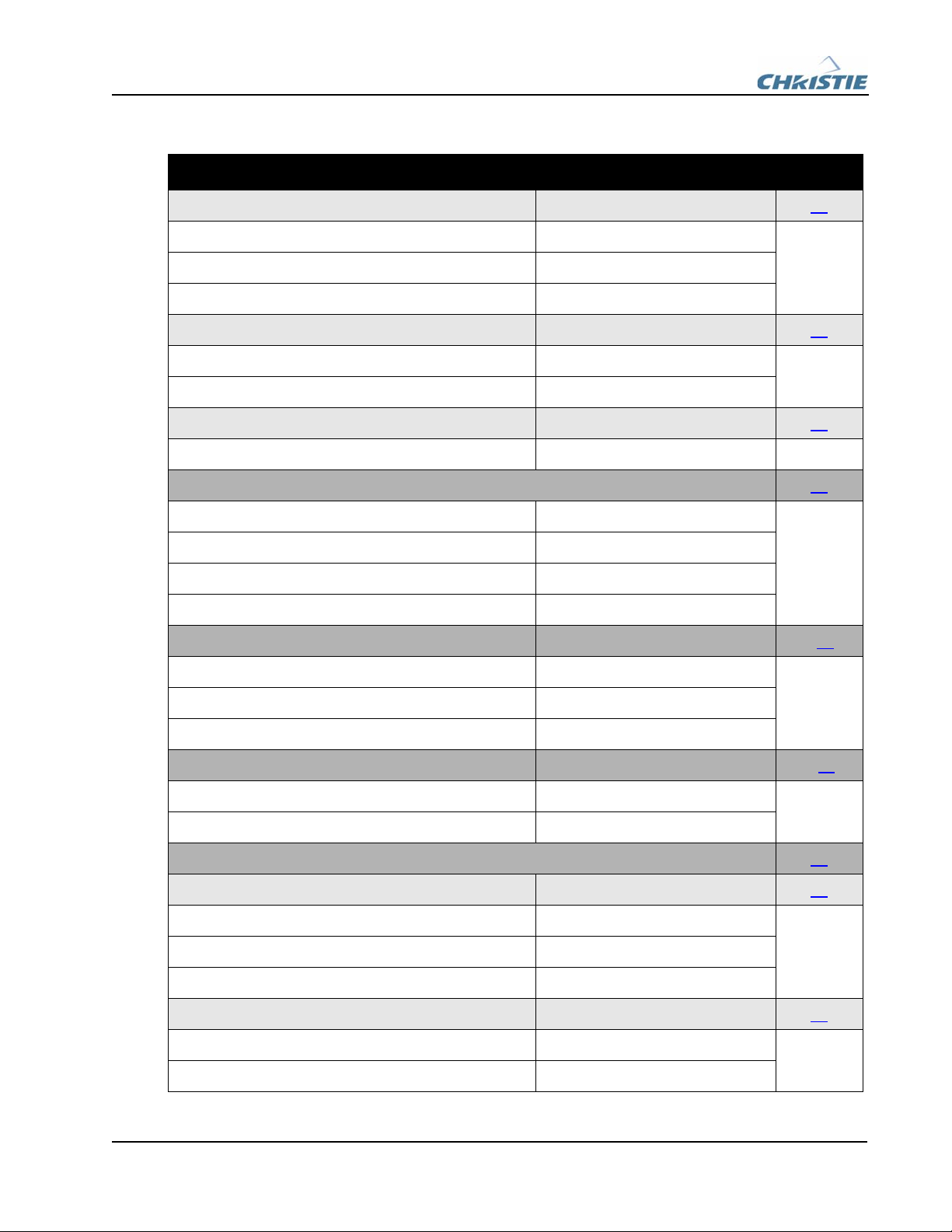

2 INDEX OF PARTS AND MODULES

provides a listing of all replaceable parts. Refer to the specific page number for the procedure

associated with the part.

