Cinergia B2C10 User manual

Electronic Load (EL DC)

Installation and operation manual

Tel: +49(0)7842-99722-00

Fax: +49(0)7842-99722-29

www.caltest.de

Kohlmattstrasse 7

D-77876 KAPPELRODECK

Caltest Instruments GmbH

2/ 56

INDEX

1. INTRODUCTION ..................................................................................................................... 5

1.1. Symbols used................................................................................................................. 5

1.2. Safety notes................................................................................................................... 5

1.3. Quality and regulations................................................................................................. 5

2. PRESENTATION...................................................................................................................... 7

2.1. Introduction .................................................................................................................. 7

2.2. Converter features ........................................................................................................ 8

2.3. Operation and connection modes ................................................................................ 9

2.4. Configuration and control of the converter.................................................................. 9

2.5. Functional diagram........................................................................................................ 9

2.6. Principle of operation.................................................................................................. 10

3. INSTALLATION ..................................................................................................................... 16

3.1. Important safety instructions...................................................................................... 16

3.2. Equipment views......................................................................................................... 16

3.3. Equipment reception................................................................................................... 20

3.3.1. Unpacking and checking the content.................................................................. 20

3.3.2. Storage ................................................................................................................ 20

3.3.3. Transport to location........................................................................................... 21

3.3.4. Location............................................................................................................... 21

3.4. Connection .................................................................................................................. 23

3.4.1. Earth protection .................................................................................................. 23

3.4.2. Input connection, terminals (X1 to X5). .............................................................. 23

3.4.3. Output connection, terminals (X6 to X10) .......................................................... 23

3.4.3.1. DC unipolar mode............................................................................................ 23

3.4.3.2. DC bipolar mode.............................................................................................. 23

3.4.4. External Emergency Power Off connection (X12)............................................... 23

3.4.5. Output signal of local Emergency Stop pushbutton (OPTIONAL) ....................... 25

3.4.6. Communications (Optional) ................................................................................ 26

3.4.7. Digital inputs and outputs................................................................................... 26

3.4.8. Analog inputs and outputs (AIO Optional).......................................................... 27

4. OPERATION ......................................................................................................................... 28

4.1. Safety........................................................................................................................... 28

4.2. State Machine ............................................................................................................. 28

EL DC Instalation and operation manual v13.docx

3/ 56

4.2.1. Initialization......................................................................................................... 29

4.2.2. Standby................................................................................................................ 29

4.2.3. Precharge ............................................................................................................ 30

4.2.4. Ready................................................................................................................... 30

4.2.5. Run ...................................................................................................................... 30

4.2.6. Alarm ................................................................................................................... 30

4.3. Operation modes ........................................................................................................ 31

4.3.1. Constant Impedance (CI)..................................................................................... 31

4.3.2. Constant Current (CC) ......................................................................................... 31

4.3.3. Constant Power (CP) ........................................................................................... 32

4.3.4. Constant Voltage (CV) ......................................................................................... 32

4.4. Connection modes ...................................................................................................... 32

4.5. Working with the equipment...................................................................................... 33

4.5.1. Start-up................................................................................................................ 34

4.5.2. Stop ..................................................................................................................... 34

4.5.2.1. Full stop........................................................................................................... 34

4.5.2.2. Standby stop.................................................................................................... 35

4.5.2.3. Ready............................................................................................................... 35

4.5.3. Emergency stop................................................................................................... 35

4.5.4. Accidental shut down.......................................................................................... 36

4.5.5. Alarms.................................................................................................................. 36

4.5.6. Alarms reset ........................................................................................................ 37

5. LOCAL TOUCHSCREEN CONTROL PANEL............................................................................. 38

5.1. Basic functions............................................................................................................. 38

5.2. Menus and submenus................................................................................................. 38

5.2.1. General................................................................................................................ 38

5.2.2. Operational ......................................................................................................... 39

5.2.3. Supervision.......................................................................................................... 42

5.2.4. Configuration....................................................................................................... 42

5.2.5. Alarms.................................................................................................................. 43

5.2.6. About EL .............................................................................................................. 44

6. REMOTE COMMUNICATIONS.............................................................................................. 44

6.1. IQ MANAGEMENT ....................................................................................................... 47

7. HUMAN MACHINE INTERFACE............................................................................................ 49

4/ 56

7.1. Operation .................................................................................................................... 49

7.1. Alarm........................................................................................................................... 50

7.2. Supervision.................................................................................................................. 51

7.3. Unipolar/Bipolar connection....................................................................................... 52

7.4. DC sequence................................................................................................................ 53

8. WARRANTY AND MAINTENANCE........................................................................................ 55

8.1. Replacing the input fuses............................................................................................ 55

8.2. Fans ............................................................................................................................. 55

8.3. DC bus capacitors........................................................................................................ 55

8.4. Warranty ..................................................................................................................... 55

8.5. Claim procedure.......................................................................................................... 56

EL DC Instalation and operation manual v13.docx

5/ 56

1. INTRODUCTION

Dear customer, on behalf of CINERGIA team, thank you for the confidence placed in our

company and for the purchase of this product. Please, read carefully this manual before using

the equipment to get familiarized with it and to obtain the maximum performance from it.

This document is intended for appropriately qualified personnel. Only personnel with the

appropriate skills are allowed to perform the electrical connection and commissioning of the

equipment.

The information in this documentation is not binding. CINERGIA reserves the right to make

changes in part or in the whole at any time and without prior notice due to technical advance or

product improvement.

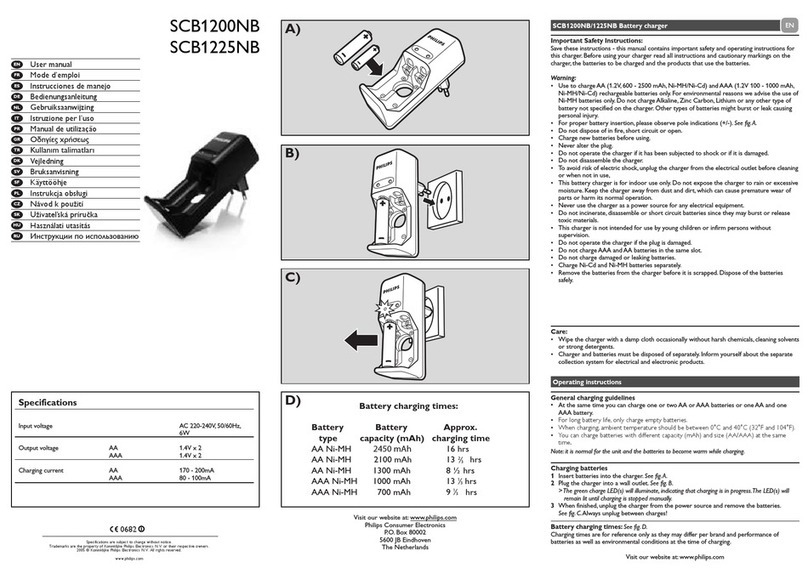

1.1. Symbols used

DANGER: Indicates a hazardous situation which can result in death or serious

injury and can cause important damage or destruction of the equipment or the

property.

