Chromalox MAXPAC PK480 User manual

PK480

P/N 0037-75428

User's Manual

www.chromalox.com

800-443-2640

© 2002 Chromalox, Inc.

- 1 -

© 2002 Chromalox®, Inc.1-888-996-9258

Thank you for choosing he Chromalox® MaxPac™ - a comple e power con rol solu ion wi h indus ry-bes

price and performance.

For more han 80 years, cus omers have relied on Chromalox for he u mos in quali y and innova ive solu ions

for indus rial hea ing applica ions. Chromalox manufac ures he world’s larges and broades line of elec ric hea

and con rol produc s.

The MaxPac Series SCR Con rollers provide he bes con rol for applica ions where consis en hea er/process

empera ure is cri ical or where fine resolu ion of power is required.

Common MaxPac features include:

• 120 - 575 Vac @ 100 - 1200 Amps

• Isola ed Con rol Circui

• Flexible I/O Power Wiring

• Easy Cus omer In erface

• Remo e Shu down

• Compac Size and Cons ruc ion

• Touch-Safe Design (op ion on 100 - 650 Amp models)

• dv/d Transien Vol age Pro ec ion

• MOV Pro ec ion

• Buil -In Power Dis ribu ion

Features for the MaxPac I, II, and III include:

• Zero Crossover Firing

• Isola ed Con rol Circui

On/Off Con rol Inpu s:

120 hru 240 Vac

5 - 32 Vdc

Dry Con ac Closure

Propor ional (DOT Firing) Inpu s:

4 - 20 mA, 0-5 Vdc, 1 - 5 Vdc, 0 - 10 Vdc

Remo e Manual Adjus

Remo e Au o/Manual Swi ch

• Elec ronically Pro ec ed wi h Tempera ure Warning and Shu down Sys em

• Single- or Three-Cycle Resolu ion (Jumper Selec able)

• Shor ed SCR De ec ion (Op ional)

Features for the MaxPac IP include:

• Phase Angle Firing

• Isola ed Con rol Circui Inpu s

0 - 5 mA, 0 - 20 mA

0 - 50 mA, 1 - 5 mA

4 - 20 mA, 10 - 50 mA

0 - 5 Vdc, 0 - 10 Vdc

• Op ional Curren Limi

• Sof S ar

• Line Vol age Compensa ion

• Zero & Gain Adjus men s

• Buil -In Manual Adjus men

• Curren Limi Adjus men (Op ional)

If you have applica ion ques ions, refer o he Engineering Resource sec ion of our websi e a

www.chromaloxhea ing.com o find he answer you’re looking for, or call one of our applica ion

engineers a 1-888-996-9258 for personal assis ance.

- 2 - © 2002 Chromalox®, Inc. 1-888-996-9258

○○○○○○○○○○○○○○○○○○○

Table of Contents

Section Topic Page

1 ................................................ Impor an Safeguards ...................................................................................... 3

2 ................................................ Descrip ion ...................................................................................................... 4

3 ................................................ Before You Ins all ............................................................................................ 5

4 ................................................ Ins alla ion ....................................................................................................... 6

4.1 ................................ Moun ing ........................................................................................................ 8

4.2 ................................ Wiring ........................................................................................................... 11

4.2.1 ................ Touch-Safe Design ....................................................................................... 11

4.2.2 ................ Cover Removal and Ins alla ion ................................................................... 12

4.2.3 ................ Power/Load Wiring ....................................................................................... 12

4.2.4 ................ Ins rumen Power ......................................................................................... 16

4.2.5 ................ Grounding ..................................................................................................... 16

4.2.6 ................ Command Signal Wiring............................................................................... 17

4.2.7 ................ Calibra ion .................................................................................................... 23

5 ................................................ Specifica ions ............................................................................................... 24

6 ................................................ Main enance ................................................................................................. 25

7 ................................................ Troubleshoo ing ............................................................................................ 26

8 ................................................ Par s and Accessories .................................................................................. 27

9 ................................................ Warran y and Re urn Informa ion ................................................................. 28

10 .............................................. EC Declara ion of Conformi y ....................................................................... 37

- 3 -

© 2002 Chromalox®, Inc.1-888-996-9258

1

Please read all ins ruc ions before ins alling and opera ing your MaxPac™.