Table 2.1 Index of Parts and Modules

PART/DESCRIPTION PART # PAGE #

Adjuster Plate Assembly M012231 8

• Base Plate M012063

• Nord Lock Washer (x7) Spaenaur #677-320

• Hex Socket Capscrew (x7) Spaenaur #366-774

• Plastic Base Plug M012899

Projector Mount 24

• Yaw Assembly M012230 24

• 3/4” Flat Washer Spaenaur #656-051

• 3/4-16 Hex Nut (x2) Spaenaur #SAN-14

• 3/4” Spherical Washer, Convex Spaenaur #656-256-RC

• 3/4” Spherical Washer, Concave Spaenaur #656-265-RC

• Hex Nut Safety Cap (x2) McMaster Carr #94818A036

• Standard Projector Corner Mount 24

• 3/4-16 Hex Nut (x9) Spaenaur #SAN-14

• 3/4” Spherical Washer, Convex (x6) Spaenaur #656-256-RC

• 3/4” Spherical Washer, Concave (x6) Spaenaur #656-265-RC

• Hex Nut Safety Cap (x9) McMaster Carr #94818A036

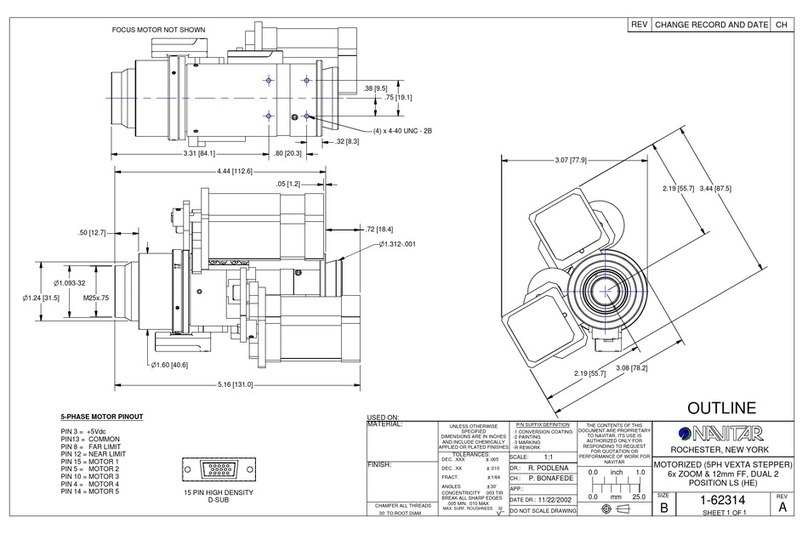

MotoBlend Brainbox Bracket M012512 9

• M6 x 12 SHCS (x2) Spaenaur #367-056

MotoBlend Brainbox Model #010-100876-01

M010105 9

• 5/16”-18 Hex Socket Button Head Capscrew (x2) Spaenaur #HX-270-RC

• 5/16”-18 Hex Nut (x2) #012-101081-01

Lens 1.2:1 Fixed #104-111101-01 11

Protective Lens Cap M012898 11

Lens Mount Assembly 1 13

4 of 25 ’Projectors 6 and 7’ Ruggedized Lens Components Installation Manual

020-100055-01 Rev. 1 (05/07)

