Thermal Care SF Series User manual

Page 1 of 6

1. AT NO TIME SHOULD THE INTERNAL PRESSURE EXCEED THE MAXIMUM RATED PRESSURE OF THE FILTER. Refer to

maximum pressure rating decals located on the filter.

2. Under no conditions should the filter lid or pressure gauges be removed while the filter is pressurized.

3. All filters with a side inlet and a bottom foot ring must be placed on a firm supporting surface. DO NOT suspend the

filter by the inlet and outlet connections. All filters with vertical inlet piping must be plumbed into properly

supported piping.

4. Units with damaged or missing parts should NEVER be operated. Contact customer service representatives for

replacement parts.

5. Back-flow prevention devices should be installed upstream of the inlet and downstream of the outlet of the filter to

prevent back flow or vacuum effects that can be damaging to the filter.

6. Pressure relief valves of a sufficient size and volume should be installed upstream of the inlet and downstream of the

outlet of the filter. They should be set so the system never exceeds the maximum rated pressure. It is recommended

that the set point is approximately 20% higher than the operating pressure. Failure to install relief valves could lead to

personal injury or product damage.

I. SAFETY CONSIDERATIONS

5680 W. Jarvis Ave. Phone: (847) 966-2260

Niles, IL 60714 Fax: (847) 966-9358

SF Series Screen Filter

OWNER’S MANUAL

Table of Contents

Safety Considerations..……………………………………….. 1

Receiving & Installation…...…….……………...…………… 2

Filter Operation, Maintenance, & Storage………. 2

Torque Recommendations…..……………………………… 3

Information Concerning Water Hammer…………….. 4

Limited Warranty……………………………………………….. 4

Spare Parts……………….…………………………………………. 5

Optional Equipment……………………………………………. 6

Ensure all appropriate personnel read owner’s manual prior to installation and/or operation of filter. Failure to

comply with instructions and safety precautions could lead to personal injury or product damage. Please call

(847) 966-2636 and ask to speak with one of our customer service representatives if there are any questions.

GENERAL WARNING

Serial # _______________

The Serial # is located on the top of the

outlet flange or pipe.

Always wear Personal Protective Equipment (PPE) - Eye protection, Ear protection, gloves, and protective footwear.

CAUTION

Page 2 of 6

1. Inspect filter to ensure there is no damage from transit.

2. Confirm all dust plugs/flange protectors (inlet, outlet, gauge ports, etc.) are removed.

3. Locate serial number on top of outlet flange or pipe (see diagrams below) and record in the box on page 1.

4. Position the filter into the piping system using the red arrows to indicate flow path.

5. All filters with a side inlet and a bottom foot ring must be placed on a firm supporting surface. DO NOT suspend the filter by the

inlet and outlet connections. All filters with vertical inlet piping must be plumbed into properly supported piping.

6. Installation of isolation valves on both the inlet and outlet sides of the filter is recommended to isolate the filter during maintenance.

7. Install a valve on the drainage port located at the bottom of the filter body (see diagram below). The valve must be plumbed to

atmosphere and the flush line should not have any elevation or be piped to a pressurized line.

8. Ensure pressure gauges (sold separately) are installed in the gauge ports located on the filter body (see diagram below). These gauges

will allow you to monitor the pressure differential across the screen.

9. Review all safety considerations from Section I. to determine if they have all been addressed.

10. Ensure all filter openings are properly connected.

11. Ensure the lid is properly installed. See diagram below and Section IV. Torque Recommendations for instruction.

II. RECEIVING & INSTALLATION

III. FILTER OPERATION, MAINTENANCE, & STORAGE

Start up

Open the downstream valve, then slowly allow fluid to flow through the filter by opening the upstream valve.

Flushing

Periodically (depending on liquid quality) the debris that settles out at the bottom of the filter will need to be flushed out. Open the flush port

valve while the filter is in operation to flush out debris. Flow rate, pressure, and amount of debris determine how long the valve should be open

to flush the debris from the filter tank. It is the user’s discretion to determine the frequency that the valve should be opened.

Never allow debris to accumulate beyond the capacity of the reservoir.