WARNING: Indicates important information that must be taken into account to

operate the equipment. Take the appropriate prevention measures.

INFORMATION: Information that is important but is not safety-relevant.

1.2. Safety notes

Improper use of this equipment can cause both important personal injury and physical damage

to the electrical power grid and the loads connected to it. Read this document carefully and

follow all safety precautions at all times.

1.3. Quality and regulations

The equipment is based on a hardware designed, manufactured and commercialized in

accordance with the standard EN ISO 9001 of Quality Management Systems. The marking shows

conformity to the EEC Directive by means of application of the following standards:

• 2006/95/EC Low voltage directive.

• 2004/108/EC Electromagnetic Compatibility directive (EMC)

In accordance with the specifications of the harmonized standards:

EL DC Instalation and operation manual v13.docx

6/ 56

• EN-IEC 62040-1. Uninterruptible power supply (UPS). Part 1-1: General and safety

requirements for UPS’s used in accessible areas by end users.

• EN-IEC 60950-1. IT equipments. Safety. Part 1: General requirements.

• EN-IEC 62040-2. Uninterruptible power supply (UPS). Part 2: Prescriptions for Electromagnetic

compatibility (EMC).

• EN-IEC 62040-3. Uninterruptible power supply (UPS). Part 3: Methods of operation

specification and test requirements.

The manufacturer responsibility is excluded in the event of any modification or intervention in

the product by the customer’s side.

EL DC Instalation and operation manual v13.docx

7/ 56

2. PRESENTATION

2.1. Introduction

As an electronic load, the EL is designed to test electric and electronic equipment in linear and

non-linear DC loading. It allows to verify the functionality of the Equipment Under Test (EUT) in

normal and fault operation.

The main functionalities of the EL are the following:

-It converts the AC input, of the main grid, in a controlled DC output by using an IGBT-

based switching topology and DSP-based state-of-the-art digital control.

-It can be operated as:

oCI: Constant Impedance output

oCC: Constant Current output

oCP: Constant Power output

oCV: Constant Voltage output

-As a bidirectional converter, energy can flow from the grid to the EUT or viceversa. It

allows energy saving during the tests by returning energy to the power grid.

-The AC current consumed from the grid is sinusoidal (THD < 6%).

-The user can define the reactive power to be injected by the EL and also choose between

capacitive or inductive.