Lens Support Base Plate 1 M012081 13

• SHCS M10 x 55mm (x2) Spaenaur #367-108

• M10 Washer (x4) Spaenaur #657-012ZP

• M10 Locknut (x2) Spaenaur #166-099

Lens Support Top Plate 1 M012080 14

• M10 Locknut (x2) Spaenaur #166-099

• M10 Washer (x2) Spaenaur #657-012ZP

Lens Support Ring 1 M012079 14

• M4 x 16 SHCS (x2) #012-100623-01

Focus Ring Lock Assembly 15

• Top Locking Bracket M012893

• Bottom Locking Bracket M012894

• M4 x 16mm SHCS (x2) #012-100623-01

• Thumbscrew M013665

Lens Shroud M013643 23

• Clips (x2) M013644

• Case Mounting Screws (x2) Existing Part

• 4-40 Black Phillips Panhead Screws (x2) #12-100278

Lens Mount Bracket M012226 16

• M10 Locknut (x2) Spaenuar #166-099

• M10 Washer (x4) Spaenuar #657-012ZP

Lens Mount Assembly 2 17

Lens Support Base Plate 2 M012084 17

• SHCS M10 x 55mm (x2) Spaenaur #367-108

• M10 Washer (x4) Spaenuar #657-012ZP

• M10 Locknut (x2) Spaenuar #166-099

Lens Support Top Plate 2 M012083 18

• M10 Locknut (x2) Spaenuar #166-099

• M10 Washer (x2) Spaenuar #657-012ZP

Table 2.1 Index of Parts and Modules

PART/DESCRIPTION PART # PAGE #

’Projectors 6 and 7’ Ruggedized Lens Components Installation Manual 5 of 25

020-100055-01 Rev. 1 (05/07)

Lens Support Ring 2 M012082 18

• M4 x 16 SHCS (x2) #012-100623-01

Bumper Bar M012892 19

• Clips (x2) M013337

• M10 Washer (x2) Spaenuar #657-012ZP

• M10 Locknut (x4) Spaenuar #166-099

1.2:1 Extension Plate M012226 16

• M10 Washer (x2) Spaenuar #657-012ZP

• M10 Locknut (x2) Spaenuar #166-099

MotoBlend Frame Assembly M012896 20

• MotoBlend Mounting Brackets (RH and LH) M012090 RH & M012090 LH

• M10 Washer (x4) Spaenuar #657-012ZP

• M10 Locknut (x4) Spaenuar #166-099

• Foam Block M014274

MotoBlend Actuators Model #010-100964-01 21

• 4-40-1/4 Flat Head Stainless Steel Screws (x6) McMaster Carr #394-67843

Filters (No Part Number: Custom Cut to Application) 22

Standoff Filter Mounting Hardware 22

• Flat Washer 1/4 ID x 5/8 O.D. #012-100501-01

• Star Washer Spaenaur #671-064

• 1/4-20 x 0.75 SHCS Spaenaur #HX-15

• Knob - Fine Ribbed Spaenaur #134-086

• Nylon Spacer Spaenaur #606-224

• 6-32 x 3/4 McMaster Carr Setscrew McMaster Carr #92695AI44

Flush Filter Mounting Hardware 22

• Flat Washer 1/4 ID x 5/8 O.D. #012-100501-01

• Star Washer Spaenaur #671-064

• 1/4-20 x 1/2 SHCS Spaenaur #HX-82

• Knob - Fine Ribbed Spaenaur #134-086

Table 2.1 Index of Parts and Modules

PART/DESCRIPTION PART # PAGE #

6 of 25 ’Projectors 6 and 7’ Ruggedized Lens Components Installation Manual

020-100055-01 Rev. 1 (05/07)

• 6-32 x 1/2 McMaster Carr Setscrew McMaster Carr #92695AI10

Table 2.1 Index of Parts and Modules

PART/DESCRIPTION PART # PAGE #

’Projectors 6 and 7’ Ruggedized Lens Components Installation Manual 7 of 25

020-100055-01 Rev. 1 (05/07)

3 SAFETY WARNING AND GUIDELINES

4 INSTALLATION PROCEDURES

NOTES: 1) Read all service instructions. 2) Observe and follow all warnings/instructions marked on

the projector. 3) Service the unit in a clean environment to prevent dust particles from settling on

optical components.

IMPORTANT! Ensure the components and hardware used for Projectors 6 and 7 have the correct

label. Each of the projectors have their own color coded labeling to ensure the correct parts are used.

The labels for Projector 6 are light green and blue for Projector 7.

4.1 RECOMMENDED TOOLS

Ensure the following tools are on-hand when performing the procedures outlined in this document:

• M5/M8 Allen Key

• 3/16” Balldriver

•3mmBalldriver

• 1/2” Wrench

• #1 Phillips Screwdriver

• 17mm Wrench

• Meter Stick, Yard Stick or Measuring Tape

• 1-1/8” Open-end Wrench

WARNING

When powering down the projector, allow the cooling fans to automatically turn OFF

(approximately five minutes) before disconnecting AC and removing covers. Always

unplug the projector before disassembling.

