warema_890275_alhb_en_v7•2022-05-01We reserve the right to make technical modifications

2

In the surface-mounted version, an optional strain relief set

is available:

Fig.3: Strain relief set for AP housing

Commissioning

After the installation work has been completed and the

supply voltage applied, the sun shading system can be

operated locally by means of the connected push buttons

or with the MABE12 hand-held control panel. The following

table informs you on which sunshade drives can be cont-

rolled using the connected sunblind push buttons (factory

setting, can be changed later):

Sunblind push but-

ton at input 2M230I 4M230I

1 (E1.1 / E1.2) Controls motor 1 Controls motor 1

2 (E2.1 / E2.2) Controls motor 2 Controls motor 2

3 (E3.1 / E3.2) / Controls motor 3

4 (E4.1 / E4.2) / Controls motor 4

However, to centrally operate the system and set up the

convenience and safety functions, the LONWORKS net-

work must be put into operation. The description can be

found in the software documentation of your control unit.

Contact your system integrator in this matter.

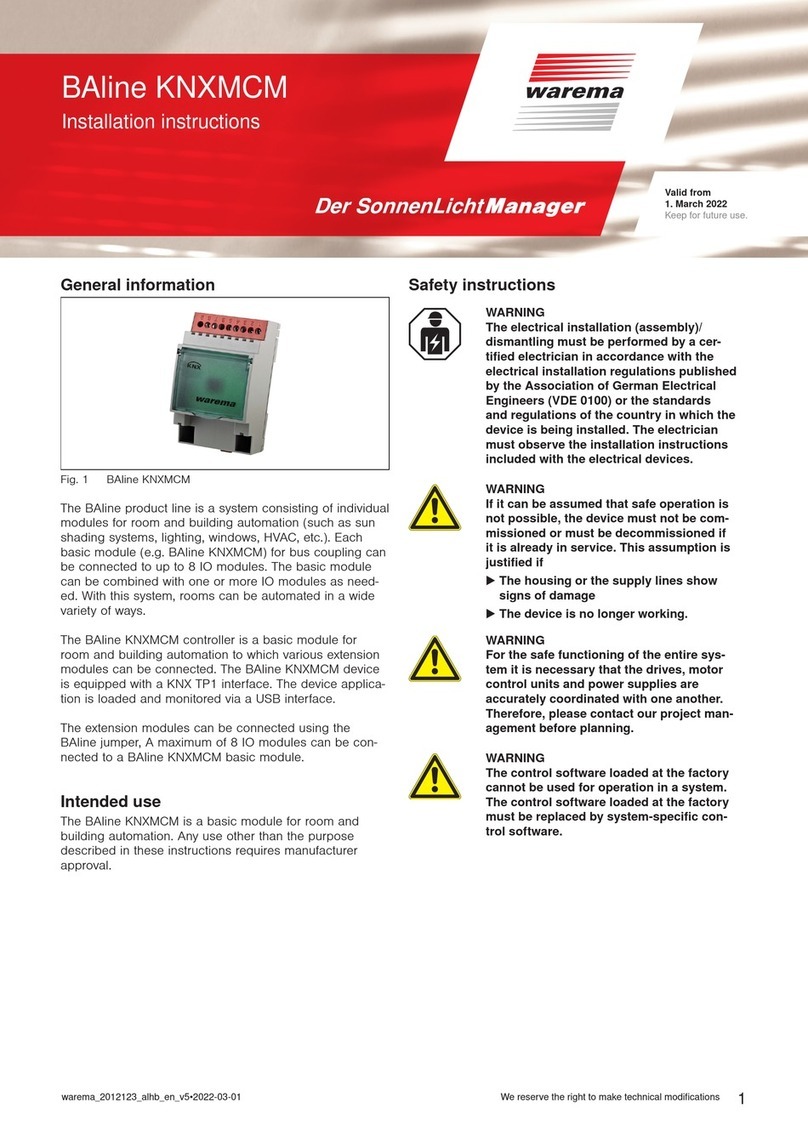

Service key and status LEDs: On the circuit board of the

LONMSE you will find a red status LED and a green ser-

vice LED as well as a service button (see Fig. 4). Perform

a simple function test: After the supply voltage is switched

on or after briefly pressing the service button, the service

LED lights up for approx. 0.5 seconds and then goes out.

If it lights up continuously, this indicates a device fault. In

this case, contact your system integrator. The status LED

then lights up for a duration of up to 20 seconds after the

supply voltage is switched on. As soon as the device is

ready for operation, this LED begins flashing irregularly.

If it lights up continuously, this indicates a device fault. In

this case, contact your system integrator.

Abb. 1

Take suitable precautions to prevent damage due

to electrostatic discharge.

Status

LED

Service

LED

Service

Push

button

X10: LON

A B

Network connection

Fig. 4: LONMSE 2M230I / 4M230I

Function of the LONMSE 2M230I / 4M230I

Convenience and safety functions

The integrated controller can be used to configure a wide

variety of different convenience, safety and energy-saving

functions. Among these are annual shading, slat tracking,

scene selection, wind alarm, etc. To prevent overheating of

the room, manual operation can be limited to between "cut

off" (from slat tracking) and "closed". A detailed descrip-

tion can be found in the software documentation of your

sunshade control unit.

Local operation

There are two parameterizable variants of the local ope-

ration and one parameterizable shade length limitation.

Operating variant A:

By briefly pressing the sunblind push button (the time

can be parameterized), you can adjust the shade inclina-

tion in small steps.

If the button is pressed for longer than the parameteriz-

able time, the shade responds by moving in the desired

direction. Pressing the button again stops the curtain.

Operating variant B (American operation):

Briefly pressing the sunblind push button (time can be

parameterized) causes the curtain to move to the upper

or lower limit position. Pressing the button again stops

the curtain.

If the button is pressed for longer than the parameteriz-

able time, the curtain changes its angle of inclination.

Parameterizable curtain length limitation

A limitation to the manual operation can be adjusted. The

operation can be limited in terms of the inclination and

the correct length.

Maintenance

There are no parts within the device that require mainte-

nance. In the event of a malfunction, the built-in miniature

fuses should only be changed by a qualified electrician.

Cleaning

Clean the housing with a soft, dry cloth. Do not use deter-

gents, cleaning agents, solvents, abrasive substances or

steam cleaners!

Liability

Failure to comply with the product information in these

instructions and use of the unit in a manner that contravenes

its intended use and purpose may result in the manufacture

refusing to honour warranty claims for product damage. In

this case, liability for consequential harm to persons or dam-

age to property will also be excluded. Follow the instructions

in the operating manual of your sun shading system. Liability

cannot be accepted for damage to the sun shading system

either due to operation in icy conditions.

Obligations for the disposal of electrical

devices

A marking with this symbol indicates the following

obligations under the scope of legal regulations:

The owner of this electrical device must dispose of it

separately from unsorted municipal waste for further

recycling.