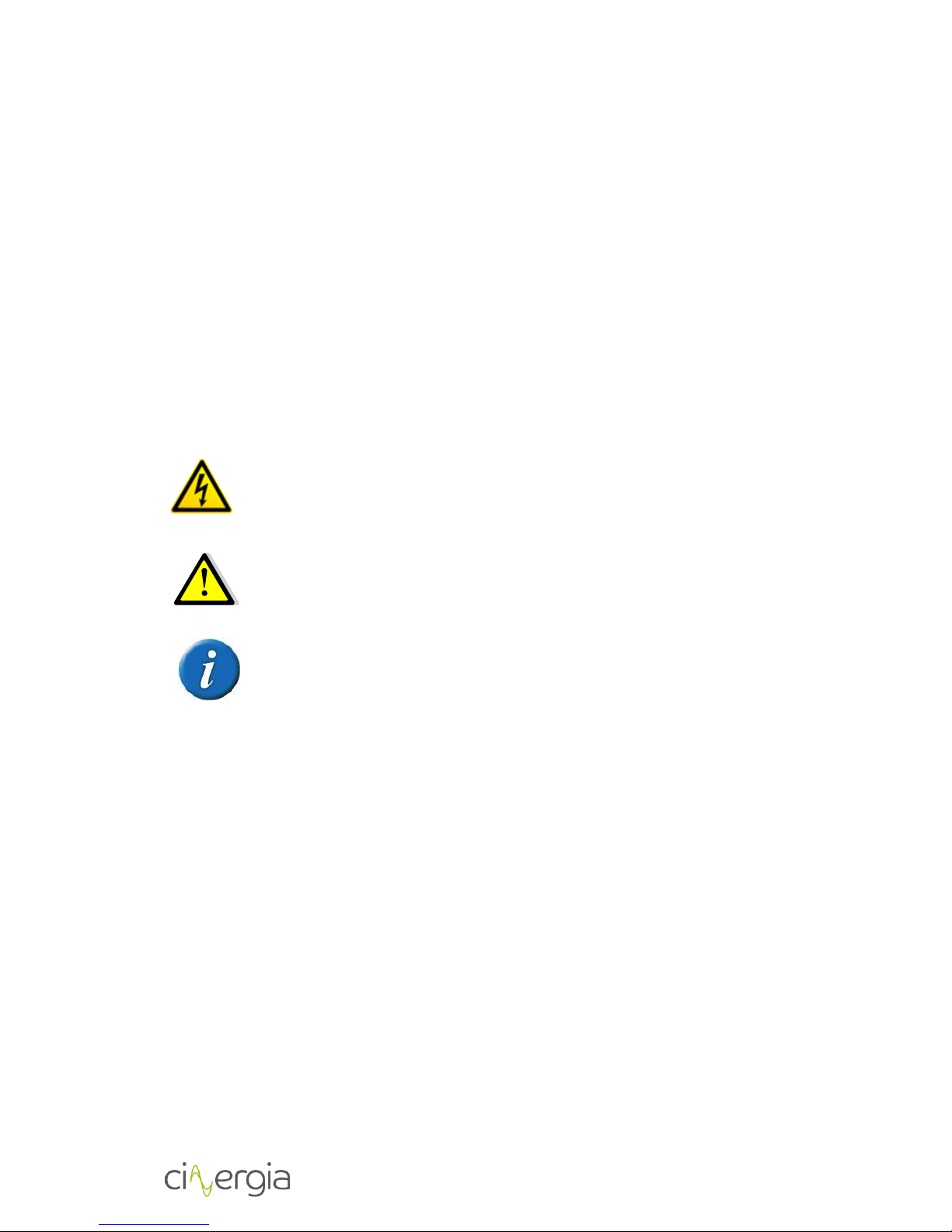

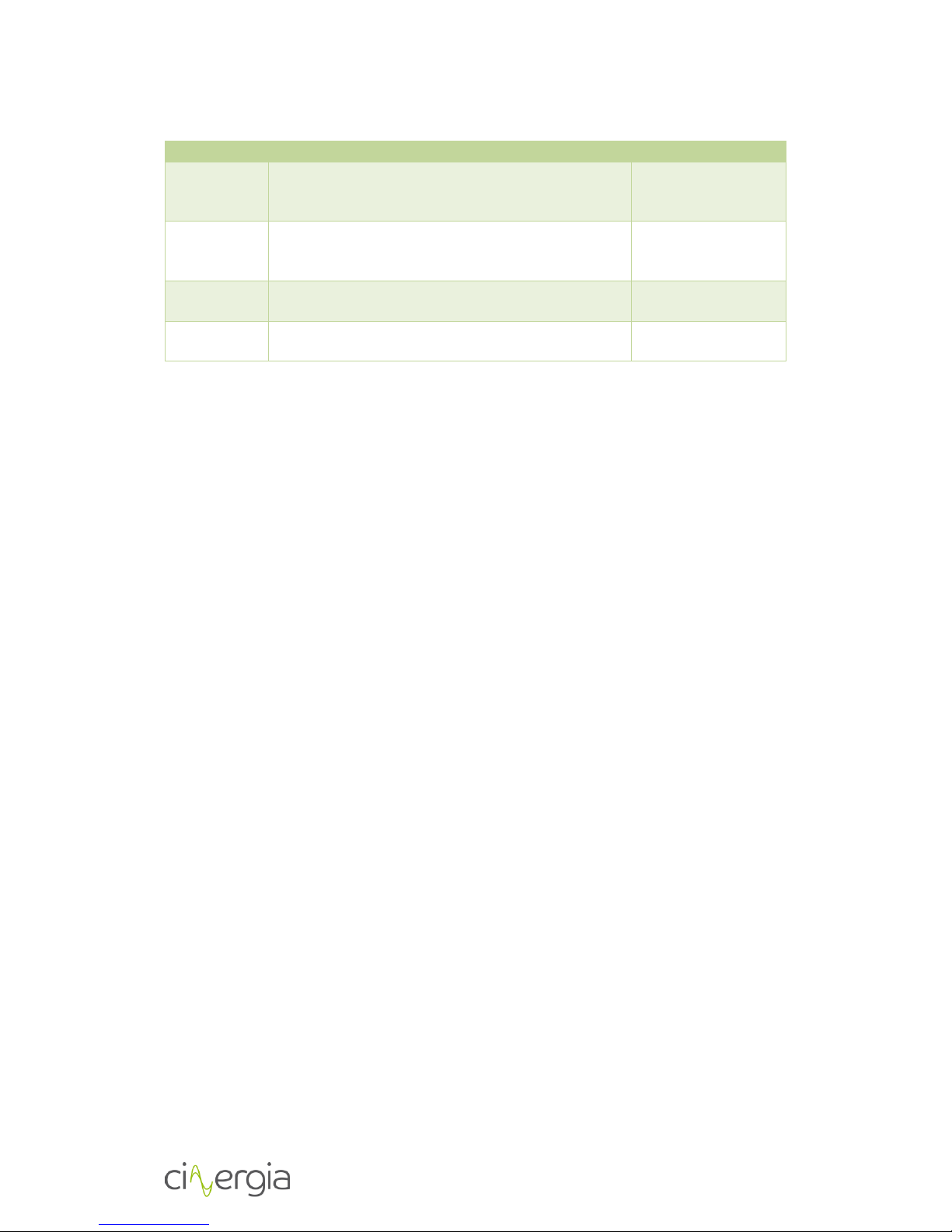

The power range covered by the EL electronic loads goes from 6.75 to 160kW. The parallelization

of ELs is also possible to increase power:

REFERENCE

RATED POWER (25ºC)

RATED CURRENT (25ºC)

WEIGHT

DIMENSIONS

kVA

kW

Independent

Parallel

Bipolar

kg

DxWxH (mm)

0-750V

0-750V

-350 to

350V

B2C7.5

7.5

6.75

±10A

±30A

±10A

150

770x450x1100

B2C10

10

9

±15A

±45A

±15A

150

B2C15

15

13.5

±20A

±60A

±20A

150

B2C20

20

18

±25A

±75A

±25A

150

B2C30

30

27

±30A

±90A

±30A

150

B2C40

40

36

±38A

±115A

±38A

185

B2C50

50

45

±47A

±140A

±47A

185

B2C60

60

54

±57A

±180A

±57A

185

B2C80

80

72

±105A

±315A

±105A

265

880x590x1320

B2C100

100

90

±130A

±390A

±130A

290

B2C120

120

108

±130A

±390A

±130A

290

B2C160

160

128

±155A

±465A

±155A

540

850x900x2000

B2C200

200

160

±185A

±555A

±185A

550

EL DC Instalation and operation manual v13.docx

8/ 56

2.2. Converter features

MAGNITUDE

VALUE

Power

7.5kVA-200kVA

Input side (GRID side)

AC Voltage

Rated

3x400Vrms+Neutral+Earth

Voltage range

+15% / -20%

Rated AC Current

Depends on model (see table)

10-290Arms per phase

Frequency

48-62Hz

THDi

(at rated power)

<3%

Power Factor

Typical at rated power

≥0.99

Configurable by user

0-1 (capacitive/inductive)

Efficiency

(at rated power)

>92%

Overload

125% for 10 min /150% for 60 s

Output side (EUT side)

DC Voltage

Channel-Com_neg

Channel_Com_neg

Channel_com_neg

20 to 750V (≤60kVA)

40 to 750V (>60kVA)

-350 to 350V

Minimum voltage

At rated power

320V

DC Current

Parallel channels mode

Independent channels mode

Bipolar output

0 to ±555A global

0 to ±185A per channel

0 to ±185A per channel

DC Overcurrent

110% during 1min

Modes of operation

Range

Resolution

Ripple

Constant Current

0-±100%

<±0.1%

<1%

Constant Power

0-±100%

<±0.1%

<1%

Constant Resistance

min.-100%

<±0.1%

<1%

Constant Voltage

0-100%

<±0.1%

<1%

Response time

Rated resistance load

1-5ms (10-90%)