NOTICE

Observe all electrostatic precautions. Use a grounded wrist strap when handling

electronic assemblies.

NOTICE

Use only replacement parts specified by the manufacturer. DO NOT use substitute parts.

NOTICE

A minimum torque of 15-inch/lb. must be applied to each screw.

8 of 25 ’Projectors 6 and 7’ Ruggedized Lens Components Installation Manual

020-100055-01 Rev. 1 (05/07)

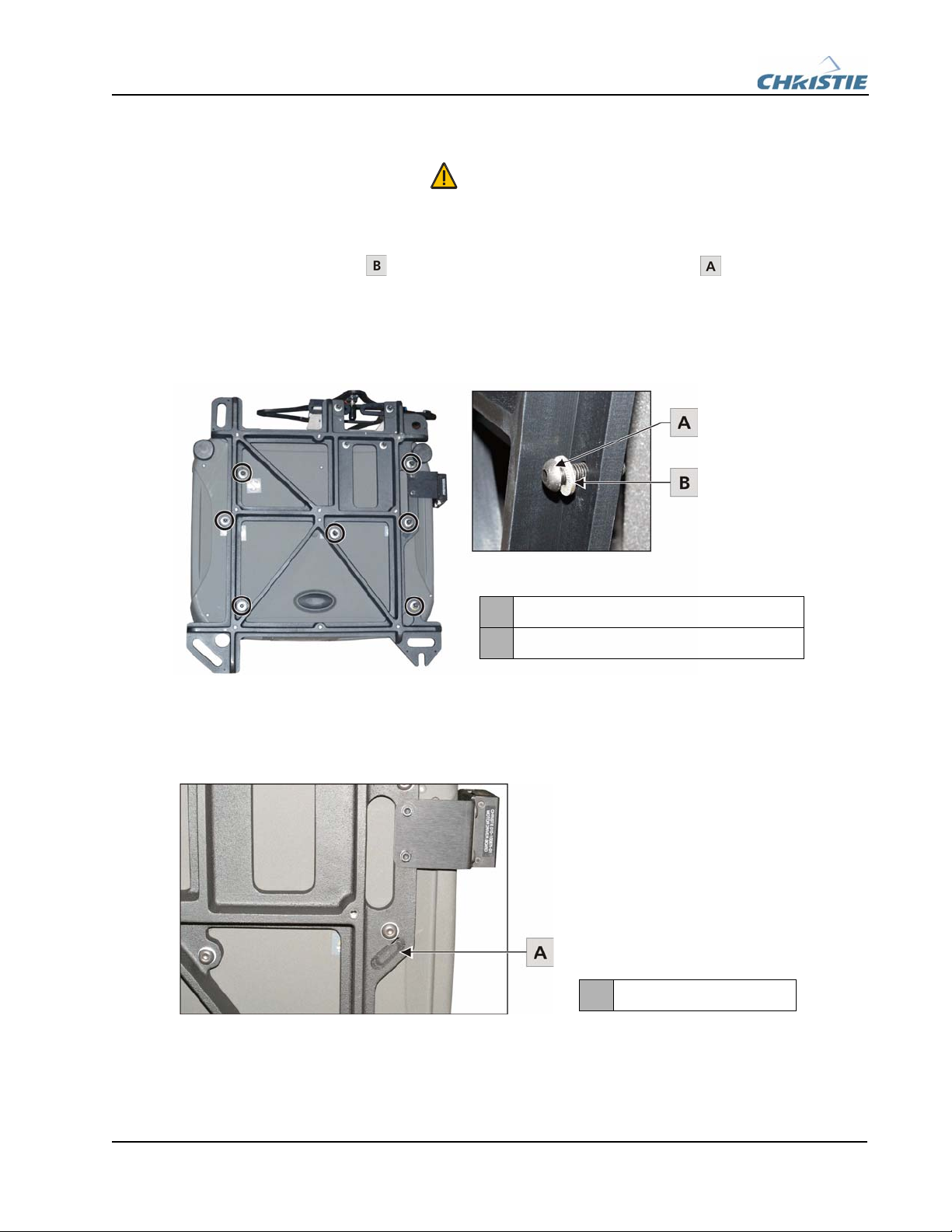

4.2 MOUNT BASE PLATE (M012231) / INSERT BASE PLATE PLUG (M012899)

1. Place a nord lock washer onto each of the seven hex socket capscrews .

2. As one person tilts the projector to expose the underside another person must position the adjuster

plate inline with the designated mounting positions.

