Chromalox MaxPac series User manual

PK480-2

P/N 0037-75428

User's Manual

www.chromalox.com

800-443-2640

© 2014 Chromalox, Inc.

PK480-2

P/N 0037-75428

User's Manual

www.chromalox.com

800-443-2640

© 2014 Chromalox, Inc.

- 1 -

© 2014 Chromalox®, Inc.

1-888-996-9258

Thank you for choosing the Chromalox®MaxPac™ - a complete power control solution with industry-best

price and performance.

For more than 80 years, customers have relied on Chromalox for the utmost in quality and innovative solu-

tions for industrial heating applications. Chromalox manufactures the world’s largest and broadest line of

electric heat and control products.

The MaxPac Series SCR Controllers provide the best control for applications where consistent heater/pro-

cess temperature is critical or where fine resolution of power is required.

Common MaxPac features include:

• 120-575Vac@100-1200Amps

• IsolatedControlCircuit

• FlexibleI/OPowerWiring

• EasyCustomerInterface

• RemoteShutdown

• CompactSizeandConstruction

• Touch-SafeDesign(optionon100-650Ampmodels)

• dv/dtTransientVoltageProtection

• MOVProtection

• Built-InPowerDistribution

Features for the MaxPac I, II, and III include:

• ZeroCrossoverFiring

• IsolatedControlCircuit

On/OffControlInputs:

120thru240Vac

5-32Vdc

DryContactClosure

Proportional(DOTFiring)Inputs:

4-20mA,0-5Vdc,1-5Vdc,0-10Vdc

RemoteManualAdjust(Optional)

RemoteAuto/ManualSwitch(Optional)

• ElectronicallyProtectedwithTemperatureWarningandShutdownSystem

• Single-orThree-CycleResolution(JumperSelectable)

• ShortedSCRDetection(Optional)

Features for the MaxPac IP include:

• PhaseAngleFiring

• IsolatedControlCircuitInputs

0-5mA,0-20mA

0-50mA,1-5mA

4-20mA,10-50mA

0-5Vdc,0-10Vdc

• OptionalCurrentLimit

• SoftStart

• LineVoltageCompensation

• Zero&GainAdjustments

• Built-InManualAdjustment

• CurrentLimitAdjustment(Optional)

Ifyouhaveapplicationquestions,refertotheEngineeringResourcesectionofourwebsiteatwww.chromal-

ox.com to find the answer you’re looking for, or call one of our application

engineersat1-888-996-9258forpersonalassistance.

-2- © 2014 Chromalox®, Inc. 1-888-996-9258

Table of Contents

Section Topic Page

1................................................. ImportantSafeguards..................................................................................... 3

2................................................. Description ..................................................................................................... 4

3................................................. BeforeYouInstall............................................................................................ 5

4................................................. Installation ...................................................................................................... 6

4.1................................. Mounting......................................................................................................... 8

4.2................................. Wiring............................................................................................................ 11

4.2.1 ............. Touch-SafeDesign ....................................................................................... 11

4.2.2 ............. CoverRemovalandInstallation.................................................................... 12

4.2.3 ............. Power/LoadWiring ....................................................................................... 12

4.2.4 ............. InstrumentPower ......................................................................................... 16

4.2.5 ............. Grounding..................................................................................................... 16

4.2.6 ............. CommandSignalWiring............................................................................... 17

4.2.7 ............. Calibration .................................................................................................... 23

5................................................ Specifications ............................................................................................... 24

6................................................ Maintenance ................................................................................................. 25

7................................................ Troubleshooting ............................................................................................ 26

8................................................ PartsandAccessories.................................................................................. 27

9................................................ WarrantyandReturnInformation ................................................................. 28

10 .............................................. ECDeclarationofConformity....................................................................... 37

-3-

© 2014 Chromalox®, Inc.

1-888-996-9258

1

Please read all instructions before installing and operating your MaxPac™.

Toavoidelectricalshockorinjury,alwaysremovepowerbeforeservicingacircuit.

Personnel working with or near high voltages should be familiar with modern methods of resuscitation. Con-

tact an area supervisor or safety personnel for more information.