Check gauges to ensure the internal pressure of the filter is relieved before removing the retaining bolts/clamp of lid.

CAUTION

Clamped Lid Operating Instructions:

To Close -

Align vertical slots in the lid assembly with

the pins inside the housing.

Lower the lid assembly until it can be

rotated.

Rotate the lid assembly clockwise to stop.

The head will drop into a locked position

and should be unable to be removed by

pulling straight up.

Install the V-Band clamp.

To Open -

Remove the V-Band clamp.

Using the handle on top of the head; pull

up and rotate the lid assembly counter-

clockwise until the head is free from the

locking pins.

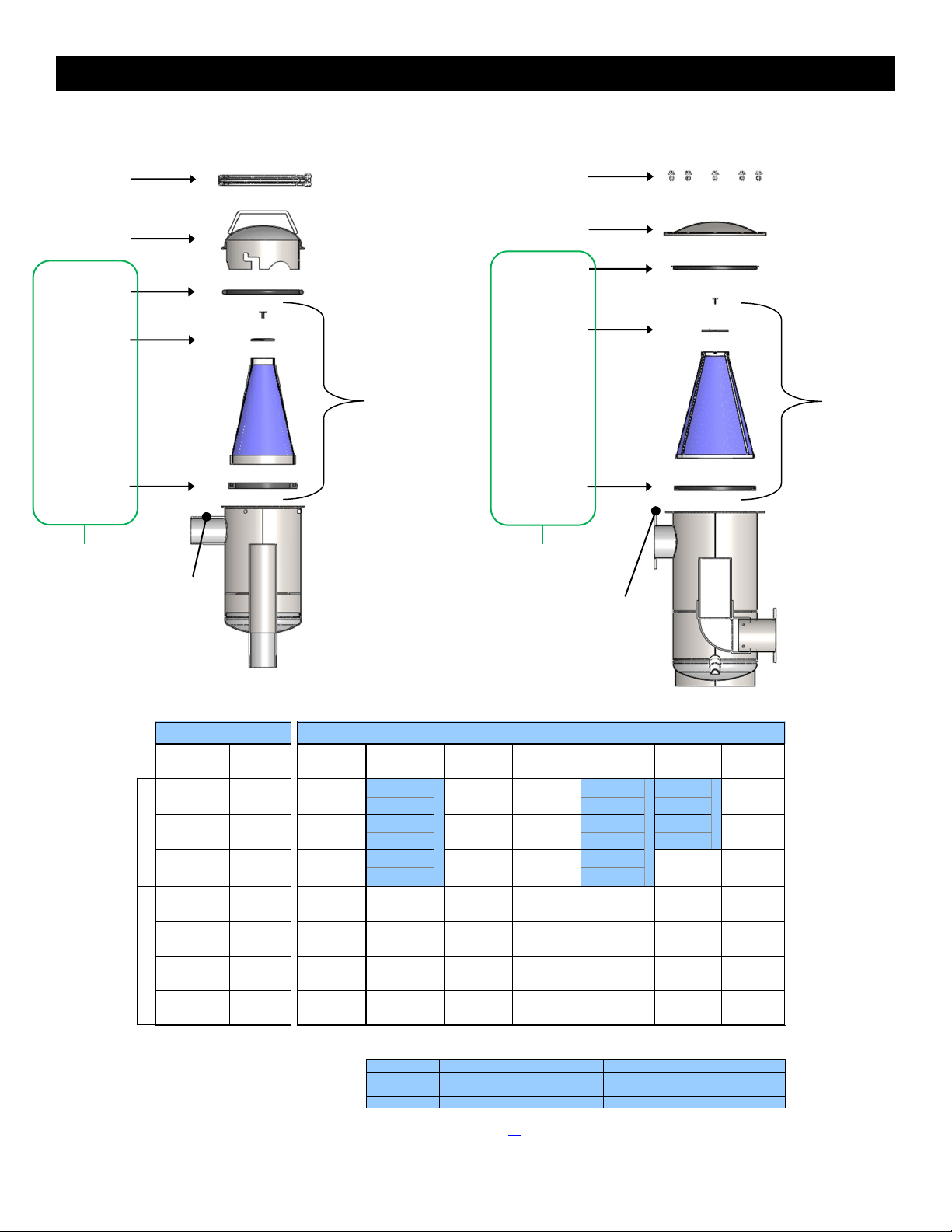

Outlet

Serial # Stamped on Outlet Flange

Foot Ring

NPT Flush Port

Outlet Pressure

Gauge Port

Inlet Pressure

Gauge Port

Inlet

Conical Screen

Element

Page 3 of 6

Cleaning

A pressure differential of approximately 5-7 PSI from the clean condition indicates that the screen requires cleaning. Please note that you must

