cimex R48HD Operator's manual

Userinstructions

R48HD andR76HD

HDScarifier

CAUTION- READTHESE INSTRUCTIONS BEFOREUSINGTHEMACHINE

http://www.truvox.com/Products/Three_Brush/Cimex_Heavy_Duty_Range

03-0000-0000Iss.108/04

2

3

DIAGRAMS

4

Contents

Page

1General information ...................................................................5

1.1Importantsafetyadvice...............................................................5

1.2Guidelinesfortheoperator..........................................................5

1.3Transportingthemachine ............................................................5

2Preparing foruse ........................................................................5

2.1Electricalconnection....................................................................5

2.2Fittingaccessories.........................................................................6

2.3Adjustingthe handleheight..........................................................6

3Controls .........................................................................................6

4Operation .......................................................................................6

4.1Startingthemachine....................................................................6

4.2Usingthe machine.......................................................................6

4.3Addingweights............................................................................7

4.4When processingisfinished........................................................7

5Storage ...........................................................................................7

6Maintenance .................................................................................7

7Aftersalesservice ......................................................................7

8Technical specification.............................................................8

9Accessories.................................................................................8

10Faultdiagnosis ...........................................................................9

11Guarantee ......................................................................................9

12Declarationof conformity .......................................................10

5

IMPORTANT

READ THESE INSTRUCTIONSCAREFULLYAND RETAINFORFUTUREREFERENCE

1Productinformation

Thesemachineswillcut throughdirtonsomeofthe

veryhardest toclean surfaces.Theyareperfectfor

tacklingjobslikeimpacted greaseonold flooring

surfacesoradhesiveresidues, orevenicebuild-upin

coldstorefloors.Thesemachinesareideal for

scarifyingconcreteindustrial floors.

Machinesincorporatetriple headcontra-rotating

planetarytechnology, producingastable machine

withnopullingaction therebyreducingoperator

fatigue.It alsomaintainsanevenpressure,

minimisingthe riskofcuttingorscoringthefloor.The

incorporationofmodernmanufacturing processes

ensuresyearsof trouble freeservice.

The followinginstructionscontain important

informationaboutthemachinesandsafetyadvicefor

theoperator.

Equipment mustbeoperated, servicedand

maintained in accordancewiththemanufacturer’s

instructions.

Ifin doubtcontactthesupplierofyourmachine.

1.1ImportantSafetyAdvice

Whenusing electricalequipmentbasicsafety

precautionsshould befollowed includingthe

following.

•Readallinstructionscarefullybeforeuse.

•Keepchildren andunauthorisedpersonsawayfrom

the machinewhenin use.

•Donot leavethemachineconnected tothe

electricitysupplywhennotin use,alwaysremove

the plugfromthesocket-outlet.

•Switchoff themachine beforeremoving theplug.

•Whenunpluggingpullthe plug,not thesupplycord.

•Donot allowtherotatingheadstocomeinto

contact withthe supplycord.

•Donot operatethe machinewithadamaged

supplycordorplug, orafterthemachine

malfunctionsorisdamagedin anyway. Contactan

authorisedServiceAgent forrepairoradjustment.

•Theplugof thepowersupplycordmust be

removedfromthesocket-outlet before

commencingcleaning ofthe machineor

undertakingmaintenanceoperations.

•Thepowersupplycordistoberegularlyinspected

forsignsofdamage.Ifdamageisfound, replace

the cordbeforefurtheruse.

•Onlyreplacethe cordwiththetypespecified in the

instructions.

•Donot usewherehazardousdust ispresent.

•Donot usein anexplosiveatmosphere.

•Takecarewhenusing amachinenearthetopof

stairstoavoidoverbalancing.

1.2Guidelinesfortheoperator

•Operatorsmustbefullytrainedin theuseofthe

machinein accordancewiththeseinstructions, able

toperformusermaintenanceand the correct

selectionofaccessories,i.e.scarifyingbrushes.