Throughout the MaxPac User Manual, the safety alert and the international electric shock/electrocution sym-

bolswillalertyoutopotentialhazards.Safetyprecautionsshouldalwaysbefollowedtoreducetheriskof

personalinjurytopersonsfromreandelectricalshockhazards.

SafetyAlertSymbol

InternationalShock/ElectrocutionSymbol

Eachsafetymessageisprecededbyasafetyalertsymbol andoneofthreewords:DANGER,WARN-

ING,orCAUTION.

Thesemean:

Important Safeguards

YouWILLbekilledorseriouslyhurtifyoudonotfollowinstructions.

YouCANbekilledorseriouslyhurtifyoudonotfollowinstructions.

YouCANbehurtifyoudonotfollowinstructions.

DANGER

WARNING

CAUTION

DamagePreventionMessages:

YouwillseeotherIMPORTANTmessagesthatareproceededbytheword CAUTION that are intended

to help prevent damage to the MaxPac™orotherequipment.NotethatDamagePreventionMessagesare

NOTaccompaniedbytheSafetyAlertSymbol.

-4- © 2014 Chromalox®, Inc. 1-888-996-9258

2

† Thiscanbesettothreecycles‘On’/threecycles‘Off’(seesectiononinstallationoptions).

Description

MaxPac I, II, and III

TheChromaloxMaxPacI,II,andIIIcontrollersarehighlyversatileSCRPowerPakswithoptionalplug-in

proportionalringandshortedSCRdetectionboards.FiringmodesincludeOn/OffandDOTproportional

zerovoltageswitching.ChromaloxexclusiveDOT(DemandOrientedTransfer)ringtechniqueswitchesthe

fewestnumberofcyclestoprovidethemostprecisezerocrossovercontrol.At50%output,theunit’soutput

alternatesbetweenonecycle“On”andonecycle“Off.”At51%,theoutputcontinueswithonecycle“On,”

onecycle“Off,”andgraduallyintegratesoneextra“On”cyclefortheadditional1%.ThisDOTredtech-

niquealsominimizestemperatureovershoot,temperatureuctuationsandhelpsextendtheload’selement

life due to reduced thermal shock.

ThepowerSCRassembliesconsistofone,two,orthreepairsofSCRsconnectedbacktoback(withan

optionalsemiconductorfuse),RCSnubber,andMOVprotection.Theringcircuitisbasedonacommon

On/OffcontrolboardwithplugandplayShortedSCRandDOTredplug-inboards.Diagnosticindicators

are included. Plug-in terminal blocks for easy customer interface are also provided.

MaxPac IP

TheChromaloxMaxPacIPutilizesSinglePhase,PhaseAngleringtomodulatepowertoaninductiveor

resistiveload.PhaseAnglecontrolhastheadvantageofproportioningeverycycletherebyprovidingvery

fine resolution of power. Fast responding loads in which the resistance changes as a function of temperature

requirePhaseAnglecontrol.TheMaxPacIPoffersaSoftStartfeaturethatassuresthattheloadpoweris

graduallyincreasedfromzerotothevaluesetbythecommandsignalintheeventofapowerinterruption.

Inaddition,optionalCurrentLimitisusedtoprotecttheload,SCRcontrollerandthetotalsystemfromlarge

surge currents that could occur at start-up.

-5-

© 2014 Chromalox®, Inc.

1-888-996-9258

3

Before You Install

ImmediatelyafterreceivingyourMaxPacI,II,IIIorIPSeriesController,visuallyinspecttheshipmentpackag-

ing and record any damage on the shipping documents. Unpack the controller and carefully inspect for obvi-

ousdamageduetoshipment.Ifanydamagehasoccurred,YOUmustleaclaimwiththecarriercompany,

sincethecarriercompanywillnotacceptaclaimfromtheshipper(Chromalox).

BesuretocheckthemodelnumberandverifythatyouhavereceivedthecorrectModelofcontroller.