General

Measurements

Input Voltage (Vrms) and current (Irms)

Input and Output Power

Output voltage (Vrms) and current (Irms)

Temperatures

User interface

3.2’’ Touchscreen

Local Control port: 4 digital inputs, 3 relay outputs (Option for AIO)

Communication Port: Ethernet (Optionals: RS485, RS232, CAN)

Communication Protocol: Modbus/TCP

Humidity

10-90% (Absolute maximum, without condensation)

Temperature

5-35ºC (Absolute maximum)

Cooling

Forced air

Protections

Over Current, Over Voltage, Shortcircuit, Overtemperature

Standards

CE Marking

Safety

EN-62040-1-2,EN-60950-1

EMC

EMC: EN-62040-2

Please note that items marked as optional shall be requested specifically at additional cost.

EL DC Instalation and operation manual v13.docx

9/ 56

2.3. Operation and connection modes

The output of the power converter is formed by three phases referenced to the neutral point of

the system (N). Consequently, the user can choose between two possible connection modes for

the electronic load:

-Independent phases: each phase (U, V, W) is controlled independently. The current

setpoint can be different in angle and magnitude for each of the three phases.

-Parallel phases: It is exactly the same as the previous case, but in this case the user has

shorted the phases. In this case the total amount of current consumed will be the sum

of all three phases.

-Unipolar mode: Electronic Load behaves as 3 independent and positive DC power

supplies.

-Bipolar mode: Electronic Load behaves as 2 independent DC power supplies. One is

positive and the other negative.

Three operation modes are allowed:

-Constant Impedance (CI): the output impedance is controlled to the set point value. The

emulator will perform as a constant R.

-Constant Current (CC): the output current is controlled to the set point value.

-Constant Power (CP): the output active power is regulated to the set point value.

-Constant Voltage (CV): the output voltage is controlled to the set point value.

2.4. Configuration and control of the converter

The converter can be interfaced by three means:

-Local touchscreen: a 3.2” color local touchscreen panel can be used to configure,

monitor and operate the electronic load. See section Local Touchscreen Control Panel

for further information.

-Analog and digital inputs: the converter owns three isolated analog inputs (+/-10V) and

tow optocoupled digital inputs.

-Remote interface: an Ethernet communication interface with protocol MODBUS/TCP

can be used to configure, monitor and operate the electronic load. By using HMI

software application provided by CINERGIA, uploading of excel files is also possible.