•Operatorsshould bephysicallycapable to

manoeuvre,transport andoperatethe machines.

•Operatorsshould beable torecogniseunusual

operationof themachineandreport anyproblems.

•Keephandsand feetwellclearofrotatingheads.

•Wearsuitablefootweartoavoidslipping.

•Wearsuitableclothingtokeepdryandwarm.

•Wherepossibleimplement jobrotationand

adequaterestperiodstoavoid continuoususe

ofthesamemuscles.

•Donot smokewhenusingthemachine.

•CAUTION -Thismachineisfordryuseonlyand

shouldnotbeused orstoredoutdoorsin wet

conditions.

1.3Transportingthemachine

CAUTION-THISMACHINEISHEAVY

Donotattempttoliftthemachinewithout

mechanical assistance. Incorrect liftingtechniques

mayresult inpersonal injury.Werecommendthe

machineisliftedbytwopeople.

CAUTION -Whenlifting themachinethebrushhead

isfree totipbackwards, ensurefingersarekept well

clearof thesidearmsofthechassis.

Whenmovingthe machinetoandfromthe working

area thehandleshouldbe locked andthe machine

tiltedbackon itswheels.

2Preparing foruse

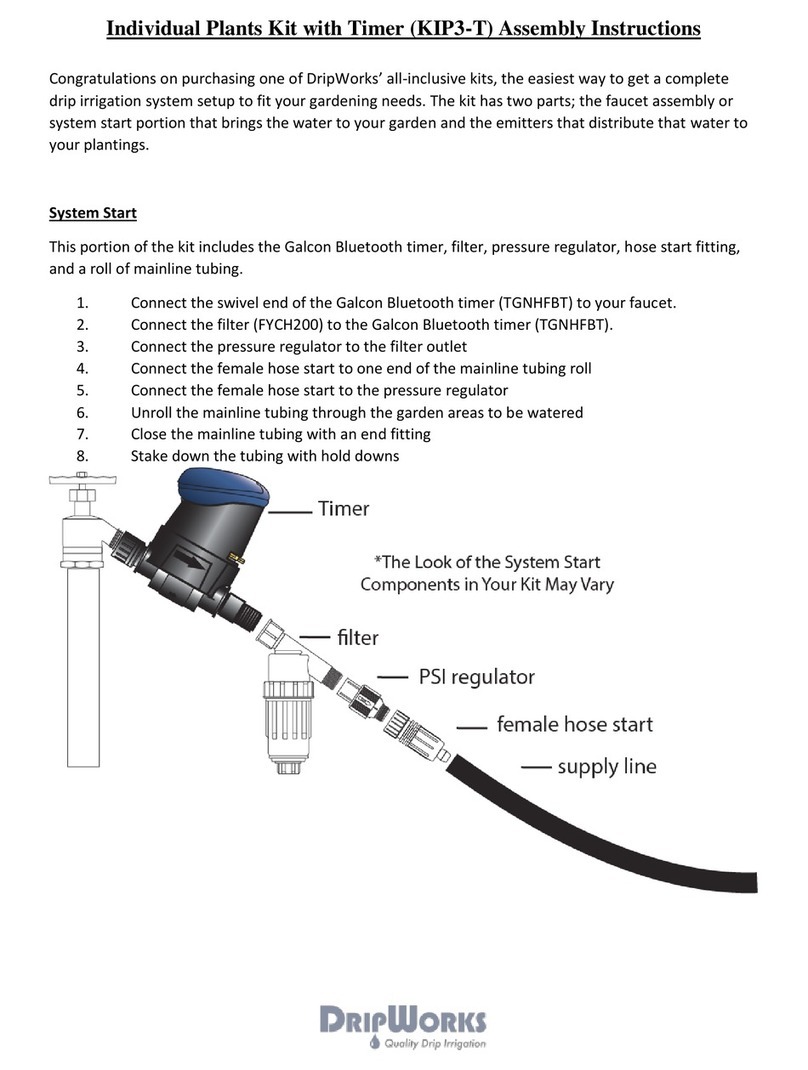

2.1Electricalconnection

Beforeconnectingthemachinetothepowersupply,

checkthat yoursupplyvoltage correspondswiththat

markedon the ratinglabel onthehandle ofthe

machine. UK only

Thesupplycordisfittedwithanonrewireable plug

containinga13 ampfuse.Shouldthefuserequire

replacementitmustonlybe replacedbya13amp

fuseconforming toBS1362,and thefusecovermust

berefitted.If thefusecoverislosttheplug mustnot

beuseduntil thecorrectreplacement coverisfitted.

IMPORTANT -Ifthesupplycordisdamaged, it must

onlybereplacedbyaspecial cordavailable fromthe

manufactureroranauthorisedserviceagent.

WARNING-THISAPPLIANCEMUSTBEEARTHED

6

2.2Fittingaccessoriesl

WARNING-Thisappliancehasbeendesignedfor

use withthebrushesandtool specifiedbythe

manufacturer. Theuseofothertypes may impair

itssafety.

Always ensuremachine isunplugged beforefittingor

removingparts.

2.2.1Fittingscarifyingbrushes

•Tip themachinebrushheadbackwardstowardsthe

handle, andpushthree scarifyingbrushesofthe

sametype ontothe fourdrivepinson eachofthe

rotating heads(Fig.2).

•Fit retainingclipontopins,ensuringitislocatedin