Ifthecontrollerisnotinstalledandplacedintooperationimmediately,itshouldbestoredinacool,dryenvi-

ronment. Temperature extremes and excessive moisture can damage the controller.

BeforechoosingalocationinwhichtomountyourMaxPac,pleaseconsiderthefollowing:

Temperature

WhenmountingtheSCRunitinacontrolpanel,attentionshouldbepaidtotheenclosuretempera-

ture.TheSCRisratedtoperformatitsnameplatecurrentratingintemperaturesupto50˚C(122˚F).

Ensurethatadequateventilationisprovidedorsomeothermethodofmaintainingthecorrectcabi-

net temperature is used.

Cleanliness

Carefulattentionmustbepaidinareassubjectedtoairborneparticles.Theefciencyoftheheat

sinksreliesontheirconductingsurfacesbeingmaintainedinacleanmanner.(SeetheMaintenance

Section.)

Dampness

High humidity or hosing down a unit should be avoided.

Clearance

Choose a location that will provide adequate spacing around the unit when mounted. This will en-

sureproperairownecessarytocoolthedevice.

WARNING

Hazardous Voltage: Disconnectandlockoutpowerbeforeinstall-

ingorservicing.Failuretocomplycouldresultinpersonalinjury

or equipment damage.

-6- © 2014 Chromalox®, Inc. 1-888-996-9258

InstallationSection

(continuationofpage5)

TheforcedairdesignoftheMaxPacseriesallowsmountinginanydirection.Itisessentialthatairflowthrough

the enclosure be planned to insure proper cooling.

The100ampthrough300ampopendesignMaxPacallowtheinputlinepowertoconnectfromeitheroftwodirections.

The output power can only be connected from one direction. The three mounting configurations

areshownbelow(MaxPacIIThree-PhaseTwo-LegShown).

Opendesignsabove300ampsandallcloseddesignsallowincoming

and outgoing wiring in either direction.

In In

Configuration One

CoolAirIn WarmAirOut

Fan Phase 1 Phase 3

orIn Out orIn Out

Configuration Two

Out Out

In In

WarmAirOut CoolAirIn

Phase 1 Phase 3Fan

orIn orIn

Configuration Three

WarmAirOut

Out

Phase 3

orIn

In

Out

Phase 1

In orIn

Fan

CoolAirIn

-7-

© 2014 Chromalox®, Inc.

1-888-996-9258

InstallationSection

(

continuation of

p

a

g

e 5

)

ExamplesofProperAirFlow

Pagoda Top

Fan

Air

Louvers Louvers

MaxPac

Air

FanMaxPac

Fan

Enclosure

AirEnclosure

Fan

Filter

Forced Air In

Forced Air Out

Louvers

Since hot air rises naturally, it is not recommended that cooling air ente

r

from the top and exhaust at the bottom of the enclosure.

- 8 - © 2014 Chromalox®, Inc. 1-888-996-9258

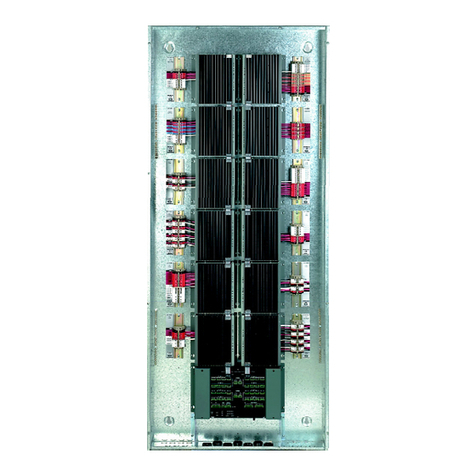

Figure Drawing Number Model

Figure Model

1................100A,150A,&200A2-LegOpenType

1................100A,150A,200A,&300A1-LegOpenType

2................100A,150A,&200A3-LegOpenType

3................300A2-LegOpenType

4................100A,150A,200A,300A&400A1-LegTouch-Safe

4................400A1-LegOpenType

5................100A,150A,200A,300A&400A2-LegTouch-Safe

5................400A2-LegOpenType

6................100A,150A,200A,300A&400A3-LegTouch-Safe

6................300A&400A3-LegOpenType

7................550A&650A1-LegTouch-Safe

7................550A&650A1-LegOpenType

8................550A&650A2-LegTouch-Safe

8................550A&650A2-LegOpenType

9................550A&650A3-LegTouch-Safe

9................550A&650A3-LegOpenType

..................800-1200Ampunits,consultfactory

4

Installation

Please read all information in this section before beginning the installation of your MaxPac.