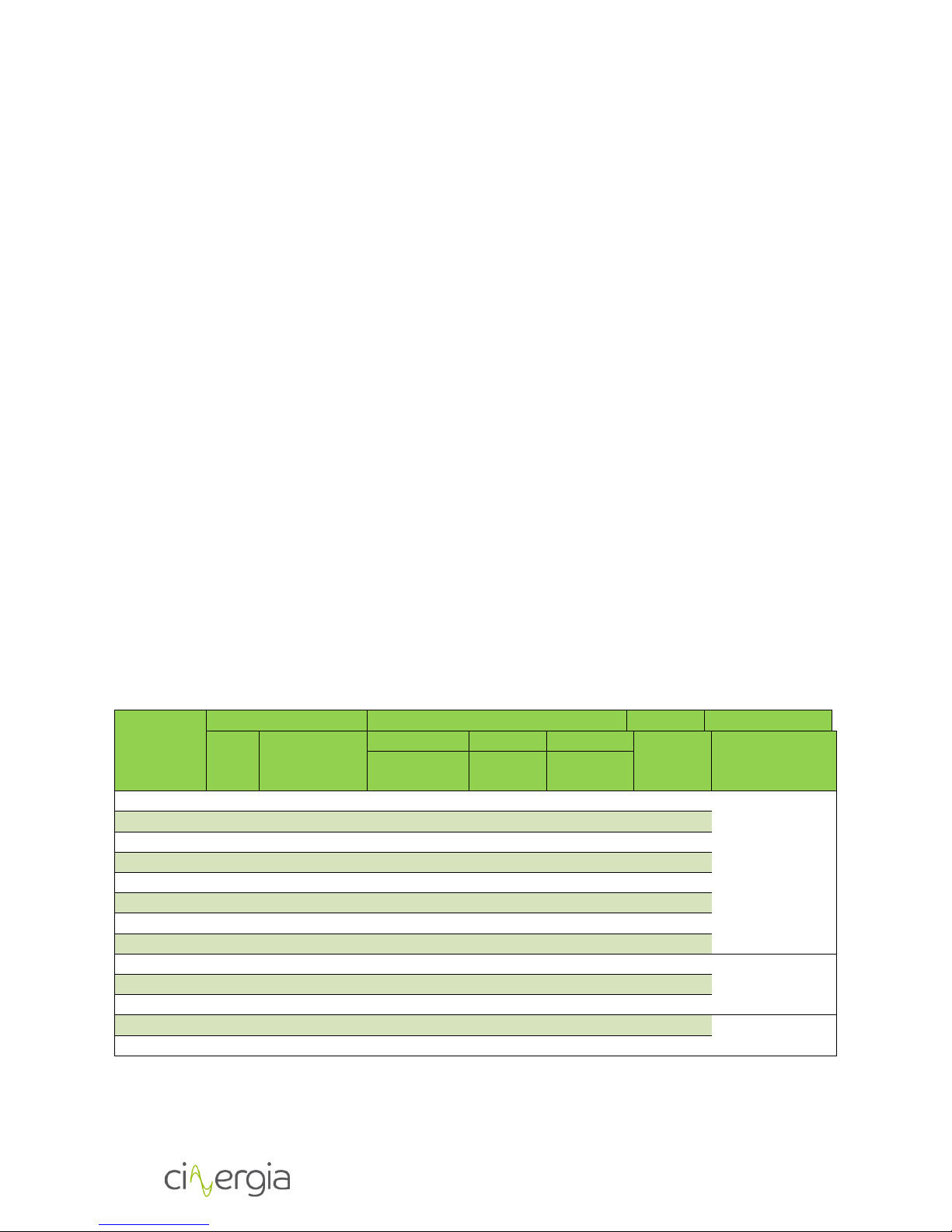

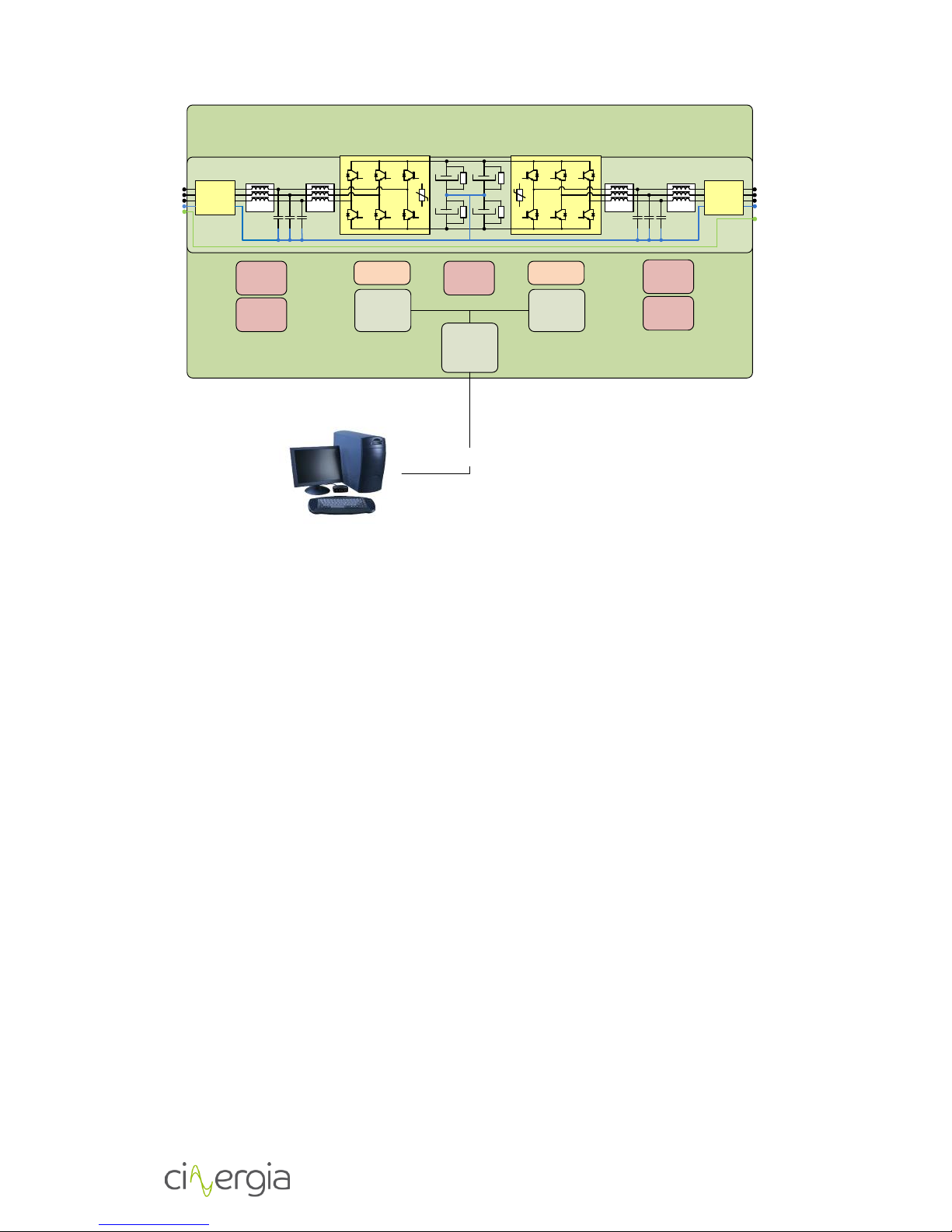

2.5. Functional diagram

The diagram below is the conceptual function block diagram of the converter:

AC

ACTIVE RECTIFIER

GRID

DC AC

DC

EUT

DC/AC

Input LCL

filter

Input EMI

filter

Protections Protections

Output EMI

filter

Output LCL

filter

OPTIONAL

ELECTRONIC LOAD

EL DC Instalation and operation manual v13.docx

10 / 56

The main components of the diagram are the following (from grid side to EUT side):

-Isolation transformer: a 50/60Hz isolation transformer can be provided optionally in

order to isolate the output phases. In this case, an isolation monitor can be integrated

in the converter to detect isolation faults also.

-Input protections: these protections include a thermal-magnetic circuit breaker and

fuses. The connection of the converter input with the grid is done by screw terminals.

Please follow the safety instructions in the Installation section to connect the electronic

load.

-Input EMI filter: an electromagnetic filter is integrated to fulfil electromagnetic

compatibility regulations. The structure of the filter is the same as the one of the output

EMI filter.

-Input LCL filter: the purpose of this filter is to reduce the current distortion at

frequencies equal to or higher than switching frequency and reduce THD.

-Active Rectifier: a three-branch IGBT active front end is integrated in the equipment to

consume/inject a sinusoidal current from/into the grid.

The DC link voltage is set to 800V providing a regulation margin for fast transients at the

output of the electronic load.

The active rectifier has bidirectional power flow capability and the injected reactive

power (grid side) can be defined by the customer.

-DC/AC output converter: it is a three-branch IGBT converter. Its topology is the three

phase inverter and allows the conversion from the DC bus to each of the output AC

phases.

The user can choose between having each phase controlled independently or having the

three of them controlled as a unique phase (sharing the same operation mode and

setpoints).

-Output LCL filter: analogously to the input LCL filter, the filter reduces the current

distortion (caused by switching) at the output of the electronic load.

-Output EMI filter: a high frequency common mode LC filter is used to reduce the

electromagnetic disturbances at the output of the electronic load.

-Output protections: a disconnector is provided to isolate the output from the EUT. Screw

terminals are also integrated to connect the EUT. Please, follow safety instructions in

Installation section to connect them.