the grooveon eachpin.

•Returnbrushheadtothefloor.

•Removebrushesbysimplyremoving retainingclip

andpullingbrushoff thedrivepins.

•Always keepbrushesin setsofthree,toensure

even wearand preventvibration.

2.2.2Fittingtools

•Thesetools(suchasstar-wheelscarbideblocks

andscrapers)must tobeboltedontothemachine.

•Tobolttooltomachinetwodrivepins (diagonally

oppositeeachother) must be removedfromeach

ofthe rotating heads.

•Fit threematchingtoolsovereachpairofdrive

pins

•Secureeachtool using twoM5bolts. Always use

springwasherswithboltstominimisechanceof

toolsworking itselfloose.

IMPORTANT–regularlycheckthatboltsaretight.

IMPORTANT–Neverallowthebrushheadtorest

onthedrivepins, alwaystip brushheadback

whennotinuse.

2.3Adjustingthehandleheight

Fromtheuprightposition,lift the handleadjustment

leverandpullthe handlebackwardstoacomfortable

workingheight, thenpress leverdowntolock handle

in position.

3Controls

The operatingcontrolsarelocatedonthehandle

(Fig.1).

1-Start/stop lever

When raisedswitchesmotorONandstartsthe

rotatingheads, whenreleasedswitchesmotorOFF

andstopstheheads.Eachtimetheleveris

operated thedirectionofheadrotationisreversed,

improvingthequalityofcleaningandprolonging

disc/padlife.

2-Handleadjustmentlever

Usedtoadjust handle toacomfortable working

height.

4Operation

4.1Startingthemachine

•Fullyunwindthesupplycordfromthehandle and

plugin toaconvenientsocket outlet.

•Withthehandleset atacomfortableworking

height, andwithbothhandson the handle,lift the

start/stop levertoSTARTthemachine.Releasing

theleverwillSTOPthemachine.

•WARNING-Neverstartthemachinewithout

brushesortoolsfitted.

•Normalmovement ofthemachine isina forward

andbackward direction.

•Alwaysworkawayfromthesupplysockettoavoid

runningintothesupplycord.

4.2Using themachine

•Fitbrushesortoolssuitable forthesurfacetobe

cleaned / prepared.

•Adjusthandletosuit operator

•Tilt themachine slightlybackwardssothatthe

brushes/ toolsareclearofthe floorandwheel the

machietothearea tobecleaned.

•Switchon themachine.Always workawayfromthe

mainssocket –thiswillhelptoavoid running into

thecable.