InstallationoftheMaxPacrequiresthreesteps:

1. Mounting

2. Powerwiring

3. 120or 230Vac50/60hzforinstrumentpower.See4.2.4,pg.16.

4.1 - Step 1: Mounting

BeforemountingyourMaxPac,pleasereadthesectiontitled“BeforeYouInstall’onpage5foradescription

of an ideal environment for the unit’s operation.

The space required for mounting the MaxPac Power Pak depends upon the model. The table below refers to

the figures on the following pages. These figures illustrate the dimensions and mounting holes for the vari-

ous MaxPac Power Pak models. Please refer to these figures before mounting your unit.

IMPORTANT: Please note that the figures on the following pages are

not drawn to the same scale.

- 9 -

© 2014 Chromalox®, Inc.

1-888-996-9258

Figure 1 Figure 2

Figure 3 Figure 4

Figure 5

4.7" [107mm]

0.0" [0mm]

1.0" [25mm]

4.75" [121mm]

8.5" [216mm]

9.5" [241mm]

6.0" [153mm]

7.3" [185mm]

FIRING PACKAGE

FAN END

Ø0.280" [Ø7.11mm]

(6 HOLES)

4.2" [107mm]

0.0" [0mm]

1.0" [25mm]

7.2" [184mm]

13.5" [342mm]

14.5" [368mm]

6.0" [153mm]

7.28" [185mm]

FIRING PACKAGE

FAN END

Ø0.280" [Ø7.11mm]

(6 HOLES)

7.2" [183mm]

0.0" [0mm]

1.3" [33mm]

7.3" [185mm]

13.3" [337mm]

14.6" [371mm]

12.0" [305mm]

13.3" [338mm]

FIRING PACKAGE

FAN END

Ø0.280" [Ø7.11mm]

(6 HOLES)

5.12" [130mm]

0.0" [0mm]

1.3" [33mm]

9.3" [237mm]

13.3" [338mm]

14.6" [371mm]

8.1" [206mm]

9.1" [232mm]

FIRING PACKAGE

FAN END

Ø.3125 [Ø7.94mm]

(8 HOLES)

5.3" [135mm]

8.4" [214mm]

0.0" [0mm]

1.3" [33mm]

9.3" [237mm]

13.3" [338mm]

14.6" [371mm]

14.7" [375mm]

15.75" [400mm]

FIRING PACKAGE

FAN END

Ø.3125" [Ø7.94mm]

(8 HOLES)

5.3" [135mm]

- 10 - © 2014 Chromalox®, Inc. 1-888-996-9258

Figure 9

13.8" [351mm]

0.0" [0mm]

1.3" [33mm]

26.5" [673mm]

16.3" [414mm]

17.6" [448mm]

11.3" [287mm]

25.5" [648mm]

FIRING PACKAGE

FAN END

Ø.3125" [Ø7.94mm]

(8 HOLES)

6.3" [160mm]

Figure 6 Figure 7

Figure 8

11.7" [298mm]

0.0" [0mm]

1.3" [33mm]

9.3" [237mm]

13.31" [338mm]

14.62" [371mm]

21.4" [543mm]

22.4" [568mm]

FIRING PACKAGE

FAN END

Ø.3125" [Ø7.94mm]

(8 HOLES)

5.3" [135mm]

5.8" [148mm]

0.0" [0mm]

1.3" [33mm]

11.3" [28mm]

16.3" [414mm]

17.6" [448mm]

9.5" [241mm]

10.5" [267mm]

FIRING PACKAGE

FAN END

Ø.3125" [Ø7.94mm]

(8 HOLES)

6.3" [160mm]

9.8" [249mm]

0.0" [0mm]

1.3" [33mm]

11.3" [287mm]

16.3" [414mm]

17.6" [448mm]

17.5" [444mm]

18.5" [470mm]

FIRING PACKAGE

FAN END

Ø.3125" [Ø7.94mm]

(8 HOLES)

6.3" [160mm]

- 11 -

© 2014 Chromalox®, Inc.