maintain an inlet pressure that is higher than the pressure differential to maintain flow.

Step 1: Check gauges to ensure the internal pressure of the filter is relieved before removing the retaining bolts/clamps of lid.

Step 2: Remove the lid of the SF Series Screen Filter.

Step 3: Lift the filter element (conical screen) out of the filter body.

Step 4: Carefully scrub down the filter element with a rigid nylon brush until all matter is loosened. Do not use a steel brush.

Step 5: Wash the filter element off with clean water. Do not use a pressure washer.

Step 6: Rinse gaskets and clean the inner-ring where the bottom of the filter element seals.

Step 7: Make sure the U-shaped gasket is fitted securely to the bottom of the filter element. Position the filter element into the body of the

filter.

Step 8: Make sure the filter head gasket is installed on the upper flange of the top of the housing. On V-Band models, the o-ring should be

seated completely in the head assembly. Position the filter lid back on the filter body. Tighten the lid following the Torque

Recommendations.

Storage (Not in Service)

When the filter is not in service, Thermal Care recommends the following to prevent premature deterioration of the filter housing and screen.

Isolate the filter to ensure no flow and release pressure.

Drain the filter body by opening the flush port. Remove the internal screen and gaskets, and thoroughly rinse them with clean fresh water.

Rinse out the inside of the filter body with clean fresh water. Remove any excess water.

The filter is not freeze protected. Proper freeze protection steps must be taken to ensure the filter will not be damaged if exposed to freez-

ing conditions.

