Cillit CB-THERMOCYCLON 12 N Manual

1. Usage 2. Characteristics of the

appliance

3. Special and

fundamental requisites

4. Installation

The CB-THERMOCYCLON filters are

used to remove particles in suspen-

sion, metal oxides and muds in

circulation in heating and cooling

systems.

C B -T HE RM OC YC LO N a re r ea l

clarifying and demudding filters with

filtering masses. With respect to

magnetic filters, which retain only the

magnetic particles of iron oxide, the

CB-THERMOCYCLON filters also

remove non-magnetic metal oxides,

mud and particles in suspension.

The CB-THERMOCYCLONS keep the

water in circulation in the system clear

and free of impurities in time, helping

the protective action of the chemical

conditioners of the Cillit series.

The CB-THERMOCYCLON filters can

also be used for sanitizing systems

where there is scale or corrosion in

progress: in this case, the filter allows

assisting the chemical action of the

sanitizing product Cillit-HS 23 RS PLUS,

cleaning the water of the circuit of

muds and impurities put into circula-

tion by the sanitizing product and

allowing flushing these away.

The CB-THERMOCYCLON filters allow

adding or topping up the conditioners

of the Cillit-HS series in the circuit, in

compliance with the requirements

currently in force.

The CB-THERMOCYCLONS are mass

filters with manual washing, made up

of a reinforced fibreglass column,

complete with upper head, easily

removed, in brass resistant to the

characteristic temperatures and

pressures of heating systems.

In the filters, special washable filtering

masses, with selected granule sizes,

allow retaining the impurities in

circulation.

On the upper head there are four

manual valves for connection in

derivation from the return pipes of the

heating system, as well as for

connection of the water supply pipes,

used for the back-washing of the filter

and for connection to the drainpipe

(fig. 1). On the head of the filters there

is also a sphere tap to draw water

from the circuit and a manual valve for

topping up the conditioning product,

flushed away during the back-

washing of the filter. Lastly, the supply

includes a funnel that can be used to

top up the conditioning product.

Tap to draw sample to check the

concentration of the conditioning

product in the circuit.

Manual valve to top up the

chemical conditioners using a

funnel.

Materials resistant to the working

pressure and temperature of

heating systems.

Optional: CB-DEVIATORE 12

CON MAGNETE (code 12345AA)

to be used for the connection and

separation of the water flow in the

THERMOCYCLON 12 model,

complete with magnet to retain

particles of a ferrous nature, which

are not deviated towards the CB-

THERMOCYCLON.

l

l

l

l

l

l

l

Special washable filtering masses

with selected granule sizes

capable of removing, as well as

magnetic iron oxides, also muds

and particles in suspension.

Simplicity of installation, use and

maintenance.

Washing with water from the

water supply allows topping up

only minimum quantities of water

and conditioning product.

Install the equipment in compliance

with local regulations in force and

with the provisions of the D.M. 37/08.

The installation must be carried out by

qualified personnel able to issue a

Declaration of Conformity.