1-888-996-9258

4.2 - Step 2: Wiring

4.2.1 - Touch-Safe Design

IftheMaxPacmodelyoupurchasedisofaTouch-Safedesign,followthestepsonthefollowingpageto

install the electrical wiring. This will ensure the wiring is done properly while maintaining the Touch-Safe

feature.IfyourMaxPacisofanOpendesignbelow400Amps,disregardthissubsection.

ThefollowingisadetaileddrawingofaTouch-Safeunit:

Careful attention must be paid when attaching the wiring to the MaxPac to ensure proper and safe opera-

tion. This section contains detailed information on how to connect the power, resistive load, ground, and

command signal wiring.

IMPORTANT: SelectinstallationwiringthatisinaccordancewiththeNational

ElectricalCodeandanylocalstandardsthatmaybeapplicable.

WARNING

Hazardous Voltage: Onlyqualiedpersonnelshouldperform

electricalwiringfortheMaxPacPowerPaks.LETHALLYHIGH

VOLTAGESareassociatedwiththisequipmentandaredanger-

ous if improperly installed.

COOLING AIR

COOLING AIR

SCR

FUSE

HEATSINK FINS

COVER PROVIDES FOR TOUCH SAFE FEATURE

TOUCH-SAFE COVER PROVIDES WIRE ENTRANCE AND

EXIT THROUGH SEALS COVERING THE WIRE WINDOW.

REMOVAL OF THE TAPE BEHIND THE WINDOWS TO

BE USED ALLOWS WIRES TO PASS. THE TAPE

REMAINS ON UNUSED WINDOWS TO PROVIDE TOUCH

SAFE FEATURE.

BUS BAR DESIGN ALLOWS

FOR WIRING FROM EITHER

DIRECTION AND MULTIPLE

LOAD CIRCUITS

BUS BAR DESIGN ALLOWS

FOR WIRING FROM EITHER

DIRECTION AND MULTIPLE

LOAD CIRCUITS

LONG LIFE, HIGH OUTPUT BALL

BEARING FANS PROVIDE RELIABLE

COOLING

-12- © 2014 Chromalox®, Inc. 1-888-996-9258

4.2.3 - Power/Load Wiring

The following illustrations depict how to connect the MaxPac to a resistive or inductive load. Make sure you

refer to the correct illustration for the MaxPac series you have purchased.

Forthepower/loaddrawings:

Onopendesignunitsupto300Amps,X1,X2,X3,L1,L2,andL3refertocopperlugs.

Onopendesignunits400AmpsandgreaterandallTouch-Safedesigns,X1,X2,X3,L1,L2,andL3refer

to bus bar connections.

MaxPac I

4.2.2 - Steps for Touch-Safe Design Cover Removal and Installation

RemoveCover:

1. Loosenthethumbscrewsonbothendsofthecover.

2. Liftthecoverfromthebase.

InstallWiring:

3. Attachthewirestothebusbarsinaccordancewiththeinstructionsinthenextsection.

4. Choosetheentranceandexitdirectionsforthewiringasdesired.

5. Afterthewiringiscomplete,removethetapefromtheinsideofthewiregasketsofthe

windows that the power wiring will enter or exit.

ReplaceCover:

6. Angletheendofthecoverwithoutscrewstowardsthe“fan-end”oftheunit.

7. Slipthatendintoplacerstwhileallowingthewiringtopassthroughthedesiredwindows.

8. Slip the opposite end of the cover into place.

9. Tighten all thumb screws.

WARNING

Hazardous Voltage: DONOTremovethetapefromthebackof

the windows that are not used, as this maintains the Touch-Safe

feature.