To avoid elec rical shock or injury, always remove power before servicing a circui .

Personnel working wi h or near high vol ages should be familiar wi h modern me hods of resusci a ion. Con ac

an area supervisor or safe y personnel for more informa ion.

Throughou he MaxPac User Manual, he safe y aler and he in erna ional elec ric shock/elec rocu ion

symbols will aler you o po en ial hazards. Safe y precau ions should always be followed o reduce he risk of

personal injury o persons from fire and elec rical shock hazards.

Safe y Aler Symbol

In erna ional Shock/Elec rocu ion Symbol

Each safe y message is preceded by a safe y aler symbol and one of hree words: DANGER, WARN-

ING, or CAUTION.

These mean:

○○○○○○○○○○○○○○○○○○○○○○○○

Important Safeguards

You WILL be killed or seriously hur if you do no follow ins ruc ions.

You CAN be killed or seriously hur if you do no follow ins ruc ions.

You CAN be hur if you do no follow ins ruc ions.

DAN ER

WARNIN

CAUTION

Damage Preven ion Messages:

You will see o her IMPORTANT messages ha are proceeded by he word ha are in ended o

help preven damage o he MaxPac™ or o her equipmen . No e ha Damage Preven ion Messages are NOT

accompanied by he Safe y Aler Symbol.

CAUTION

- 4 - © 2002 Chromalox®, Inc. 1-888-996-9258

2

† This can be se o hree cycles ‘On’ / hree cycles ‘Off’ (see sec ion on ins alla ion op ions).

○○○○○○○○○○○○

Description

MaxPac I, II, and III

The Chromalox MaxPac I, II, and III con rollers are highly versa ile SCR Power Paks wi h op ional plug-in

propor ional firing and shor ed SCR de ec ion boards. Firing modes include On/Off and DOT propor ional zero

vol age swi ching. Chromalox exclusive DOT (Demand Orien ed Transfer) firing echnique swi ches he fewes

number of cycles o provide he mos precise zero crossover con rol. A 50% ou pu , he uni ’s ou pu al er-

na es be ween one cycle “On” and one cycle “Off.” A 51%, he ou pu con inues wi h one cycle “On,” one

cycle “Off,” and gradually in egra es one ex ra “On” cycle for he addi ional 1%. This DOT fired echnique also

minimizes empera ure overshoo , empera ure fluc ua ions and helps ex end he load’s elemen life due o

reduced hermal shock.

The power SCR assemblies consis of one, wo, or hree pairs of SCRs connec ed back o back (wi h an

op ional semiconduc or fuse), RC Snubber, and MOV pro ec ion. The firing circui is based on a common On/Off

con rol board wi h plug and play Shor ed SCR and DOT fired plug-in boards. Diagnos ic indica ors are included.

Plug-in erminal blocks for easy cus omer in erface are also provided.

MaxPac IP

The Chromalox MaxPac IP u ilizes Single Phase, Phase Angle firing o modula e power o an induc ive or

resis ive load. Phase Angle con rol has he advan age of propor ioning every cycle hereby providing very fine

resolu ion of power. Fas responding loads in which he resis ance changes as a func ion of empera ure

require Phase Angle con rol. The MaxPac IP offers a Sof S ar fea ure ha assures ha he load power is

gradually increased from zero o he value se by he command signal in he even of a power in errup ion. In

addi ion, op ional Curren Limi is used o pro ec he load, SCR con roller and he o al sys em from large surge

curren s ha could occur a s ar -up.

- 5 -

© 2002 Chromalox®, Inc.1-888-996-9258

3

○○○○○○○○○○○○○○○○○○○

Before You Install

Immedia ely af er receiving your MaxPac I, II, III or IP Series Con roller, visually inspec he shipmen packaging

and record any damage on he shipping documen s. Unpack he con roller and carefully inspec for obvious

damage due o shipmen . If any damage has occurred, YOU mus file a claim wi h he carrier company, since

he carrier company will no accep a claim from he shipper (Chromalox).