3. Use an M8 Allen key to tighten each of the seven hex socket capscrews (Figure 4-1).

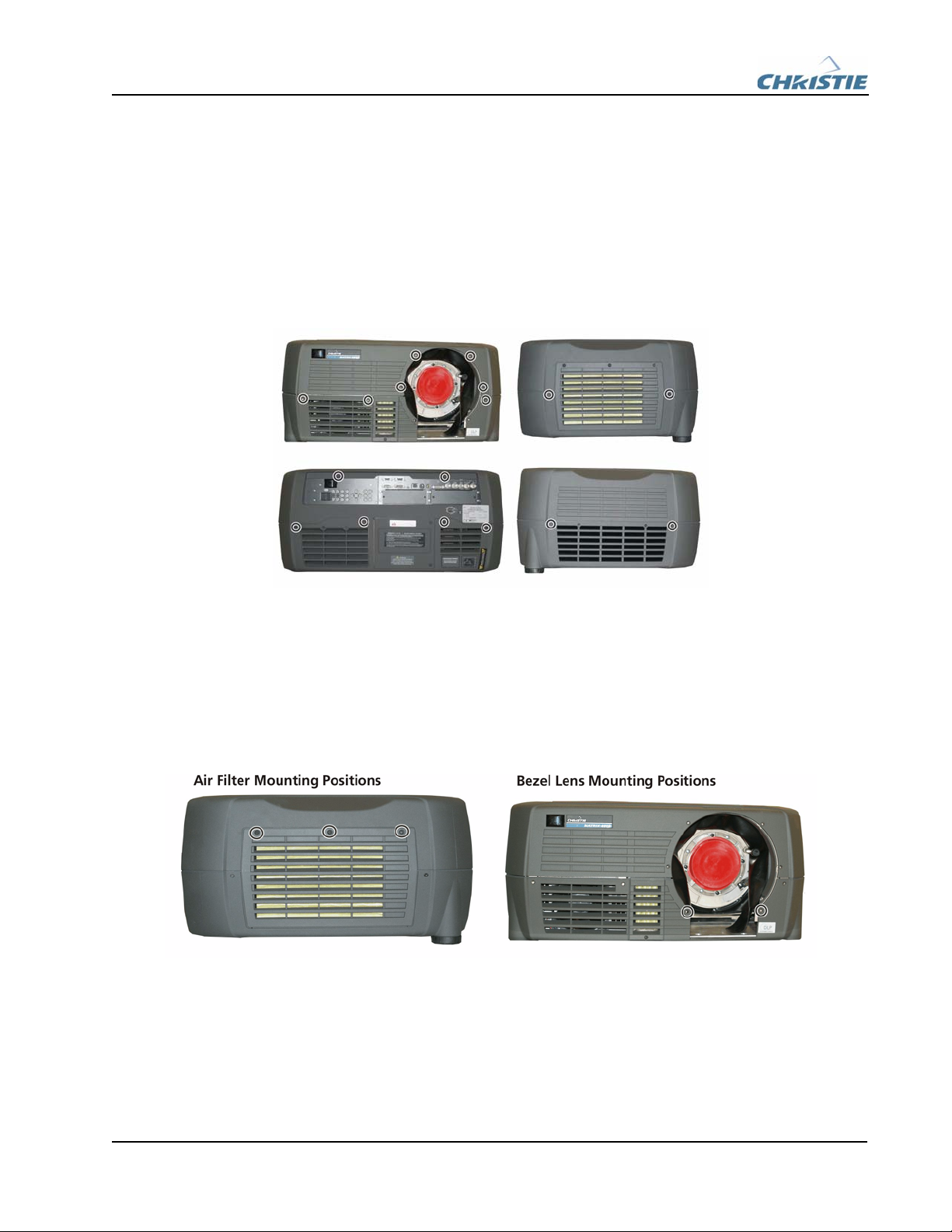

Figure 4-1 Base Plate Mounting Positions

4. Snap a base plug into the designated position on the adjuster plate (Figure 4-2). The base plate plug

must be removed when access to the cold mirror adjust is required.

Figure 4-2 Base Plug

WARNING

To avoid possible injuries, a minimum of two people are required to complete this

procedure.

AHex Socket Capscrew (Spaenaur #366-744)

BNord Lock washer (Spaenaur #677-320)

ABase Plug (M012899)

’Projectors 6 and 7’ Ruggedized Lens Components Installation Manual 9 of 25

020-100055-01 Rev. 1 (05/07)

4.3 MOUNT MOTOBLEND BRAINBOX BRACKET (M012512)

1. As one person tilts the projector to expose its underside another person must position the bracket

in-line with the designated mounting positions on the base plate (Figure 4-3).

2. Use an M5 Allen key to tighten the two M5 x 12 socket head capscrews .

Figure 4-3 MotoBlend Brainbox Bracket

4.4 Mount Motoblend Brainbox (#010-100876-01 / M010105)

1. Position the MotoBlend brainbox so it is flush with the outside of the mounting bracket. The

brainbox must be mounted with the DB9 connectors facing the back of the projector.

2. Insert two hex socket button head capscrews through the designated mounting holes.