MAX PAC I

L2

L1 X1

Single Phase

Resistive

L2 Connection is

NOT on MaxPac

-13-

© 2014 Chromalox®, Inc.

1-888-996-9258

MaxPac II

MaxPac III

Three Wire

2 Leg Control

MAX PAC II

L1

L3

L2

X1

X3

L2 Connection is

NOT on MaxPac

Four Wire

3 Leg Control

MAX PAC III

L1

L2

L3

X1

X2

X3

N

N Connection is

NOT on MaxPac

IMPORTANT: TheI2t fuses installed on the SCR are designed to protect the SCR

from faults on the load connection side. They are NOT intended to provide

wire protection.

CAUTION

-14- © 2014 Chromalox®, Inc. 1-888-996-9258

MaxPac III

MaxPac IP

IMPORTANT: TheI2t fuses installed on the SCR are designed to protect the SCR

from faults on the load connection side. They are NOT intended to provide

wire protection.

CAUTION

Three Wire

3 Leg Control

MAX PAC III

L1

L2

L3

X1

X2

X3

Single Phase

transformer

Coupled

MAX PAC IP

L2

L2

L1 X1

L2 connection to

MaxPac is instrument

power only

-15-

© 2014 Chromalox®, Inc.

1-888-996-9258

ThebusbarsaredesignedtoacceptNEMAstandardtwo-holecrimplugsinaccordancewiththechartsbelow.

Thefollowingdrawingsshowproperinstallationofthecrimplugsonthebusbars:

Illustration 1:ViewFromRearVentilatedPanel

FUSE

Smaller wire, #1 through #8, often used

for power distribution, can be connected

tobothsidesoftheloadbus.Wiringmust

be bent slightly to align with the windows

in the top of the touch safe units.

LINEBUSBAR

LOADBUSBAR

FANEND

SCR

1/0through500mcm

wire must mount on the

fuse side of the bus

bar as shown to

maintain required

electrical clearances

Illustration 2:ViewFromTop

Touch-Safe Units

100-400Amps

InputBus

Upto(3)1/0-300mcm(70mm2—150mm2)

Upto(2)350-500mcm(185mm2—240mm2)

OutputBus

Upto(10)#8-#1(10mm2—50mm2)

Upto(3)1/0-300mcm(70mm2—150mm2)

Upto(2)350-500mcm(185mm2—240mm2)

550-650Amps

InputBus

Upto(4)1/0-300mcm(70mm2—150mm2)

Upto(3)350-500mcm(185mm2—240mm2)

OutputBus

Upto(12)#8-#1(10mm2—50mm2)

Upto(4)1/0-300mcm(70mm2—150mm2)

Upto(3)350-500mcm(185mm2—240mm2)

800-1200AmpsOpenDesign

Inputandoutputbusdrilledtoaccomodateqty(4)1/0-500mcmNEMAstandardtwo-holecrimplugsperphase.

Allboltsmustmount

with excess bolt lengths

toward the fuse to main-

tain required electrical

clearances.

-16- © 2014 Chromalox®, Inc. 1-888-996-9258

The power wiresmustalwaysconnecttothefuseside(refertoillustration1onpage15)ofthebusbar.This

is essential to maintain the required spacing between the phases and sides, and to align with the openings in

thetop.Theonlyexceptiontothisiswhenusingpowerdistributionusingconnectorsofsizes#8to#1.There

is adequate spacing for these connectors to be mounted on both sides of the bus bar, if necessary.

The bolt headshouldalwaysbeontheoutsideofthebusbar(refertoillustration2onpage15)withthebolt

extending towards the fuse.

Flat washers should be used on both the bolt head and the nut, and a lock-washer should be under the

nut.

The Touch-Safe MaxPac is designed to allow both input and output wiring to enter/exit in either direction.

Onthe550Ampand650Ampmodels,itisnecessarytomountthewireintheholesthatmaximizethe

distanceforthewiretoexittheenclosure.Thismaximizesthedistancefromthecovertothenon-insulated

connector.