1

2

3

4

5

6

7

8

Recommended

Torquing

Sequence

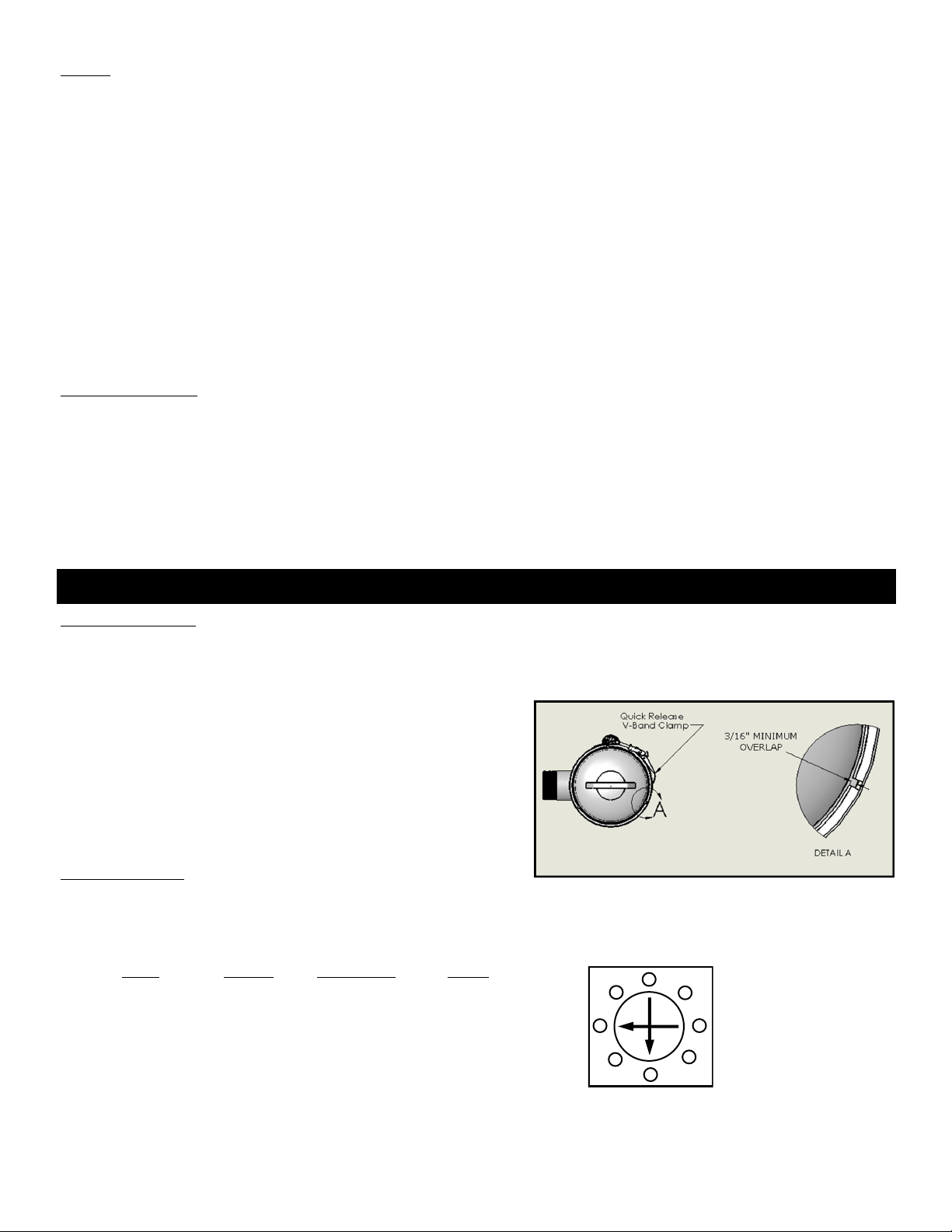

NEVER operate the filter unless all bolts are properly fastened. It is important to follow the torque recommendations as over-torquing may result

in premature failure of the bolt. When tightening the bolted lid, follow the recommended torque sequence above. Complete the torque se-

quence 2 times.

BAND CLAMP MODELS:

The over-center latch clamp is used on the band clamp models and is installed by placing the clamp around the filter, latching the T-bolt with the

receiver, then pushing the latch handle towards the filter body until the safety catch engages. The over-center clamp does not require

adjustment to be installed and removed. The lock nut is set at the factory for proper clamp compression and normally requires no initial field

adjustment. Minor adjustments may be necessary over time. When tightening

the lock nut, ensure that the clamp is compressing the o-ring to seal joint while

not creating an excessive amount of latch handle closing force. When the clamp

is closed, there should be a minimum overlap of 3/16” between the clamp inside

diameter and the outside diameters of both the lid and housing flanges.

(see diagram)

BOLTED LID MODELS:

The bolted lid Filters require that the attachment bolts be tightened sufficiently to make a complete seal without damaging the bolts or the filter

head. Bolts, nuts and washers are used to attach the heads to these filters. The size and recommended torque of the bolt is dependent on the

filter size. The following table shows the bolt size and torque rating for each filter.

Model Bolt Size TorqueBolt Quantity

4” Bolted (3/8”-16) 15 to 25 ft. lbs.10

6” (1/2”-13) 45 to 55 ft. lbs.10

8” (1/2”-13) 45 to 55 ft. lbs.15

10” (5/8”-11) 80 to 100 ft. lbs.20

IV. TORQUE RECOMMENDATIONS

Page 4 of 6

WHAT IS WATER HAMMER?

Water hammer is a phenomenon that can occur in fluid systems with long pipes between the fluid source and the outlet. The term itself refers to

the sound made when water hammer occurs which resembles banging a hammer on a long pipe. Water hammer is a rapid change of pressure

caused by a rapid change in velocity. When the velocity is changed a pressure wave that travels at the speed of sound is initiated and travels in

the upstream direction until it reaches some stationary energy level, like a reservoir. A rarefaction wave (at the pressure of the water source)

then travels downstream at the same speed. If the flow has been shut off down stream the pressure wave impacts the blockage and the pressure

in the entire system is raised very quickly.

WHAT CAUSES WATER HAMMER?