1

Replaces AL.02.A.9

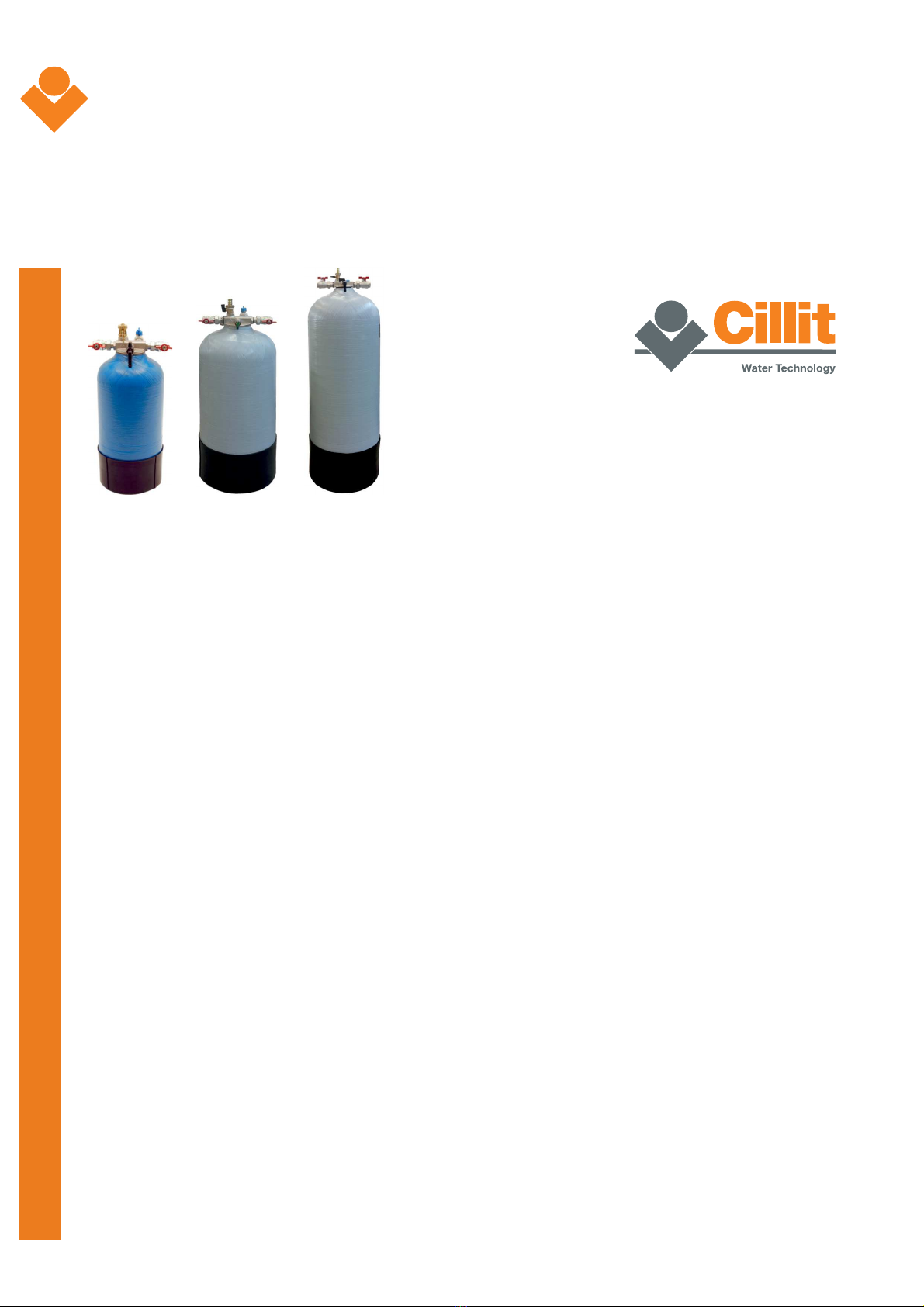

CB-THERMOCYCLON 12 N

CB-THERMOCYCLON 25 N

CB-THERMOCYCLON 50 N

Clarifying and demudding mass filters for heating and

cooling systems.

AL.02.A.10

Edition 11/17

Index key AL

Technical information

2

The CB-THERMOCYCLON filter is

installed as a by pass on the return

pipe from the heating or cooling circu-

it (figure 1).

Allow opportune shut-off valves at

the entrance, exit and on the pipe of

arrival of the washing water. In the

case of the CB-THERMOCYCLON 50

allow a special circulator with an

hourly flow rate of 1000 l/h and a head

of 0.5 bar on the pipe upstream.

The pressure and the temperature of

the recirculating water must not

exceed the maximum allowed.

For correct management and func-

tioning of the filter, it should be

checked at least twice a year by a spe-

cialized technician from the Assis-

tance organization.

In heating installations, the water has

to be adequately treated to avoid

phenomena of scaling and corrosion

as required by DMiSE of 26/06/2015

on energy efficiency in building, by

D.M. 37/08 on the safety of installa-

tions and by the technical standard

UNI CTI 8065 on the treatment of

water in heating systems for civil use.

demudding, clarifying filter, with a

multi-layer filtering bed, washable in

counter-current to filter, demud and

clarify the water in circulation in

heating systems with hot water,

capable of retaining metal scales,

lumps or rust and mud, leaving the

water clear and transparent.

The supply includes the pipes and

fittings, the shut-off valves, the valves

for samples and adding conditioners.

The supply includes:

reinforced fibreglass body,

designed for hot water (80°C);

hydraulic connection unit in

brass/bronze, complete with

fittings and shut-off valves;

special multi-layer filtering masses

in spherical quartz washable in

counter-current;

tap for taking samples;

fitting and valve for adding and

Please follow in detail the specific

instructions shown in the assembly

and service manual supplied with the

appliance; if these are lost, please

request another copy.

Make sure that the present technical

information is up to date, eventually

make reference to the site

or request an update.

5. Warnings

7. Description for offer

6. Legislations

CB-THERMOCYCLON 12-25-50 N,

l

l

l

l

l

Protect the filter from cold, weather

and direct sunlight. Avoid contact

with oil, solvents, acidic and basic

detergents.

www.cillit.it

Please observe the detailed specifica-

tion given in the installation instruc-

tion manual supplied with the equip-

ment; in case of loss request us a copy.

In the CB-THERMOCYCLON 12

model, for the connection in

derivation to the return pipe of the

heating system, the CB-DEVIATORE

12 CO N M AG N E T E (co d e

12345AA) can be used.