Be sure o check he model number and verify ha you have received he correc Model of con roller.

If he con roller is no ins alled and placed in o opera ion immedia ely, i should be s ored in a cool, dry environ-

men . Tempera ure ex remes and excessive mois ure can damage he con roller.

Before choosing a loca ion in which o moun your MaxPac, please consider he following:

Temperature

When moun ing he SCR uni in a con rol panel, a en ion should be paid o he enclosure empera ure.

The SCR is ra ed o perform a i s namepla e curren ra ing in empera ures up o 50˚C (122˚F).

Ensure ha adequa e ven ila ion is provided or some o her me hod of main aining he correc cabine

empera ure is used.

Cleanliness

Careful a en ion mus be paid in areas subjec ed o airborne par icles. The efficiency of he hea sinks

relies on heir conduc ing surfaces being main ained in a clean manner. (See he Main enance Sec ion.)

Dampness

High humidi y or hosing down a uni should be avoided.

Clearance

Choose a loca ion ha will provide adequa e spacing around he uni when moun ed. This will ensure

proper air flow necessary o cool he device.

WARNIN

Hazardous Voltage: Disconnec and lockou power before ins alling

or servicing. Failure o comply could resul in personal injury or

equipmen damage.

- 6 - © 2002 Chromalox®, Inc. 1-888-996-9258

Installation Section

(continuation of page 5)

The forced air design of the MaxPac series allows mounting in any direction. It is essential that air flow through

the enclosure be planned to insure proper cooling.

The 100 amp through 300 amp open design MaxPac allow the input line power to connect from either of two directions.

The output power can only be connected from one direction. The three mounting configurations

are shown below (MaxPac II Three-Phase Two-Leg Shown).

Open designs above 300 amps and all closed designs allow incoming

and outgoing wiring in either direction.

In In

Configuration One

Cool Air In Warm Air Out

Fan Phase 1 Phase 3

or In Out or In Out

Configuration Two

Out Out

In In

Warm Air Out Cool Air In

Phase 1 Phase 3 Fan

or In or In

Configuration Three

Warm Air Out

Out

Phase 3

or In

In

Out

Phase 1

In or In

Fan

Cool Air In

- 7 -

© 2002 Chromalox®, Inc.1-888-996-9258

Installation Section

(

continuation of

p

a

g

e 5

)

Examples of Proper Air Flow

Pagoda Top

Fan

Air

Louvers Louvers

MaxPac

Air

Fan MaxPac

Fan

Enclosure

Air Enclosure

Fan

Filter

Forced Air In

Forced Air Out

Louvers

Since hot air rises naturally, it is not recommended that cooling air ente

r

from the top and exhaust at the bottom of the enclosure.

- 8 - © 2002 Chromalox®, Inc. 1-888-996-9258

FigureFigure

FigureFigure

Figure Drawing NumberDrawing Number

Drawing NumberDrawing Number

Drawing Number ModelModel

ModelModel

Model

FigureFigure

FigureFigure

Figure ModelModel

ModelModel

Model

1 .............. 100A, 150A, & 200A 2-Leg Open Type

1 .............. 100A, 150A, 200A, & 300A 1-Leg Open Type

2 .............. 100A, 150A, & 200A 3-Leg Open Type

3 .............. 300A 2-Leg Open Type

4 .............. 100A, 150A, 200A, 300A & 400A 1-Leg Touch-Safe

4 .............. 400A 1-Leg Open Type

5 .............. 100A, 150A, 200A, 300A & 400A 2-Leg Touch-Safe

5 .............. 400A 2-Leg Open Type

6 .............. 100A, 150A, 200A, 300A & 400A 3-Leg Touch-Safe

6 .............. 300A & 400A 3-Leg Open Type

7 .............. 550A & 650A 1-Leg Touch-Safe

7 .............. 550A & 650A 1-Leg Open Type

8 .............. 550A & 650A 2-Leg Touch-Safe

8 .............. 550A & 650A 2-Leg Open Type

9 .............. 550A & 650A 3-Leg Touch-Safe

9 .............. 550A & 650A 3-Leg Open Type

................ 800-1200 Amp uni s, consul fac ory

4

○○○○○○○○○○○○

Installation

Please read all informa ion in his sec ion before beginning he ins alla ion of your MaxPac.