2.6. Principle of operation

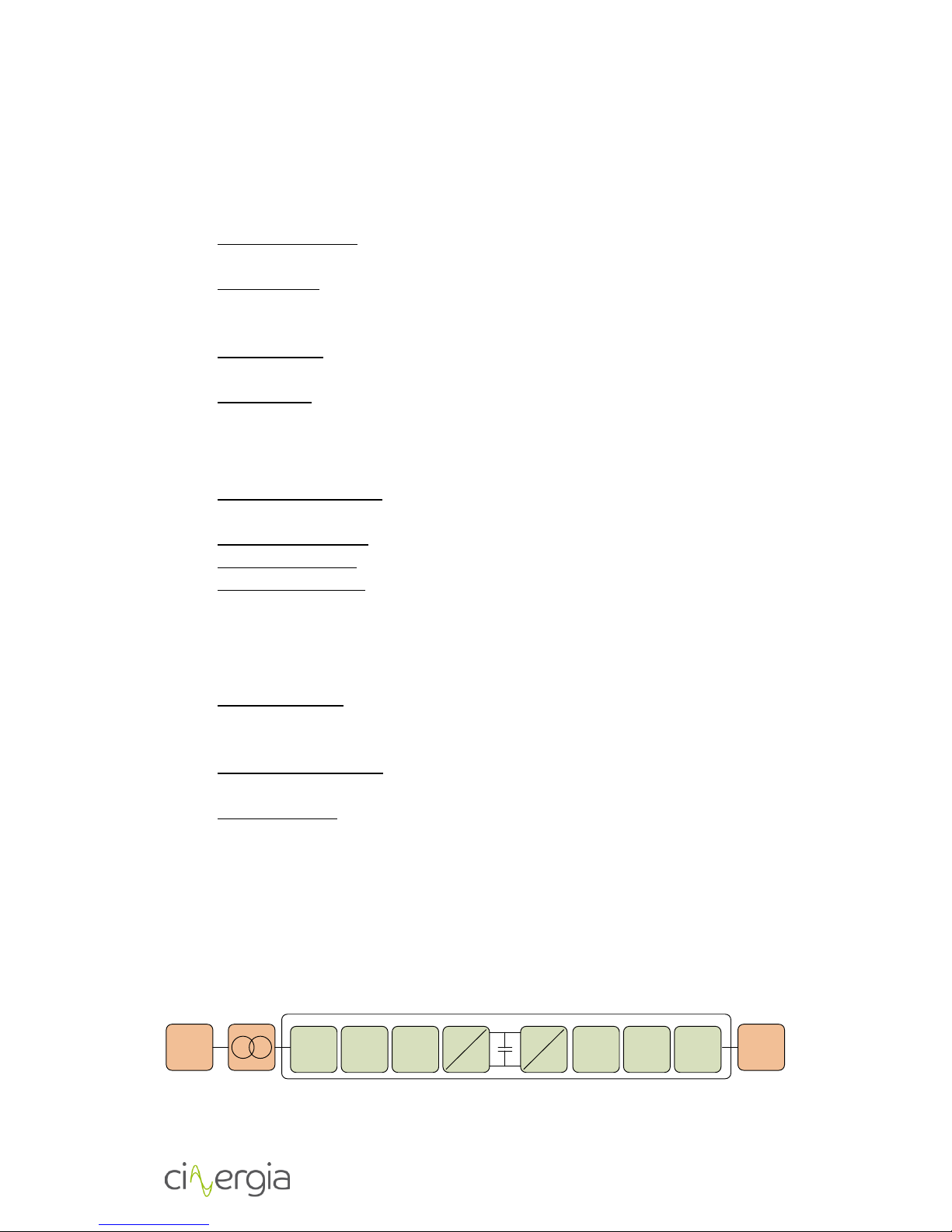

Below, a technical diagram of the converter is shown:

EL DC Instalation and operation manual v13.docx

11 / 56

Drivers x6 Drivers x6

Current

sensor x3

Voltage

sensor x2

Voltage

sensor x3

Current

sensor x3

Voltage

sensor x3

PE

-U

-U

PE

PE

EMC

filter

EMC

filter

AC output

PE

EL

U

DSP

board

DSP

board

CAN/

Ethernet

board

CAN

MODBUS/TCP

ETHERNET

V

W

N

PE

R

S

T

N

PE

(Please note that earth protection cable is only connected to the cabinet chassis).

State-of-the-art digital control is used in all CINERGIA products. In the EL case, the control system

algorithms are computed in two DSP based hardware, designed by CINERGIA, allowing a

multitask execution of the regulation systems for the Active Rectifier and the Inverter output.

This produces a fast transient response and a high performance against EUT changes. A 12 bits

analog to digital conversion, with digital processing, allows a high resolution output up to 0.1%.

Resonant control (only AC)

Control algorithms based on Resonant controllers are used in both AC sides; i.e. Resonant

Control is always used in grid side but it is used in EUT side only when AC output option is chosen

for the electronic load.

The algorithms regulation is structured in blocks resonating at a given frequency. Within the

resonant frequency each block allows the suppression of gain and phase errors of the current.

Thanks to this, each harmonic can be controlled independently and thus it can be generated or

suppressed, as needed.

The following diagram illustrates how the mentioned algorithms operate:

EL DC Instalation and operation manual v13.docx

12 / 56

PR ω0 PWM x3

Σ

PR ω1

PR ω2

PR ω3

...

Feedback

+

-

KR

KFF

Setpoint

generator

Therefore, the main characteristics of the Resonant Control applied are the ones listed below:

-Control loop rate of 15 kHz.

-15 harmonics controlled*: 1st-15th

-15 control loops executed per phase.

-45 control loops executed in total (for the 3 phases).

-Each control loop controls independently magnitude and angle of one harmonic.

-Any kind of load can be implemented in the EUT side.

-All harmonics can be suppressed in the grid side.

* It should be noted that the equipment bandwidth is 800 Hz. Therefore, the harmonic content

will be determined by the bandwidth as well as by the fundamental frequency specified by the

user.

Finally, the following pictures are some examples of how the EL Resonant Control can work. It is

important to take into account that, in these three pictures:

-Yellow waveform: input Uphase-N

-Green waveform: input Iphase-N

-Pink waveform: output Uphase-N

-Blue waveform: output Iphase-N

EL DC Instalation and operation manual v13.docx

13 / 56

In this case, there is reactive power consumption from the EUT (PF = 0) and no power is injected

into the grid.

In this second picture, the EL is behaving like a single-phase rectifier.

EL DC Instalation and operation manual v13.docx

14 / 56

In this last case, the EL is behaving like a three-phase rectifier.

PID control

The EUT side control algorithm is based on a traditional current PID controller. In case controlling

power, or even the impedance, both magnitudes are decoupled and translated to current set

points on each control loop.

The following diagram illustrates how the algorithms operate:

Both in voltage mode and current mode, the equipment is regulated for the limits imposed by

the interface: maxIout, minIout, maxVout and minVout. In case that those limits are not

configured, the equipment is protected by the natural limits (110% of the nominal current).

