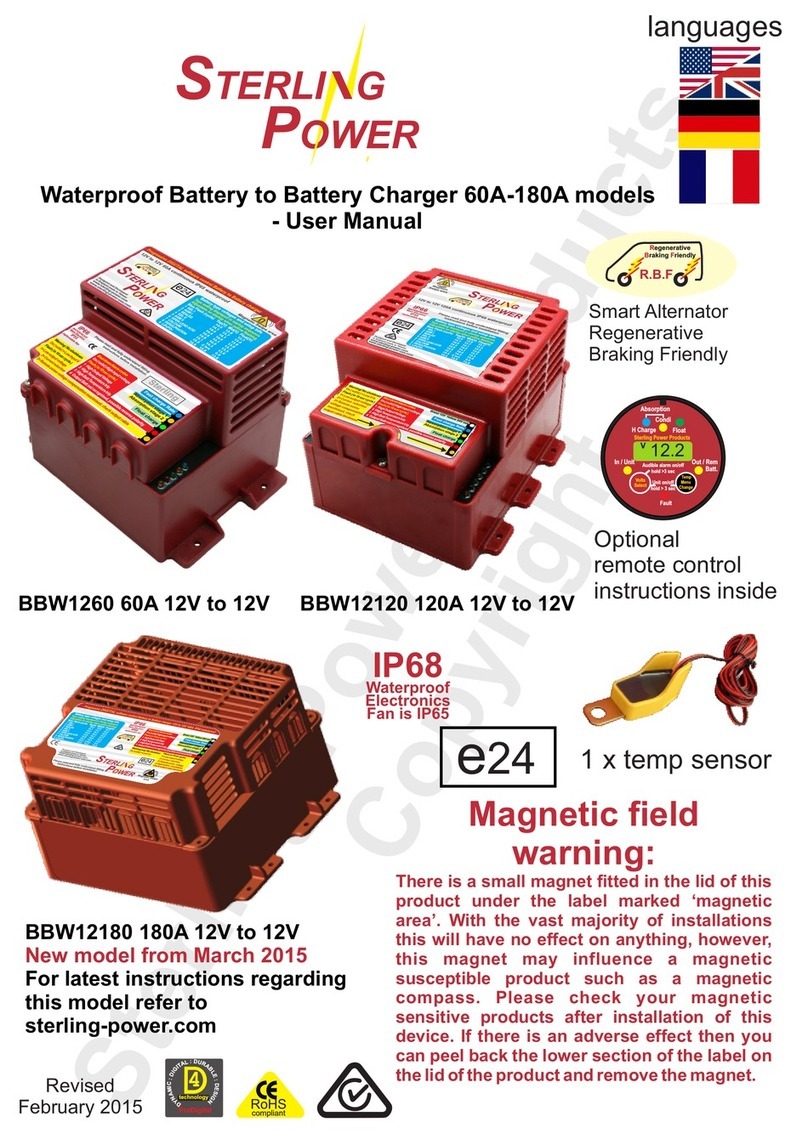

Sterling Power Pro Batt Ultra BB1260 User manual

Sterling Power Products

Copyright

STERLI G

POWER

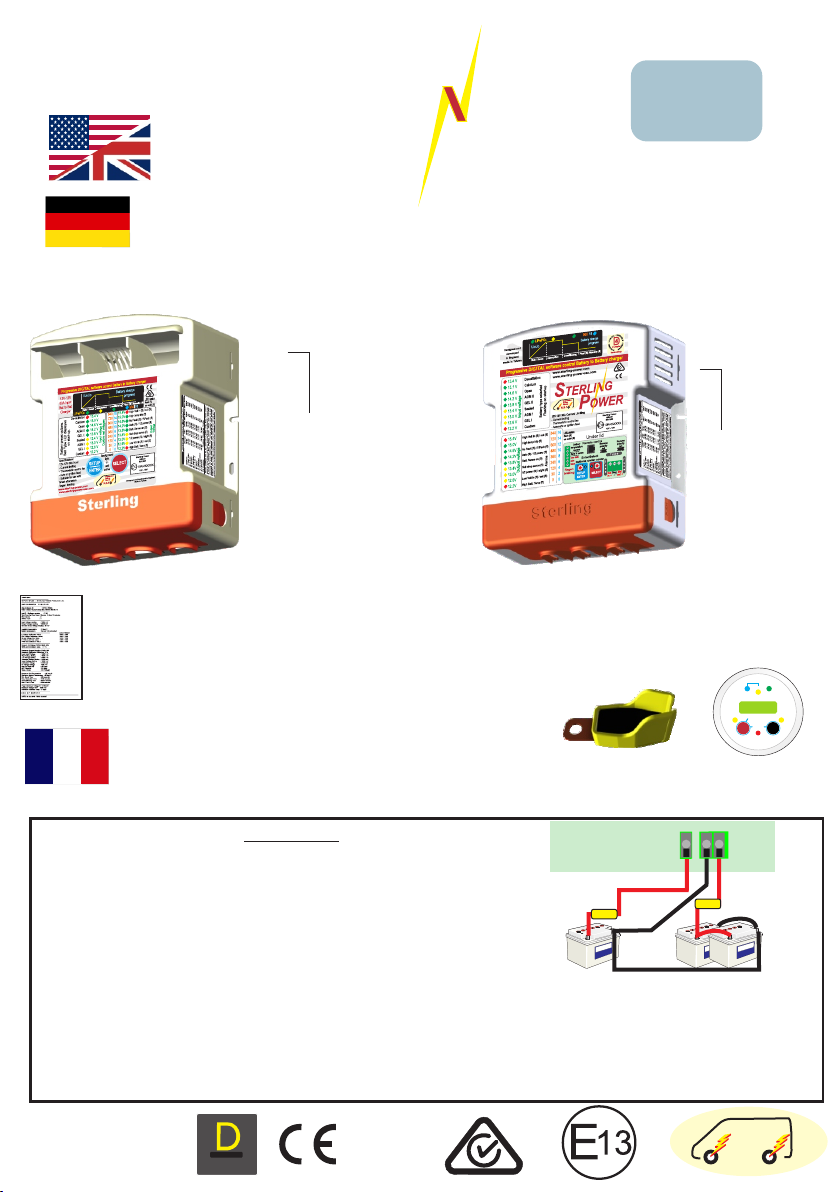

Pro Batt Ultra - Battery to Battery Charger

Copyright © 2017

Sterling Power

V60 July 2017

Starter

Engine Bat.