The CB-DEVIATORE 12 is a patented

connecting fitting which allows,

through a diaphragm, efficiently

deviating part of the water to the

CB-THERMOCYCLON filter allowing

its filtration.

Downstream of the diaphragm

there is a magnet which retains the

particles of a ferrous nature which

are not deviated towards the CB-

THERMOCYCLON and which would

therefore continue to circulate with

the water flow in the circuit. The

magnet can be extracted to be

periodically checked and cleaned if

necessary.

Technical data

CB-DEVIATORE 12 CON

MAGNETE for

CB-THERMOCYCLON 12

(code 12345AA)

CB-DEVIATORE 12 CON MAGNETE (code 12345AA)

Inlet/outlet fittings inches

inches

m /h

3

bar

1 ¼"

½"

9

0,15 to 5 m /h

0,45 to

3

9 m /h

3

Inlet/outlet fittings to CB-THERMOCYCLON

Max. operating flow rate

Pressure drop at min./max. flow rate

magnet closure cap

140

65

from theCB-Thermocyclon

to CB-Thermocyclon

In accordance with the law, the reproduction, even partial, of this brochure is prohibited and it remains the property of BWT ITALIA - BWT ITALIA reserves the right to modify its products - 11/17 - AL.02.A.10 - DM - mail

3

Drawings and overall dimensions

s e a s o n a l t o p p i n g u p o f

conditioners.

IQ - Quality Information:

perfect removal of oxides, muds

and impurities in general;

can also be used to filter muds

during the sanitizing of old

systems;

washing in counter-current using

water supply water without using

the system water containing

conditioners;

easy installation using fittings

already prepared;

tap to take samples of water

directly from the circuit;

fitting with valve to add and top up

conditioners required by DMiSE

26/06/2015;

appliance designed to resist the

pressure and temperature of the

water in the heating system.

C B - D E V I A T O R E 1 2 C O N

MAGNETE,is a patented connect-

ing fitting which allows, through a

diaphragm, efficiently deviating part

o f t h e w a t e r t o t h e C B -

THERMOCYCLON filter allowing its

filtration, complete with removable

and cleanable magnet, placed

downstream of the diaphragm, for

the retention of ferrous particles that

a r e n o t d i v e r t e d t o C B -

THERMOCYCLON. Made of brass

with threaded fittings and cap for

magnet extraction.

l

l

l

l

l

l

l

Technical data

Max. operating flow rate m /h

3

inches

-

°C

°C

bar

m /h

3

bar

0,50,35

25 N12 N

1,0

50 N

CB-THERMOCYCLON

½"½" ¾"

13-25up to 12 26-50

8080 80

5-405-40 5-40

55 5

1,51,0 3,0

22 2

Fittings

Number of apartments approx.

Max. temperature water

Environment temperature min./max.

Max. operating pressure

Backwash flow rate approx.

Min. backwash water pressure

CB-THERMOCYCLON 25 N

680

610

HOT WATER

INLET

WASHING

DISCHARGE

HOT WATER

OUTLET

WASHING

INLET

ø265

ø275

CB-THERMOCYCLON 12 N

HOT WATER

INLET

WASHING

DISCHARGE

HOT WATER

OUTLET

WASHING

INLET

ø215

ø200

530

465

CB-THERMOCYCLON 50 N

WASHING

DISCHARGE

WASHING

INLET

HOT WATER

INLET

HOT WATER

OUTLET

1000

1100

ø360

ø342

In accordance with the law, the reproduction, even partial, of this brochure is prohibited and it remains the property of BWT ITALIA - BWT ITALIA reserves the right to modify its products - 11/17 - AL.02.A.10 - DM - mail

4

Fig. 1 - Examples of installation of CB-THERMOCYCLON filters

Fig. 2 - Example of installation of CB-THERMOCYCLON 12 N filter with CB-Dispenser 12 (when applicable)

Caption

1. Shut-off valve

2. Check valve

3. By-pass valve

4. Discharge

5. Product entry

6. Circulator

CB-THERMOCYCLON 50 NCB-THERMOCYCLON 12-25 N

11

6

1 2

5

3

return pipe from

the heating system

44

return pipe from

the heating system

1

1

21

washing

inlet

washing

inlet

5

3

Caption

1.

2.

Shut-off valve

Check valve

3. CB-DEVIATORE 12 CON MAGNETE (code 12345AA)

4. Discharge

5. Product entry

CB-THERMOCYCLON 12 N

return pipe from

the heating system

4

1

1 1

11

2

washing

inlet

5

3

BWT ITALIA Srl

Via Plinio, 59 - 20129 Milano

Tel. 02 2046343 ric.aut.

