EN - 2

1 - INTRODUCTION

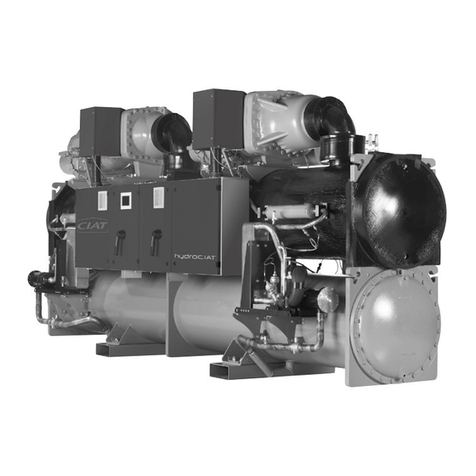

HYDROCIAT water-cooled condensation chilled water

production units, with LW series screw compressors, and

LWP series heat pump, provide the perfect solution to the

problems encountered in the fields of air conditioning or the

industrial process.

These units comply with standards EN 60-204 and EN 378-2,

as well as the following directives:

- Machinery 2006/42 CE

- EMC 2004/108 EC

- LVD 2006/95 EC

- PED 97/23 EC

-> Category 3 models LW - LWP 1800BX (HPS) to 2800BX (HPS)

-> Category 4 models LW - LWP 3050BX (HPS) to 4800BX (HPS)

Test pressure (TP): Test not executed given the

harmfulness of a hydrostatic pressure test. CIAT has set up

compensatory measures (tests on a model representative

of all 3 x PS assemblies) in compliance with § 5.3.2.2 a and

6.3.3 iii of standard 378-2.

Shipment temperature:

LW 1800 to 2800 → Min. -30°C - Max. 50°C.

LW 3050 to 4800 → Min. -30°C - Max. 60°C.

Storage temperature:

LW 1800 to 2800 → Min. -30°C - Max. 50°C.

LW 3050 to 4800 → Min. -30°C - Max. 60°C.

Operating temperature:

Refer to the section on "operating limits" in these instructions.

2 - SHIPMENT OF THE UNIT

- During shipment, the load must be securely strapped in place

to prevent any movement, and to protect the unit from damage.

- Models LW 1800BX (HPS) to 4800BX HPS must be shipped

on a curtain-sided lorry

- Container shipment:

The container must be selected to prevent any loading or

unloading problems.

The units will be mounted on a wooden frame, and covered

with a plastic film. The whole bundle will be inside a wooden

crate. Loading and unloading by forklift truck.

Do not lift the unit by its accessories.

3 - RECEIPT OF GOODS

3.1 Check equipment on delivery

- Check the condition of the unit and the compliance of the

delivery upon its arrival on-site.

Complete the associated documents, and return them to CIAT.

Note any damaged or missing parts on the delivery slip.

IMPORTANT: you must notify the carrier of any damage

and/or missing parts by registered letter within three days of

delivery.

- Systematically leak test all the refrigeration connectors.

- Similarly, be sure not to store the unit in an outdoor location

exposed to adverse weather and frost.

3.2 Identifying the equipment

Every unit has a

manufacturer's plate

(A) displaying an

identification number

Check the plate on the unit to ensure that it is the correct

model.

Please include the identification number

in all correspondence with CIAT.

4 - SAFETY INSTRUCTIONS

To prevent accidents while installing, activating and adjusting

the unit, the following equipment specifics must be taken into

account:

- Pressurised refrigeration circuits.

- Presence of refrigerant.

- Presence of electrical voltage.

- Location.

Only experienced and qualified persons may work on this

equipment.

The recommendations and instructions in this manual and on

each drawing provided with the unit must be followed.

In the case of units with pressure equipment or components,

we recommend that you contact your professional organisation

for information on the regulations that apply to operators

or owners of pressure equipment or components. The

specifications of this equipment or components are given on

the manufacturer's plate or in the regulatory documentation

provided with the product.

A fire protection device is fitted as standard on the units. This

device can only be removed under the responsibility of the

operator, and if the risk of fire is fully under control.

Always comply with applicable standards and regulations.

IMPORTANT: Make sure the main disconnect switch in the

unit's electrical panel is in the OFF position before working on

the unit.

5 - MACHINE

COMPLIANCE

6 - WARRANTY

The warranty is effective

for a period of 12 months

from the date the unit is

activated, provided said

date occurs within three

months of the invoice date.

It is effective for a period

of 15 months from the unit

invoice date in all other

cases.

NOTE: Refer to our general

terms and conditions of

sale for further information.

7 - UNIT

LOCATION

Before setting up the unit in its intended location and connecting

it, the installer must check the following points:

- These units are designed to be installed and stored

inside a machine room that is sheltered from the frost

and the elements. Failure to do so will incur the loss of

the manufacturer's warranty.

- The room housing the unit must comply with the requirements

of regulation EN 378-3 and other specifications applicable at

the installation site.

Min. room ventilation flow rate

Q min. = 15 x s x (mc/φ) with at least 2 m3/h, where

s: Safety coefficient = 4

φ: Density of refrigerant (R134a) at atmospheric pressure and

25°C = 4.258 kg/m3.

mc: Mass of refrigerant (kg)

please refer to section 18, Electrical specifications:

Q min. = mc

14.09

A