Pos

in Pos

out

Neg

fuse fuse

House / Domestic / Aux

/ Bow thruster

Main Power

Terminals

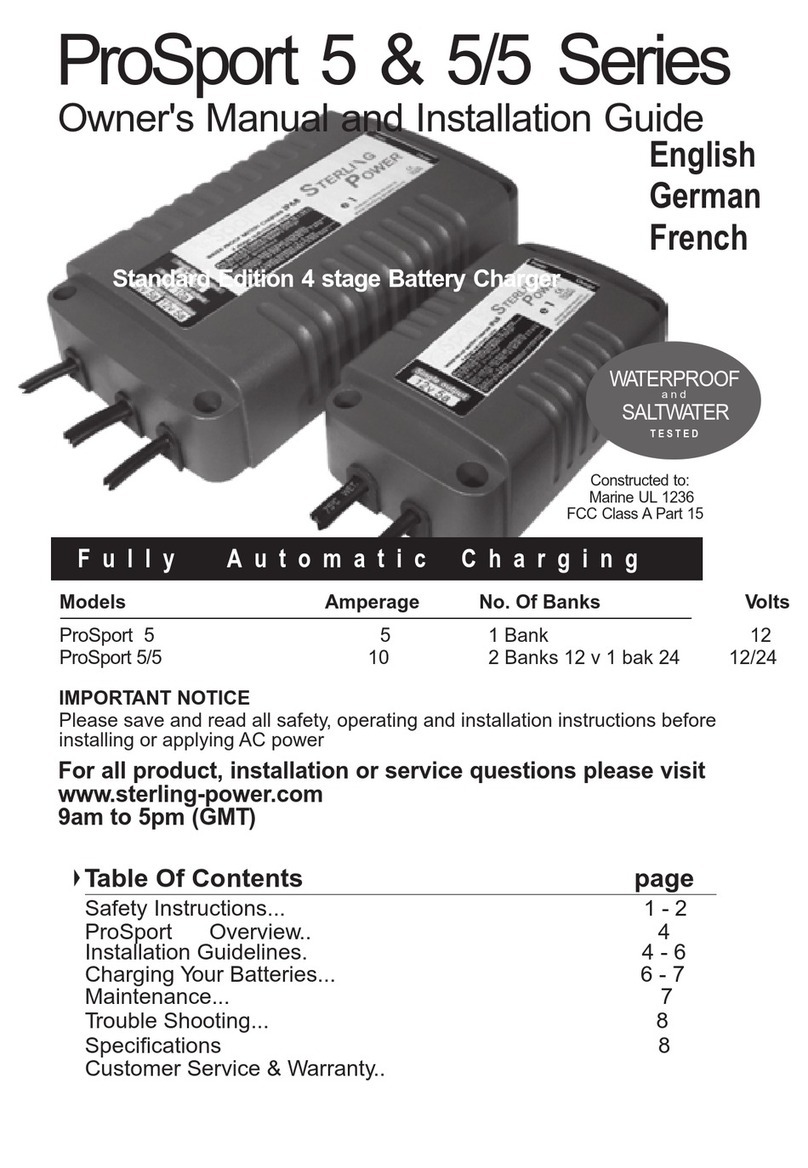

MUST READ

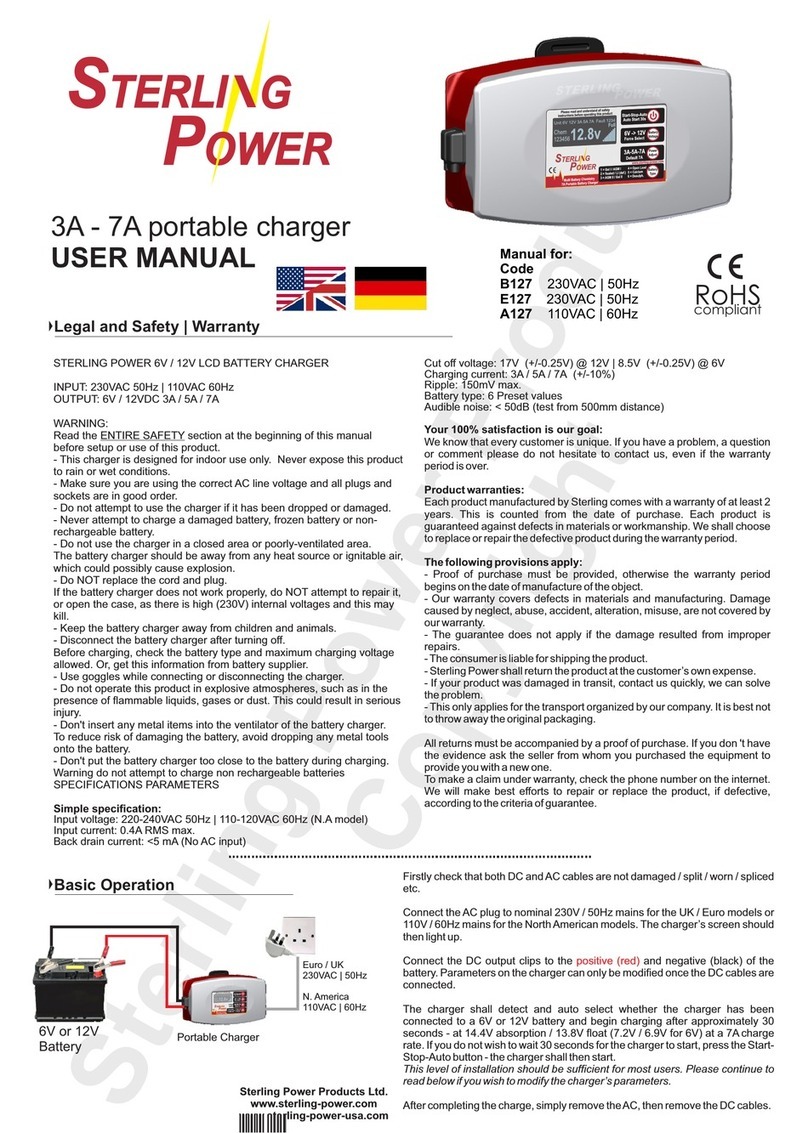

For the vast majority of users (90%+) reading this paragraph should

be sufficient for installation. The unit can be installed by simply

connecting it between an input and output battery as depicted. The

unit, by default, shall start charging when the input voltage exceeds

13.2V and switches off when the voltage drops below 13.0V for more

than 240s (adjustable). Going above 13.2V for 5 seconds shall reset

this timer . The default charging profile is 14.4V abs. and 13.6V float -

for sealed lead acid batteries (x2 for 24V | x3 for 36V | x4 for 48V). This

means that the vast amount of installations can be fitted out of the box

without any adjustments.

There is also an ignition feed option - Unit on when ignition is on, unit off

when ignition is off. Please read the manual for additional information.

Code:

BB1230

12V-12V 30A input

BB122440

12V-24V 40A input

battery temp

sensor

USERS MANUAL.

Sterling Power Products

H Charge Float

In / Unit Out / Rem

Batt.

V12.2

Temp

Menu

Change

Volts

Select

Audible alarm on/off

hold > 3 sec

On / Off

hold>3 sec

Fault

Absorption

Cond.

Optional Remote

Instructions inside

technology

4

D

U

:

L

R

A

A

T

I

B

G

L

I

E

D

:

:

D

C

I

E

S

M

I

A

G

N

N

Y

D

ProDigital

RoHS

compliant R.B.F

Regenerative

raking riendly B F

Test Report Sheet

Each product gets uniquely tested and a report is generated.

This unique test report is present inside this box.