Ins alla ion of he MaxPac requires hree s eps:

1. Moun ing

2. Power wiring

3. 120 or 230 Vac 50/60hz for ins rumen power. See 4.2.4, pg. 16.

4.1 - Step 1: Mounting

Before moun ing your MaxPac, please read he sec ion i led “Before You Ins all’ on page 5 for a descrip ion of

an ideal environmen for he uni ’s opera ion.

The space required for moun ing he MaxPac Power Pak depends upon he model. The able below refers o

he figures on he following pages. These figures illus ra e he dimensions and moun ing holes for he various

MaxPac Power Pak models. Please refer o hese figures before moun ing your uni .

IMPORTANT: Please no e ha he figures on he following pages are

not drawn to the same scale.

- 9 -

© 2002 Chromalox®, Inc.1-888-996-9258

Figure 1 Figure 2

Figure 3 Figure 4

Figure 5

4.7" [107mm]

0.0" [0mm]

1.0" [25mm]

4.75" [121mm]

8.5" [216mm]

9.5" [241mm]

6.0" [153mm]

7.3" [185mm]

FIRING PACKAGE

FAN END

Ø0.280" [Ø7.11mm]

(6 HOLES)

4.2" [107mm]

0.0" [0mm]

1.0" [25mm]

7.2" [184mm]

13.5" [342mm]

14.5" [368mm]

6.0" [153mm]

7.28" [185mm]

FIRING PACKAGE

FAN END

Ø0.280" [Ø7.11mm]

(6 HOLES)

7.2" [183mm]

0.0" [0mm]

1.3" [33mm]

7.3" [185mm]

13.3" [337mm]

14.6" [371mm]

12.0" [305mm]

13.3" [338mm]

FIRING PACKAGE

FAN END

Ø0.280" [Ø7.11mm]

(6 HOLES)

5.12" [130mm]

0.0" [0mm]

1.3" [33mm]

9.3" [237mm]

13.3" [338mm]

14.6" [371mm]

8.1" [206mm]

9.1" [232mm]

FIRING PACKAGE

FAN END

Ø.3125 [Ø7.94mm]

(8 HOLES)

5.3" [135mm]

8.4" [214mm]

0.0" [0mm]

1.3" [33mm]

9.3" [237mm]

13.3" [338mm]

14.6" [371mm]

14.7" [375mm]

15.75" [400mm]

FIRING PACKAGE

FAN END

Ø.3125" [Ø7.94mm]

(8 HOLES)

5.3" [135mm]

- 10 - © 2002 Chromalox®, Inc. 1-888-996-9258

Figure 9

13.8" [351mm]

0.0" [0mm]

1.3" [33mm]

26.5" [673mm]

16.3" [414mm]

17.6" [448mm]

11.3" [287mm]

25.5" [648mm]

FIRING PACKAGE

FAN END

Ø.3125" [Ø7.94mm]

(8 HOLES)

6.3" [160mm]

Figure 6 Figure 7

Figure 8

11.7" [298mm]

0.0" [0mm]

1.3" [33mm]

9.3" [237mm]

13.31" [338mm]

14.62" [371mm]

21.4" [543mm]

22.4" [568mm]

FIRING PACKAGE

FAN END

Ø.3125" [Ø7.94mm]

(8 HOLES)

5.3" [135mm]

5.8" [148mm]

0.0" [0mm]

1.3" [33mm]

11.3" [28mm]

16.3" [414mm]

17.6" [448mm]

9.5" [241mm]

10.5" [267mm]

FIRING PACKAGE

FAN END

Ø.3125" [Ø7.94mm]

(8 HOLES)

6.3" [160mm]

9.8" [249mm]

0.0" [0mm]

1.3" [33mm]

11.3" [287mm]

16.3" [414mm]

17.6" [448mm]

17.5" [444mm]

18.5" [470mm]

FIRING PACKAGE

FAN END

Ø.3125" [Ø7.94mm]

(8 HOLES)

6.3" [160mm]