Any action that can cause a rapid change in the velocity of the flow can set off a water hammer - closing a downstream valve, pipe fracture, pump

stoppage, etc. The critical time for which a valve may be closed depends on the length of piping between the valve and the source reservoir. The

longer the distance the slower the valve may be shut to cause a water hammer. Typically for short lengths of pipe (below 500 ft) the critical time

is less than 1/10 second.

WHAT CAN WATER HAMMER DO?

Pressure spikes from water hammer can raise fluid pressures to very high values (in excess of 1000 PSI depending on the situation). Such

pressure spikes can result in mechanical failures such as broken valves, pipes, filters, joints, etc. Water hammer does not have to occur fully to

raise the pressure. A partial hammer can occur that raises the pressure to a certain percentage of the theoretical maximum. The SF Series Screen

Filter is rated to an absolute maximum pressure of 150 PSI for bolted lid models, 125 PSI for band clamp lid models. A water hammer pressure

spike that raises the pressure higher than the maximum rated pressure may result in filter damage.

WHAT CAN I DO TO PREVENT WATER HAMMER?

There are precautions that can be taken to prevent or decrease the effect of water hammer. A pressure relief valve that leads to a surge tank or

accumulator may protect other key components from water hammer. A close adherence to operational policies will also help prevent valves or

pumps from being accidentally shut off thereby causing a water hammer. A close examination of a system will inform you of potential hazards.

V. INFORMATION CONCERNING WATER HAMMER

VI. LIMITED WARRANTY

Thermal Care warrants its equipment to be free from defects in material and workmanship when used under recommended operating conditions.

Thermal Care's obligation is limited to repair or replacement (not adjustment or maintenance), F.O.B. the factory of any parts supplied by Thermal

Care within a period of twelve (12) months from the date of shipment to the original purchaser.

This warranty does not cover the cost of labor during overtime hours (after normal working hours or during weekends and holidays). Any cost

differential for overtime labor will be the responsibility of the customer. Thermal Care is not responsible for any sales, use, excise or other appli-

cable taxes associated with the replacement of parts under this warranty. This warranty will be voided when, in Thermal Care's opinion, the

equipment and/or system has been subject to misuse, negligence or operation in excess of recommended limits, including freezing, or has been

altered, and/or repaired without express factory authorization. If equipment is installed in hostile environments, unless such conditions were

specified at the time of purchase; or the serial number has been removed or defaced, this warranty shall not apply. All labor warranty coverage

provided by the Seller is based on normal ground mounted equipment with proper clearance and equipment access. The Buyer is responsible for

any additional costs associated with special rigging or access platforms required to perform the warranty work and/or any additional labor cost

associated with delays caused by the Buyer which prevent the Seller's service technician from performing their repair work in a proper timely

manner. This warranty is not transferable.

Under no circumstances shall Thermal Care be liable for loss of prospective or speculative profits, or special, indirect, incidental or consequential

damages.

Thermal Care must authorize all warranty service prior to work being performed and have a Thermal Care purchase order issued. All defective

parts become the property of Thermal Care and must be returned as advised by Thermal Care.

Thermal Care neither assumes, nor authorizes any person to assume for it, any liability not expressed in this warranty. There is an implied war-

ranty of merchantability and of fitness for that particular purpose; all other implied warranties, and any liability not based upon contract are

hereby disclaimed and excluded by this warranty. This warranty is part of the standard conditions and terms of sale of Thermal Care.

Page 5 of 6

VII. SPARE PARTS

Model Inlet/Outlet Replacement Filter Disc Gasket Top Lid Clamp

Number Size &

Screen (a) Gasket Gasket Kit (b) Head or

Type *(EPDM) (EPDM) (EPDM) Fasteners

MLS-02-XXX 2" NPT

OR-02-2 GK-02-2 TH-02-2

MLS-03-XXX 3" NPT

OR-03-2 GK-03-2 TH-03-2

MLS-04B-XXX 4" Flanged

MLS-06-XXX 6" Flanged

MLS-08-XXX 8" Flanged

MLS-10-XXX 10" Flanged

Select proper O-Ring, Gasket Kit, and/or Top Head corresponding to serial number stamped on strainer outlet pipe/flange.