You must keep this test sheet in this box and keep this box safe.

This sheet should be present when the charger is being warranted.

For other European languages refer to website:

Europe / RoW: www.sterling-power.com

North America: www.sterling-power.usa.com

*default mode does not require ignition feed*

Code:

BB1260 12V-12V 60A input

BB122470 12V-24V 70A input

BB123670 12V-36V 70A input

BB124870 12V-48V 70A input

BB242435 24V-24V 35A input

BB241235 24V-12V 35A input

BB123670 12V-36V 70A input

BB124870 12V-48V 70A input

++

+

Please read the legal and safety

information first before proceeding

and we strongly advise hiring a

professional to fit.

STERLI G

POWER

Important

upgrades

and features

Due to the fast and fluid changes being

made in the vehicle industry with the euro 6

+ variants between vehicle manufacturers,

Sterling power is constantly upgrading the

software in the products to keep up with

changes, unfortunately the printed

installation instructions simply don't keep

pace with the changes. The latest installation

instructions can be downloaded from the

internet.

To download the latest instructions, to

access the above features simply go to:

German, second half of this manual

These instructions are constantly

being modified and updated. The

Sterling website is worth referring to

for the latest instruction download.

Sterling Power Products

Copyright

STERLI G

POWER

Contents Page

Product Specifications

BB1230 BB1260 BB122470 BB123670 BB124870 BB241235 BB242435

Input Voltage (V DC) 11 - 20 11 - 20 11 - 20 11 - 20 11 - 20 22 - 40 22 - 40

Input Current (A) 30 60 70 70 70 35 35

Battery types (all models)

IP rating IP21 IP21 IP21 IP21 IP21 IP21 IP21

Ignition Protected Yes Yes Yes Yes Yes Yes Yes

Quiescent Current (mA) 1 1 1 1 1 1 1

Battery Connector WJ116VW WJ116VW WJ116VW WJ116VW

Weight (Kg) 1.2 1.4 1.4 1.4 1.4 1.4 1.4

Dimensions (LxWxD) mm 190 x 160 x 50

AGM (2) | GEL (2) | SEALED | OPEN | LiFePO4 | CALCIUM | CUSTOM

8mm input | WJ116VW output

190 x 160 x 70

Seite 16 Deutsch

Page 16 for German

2

Legal and Safety Information Page 3 Force Options - Device options Page 10

How to use the instructions Factory Reset

Copyright and Plagiarism Force operation w ithout output voltage

Maintenance and Repair Force Float mode

Safety and Precautions Force Unit on / off

Display annotations Page 4 - 5 Force Unit to half pow er mode

Front Label display annotated Sleep timer / Off timer adjust.

Under the lid annotation Custom Battery Profile Selection Pages 11 - 12

Recommended cable and fuse sizes Customise Boost / Absorption voltage

Quick Installation guide Page 6 Customise Conditioning voltage

Basic w iring diagram Customise Float voltage

Basic operational modes 1 | 2 | 3 Customise Absorption time factor

Guide to Buttons Page 7 Customise minimum and maximum absorption times

Detailed Installation guide Page 8 Customise Operational Voltages

Operational modes 1 | 2 | 3 Remote Control Operations Page 13

Installation diagram Comprehensive breakdow n of remote functions

Choosing the correct operational mode Fault Finding | Troubleshooting Page 14

Wiring the correct operational mode Fundamental fault + troubleshootings

First Turning the unit on Page 9 LED displays w / meanings and solutions

Changing the Battery Chemistry Profile Sterling's Warranty Statement Page 15

Battery Chemistry voltage values table Customer service and w arranty declaration

Front panel meter readings / meanings

Sterling Power Products

Copyright

4

2

Using the Instruction Manual

This manual must be read throughout before installing

this electronic device. Do not lose these instructions -

keep them safe. The most up to date instructions can

be found on the Sterling Power website. Please refer to

the latest instruction manual before contacting Sterling.

At Sterling, we endeavour to include all of the product

information that we can think of into the manual.

Installation of the electronic device must be carried out

by a qualified and trained personnel only. The

personnel must be familiar with the locally accepted

guidelines and safety measures.

Sterling Power’s warranty statement

A comprehensive warranty statement is provide at the

back of the instruction manual. A comprehensive

warranty statement can also be found on sterling-

power.com.

Copyright and plagiarism

Copyright © 2015 Sterling Power. All rights reserved.

Reproduction, transfer, distribution or storage of part or

all of the contents of this document is strictly prohibited.

If you wish to use all of this document, or excerpts from

it, Sterling Power must be contacted.

Liability

Sterling Power can not accept liability for:

Ÿconsequential damage due to use of this device

Ÿpossible errors in the manuals and the results

thereof

Device modification

Please do not modify the device unless you have been

instructed to do so by Sterling Power, directly. Product

modification shall be done at Sterling, when needed.

Warranty shall be voided if personal attempts are made

to modify the device, without Sterling’s approval.

Use the battery to battery charger only:

ŸFor DC to DC conversion.

ŸFor DC current limiting.

ŸWith fuses protecting the DC cables.

ŸIn a well ventilated, dry, dust-free and condensation

free environment.

ŸWhen instruction manual has been read through.

Safety Symbols

ŸExample - WARNING. Never use the device in

situations where there is danger of gas / dust

EXPLOSION or potentially flammable products.

General maintenance and repair

The device must be switched off during maintenance. It

must also be protected against unexpected switching

off. Remove battery connections and ensure unit is off.

If repair is required, only use original parts.

General safety and installation precautions

ŸInstall device in well ventilated space. Do not

expose device to: Rain, snow, spray, moisture,

pollution, condensation. Do not cover or obstruct

ventilation openings.

ŸDevice connects to common negative. Common

negative must be earthed.

ŸIn case of fire use a fire extinguisher.

ŸEnsure reverse polarity and short circuiting is

avoided - to prevent damage to battery.

ŸProtect DC wires with the appropriate sized fuse.

ŸCheck cabling annually- fix where needed.

ŸAvoid contact with device with damp hands.

ŸEnsure the device is adequately and securely

mounted to prevent the unit from displacement.

ŸUse a professional to install device.

Battery safety

Excessive charge or discharge and high voltages can

cause serious damage to batteries. Never exceed the

recommended limits. If battery acid contacts skin or

clothing, wash immediately with soap and water. If acid

enters the eye(s), immediately flood the eye(s) with

running cold water for 20 minutes and seek medical

attention.

Give extra care to not drop metal tools or jewellery on to

the battery terminals as short circuiting can take place.

Refrain from charging battery up to 4 hours prior of

installation to avoid the formation of explosive gases.

Never smoke / generate a spark around batteries.