Whenusingthepower distribution feature and mounting terminals on both sides of the bus bar, the wires

mountedontheoutsideofthebusbarmustbebentinwardslightlytoalignwiththeopeninginthetop.All

wiring,especiallythelargerwires,shouldbebentpriortomountingtothebusbars.DONOTusethebus

bars as an anchor to bend the power cables.

4.2.4 - Instrument Power

MaxPac requires 120 or 230 Vac 50/60Hz for instrument power. This voltage supplies power for

the control circuits, fans, high temperature warning indicator, and shorted SCR Indicators (see

Fig. 1 on page 21).

This supply is fused on the main circuit board.

4.2.5 - Grounding

ChasisisprovidedwithholepatternforstandardNEMAtwo-holecrimplugs.

WARNING

Hazardous Voltage: ThisElectricalEquipmentmustbeinstalledby

a qualified person and effectively grounded in accordance to the

NationalElectricCodeandlocalcodes.

IMPORTANT

-17-

© 2014 Chromalox®, Inc.

1-888-996-9258

4.2.6 - Command Signal Wiring

Pleaserefertotheguresonpage19forillustrationsofthe6-,8-,and10-pininputterminals.

MaxPac I, II, and III

On/Off Control Signals

AC Input–The120thru230VacsignallinesareconnectedtoterminalJ1-7&8(seeFig.9onpage

21).Aninputvoltageof120to230VacturnsthepowerOn.TheturnOFFvoltageis0Vac.

DC Input–The5-32VdcsignallinesareconnectedtoterminalJ3-1&4(seeFig.10onpage21).

Aninputvoltageof5to32VdcturnsthepowerOn.TheturnOFFvoltageis0Vdc.

Contact Closure Input–ThedrycontactsignallinesareconnectedtoterminalJ3-1&2(seeFig.

11onpage21).AclosedcontactturnsthepowerOn.TheturnOFFvoltageisanopencontact.

Process Analog Control Signals

MaxPacI,II,andIIIhavebeenfactorycalibrated.Theseunitsaccept0-5,1-5,0-10Vdc,and4-

20mAinputsignalsthatareconnectedtoTerminalBlockJ2.Thefollowingsignalsareconnectedto:

0-5Vdc: TerminalJ2-9(+)&7(-)(seeFig.7onpage21)

1-5Vdc: TerminalJ2-5(+)&7(-)(seeFig.5onpage21)

0-10Vdc:TerminalJ2-10(+)&7(-)(seeFig.8onpage21)

4-20mA: TerminalJ2-6(+)&7(-)(seeFig.6onpage21)

Auto/Manual Input

TheMaxPacI,II,andIIIcan

be wired to make it possible

to select an input from either a

temperature process controller

or a manual input potentiom-

eter.Aswitchisusedtoselect

between the input from a 1K

potentiometer and a linear

controlinput(seeFig.4onpage

21).Theunitisshippedwitha

jumperfromterminals2and3

ofterminalblockJ2(seeillustra-

tion3).Removejumpertoinstall

auto/manual input.

Demand Indicator

TheLEDdemandindicatorislocatedonthemainPCboardandisviewablethroughthecover.With

theOn/Offcontroloption,theindicatorwilldisplaysteady“on”andsteady“off”.WiththeDOTFiring

option, the indicator will display the rapid firing sequence.

IMPORTANT: WhenenablingtheAuto/ManualInput,thejumperfromterminals2

and3ofterminalblockJ2mustberemoved.

CAUTION

Illustration 3

N

C

N

O

CO

NTA

CT

N

O

RMALLY

C

L

OS

E

D

(

SWNC

)

CO

NTA

CT

N

O

RMALLY

O

PE

N

(

SWNO

)

S

WIT

CH

A

SS

EMBLY

(

SW

)

PANEL T

O

B

E

M

OU

NTED T

O

LE

G

EN

D

PLATE

(

LP

)

A

U

T

O

HAND

S

WIT

C

H KN

OB

(

SW

)

A

U

T

O

HAND

WIRIN

G

1

4

N

C

N

O

1K

P

O

TENTI

O

METE

R

CW

2

3

- 18 - © 2014 Chromalox®, Inc. 1-888-996-9258

SCR Control Board

TheBasiccontrolboardprovidesthefollowingfunctions:

Thelowvoltagedctooperatethecircuitry:

Aswitchingregulatorcircuitconvertstheinstrumentpowervoltageto+12Vdc.