•Scarifyingisnormallyadryprocess. Becauseofthe

extremelyharshabrasiveactionofscarifying

brushesandtools, onlyresiliantfloorssuchas

concrete, metal tileetc.shouldbescarified

•Walkslowlybehindthemachine, overlappingeach

passtoensurean evenfinish.

•Do not keepthemachinerotatingononespot as

thiscould damagethefloorsurface.

•Should themachinestarttovibrate,orresist the

cleaningaction onthefloor,checkthebrushes/

toolsforwear.

•Eachareaofthefloorshouldbecoveredathalf

walkingpace.Somefloorsmayrequireextra

passestoprocess itthoroughly.

•Onreachingthe originalstartingpoint, position the

machinetoprocess anotherpathparallel tothefirst

andoverlapping by50mm.

•Whenthe entirefloorareahasbeencovered, clear

debrisusingsuitable vacuumcleanerorsweeper.

4.3Addingweights

•Beforeaddingadditionalweightsswitchoff the

machine.

•Unscrewknobandlift off clampingbar.

•Addadditionalweight asrequired, andrefit

clamping bar.

4.4Whenworkisfinished

•Whenworkisfinished,unplugthemachinefrom

thepowersupply,removeweights, raisethebrush

headandremovethedrivebacks,and abrasive

discs orpads.Wipeoverthemachine withadamp

cloth.

•Removeandclean brushesortools.

7

5Storage

Afterusealwayswipedownthemachine, andremove

andcleanthedrivebacks discsandpads. Cleanthe

rotating dust cover(A) andcheck theconditionofthe

brushseals(B).Thesealsshould becleaned

periodicallytomaintain theireffectiveness (Fig.2).

The machineshouldnormallybestoredwiththe

handlein the fullyuprightposition,withthebrush

headtippedback. Neverleavethebrushhead

restingonthedrivepins.

Wrapsupplycordaroundthe cable storagehooks

ensuringthattheplugisnot trailingonthefloor.

Storethe machinein adryindoorareaonly.

6Maintenance

WARNING-Beforeundertakingmaintenance

operationsoradjustmentsswitchoffmachine

and unplug fromtheelectricitysupply.

The machinerequiresminimummaintenanceapart

fromthe followingchecksbyatrained operator.

•Supplycord -Regularlyinspectsheath, plugand

cordanchoragefordamageorlooseconnection.

Onlyreplacethesupplycordwiththe typespecified

in theseinstructions.

•Solutiontank -Checkwaterflow,ifrestricted

inspect hoseforblockageorkinks.Dismantle

control valvetocleanifnecessary.

7Aftersales service

Should yourequireaftersalesservicepleasecontact

thesupplierfromwhomyoupurchased the

machine,whowillarrange service. Repairsand

servicingofTruvoxproductsshouldonlybe

performedbytrained staff.Improperrepairscan

causeconsiderabledangerstotheuser.

8

8Technicalspecification

MachineisofClassIconstruction.EnclosuretoIP2X.

Models-230V~50Hz. fitted with15msupplycordtypeH05VV-F3x1.0mm²(10A), andplug.

ModelR48HRR76HD

MotorratingW15001500

Headspeedrpm400300

Brush/ tooldiametercm2030

Workingwidthcm4876

Weight (machineonly)(see note3) kg6068

Lengthcm75

Widthcm4876

Height (handle upright) cm112112

Soundpressurelevel(seenote 1) dB(A) 6565

Handlevibration(see note2) m/s² <2.5 <2.5

1-Soundpressurelevelsmeasured at adistanceof1metrefrommachineand 1,6metresabove

thefloor,whenusedonahardfloor. Measurementsrecordedusing ahandheld meter.

2-Handlevibrationdoesnotexceed2,5m/s²,when operating onanysurface.

Measurementsrecordedbyanindependent testlaboratory.

3-All machinessuppliedwithtwo17kgweights.

9Accessories

ItemsApplication PartNo.

Foruse with

R48HD

PartNo.