CAUTION

WARNING

EXPLOSION

Legal and Safety

3

Sterling Power Products

Copyright

10

11

13

8

9

7

6

5

4

3

2

1

12 14 15

High bat temp (fl) SVEM (S)

Regen timer off (S) / on (fl)

16

17

18

19

20

21

22

23

24

25

26

27

28

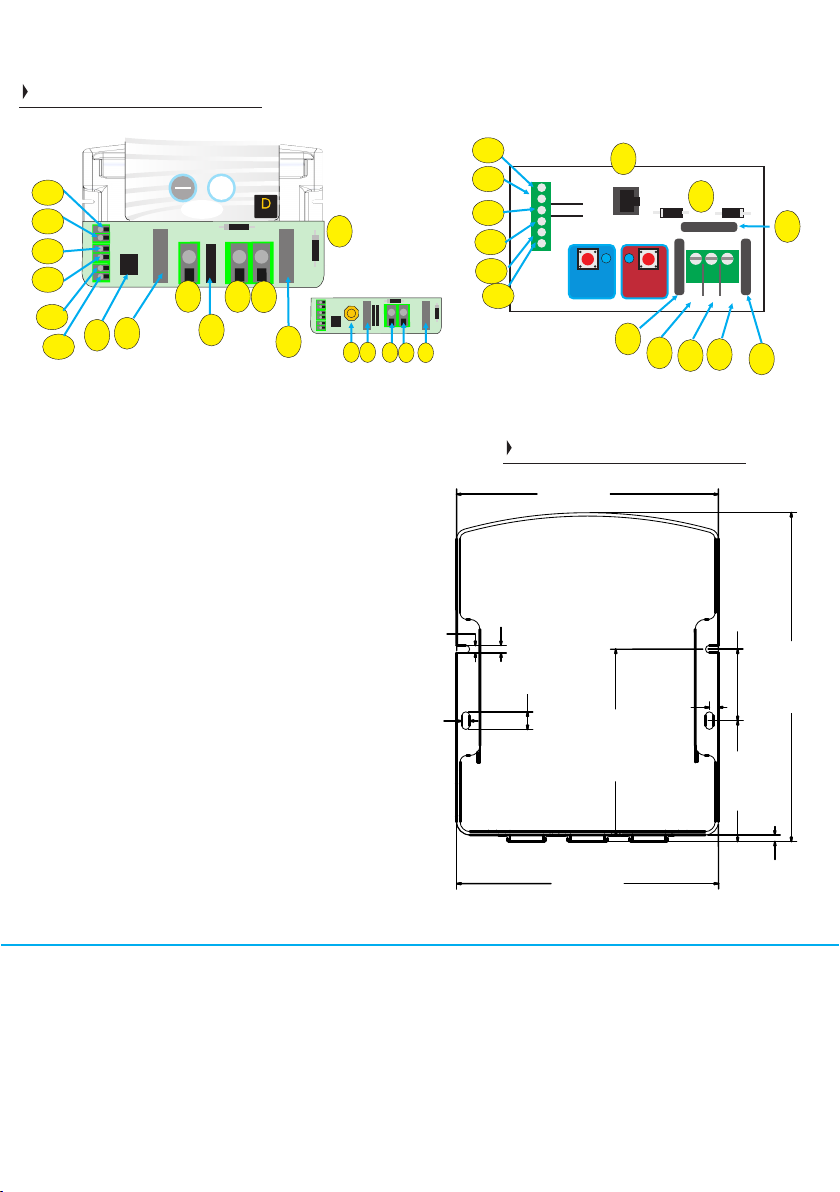

Front label display

1 & 26) ENTER / SETUP and SELECT buttons, used to

adjust settings.

2 & 25) Background light for button, used also to show

unit is operational.

3)-11) The left column of LEDs have 3 different

functions. Firstly, on unit start up the battery type is

displayed. Secondly, after startup it becomes an input

voltmeter. Thirdly, during custom setting the voltage

scale is used to set the voltage - refer to later.

12) This LED has 3 meanings. Firstly, when on battery

type selection mode this is the LiFePO4 lithium battery

indicator. Secondly, on default mode (most times) this

shows the charger is on fast charge mode. Thirdly, if

flashing, then the unit is in standby and was in fast

charge prior to entering standby.

13-15) These LEDs show the battery charge

progression through its cycle.

15) Flash when in standby.

16-24) Has 3 functions: Firstly, on start up they show the

output voltage. Secondly, if an alarm is present the alarm

shows up. Thirdly, this row is used in the custom setup

procedure to set timing functions, voltages and time

factors. Its general function is as an output voltmeter, in

the event 2 LEDs are on the voltages is between the 2

settings, if the top or bottom red LED is on then the

voltage is outside the parameters off the voltmeter.

16) High voltage, if on solid it is high output voltage, if

flashing it is high input voltage.

10

11

13

8

9

7

6

5

4

3

12 14 15

16

17

18

23

24

19 126

21

17) High temp trip, if flashing then high unit

temperature trip.

18) No faults (solid on). Power Pack mode / live

voltage output (flashing).

19) No regen. mode or regen. timer at 0 = solid LED.

Regen on / timer on = flashing LED.

20) Remote Battery sense cable connected (solid).

Battery sense voltage drop in cable outside the 21)

prescribed 1.5V drop maximum, thicker cable

required - LED flashing.

22) Device’s power ability reduced due to high

ambient temperature or voltage drop in output cable

to big. Alarm will be in conjunction with other

information alarm. If flashing unit is in night mode

with reduced power and low fan speed.

23) Low voltage alarm, low voltage on input =

flashing LED. Input alternator not supplying enough

power or failed. Low voltage output = solid LED.

Something consuming a lot of power or unit not

working. No voltage output then LED on solid.

24) If flashing then battery temperature too high.

Solid LED is in SVEM mode - Stationary Vehicle

Engage Mode.

27) Numbers relating to battery custom setup (if

used) this is the charge factor number.

28) Numbers relating to custom setup mode these

numbers relate to timing, i.e. maximum and

minimum time settings.

20

22

Models:

BB1260 / BB122470 / BB123670 / BB124870 /

BB242435 / BB241235 / BB123670 / BB124870

Model:

BB1230

BB122440

Front Panel

Regen timer off (S) / on (fl)

High bat temp (fl) SVEM (S)

4

SELECT

Specification:

12V-12V 60A

Current limiting

Thermostatic control fan

Auto or ignition feed

SETUP

ENTER

Background

light

on

unit

active

www.sterling-power-usa.com

www.sterling-power.com

Designed and

developed

in England

Made in Taiwan

technology

4

L

:

D

U

R

A

A

I

T

B

L

I

G

E

D

:

:

D

C

E

I

M

S

A

G

I

N

N

Y

D

ProDigital

1

2

3

4

5

7

10

11

8

9

14

+

+

+

+

+

+

Remote control

Battery

temperature

sensor

Rem V sense

see side

info

label

SETUP

ENTER SELECT

Reverse

polarity

tell

Enter/Select

buttons under cover

f

u

s

e

Reverse

polarity

tell

f

u

s

e

f u e s

regen

braking

Bat

in + Bat

out +

Neg

-

12

13

6

The mm2 figures have been rounded up to suit European cable availability.