- 11 -

© 2002 Chromalox®, Inc.1-888-996-9258

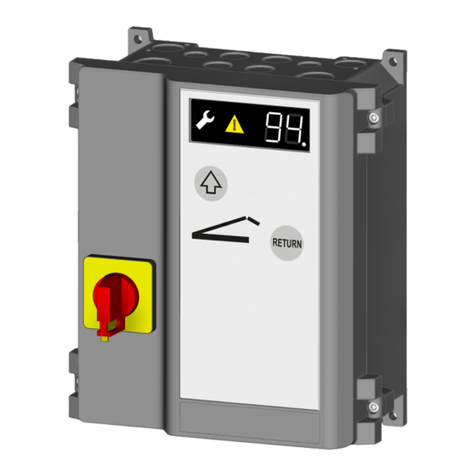

4.2 - Step 2: Wiring

4.2.1 - Touch-Safe Design

If he MaxPac model you purchased is of a Touch-Safe design, follow he s eps on he following page o

ins all he elec rical wiring. This will ensure he wiring is done properly while main aining he Touch-Safe

fea ure. If your MaxPac is of an Open design below 400 Amps, disregard his subsec ion.

The following is a de ailed drawing of a Touch-Safe uni :

Careful a en ion mus be paid when a aching he wiring o he MaxPac o ensure proper and safe opera ion.

This sec ion con ains de ailed informa ion on how o connec he power, resis ive load, ground, and command

signal wiring.

IMPORTANT: Selec ins alla ion wiring ha is in accordance wi h he Na ional

Elec rical Code and any local s andards ha may be applicable.

WARNIN

Hazardous Voltage: Only qualified personnel should perform

elec rical wiring for he MaxPac Power Paks. LETHALLY HIGH

VOLTAGES are associa ed wi h his equipmen and are danger-

ous if improperly ins alled.

COOLING AIR

COOLING AIR

SCR

FUSE

HEATSINK FINS

COVER PROVIDES FOR TOUCH SAFE FEATURE

TOUCH-SAFE COVER PROVIDES WIRE ENTRANCE AND

EXIT THROUGH SEALS COVERING THE WIRE WINDOW.

REMOVAL OF THE TAPE BEHIND THE WINDOWS TO

BE USED ALLOWS WIRES TO PASS. THE TAPE

REMAINS ON UNUSED WINDOWS TO PROVIDE TOUCH

SAFE FEATURE.

BUS BAR DESIGN ALLOWS

FOR WIRING FROM EITHER

DIRECTION AND MULTIPLE

LOAD CIRCUITS

BUS BAR DESIGN ALLOWS

FOR WIRING FROM EITHER

DIRECTION AND MULTIPLE

LOAD CIRCUITS

LONG LIFE, HIGH OUTPUT BALL

BEARING FANS PROVIDE RELIABLE

COOLING

- 12 - © 2002 Chromalox®, Inc. 1-888-996-9258

4.2.3 - Power/Load Wiring

The following illus ra ions depic how o connec he MaxPac o a resis ive or induc ive load. Make sure you refer

o he correc illus ra ion for he MaxPac series you have purchased.

For he power/load drawings:

On open design uni s up o 300 Amps, X1, X2, X3, L1, L2, and L3 refer o copper lugs.

On open design uni s 400 Amps and grea er and all Touch-Safe designs, X1, X2, X3, L1, L2, and L3 refer o

bus bar connec ions.

MaxPac I

4.2.2 - Steps for Touch-Safe Design Cover Removal and Installation

Remove Cover:

1. Loosen he humb screws on bo h ends of he cover.

2. Lif he cover from he base.

Ins all Wiring:

3. A ach he wires o he bus bars in accordance wi h he ins ruc ions in he nex sec ion.

4. Choose he en rance and exi direc ions for he wiring as desired.

5. Af er he wiring is comple e, remove he ape from he inside of he wire gaske s of he

windows ha he power wiring will en er or exi .