3. Hand-tighten two hex nuts onto the back of the capscrews.

4. Position a 1/2” wrench onto the hex nut and use a 3/16” balldriver to completely tighten the hex

socket button head capscrew.

Figure 4-4 MotoBlend Brainbox

WARNING

To avoid possible injuries, a minimum of two people are required to complete this

procedure.

AM5 x 12 SHCS (Spaenaur #367-056)

AMotoBlend Brainbox (#010-100876-01)

B5/16”-18 Hex Nut (#012-100553-01)

CHex Socket Button Head Capscrew

5/16”-18 (Spaenaur #HX-270-RC)

10 of 25 ’Projectors 6 and 7’ Ruggedized Lens Components Installation Manual

020-100055-01 Rev. 1 (05/07)

4.5 Remove Top Cover

1. Use a #1 Phillips screwdriver to remove the 17 screws securing the top cover (Figure 4-5).

2. Slowly, lift the top cover up from the lens end to remove.

Figure 4-5 Removing Projector Top Cover

4.6 Remove Side Filter / Bezel Lens Mount

1. Use a #1 Phillips screwdriver to remove the three screws securing the left-side filter door. Note the

orientation of the filter before removing it.

2. Use a #1 Phillips screwdriver to remove the two screws securing the bezel mount to the bottom

cover.

Figure 4-6 Air Filter / Bezel Lens Mounting Positions

NOTICE

The front IR sensor PCB is located in the front left corner and can be damaged if it is hit

when the cover is removed.