Thepowerdistributionforthecoolingfans:

The incoming instrument power is fused and then routed to the fan power terminals.

Thesignalconditionfortheon/offinputandanaloginputs:

The120to240on/offinputisisolatedbyanopto-coupler.Thedcandcontact

closureinputsarebufferedbythecircuitry.Ampliersconverttheanaloginputsand

the potentiometer input to a signal level compatible with the optional proportional

firing board. The plug-in receptacle for the optional proportional board allows for an

easy upgrade to proportional control.

ThedrivesignaltotheSCRtriggerboards:

Thetemperaturealarm:

The heat sink temperature is derived from a solid state sensor mounted on the

heat sink. This is then compared to two set points. The first alarm is a warning and

activates the externally connected device. This allows time to correct the problem

before the second alarm inhibits the firing circuit.

TheShortedSCRAlarm:

The plug-in receptacle for the shorted SCR board is located on this board. Signals

fromtheSCRareroutedtotheoptionboard.Whenashortisdetectedtheexternally

connected device output is activated.

2AMP(2AG)

CHROMALOXP/N0024-01097

LITTLEFUSEP/N225002

(@)

()

()

()

- 19 -

© 2014 Chromalox®, Inc.

1-888-996-9258

Proportional DOT Firing Board

Chromalox’sexclusiveDOT(De-

mandOrientedTransfer)ringtech-

nique switches the fewest number

of cycles to provide the most pre-

cisezerocrossovercontrol.At50%

output, the unit’s output alternates

betweenonecycle“On”andone

cycle“Off.”At51%,theoutput

continueswithonecycle“On,”one

cycle“Off,”andgraduallyinte-

gratesoneextra“On”cycleforthe

additional1%.

Remote Shutdown

Whenitisnecessarytodisabletheoutput,connectadrycontactbetweenJ3-3&4(seeFig.12on

page21).Whenitisclosed,thepowercontrolwillshutOFF.

Shorted SCR Detection (optional)

Thisoptionprovidesameansofalertinganoperatortoaproblemwiththesystem.Anexternal

indicatinglamporrelaycanbeconnectedtoJ1-5&6(seeFig.2onpage21).Thisindicatormust

beratedfortheinstrumentpowerappliedtoJ1-1&2.ThreediagnosticLEDsshowwhichSCRpair

isfaulted.Theselightsaresynchronizedwiththedemandindicatorandcanonlyindicatewhilethe

demandisactive.ShortingJ3-5&6candisabletheoutputatJ1-5&6.Thealarmcanbeselected

as latching or non-latching.

Alatchingalarmmeansthatifthealarmactivatesandthesystemsubsequentlyreturnstonormal,

thealarmwillremainlatcheduntilaresetbutton(externalswitch–customerprovided)ispressed.A

non-latching alarm resets automatically.

IMPORTANT: Thisshutdownoverridesthecontrolinputonly.ItwillNOTprotect

against faulted or damaged SCRs.

CAUTION

SHORTEDSCRDETECTION

DEMAND

123

SHORTJ3-1&2FOR

1CYCLEFIRING

SHORTJ3-2&3FOR

3CYCLEFIRING

Unitshippedfor3cycleoperation

This manual suits for next models

4

Table of contents

Other Chromalox Control System manuals

Popular Control System manuals by other brands

Mitsubishi Electric

Mitsubishi Electric CITY MULTI PAR-40MAAU Instruction book

Comunello Automation

Comunello Automation BORDER 400 Installation and user manual

RF SOLUTIONS

RF SOLUTIONS ESPRIT LOW VOLTAGE Series quick start guide

Siemens

Siemens SINUMERIK 840D Operator's guide

iAIRE

iAIRE ION KIT Series manual

VIA Technologies

VIA Technologies ARTiGO-A600 Evaluation guide