Replace Cover:

6. Angle he end of he cover wi hou screws owards he “fan-end” of he uni .

7. Slip ha end in o place firs while allowing he wiring o pass hrough he desired windows.

8. Slip he opposi e end of he cover in o place.

9. Tigh en all humb screws.

WARNIN

Hazardous Voltage: DO NOT remove he ape from he back of he

windows ha are no used, as his main ains he Touch-Safe

fea ure.

MAX PAC I

L2

L1 X1

Single Phase

Resisti e

L2 Connection is

NOT on MaxPac

- 13 -

© 2002 Chromalox®, Inc.1-888-996-9258

MaxPac II

MaxPac III

Three Wire

2 Leg Control

MAX PAC II

L1

L3

L2

X1

X3

L2 Connection is

NOT on MaxPac

Four Wire

3 Leg Control

MAX PAC III

L1

L2

L3

X1

X2

X3

N

N Connection is

NOT on MaxPac

IMPORTANT: The I2 fuses ins alled on he SCR are designed o pro ec he SCR

from faul s on he load connec ion side. They are NOT in ended o provide wire

pro ec ion.

CAUTION

- 14 - © 2002 Chromalox®, Inc. 1-888-996-9258

MaxPac III

MaxPac IP

IMPORTANT: The I2 fuses ins alled on he SCR are designed o pro ec he SCR

from faul s on he load connec ion side. They are NOT in ended o provide wire

pro ec ion.

CAUTION

Three Wire

3 Leg Control

MAX PAC III

L1

L2

L3

X1

X2

X3

Single Phase

transformer

Coupled

MAX PAC IP

L2

L2

L1 X1

L2 connection to

MaxPac is instrument

power only

- 15 -

© 2002 Chromalox®, Inc.1-888-996-9258

The bus bars are designed o accep NEMA s andard wo-hole crimp lugs in accordance wi h he char s below.

The following drawings show proper ins alla ion of he crimp lugs on he bus bars:

Illustration 1: View From Rear Ven ila ed Panel

F

U

S

E

LINE BUS BAR

LOAD BUS BAR

FAN END

SCR

Illustration 2: View From Top

Touch-Safe Units

100 - 400 Amps

Inpu Bus

Up o (3) 1/0 - 300 mcm (70 mm2 — 150 mm2)

Up o (2) 350 - 500 mcm (185 mm2 — 240 mm2)

Ou pu Bus

Up o (10) #8 - #1 (10 mm2 — 50 mm2)

Up o (3) 1/0 - 300 mcm (70 mm2 — 150 mm2)

Up o (2) 350 - 500 mcm (185 mm2 — 240 mm2)

550 - 650 Amps

Inpu Bus

Up o (4) 1/0 - 300 mcm (70 mm2 — 150 mm2)

Up o (3) 350 - 500 mcm (185 mm2 — 240 mm2)

Ou pu Bus

Up o (12) #8 - #1 (10 mm2 — 50 mm2)

Up o (4) 1/0 - 300 mcm (70 mm2 — 150 mm2)

Up o (3) 350 - 500 mcm (185 mm2 — 240 mm2)

800 - 1200 Amps Open Design

Inpu and ou pu bus drilled o accomoda e q y (4) 1/0 - 500 mcm NEMA s andard wo-hole crimp lugs per phase.

- 16 - © 2002 Chromalox®, Inc. 1-888-996-9258

The power wires mus always connec o he fuse side (refer o illus ra ion 1 on page 15) of he bus bar. This

is essen ial o main ain he required spacing be ween he phases and sides, and o align wi h he openings in

he op. The only excep ion o his is when using power dis ribu ion using connec ors of sizes #8 o #1. There

is adequa e spacing for hese connec ors o be moun ed on bo h sides of he bus bar, if necessary.

The bolt head should always be on he ou side of he bus bar (refer o illus ra ion 2 on page 15) wi h he bol

ex ending owards he fuse.

Flat washers should be used on bo h he bol head and he nu , and a lock-washer should be under he nu .

The Touch-Safe MaxPac is designed o allow bo h inpu and ou pu wiring o en er/exi in ei her direc ion. On

he 550 Amp and 650 Amp models, i is necessary o moun he wire in he holes ha maximize he dis ance

for he wire o exi he enclosure. This maximizes he dis ance from he cover o he non-insula ed connec or.