The following table explains how those limits work.

EL DC Instalation and operation manual v13.docx

15 / 56

Parameter

Description

Default

maxIout

Maximum limitation of positive output current:

maximum current the equipment is able to inject

Maximum current

limitation

110% Irated

minIout

Maximum limitation of negative output current:

maximum current the equipment is able to drain

Maximum current

limitation

110% Irated

maxVout

Maximum limitation of voltage the equipment is

able to put in the output

750V

Range: 0V-750V

minVout

Minimum limitation of voltage the equipment is able

to put in the output

30V

Range: 0V-750V

EL DC Instalation and operation manual v13.docx

16 / 56

3. INSTALLATION

3.1. Important safety instructions

As a device with class l protection against electric shocks, it is essential to install a protective

earth wire (connect earth ). Connect the protection earth wire to the terminal (X5) before

connecting the grid to the electronic load input.

All the electrical connections, including those for control (interface, remote control…etc.), shall

be done with all the switches in OFF position and with the mains supply disconnected (thermal-

magnetic circuit breaker in OFF position too).

It must never be forgotten that the EL is a power converter, so users must take all

necessary precautions against direct or indirect contact.

Warning labels should be placed on all primary power switches installed in places far from the

device to alert the electrical maintenance personnel of the presence of a voltage in the circuit

up to 10 minutes after stopping the device.

In devices without isolation transformer, precautions must be taken as they are not

isolated from the alternating input line, and there might be dangerous voltage

between the output phases and the ground.

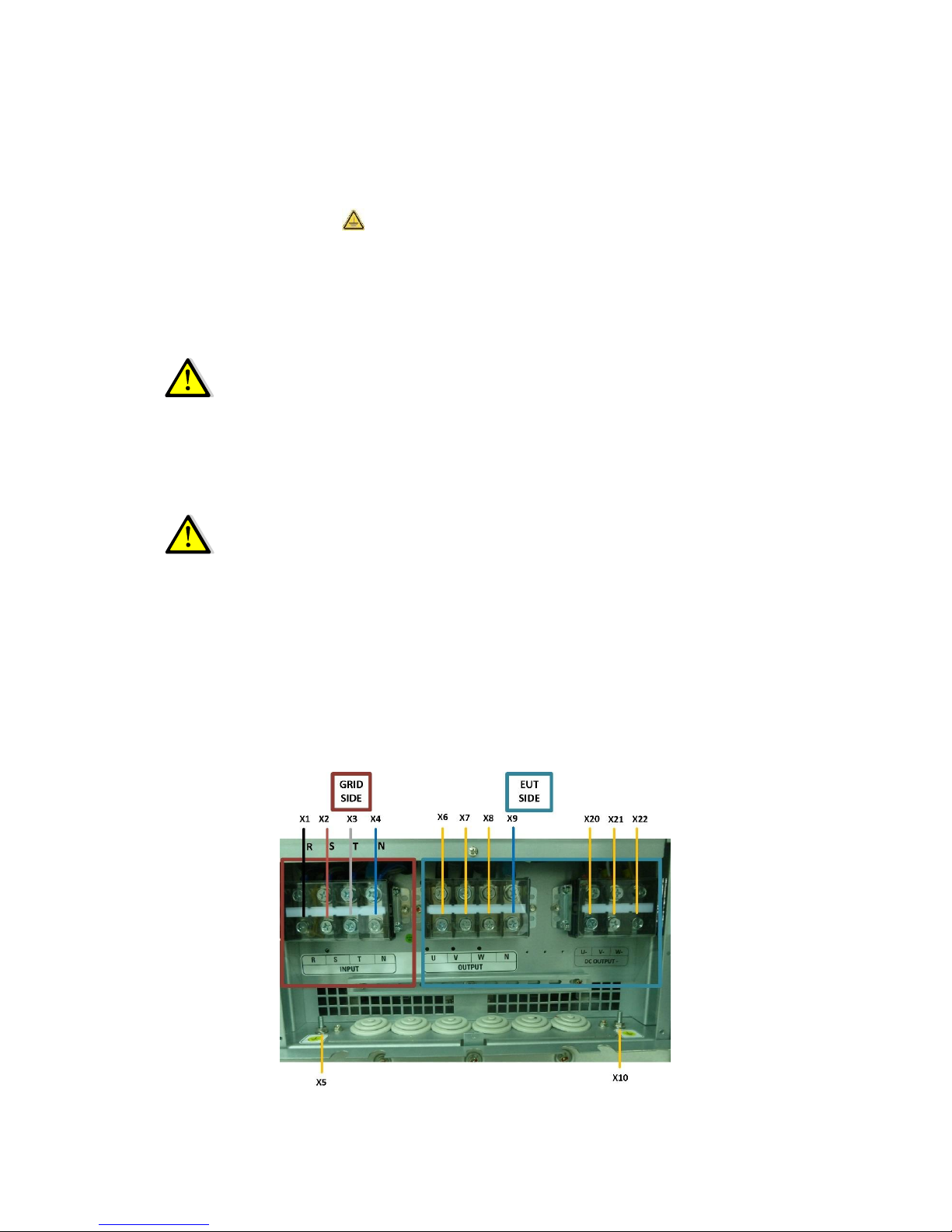

3.2. Equipment views

Electrical connections:

EL DC Instalation and operation manual v13.docx

17 / 56

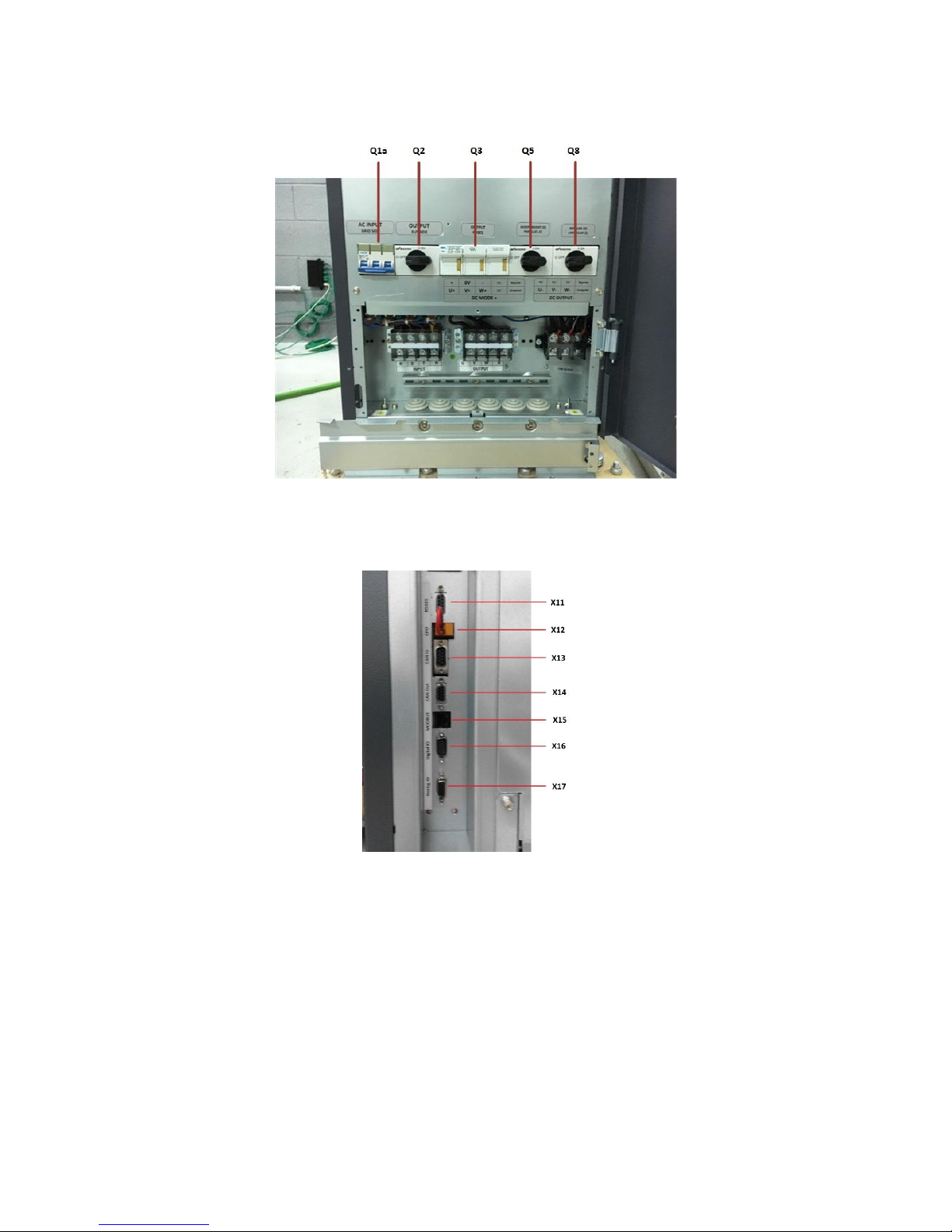

Local front panel:

Front view (with the door open):

LCD

EPO

EL DC Instalation and operation manual v13.docx

18 / 56

Detailed view of the front protections and switches:

Detailed view of the signal connectors:

EL DC Instalation and operation manual v13.docx

19 / 56

General view (with the front door closed):

Protection elements (Q*):

(Q1a) Input thermal-magnetic circuit breaker or disconnector according to power of

the equipment

(Q2) Output disconnector

(Q3) Output fuses

(Q5) Parallel connection switch

(Q7) Isolation detector (which is inside the cabinet and it is optional)

(Q8) Bipolar/unipolar switch

Connection elements (X*):

(X1) Phase input terminal R.

(X2) Phase input terminal S.

(X3) Phase input terminal T.

(X4) Neutral input terminal N.

(X5) Earth connection terminal for main supply input ( ).

(X6) Phase output terminal U.

(X7) Phase output terminal V.

EL DC Instalation and operation manual v13.docx

20 / 56

(X8) Phase output terminal W.

(X9) Neutral output terminal N.

(X20) Negative output terminal U.

(X21) Negative output terminal V.

(X22) Negative output terminal W.

(X10) Earth connection terminal for EUT ( ).

(X11) DB9 connector for RS485 communications.

(X12) Terminals for external Emergency Power Off (EPO) button.

(X13) DB9 connector for CAN communications (input).

(X14) DB9 connector for CAN communications (output).

(X15) RJ45 connector for MODBUS interface.

(X16) DE15 connector for digital inputs and outputs.

(X17) DE15 connector for analogic inputs and outputs.

3.3. Equipment reception

3.3.1. Unpacking and checking the content

On receiving the device, make sure that the converter has not suffered any damage during the

transportation. Otherwise, make all pertinent claims to the supplier or to CINERGIA.

The packing of the device consists of a wooden palette, a cardboard or wooden packaging

(depending on the case), expanded polystyrene corner pieces, a polyethylene sleeve and bands;

all recyclable materials. Therefore, they should be disposed of according to current regulations.

We recommend to keep the packaging in case its use is necessary in the future.

In order to unpack, cut the bands and remove the cardboard packaging with a vertical

movement. In case of wooden packaging, remove it with the appropriate tools. Afterwards,

remove the corner pieces and the plastic sleeve. At this point the equipment will be unpacked

on the pallet. Please, use suitable tools to lower the converter from the pallet.

After unpacking the equipment, check that the data in the nameplate (stuck on the inner part

of the front door) correspond to those specified in the purchase order. Contact the supplier or

CINERGIA in case of disconformity.

Keep the equipment in the original package if it will not be used in order to protect it from any

possible mechanical damages, dust, dirt, etc…

3.3.2. Storage

The equipment shall be stored in a dry, ventilated place and protected against rain, water jets

or chemical agents. It is advisable to keep the converter into its original package, which has been

designed to assure the maximum protection during the transport and storage.

Do not store the unit where the ambient temperature exceeds 40ºC or falls

below -20ºC

This manual suits for next models

25

Table of contents

Popular Batteries Charger manuals by other brands

Sterling Power

Sterling Power Pro Batt Ultra BB1260 user manual

TCE

TCE NEOS Series instruction manual

Chargery

Chargery 320B operating instructions

LXE

LXE HX1A376 user guide

Associated Equipment

Associated Equipment Heavy Load Electronic Battery Tester 6033 Operator's manual

GNB

GNB Tubular LMX Installation and operating instructions

ABL

ABL eMH3 installation manual

Circontrol

Circontrol Rapid Series Installation & user manual

EXTOL PREMIUM

EXTOL PREMIUM 8891894 Translation of the original user manual

Goobay

Goobay 54334 quick start guide

Helvi

Helvi DIGICAR 600 Operating instructions manual

Nordelettronica

Nordelettronica NE284 instruction manual