«

»

Company that operates with Quality Management Systems

UNI EN ISO 9001:2008 certified by Certiquality

Technical information available on the website

This technical information takes into account the experience of the company and applies to normal use of the product according to the above description; other uses must be authorized each time in

writing. For regular operation and maintenance of the systems, an agreement should be made with our Technical Assistance Centres which are present nationwide. BWT reserves the right to make any

modification to its products, including without notice.

The addresses and telephone numbers of our assistance organization and technical consulting service as well as for the sale of our products and systems can also be found in the Yellow Pages under

"Water purification systems, appliances, swimming pools" or by consulting the website.

In accordance with the law, the reproduction, even partial, of this brochure is prohibited and it remains the property of BWT ITALIA - BWT ITALIA reserves the right to modify its products - 11/17 - AL.02.A.10 - DM - mail

This manual suits for next models

2

Other Cillit Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Trion

Trion AIR BOSS owner's manual

Netafim

Netafim Arkal 2" Spin-Klin Compact Stand Alone... Installation and operation instructions

Klingenburg

Klingenburg AS2 manual

SimPure

SimPure T1-400 owner's manual

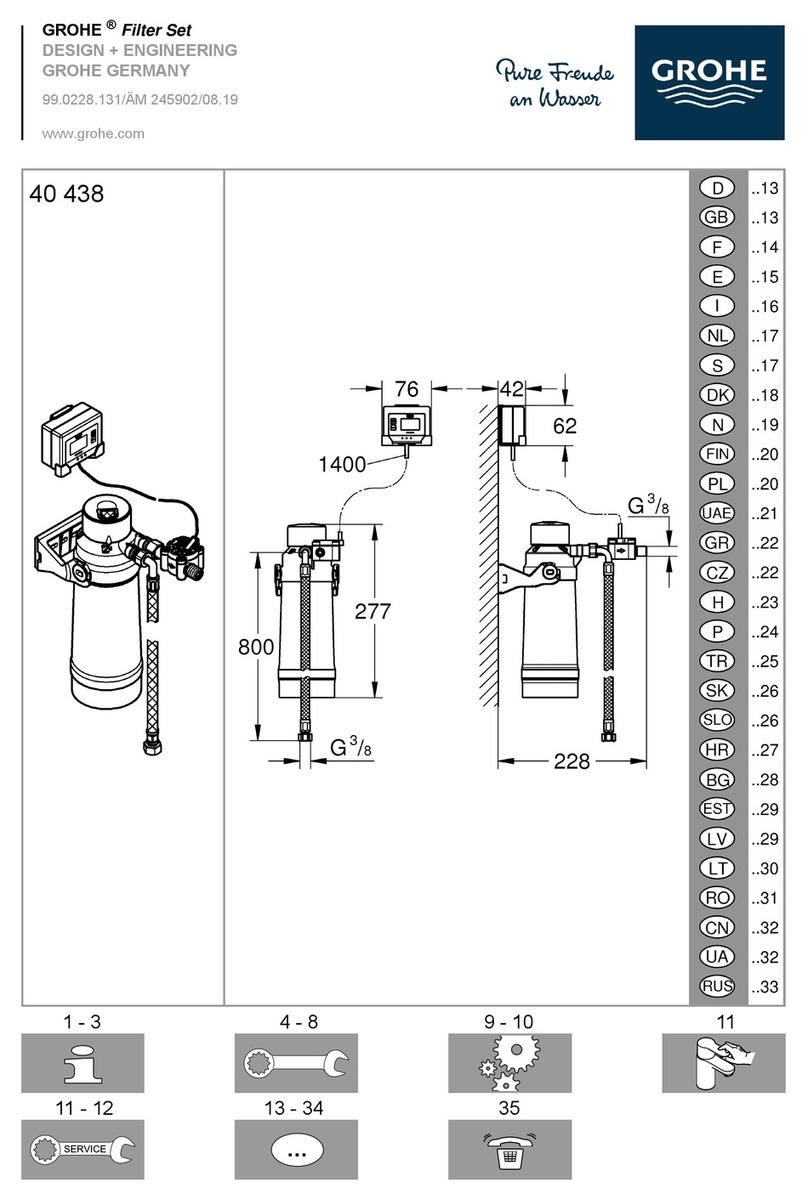

Grohe

Grohe 40 438 manual

KAESER KOMPRESSOREN

KAESER KOMPRESSOREN AQUAMAT CF9 Instructions for installation and operation

SIBRAPE

SIBRAPE MINIFILTRO 10010006 installation manual

Commodity Axis

Commodity Axis Poly-Reactor ViaAqua PR 20/20 Booklet

Steinbach

Steinbach 040050 instruction manual

Thermal Care

Thermal Care SF Series owner's manual

Spectra Watermakers

Spectra Watermakers AQUIFER 360 EXPEDITION owner's manual

Pontec

Pontec PonDuett 5000 operating instructions