Strainer Model Serial No. Part Number Serial No. Part Number

MLS-2 0001-4999 OR-02 / GK-02 / TH-02 5000 & higher OR-02-2 / GK-02-2 / TH-02-2

MLS-3 0001-1999 OR-03 / GK-03 / TH-03 2000 & higher OR-03-2 / GK-03-2 / TH-03-2

MLS-4C 0500-1999 OR-04 / GK-04 2000 & higher OR-04-2 / GK-04-2

SCREEN OPTIONS:

"XXX" (in above part numbers) = MESH or PERFORATED SIZE of SCREEN

Complete Strainer and Replacement Screen orders must specify mesh or perforated size of screen. See catalogue for micron equivalent to mesh. Consult factory for assistance.

Screen Mesh Options: Standard Mesh - 16, 20, 30, 40, 50, 60, 80, 100, 120, 150, 200

Heavy-Duty Mesh - 24x110, 30x150, 40x200, 50x250 (Dutch-weave screens: heavier wire gauge, lower open area %)

Perforated Options: 1/4", 1/8", 1/16"

Select P/N from Table 1 below

Select from Table 1

TH-02

TH-03

GK-02

GK-03

GK-04

OR-03

OR-02

P/N: 2S-XXX

P/N: 3S-XXX

P/N: 4S-XXX

Head/O-Ring

Gasket

(EPDM)

Select P/N from Table 1 below

Table 1

STRAINER

REPLACEMENT PARTS

OR-04

OR-04-2

BAND CLAMP LID

BOLTED LID

GK-04-2

MLS-04C-XXX

4" Flanged

FG-02

DG-02

FG-03

DG-03

FG-04

DG-04

FG-08

DG-08

P/N: 4S-XXX

P/N: 6S-XXX

P/N: 8S-XXX

P/N: 10S-XXX

GK-04B

GK-06

FG-04

DG-04

FG-06

DG-06

TH-10

FASTENERS-10

FG-10

DG-10

BC-02

BC-03

BC-04

TH-04C

TH-04B

FASTENERS-04

HG-04

HG-06

HG-08

HG-10

TH-06

FASTENERS-06

GK-08

TH-08

FASTENERS-08

GK-10

Lid Clamp

*Top Head

*O-Ring Gasket

Disc Gasket

Filter Gasket

Replacement Screen

*Gasket Kit

Gaskets also

Available in

BUNA & VITON

*Part No. based on serial No. of

unit. Please have serial No.

available when ordering

Serial No. Location

SF Series Screen Filter - 2” thru 4C”

Fasteners

Top Head

Head Gasket

Disc Gasket

Filter Gasket

Replacement Screen

Gasket Kit

Gaskets also

Available in

BUNA & VITON

Serial No. Location

SF Series Screen Filter - 4B” thru 10”

Page 6 of 6

5680 W. Jarvis Ave.

Niles, IL 60714

Phone: (847) 966-2260

Fax: (847) 966-9358

OPTIONAL EQUIPMENT

Please note that the following equipment is not included with the purchase of the filter. Please call for information and pricing.

VIII. OPTIONAL EQUIPMENT

Pressure Differential Alarm Package (PDA)

Continuously monitors the pressure drop across the conical

screen.

Visual and audio alarm.

(1) dry output contact.

Automatic Timer Flush Package (ATF-EA-1.5)

Automatically purges particles that have gravitated down

into the debris reservoir at the base of the filter.

Dial in frequency and duration.

110V / 12VDC power supply included.

Full Cone Spray Nozzle Assembly Option

Rinse particles off the screen.

Decrease frequency of screen maintenance.

Other manuals for SF Series

2

Table of contents

Other Thermal Care Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Axeon

Axeon SOLO I quick start guide

Intewa

Intewa SEPAMAT F 20 Installation and user manual

Hydor

Hydor BLUWAVE 05 user manual

Lectranator Systems

Lectranator Systems CRISTAL MAGIC CM3-1 Installation & operation manual

Bestway

Bestway FLOWCLEAR 58271 owner's manual

SpectraPure

SpectraPure Eliminator 90 Installation and operating manual