This manual suits for next models

1

Table of contents

Other Christie Lens manuals

Popular Lens manuals by other brands

Tamron

Tamron SP 70-300mm F/4-56 Di VC USD Brochure & specs

Panasonic

Panasonic VW-W4907 operating instructions

Navitar

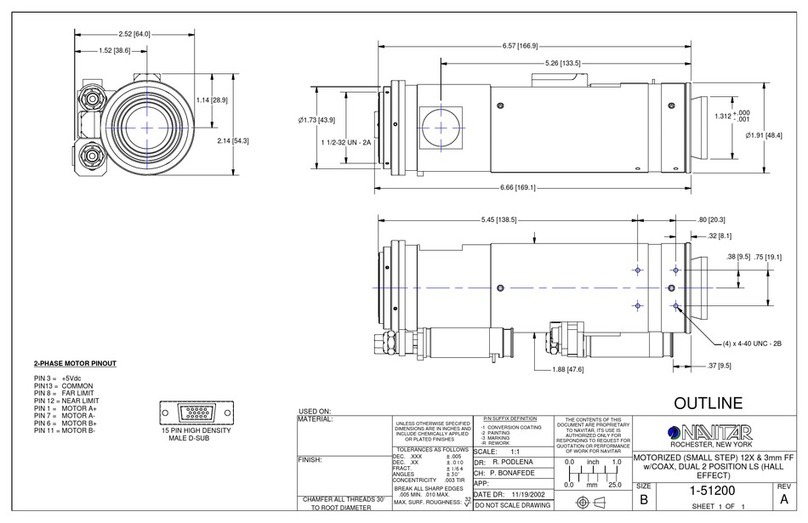

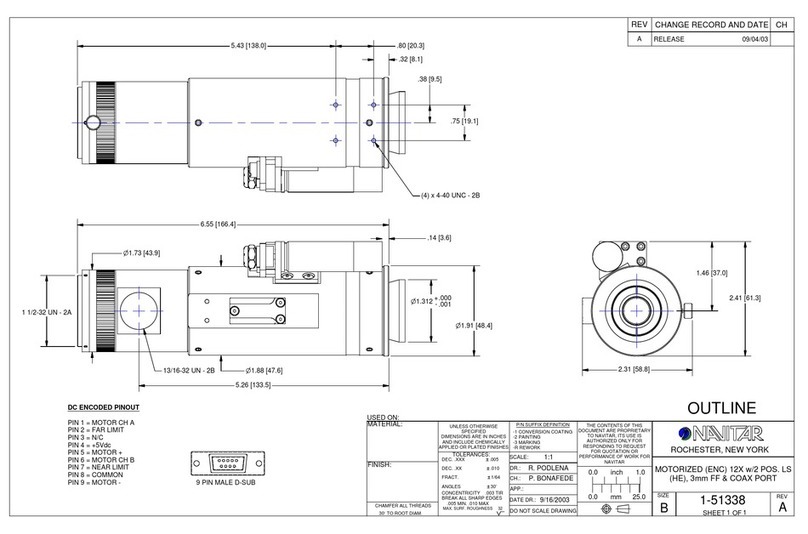

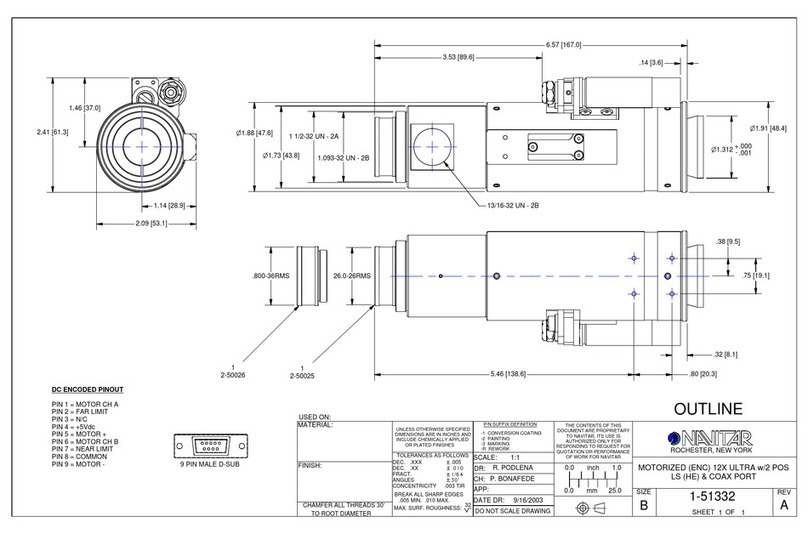

Navitar 1-51332 Dimensional drawing

Leica

Leica APO-SUMMICRON-SL 1:2/50 ASPH. instructions

Sony

Sony LKRL-Z200 Series Product information

Cosina

Cosina Voigtländer SUPER NOKTON 29mm F0.8... instruction manual