30A

Distance 3m (10 ft) 5m (15ft) 7m (22ft) 8m (25ft) 9m (30ft)

mm2 / 6.0 / 6.0 / 6.0 / 6.0 / 10.0 /AWG 10 10 10 10 8

60A

Distance 3m (10 ft) 5m (15ft) 7m (22ft) 8m (25ft) 9m (30ft)

mm2 / 16.0 / 16.0 / 16.0 / 16.0 / 25.0 / AWG 6 6 6 6 4

Nominal

Fuse size for

input & output

40A

70A

Recommended cable size for current required

Models:

BB1260 / BB122470 / BB123670 / BB124870 /

BB242435 / BB241235

STERLI G

POWER

Models:

BB1230

BB122440

Front Panel II

+

++

+

++

++

+

81

2

3

4

6

7

10

11

12

13

95

14

+

++

++

+

++

53

41

6

BB122470

BB123670

BB124870

BB1260

BB242435

BB241235

4.60

73.00

4.60

158.00

198.51

43.13

158.00

5.50

10.60

4.60

112.13

4.00

199mm(H)

158mm(W)

70mm(D)

units in millimetres (mm)

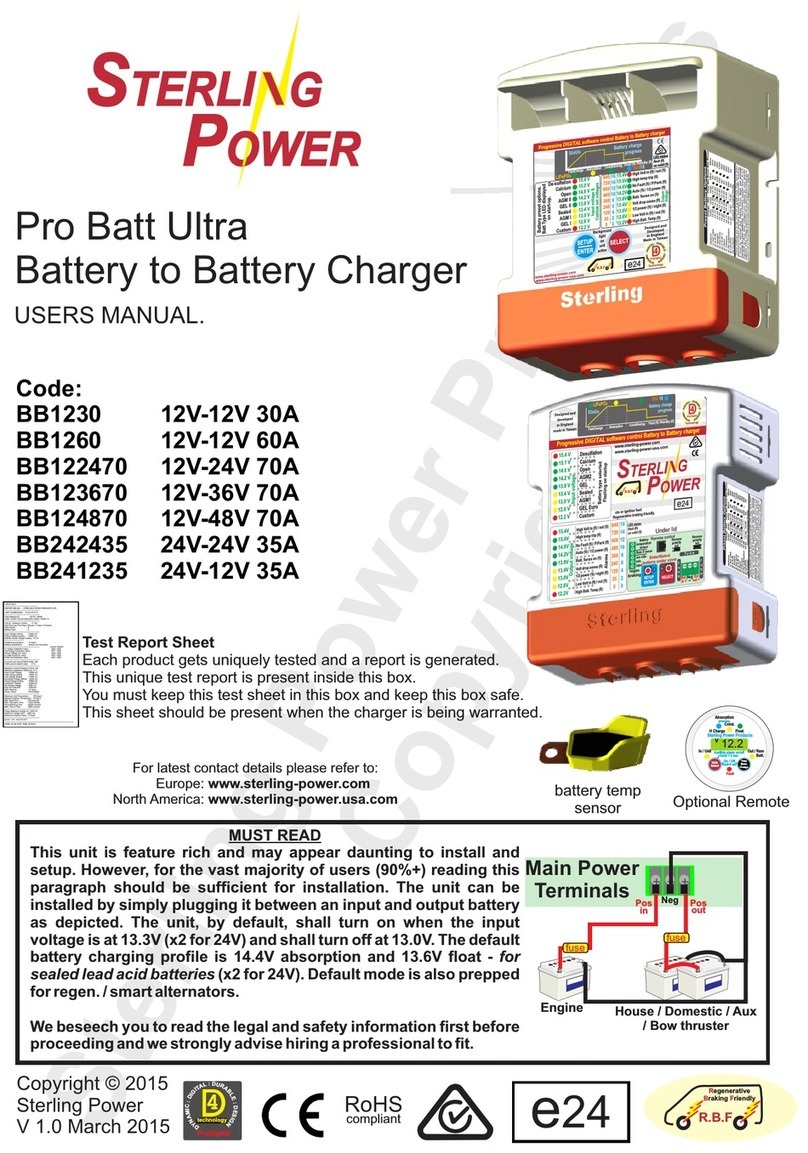

Under the lid

1) DC output fuse

2) Negative fuse (position, model dependent)

3) DC output to aux battery

4) Common negative

5) DC input from start battery (green connector or

brass nut/bolt - model dependent).

6) DC input fuse

7) Remote control socket

8) Ignition force (immediate activation down to

10V input voltage).

9) Ignition feed connector (on/off)

10) Auto regen. mode (default linked w/ ign feed)

11) Remote battery sense wire to compensate for

voltage drop in cable (optional, does not need to

be used).

12) Battery temperature sensor, optional fit, if not

used product will work on default of 20 deg C

setting.

13) Other wire associated with the temp sensor

as per 12.

14) Reverse polarity tell tale diodes. If damaged,

will show if unit has been reverse polarity and not

under warranty. Position of diodes are model

dependent.

Dimensions

5

100A

Sterling Power Products

Copyright

Engine Starter

Battery

(connected to alternator)

Important

NEGATIVES

should all be common.

We recommend joining

the BB’s neg. to the

starter battery negative.

For improved efficiency.

+

++

++

+

F

U

S

E

2

F

U

S

E

3

Pos

in Pos

out

Bat out fuse

Battery temp

sensor

Remote sense

Remote

socket

ign

ctrl

auto

fuse

fuse

House / Domestic / Aux

Battery Bank

Temp

Sensor on

negative

+

+

+

Link

+

+

+

Auto

Low V

regen. braking

To Ignition feed*

+

+

+

To Ignition feed

Link

(optional)

To Ignition feed*

Auto

Automatic

Activation.

Unit on when input voltage above 13.2V

(input), off below 13.0V (input). If input

voltage is 13.2V - 19.0V the regen. braking

timer begins. This triggers the 240 second

timer which starts when the input voltage

drops to between 11.9V-13.0V. The timer

and voltages can be adjusted. This allows

it to be used with smart alternators /

Regen. Braking.

Ignition feed w/ safe voltage activation

Same as operation mode 1. The only

addition is that an ignition signal is

required for charging. If you have 13.2V+

on the input terminal with no live ignition

feed then the charger is in sleep or

standby mode and not charging.

This signal can be used to turn the charge

on and off if required

Operational Modes

1

2

3

12

3

Unit will work on default setting if temperature sensor not fitted

Ignition Force mode.

For true ignition on/off mode the ‘Link’ should be removed.

As soon as there is a signal (> 4V) on this connector, the unit will

wake up (can take up to 60 seconds) and will start to charge the

output battery. The only limit is the input voltage. It will charge down

to 10V on the input side.

WARNING: In case the alternator / engine is not running or

delivers less than 60A (depends on the charge state of the

output battery) you can discharge your starter battery.

With the Auto link connected and no signal from the ignition then

the BB shall operate identically to Mode 1.

If you have both the link and a live ignition the BB shall operate at

any input voltage (down to 10V). When the ignition feed turns off

the BB shall still charge with Auto Mode (mode 1) parameters.

Ideal if you have shore power charger charging up the input battery

and wish for the BB to turn on and charge the domestic battery etc..