Forusewith

R76HD

HorseshoeweightSpareweights17kgeach03-7004-000003-7004-0000

RetainingclipsHoldbrushesntoHD machiens03-6938-0000

CrimpedwirebrushChequerplatecleaning 11-2041-050011-3041-0500

ConcretefinishingbrushSteelwire18G11-2043-050011-3043-0500

SparkfreescarifyingbrushBronzewire18G11-2045-0000

General scarifyingbrushSteelwire3x16G11-2049-050011-3049-0500

HDscarifyingbrushSteelwire2x14G11-2051-050011-3051-0500

Rubberremoval Starwheels05-4084-000002-3980-0000

Concreteremoval Wideawheels05-4083-0000

ConcretepreparationFinecarbide block 05-4078-0000

PaintremovalMediumcarbideblock 05-4079-0000

CoatingsremovalCoarsecarbideblock 05-4080-0000

Foamremoval Twistedwire05-3886-000005-3893-0000

Flat tip scraperIcebreaking 05-4082-0000

IMPORTANT: Genuineaccessoriesareonlyavailable fromauthorisedServiceAgentsorTruvoxCustomer

ServiceDept.

9

10Faultdiagnosis

The followingsimple checksmaybe performedbythe operator.

FaultReasonRemedy

Machinenot working.Lack ofvoltage/electrical supply.

Safetycut-outswitchfaulty.

Check fuse*, supplycord, plug

andsocket outlet.

ContactServiceAgent.

Motorrunning,butbrushesnot

rotating. Looseorbrokendrivebelt.Removerotatingdust cover

andfit newdrivebelt, orcall

ServiceAgent.

*If the fuseblowsseveral times,themachineshouldbe checked byanauthorisedServiceAgent.

11Guarantee

Yourproductisguaranteed foroneyearfromthedate

oforiginalpurchase,orhirepurchase,against defects

in materialsorworkmanship duringmanufacture.

Within the guarantee periodweundertakeatour

discretion,torepairorreplacefree ofchargetothe

purchaser, anypartfoundtobedefective,subjectto

thefollowingconditions.

CONDITIONS

1. Claimsmadeunderthetermsoftheguarantee

must besupported bytheoriginal invoice/billof

sale issuedat thetimeof sale,orthemachine

SerialNo.

2. Forclaimsunderthisguaranteecontact the

supplierfromwhomyou purchasedtheproduct

whowillarrangetheappropriateaction.Donot

initiallyreturntheproduct asthiscouldresultin

transitdamage.

3. NeitherTruvoxnoritsdistibutorshallbe liable for

anyincidental orconsequentialloss.

4. Thisguaranteeisgoverned bythelawsofEngland.

5. Thisguaranteedoesnot coveranyofthefollowing:

-Periodicmaintenance, andrepairorreplacement

ofpartsduetonormalwearandtear.

-Damagecausedbyaccident, misuseorneglect,

orthefittingofotherthangenuineTruvoxparts.

-DefectsinotherthangenuineTruvoxparts, or

repairs, modificationsoradjustmentsperformed

byotherthan aTruvoxserviceengineeror

authorised serviceagent.

-Costsandrisksoftransport relatingdirectlyor

indirectlytotheguaranteeof thisproduct.

-Consumable itemssuchas, drivebacks,abrasive

discs, padsanddrivebelts.

Thisguaranteedoesnotaffectyourstatutoryrights,

noryourrightsagainst the supplierarisingfromtheir

salesorpurchasecontract.

TruvoxInternational Limitedhasapolicyof continual

productdevelopment andwereservetherighttoalter

specificationswithout priornotice.

10

12 Declaration of conformity

EC Declaration of conformity

We,TruvoxInternational Ltd.

ofThirdAvenue

MillbrookTrading Estate

SouthamptonSO150LE

England

declarethat themachinery

Make: HD scarifier

Type : HD

Model : R48HD, R76HD

SerialNumber:

YearofConstruction: 2004

hasbeenmanufacturedusingthefollowing transposed harmonized EuropeanStandardsand

technical specifications.