When using he power distribution fea ure and moun ing erminals on bo h sides of he bus bar, he wires

moun ed on he ou side of he bus bar mus be ben inward sligh ly o align wi h he opening in he op. All

wiring, especially he larger wires, should be ben prior o moun ing o he bus bars. DO NOT use he bus bars

as an anchor o bend he power cables.

4.2.4 - Instrument Power

MaxPac requires 120 or 230 Vac 50/60Hz for instrument power. This voltage supplies power for the

control circuits, fans, high temperature warning indicator, and shorted SCR Indicators (see Fig. 1 on

page 21).

This supply is fused on the main circuit board.

4.2.5 - rounding

Chasis is provided wi h hole pa ern for s andard NEMA wo-hole crimp lugs.

WARNIN

Hazardous Voltage: This Elec rical Equipmen mus be ins alled by

a qualified person and effec ively grounded in accordance o he

Na ional Elec ric Code and local codes.

IMPORTANT

- 17 -

© 2002 Chromalox®, Inc.1-888-996-9258

4.2.6 - Command Signal Wiring

Please refer o he figures on page 19 for illus ra ions of he 6-, 8-, and 10-pin inpu erminals.

MaxPac I, II, and III

On/Off Control Signals

AC Input – The 120 hru 230 Vac signal lines are connec ed o erminal J1 - 7 & 8 (see Fig. 9 on

page 21). An inpu vol age of 120 o 230 Vac urns he power On. The urn OFF vol age is 0 Vac.

DC Input – The 5 - 32 Vdc signal lines are connec ed o erminal J3 - 1 & 4 (see Fig. 10 on page 21).

An inpu vol age of 5 o 32 Vdc urns he power On. The urn OFF vol age is 0 Vdc.

Contact Closure Input – The dry con ac signal lines are connec ed o erminal J3 - 1 & 2 (see Fig. 11

on page 21). A closed con ac urns he power On. The urn OFF vol age is an open con ac .

Process Analog Control Signals

MaxPac I, II, and III have been fac ory calibra ed. These uni s accep 0 - 5, 1 - 5, 0 - 10 Vdc, and 4 - 20

mA inpu signals ha are connec ed o Terminal Block J2. The following signals are connec ed o:

0 - 5 Vdc: Terminal J2 - 9(+) & 7(-) (see Fig. 7 on page 21)

1 - 5 Vdc: Terminal J2 - 5(+) & 7(-) (see Fig. 5 on page 21)

0 - 10 Vdc: Terminal J2 - 10(+) & 7(-) (see Fig. 8 on page 21)

4 - 20 mA: Terminal J2 - 6(+) & 7(-) (see Fig. 6 on page 21)

Auto/Manual Input

The MaxPac I, II, and III can be

wired o make i possible o

selec an inpu from ei her a

empera ure process con roller

or a manual inpu po en iome er.

A swi ch is used o selec

be ween he inpu from a 1K

po en iome er and a linear

con rol inpu (see Fig. 4 on page

21). The uni is shipped wi h a

jumper from erminals 2 and 3 of

erminal block J2 (see illus ra-

ion 3). Remove jumper o ins all

au o/manual inpu .

Demand Indicator

The LED demand indica or is loca ed on he main PC board and is viewable hrough he cover. Wi h he

On/Off con rol op ion, he indica or will display s eady “on” and s eady “off”. Wi h he DOT Firing op ion,

he indica or will display he rapid firing sequence.

IMPORTANT: When enabling he Au o/Manual Inpu , he jumper from erminals 2

and 3 of erminal block J2 mus be removed.

CAUTION

Illustration 3

N

C

N

O

CO

NTA

CT

N

O

RMALLY

C

L

OS

E

D

(

SWNC

)

CO

NTA

CT

N

O

RMALLY

O

PE

N

(

SWN

O)

S

WIT

C

H

A

SS

EMBLY

(

SW

)

PANEL T

O

B

E

MOU

NTED T

O

LE

G

EN

D

PLATE

(

LP

)

A

U

T

O

HAND

S

WIT

C

H KN

OB

(

SW

)

A

U

T

O

HAND

WIRIN

G

1

4

N

C

N

O

1K

P

O

TENTI

O

METE

R

J2

CW

2

3

- 18 - © 2002 Chromalox®, Inc. 1-888-996-9258

SCR Control Board

The Basic con rol board provides he following func ions:

The low vol age dc o opera e he circui ry:

A swi ching regula or circui conver s he ins rumen power vol age o +12Vdc.