How to get the charger to turn on and operate

- ensure the charger is wired up as depicted above

- when engine is running, the alternator should charge the starter battery.

Because the starter battery is connected to the positive input terminal (Pos in) of the Pro Batt Ultra there should

be at least 13.4V+ (x2 for 24V | x3 for 36V | x4 for 48V) at this terminal, when the engine is running. This shall turn the charger on.

The charger, from default, requires a battery voltage on the positive output terminal (Pos out) in order to start charging, so ensure that there is

battery voltage on the Pos out. If so, the charger shall start charging at the default charging profile (sealed lead acid).

Quick Installation

input cutoff voltage 20s

reset unit to default 30s

1/2 5 seconds

10+ set auto regen

15+ Power supply mode (live)

battery temp

sensor

Temperature sensor

Not obligatory to connect.

If you wish to install, connect the temp

sensor to the negative of the domestic

/ aux. batteries.

When temp sensor senses the

temperature lower than 20Deg C the

voltage shall go up on the charger’s

output and when the temperature is

higher than 20Deg C the voltage.

Sensor shall trip the charger if the

temperature of battery >55DegC

compensates for voltage drop across long cables

++

Neg

+

OEM lock

Numerous OEMs fitters requested the ability to lock

the BB’s functions upon completion of the installation.

This is to prevent their operators playing with the unit

buttons and upsetting the product, in the field.

Factory lock procedure:

Once you have completed the installation and no

more work is required.

Press the left hand button (Setup/Enter) for more than

30 seconds (over 30 blue flashes of the button) then

remove. The 4 corner red LEDs should flash, this

shows lock is now engaged.

Proof of OEM lock:

After lock is engaged push and hold for a few seconds

the right hand button (enter) and the 4 red LEDs will

appear to show the button is not active.

Display / status check: Left hand button can still

select product status (this cannot adjust any of the

settings), it simply allows the customer to access fault

information in event of a problem.

Push the left button for 1 second.

Remove lock and return product to normal

operation:

To remove the lock do a factory reset (explained

earlier in the instructions). This will remove all

programmed features and put the product back, as

new.

6

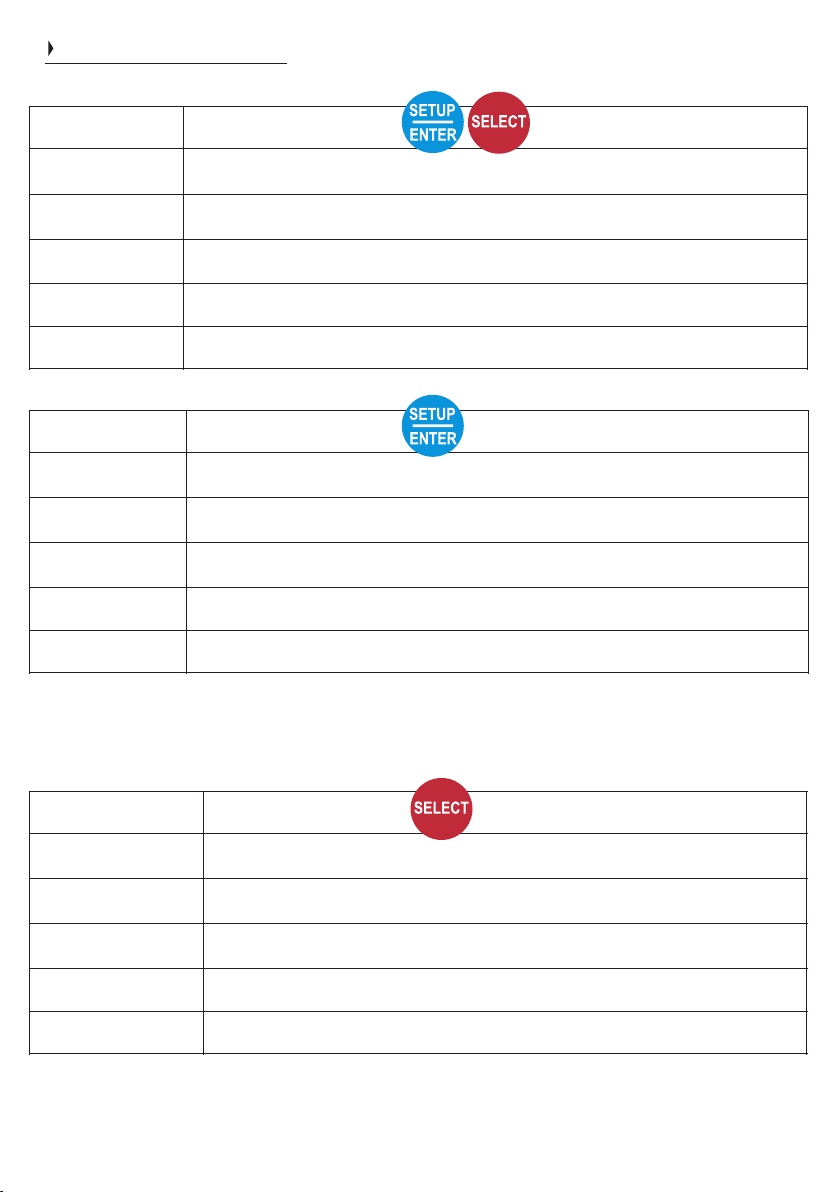

Quick Guide to the

buttons on the front panel.

Refer to Pages 8 - 11 for in depth procedure

To operate the Pro Batt Ultra

refer to page 7 (next page)

for instructions.

Force unit to float. On/off toggle.

Turn unit on / off toggle.

Battery type select.

Change Operational on/off voltages

Reset unit to default.

30+

20+

Toggle Power Supply mode

(provides live output voltage)

15+

Display software version

SVEM*

Stationary Vehicle Engage Mode

15+ SVEM*

Stationary Vehicle Engage Mode

Pro Batt Ultra starts charging when input is >13.1V.

Turns off when input is <13.0V.

30+ OEM* lock - disables further

adjustment of unit’s functions

OEM lock - press Setup button for 30+ seconds -

4 x red LEDs should light to confirm.

repeat procedure to remove the lock.

this mode prevents operators tampering with the unit’s

settings when in the field. The OEM / fitter can set the

unit up as they desire first, the settings shall be stored,

then they can apply this lock.

Guide to buttons

Press Length (s)

Action

2-5

Forces unit into float mode. Press again to take out of float mode.

5-10

Turns unit on / off toggle.

10-20

Battery type select - use SETUP / SELECT to toggle between types. Both to confirm.

20-30

Change operational on/off voltages - use both buttons to scroll between voltages.

30+

Reset unit to default - press and hold both buttons for 2 seconds to confirm.

Press Length (s)

Action

0-1

Change to status fault display / back to Voltage display mode.

5-10

Toggles between 1/2 and 1/1 (full) power.

10-15

Set Auto Regen. time - use either buttons to toggle between the preferred time.

15-30

Live output voltage (power supply mode) - press SELECT to change to LED 24.