BSEN60335-1andBSEN60335-2-67

andisin conformitywithECDirectives,98/37/EC,73/23/EECand89/336/EECandall

amendments.

Signedin : SOUTHAMPTON,England

on the30thdayofJuly2004

Signature:

Name: MREneas

Position:NewProduct DevelopmentManager

TruvoxInternationalLimited,ThirdAvenue,Millbrook, Southampton,HampshireSO150LEEngland

Tel: +44(0)2380702200Fax:+44(0)2380705001

e-mail: truvox@truvox.com Web: www.truvox.com

This manual suits for next models

1

Table of contents

Popular Lawn And Garden Equipment manuals by other brands

FRAME IT ALL

FRAME IT ALL 300001058 quick guide

Graf

Graf EcoLoop SP 1100 DN 200 Installation and servicing

Bio Green

Bio Green CITYJUNGLE HEIDELBERG installation manual

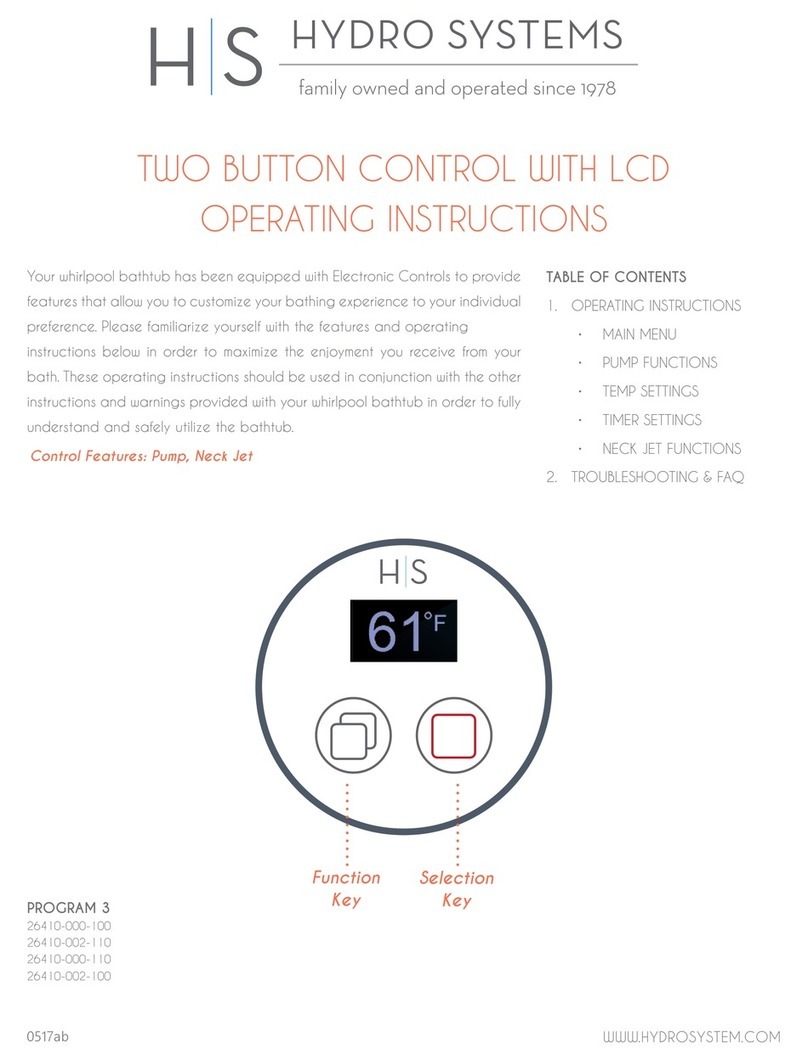

Hydro systems

Hydro systems PROGRAM 3 operating instructions

Salsco

Salsco Electric Greens Roller QC Operator and parts manual

HammerSmith

HammerSmith Water Dragon Instructions for use