The power dis ribu ion for he cooling fans:

The incoming ins rumen power is fused and hen rou ed o he fan power erminals.

The signal condi ion for he on/off inpu and analog inpu s:

The 120 o 240 on/off inpu is isola ed by an op o-coupler. The dc and con ac closure inpu s are

buffered by he circui ry. Amplifiers conver he analog inpu s and he po en iome er inpu o a

signal level compa ible wi h he op ional propor ional firing board. The plug-in recep acle for he

op ional propor ional board allows for an easy upgrade o propor ional con rol.

The drive signal o he SCR rigger boards:

The empera ure alarm:

The hea sink empera ure is derived from a solid s a e sensor moun ed on he

hea sink. This is hen compared o wo se poin s. The firs alarm is a warning and

ac iva es he ex ernally connec ed device. This allows ime o correc he problem

before he second alarm inhibi s he firing circui .

The Shor ed SCR Alarm:

The plug-in recep acle for he shor ed SCR board is loca ed on his board. Signals from

he SCR are rou ed o he op ion board. When a shor is de ec ed he ex ernally

connec ed device ou pu is ac iva ed.

2AMP (2AG)

CHROMALOX P/N 0024-01097

LITTLEFUSE P/N 225 002

- 19 -

© 2002 Chromalox®, Inc.1-888-996-9258

Proportional DOT Firing Board

Chromalox’s exclusive DOT (De-

mand Orien ed Transfer) firing

echnique swi ches he fewes

number of cycles o provide he

mos precise zero crossover con rol.

A 50% ou pu , he uni ’s ou pu

al erna es be ween one cycle “On”

and one cycle “Off.” A 51%, he

ou pu con inues wi h one cycle

“On,” one cycle “Off,” and gradually

in egra es one ex ra “On” cycle for

he addi ional 1%.

Remote Shutdown

When i is necessary o disable he ou pu , connec a dry con ac be ween J3 - 3 & 4 (see Fig. 12 on

page 21). When i is closed, he power con rol will shu OFF.

Shorted SCR Detection (optional)

This op ion provides a means of aler ing an opera or o a problem wi h he sys em. An ex ernal

indica ing lamp or relay can be connec ed o J1 - 5 & 6 (see Fig. 2 on page 21). This indica or mus

be ra ed for he ins rumen power applied o J1 - 1 & 2. Three diagnos ic LEDs show which SCR pair

is faul ed. These ligh s are synchronized wi h he demand indica or and can only indica e while he

demand is ac ive. Shor ing J3 - 5 & 6 can disable he ou pu a J1 - 5 & 6. The alarm can be selec ed

as la ching or non-la ching.

A la ching alarm means ha if he alarm ac iva es and he sys em subsequen ly re urns o normal, he

alarm will remain la ched un il a rese bu on (ex ernal swi ch – cus omer provided) is pressed. A non-

la ching alarm rese s au oma ically.

IMPORTANT: This shu down overrides he con rol inpu only. I will NOT pro ec agains

faul ed or damaged SCRs.

CAUTION

SHORTED SCR DETECTION

DEMAND

123

SHORT J3-1 & 2 FOR

1 CYCLE FIRING

SHORT J3-2 & 3 FOR

3 CYCLE FIRING

Uni shipped for 3 cycle opera ion

Table of contents

Other Chromalox Control System manuals

Popular Control System manuals by other brands

Tormatic

Tormatic HA MS 400V Assembly and operating instructions

zipwake

zipwake E Series installation guide

Hybernite

Hybernite Superday ROC 2300 Instructions for use

RichAuto

RichAuto AutoNow F141 user manual

Danfoss

Danfoss ADAP-KOOL AK-SM 800 Service guide

Lutron Electronics

Lutron Electronics RadioRA 2 manual