30+

OEM lock - disables further adjustment of unit’s functions.

Press Length (s)

Action

2-5

Night mode = 1/2 power for 8 hours, then back to full power.

5-10

Enter standby mode. To take out of standby, repeat.

10-15

Display software version (displayed in binary on display).

15+

SVEM - Stationary Vehicle Engage Mode

7

Sterling Power Products

Copyright

Product Information

The Sterling Battery-to-Battery Charger is

a DC to DC charger designed to be put

between a starter battery and an auxiliary /

house / domestic battery. The product’s

advantages are:

5-10+ times faster charging over

i

conventional charging systems (e.g. the

stand alone alternator).

Fool the alternator into working at its

i

maximum ability in order to ensure all its

surplus power is utilized to charge the

auxiliary battery bank to its maximum

capacity without allowing the starter battery

to become discharged.

Allows the correct voltage and charging

i

curve to be selected for you specific

battery chemistry.

Fixes problems associated with vehicles

i

with smart alternators on Euro 5 / 6

engines. It saves your batteries from high

voltage (e.g. Mercedes 15.4V) - gassing

and low voltages (low as 12.2V) - sulfation.

All unwanted side effects to these new

smart alternators.

Fast and easy installation. Simply

i

connect the unit to your starter battery and

your aux battery.

No extra connections to the alternator

i

and no extra wiring for a split charge

system required.

Voltage drops in cabling compensated

i

for.

Several battery-to-battery chargers can

i

be used in parallel for higher output power

or multiple battery banks.

No voltage rises on the alternator or the

i

starter battery. Therefore, no problems with

the engine's management system.

No vehicle warranty issues as the

i

alternator and the main electrical system

remains untouched.

Engine Starter

Battery

(alternator)

+

++

Pos

in Pos

out

Neg

fuse fuse

House / Domestic / Aux

Battery Bank

1) Automatic activation (default setting).

The most common mode, used in 99% of

all installations including vehicles with

Regen. braking system. This means that

the unit is voltage sensitive (no ignition

feed required). The moment the charger is

installed onto an input and output battery it

shall start charging for 120 seconds then turn

off. Only when the input voltage goes to

13.2V-19.0V then the unit will simply start

charging. If the voltage drops below 13.0V the

unit shall turn off. With a caveat, read on.

However, if the input voltage has exceeded

13.2V for 5 seconds the regen. braking timer

is prepped and shall become active if the

input voltage drops down to 12.0V-13.3V.

This timer is 240s (default - can be changed)

and allows the charger to continue charging

at these lower input voltages. If the voltage

drops below 11.9V the charger goes to sleep

irrespective of the timer. If the input voltage

remains between 11.9V-13.0V for over 240s

the charger also goes to sleep. To wake the

charger, the input voltage needs to rise above

13.2V - this shall also reset the regen. braking

timer.

+

+

+

Auto

Ignition

Low V

regen.

braking

Link

2) Ignition feed w/ safe voltage activation

Mode 2 is identical to Mode 1. The only

difference is that it requires a live signal on the

ignition AND the aforementioned input

voltages for it to remain charging. For

example, if you have over 13.2V on the input

terminal with no live feed then the Pro Batt

Ultra shall be in standby. Only once you apply

the ignition feed signal the Pro Batt shall start

charging. The charger turns off when you turn

off your ignition.

This mode is beneficial as it give you more

control over when the charger operates. With

a live ignition and low input voltage the

charger shall still charge for 240 seconds,

then turn off.

How to connect?

Link the Auto and the

Ignition terminals on

the block together,

as shown.

+

+

+

Auto

Ignition

Low V

regen.

braking

How to connect?

Conn ect igni tion

feed to the Ignition

terminal. Can be any

live feed.

+

+

+

Auto

Link

(optional)

3) Pure ignition feed - WARNING flat batt.

If you just connect the ignition feed only to the

bottom connector (remove the link) the BB

shall operate when the ignition is live and turn

off when the ignition is off. There is no timer,

no trigger voltages - only a 10V (20V at 24V)

low voltage trip.

With the link wire connected and the ignition

feed connected the BB shall operate when

the ignition is live. However, it shall also

operate when there is no ignition under the

conditions of mode 1 (above).

This mode is ideal for those who have Euro 6

engines that start up with the alternator off.

Where the starter battery’s voltage does not

exceed 13.3V, but you want the BB to charge.

How to connect?

Connect ignition feed

to Low V regen braking.

Link Auto to ignition

connector.

6

R.B.F

Regenerative

raking riendly B F

STERLI G

POWER

Main Power

Terminals

Auxiliary

Control

Terminals

Fit in a cool dry well ventilated space.

Should be installed by a competent

person, conforming with the laws of the

country. Connect positive cables (in red) to

the terminal block, as shown below. Similarly,

ensure fuses are installed and negatives are

common.

R.B.F

Regenerative

raking riendly B F

R.B.F

Regenerative

raking riendly B F

8Double all voltages for 24V, triple for 36V

and quadruple for 48V.

Ensure the charger is wired up as

depicted above (larger diagram on

previous page). The Pro Batt Ultra shall

light up provided it has battery voltage

across the and neg terminal. If Pos in

Pos out is also connected the unit shall

start charging for 120 seconds (1/2 of the

regen. braking timer). During the first

start up you can change the battery

chemistry profile.

In default mode (1) or mode (2) the Batt

Ultra shall simply turn off and goes to

sleep after 240 seconds (can be

changed) if the input voltage has not

risen above 13.2V. If you WARNING,

have it set to mode (3) (Ignition Force

Mode) and the ignition is live then the

charger shall continue charging until the

input battery drops to (default) x2 10.0V

for 24V. . VERY LOW

In default mode (1) or mode (2) the input

voltage needs to rise to above 13.2V-

19.0V (x2 for 24V) in order for the Batt

Ultra to start charging. This can be

achieved by starting your engine. Above

13.2V, for 5 seconds, the regenerative

braking timer activates (120 sec (first

time after start/wakeup) then 240

seconds default).

There may be a delay of up to 60

seconds before the BB ultra starts.

This is required to complement the

regenerative braking aspect of modern

Euro 5/6+ engi n es - wh e re t he

alternator’s voltage can drop below 13V

for a short period of time. When the

alternator’s voltage rises above 13.2V

the 240 second timer ends (+ reactivates

the timer) and the charger remains

charging.

Basic Operation / Installation

++

Pos

in Pos

out

Neg

fuse fuse House / Domestic / Aux

/ Bow thruster

Main Power

Terminals

If your engine is running and you’re confident your alternator is connected, yet you are only getting 12-13V on the input terminal, please connect the ignition feed to the unit (see right). This shall turn the charger on when the ignition is on.

+

With the Auto link connected and no signal from the ignition then

the BB shall operate identically to Mode 1. If you only connect

the ignition feed but remove the link connector then the unit is

solely ignition feed dependent. Live ignition - the BB is on,

ignition off then the BB turns off. There is a low cut off at 10V

(20V at 24V) on the input. If you have both the link and a live

ignition the BB shall operate at any input voltage (down to 10V).

