Page 3

CHAPTER 1 - INTRODUCTION

1. General ............................................................................5

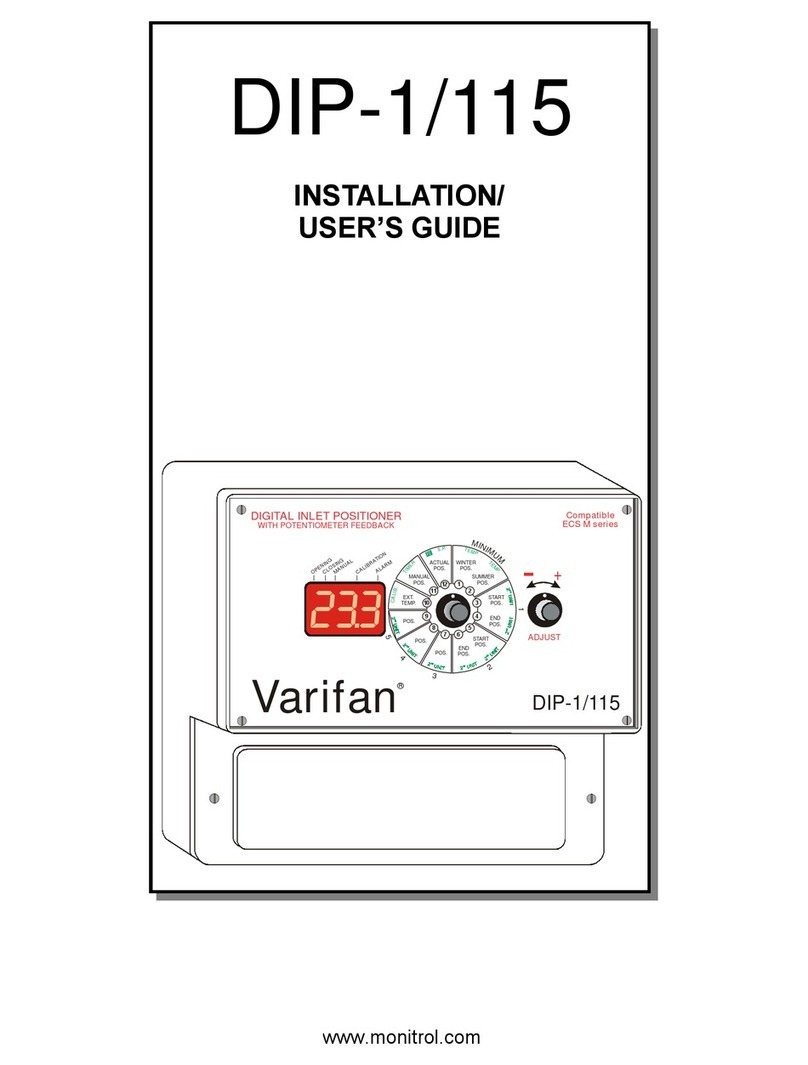

1.1 Description .......................................................................5

Definition of terms .........................................................................7

CHAPTER 2 - INSTALLATION

2.1 Unpacking ........................................................................9

2.2 Installation.......................................................................10

2.3 Switch settings ................................................................10

2.3.1 Line voltage selector switch ............................................10

2.3.2 Software setting switches ...............................................11

2.4 Connection procedure.....................................................11

2.4.1 Input power .....................................................................11

2.4.1.1 115 VAC..........................................................................11

2.4.1.2 230 VAC..........................................................................12

2.4.2 Mist output ......................................................................12

2.5 Temperature probes .......................................................12

2.5.1 Single temperature probe ...............................................12

2.5.2 Averaging........................................................................12

2.6 Alarm...............................................................................13

2.7 Powering up ....................................................................13

CHAPTER 3 - USER’S GUIDE

LED status window ......................................................................16

Control dials .................................................................................16

PRIMARY FONCTIONS

Main set point...............................................................................18

Stage 1 differential .......................................................................19

Stage 1 timer run time..................................................................20

Stage 1 timer idle time .................................................................21

Stage 2 relative set point .............................................................22

Stage 2 differential .......................................................................23

Stage 2 timer run time..................................................................24

Stage 2 timer idle time .................................................................25

Ramping.......................................................................................26

Low temperature record...............................................................27

High temperature record ..............................................................28

Ambient room temperature display..............................................29

TABLE OF CONTENTS