When the ignition feed turns off the BB shall still charge with

Auto Mode parameters. Ideal if you have shore power charger

charging up the input battery etc.

WARNING - this mode may lead to flat batteries.

Please re-write as it tells you 3 times the same thing.

line to

ignition

Sterling Power Products

Copyright

On first start up all LEDs will light up. A beep should

sound. The fan shall then start running for around 5

seconds. If, after this, 2 red LEDs flash for 8 seconds

you may have a calibration issue and the unit should be

returned to Sterling. If 2 solid red LEDs are on at the top

or bottom then you either have high or low input voltage

(respectively) - check your voltages.

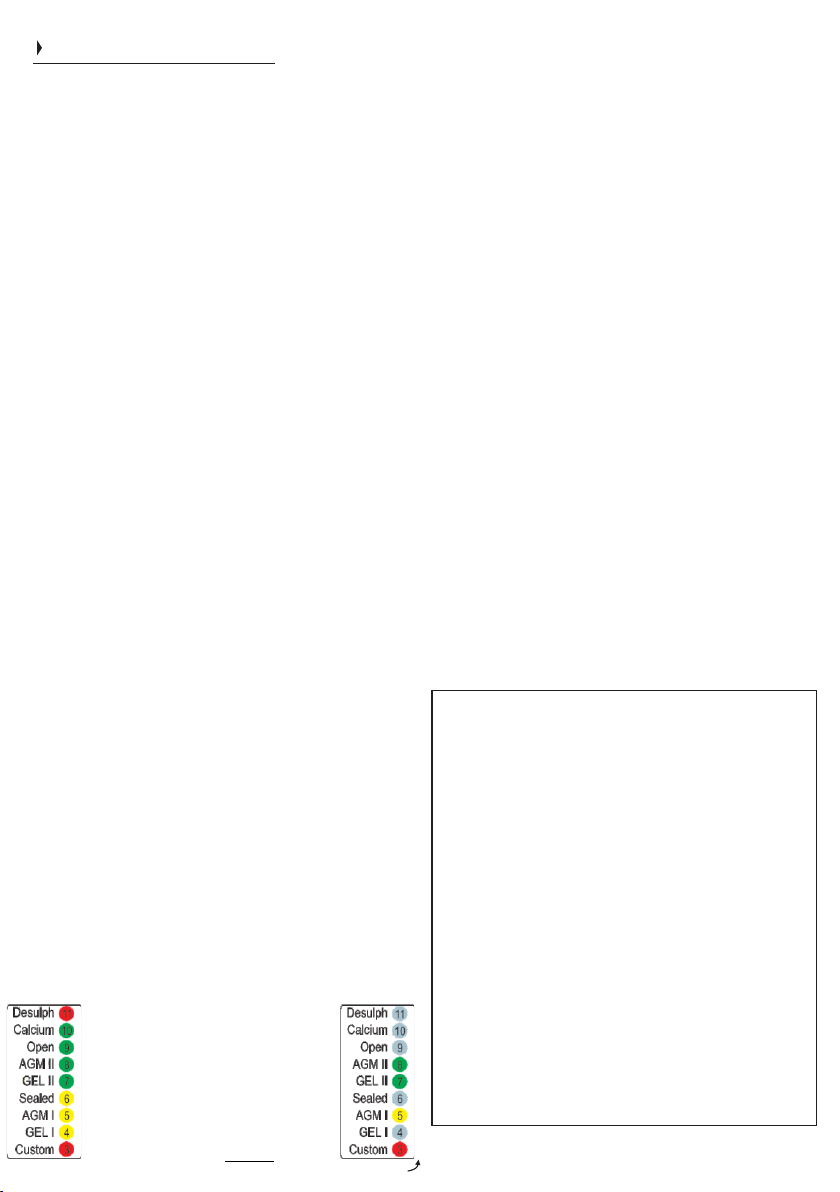

Changing charging profile during startup

After the initial start up an LED on the left panel shall

light up for 5 seconds, this shall indicate the battery type

selected - default is sealed lead acid. This is your

window of opportunity to change the charging profile. If

you have missed the opportunity, you can wait for the

unit to go in to normal operation and follow the

instructions on the right of the page or restart the device.

Hold down both buttons on the front panel (SELECT

and SETUP/ENTER) for more than 10 seconds (less

than 20 seconds!). All LEDs on the left column shall now

flash. By using these two buttons toggle through the

various profiles (see below). The right button is up the

column and the left button takes you down the column.

The LED shall light up demonstrating which profile you

have selected. When the LED has illuminated at your

desired profile simply hold both buttons for a couple of

seconds or simply just leave the charger alone for 30

seconds and it will change. The chosen profile LED

shall then flash. The unit shall then restart and go

through the starting cycle again.

Note - if you can only see LEDs on the right column the

chances are you are in an error mode. This could be

down to: Very low output voltages (<5V), no output

connection, reverse polarity or the device is not

detecting a valid operational mode as the connector

wire is either not connected or the connection

configuration is wrong. Please refer to previous page.

Left and right meter readings.

During normal operation

Out of range voltage values

If voltage exceeds the meter’s range the upper right

LED shall flash. If the voltage falls short of the meter’s

range the lower LED shall flash. If two neighbouring

LEDs, on the voltmeter, are on simultaneously then the

real voltage is between these two parameters.

Example, if LEDs at 14.6V and 14.2V were on then the

approximate voltage shall be ~14.4V.

Low or high output voltages

If the output voltage is below 1V (2V at 24V) or reverse

polarity then the low output voltage LED will flash

(number 23). Similarly, if the output voltage is above

15.5V (31.0V at 24V) the high voltage LED shall flash

(number 16). To resurrect these problems, bring the

voltage above 1V on the output and below 15.5V,

correct the polarity and then restart the device.

Return to factory default: This shall irreversibly

erase all previously entered settings. Press and hold

both buttons for 30 seconds+ and let go. The LED

columns shall alternatively flash. To confirm factory

default press BOTH buttons again for 2 seconds. Once

confirmed, 3 green LEDs on both columns shall flash.

Then, LEDs on the front panel shall light up in a clockwise

pattern. The unit should then reboot with the default

settings. To reject factory default settings, simply let the

LED columns continue alternatively flashing.

To view charger’s status:

Simply hold the SELECT button for 1 second and the right

LED should flash indicating the status of the charger. This

shall flash for 8 seconds. To return quickly, press the

SETUP/ENTER button once.

After unit has gone through its startup sequence the

LEDs displayed should be the input voltage on the left

column and the output voltage on the right column.

Also, the top left LED (number 12) should be on solid

which is the fast charge (bulk) LED.

15.4 V

15.0 V

14.6 V

14.2 V

13.8 V

13.4 V

13.0 V

12.6 V

12.2 V

Input voltage

(x2 for 24V)

Output voltage

(x2 for 24V)

Bulk / Boost Absorb Cond. Float (s) / Standby (fl)

IUOU Battery charge

progress

Charge state ->

Remember it is the voltages which are more important

than our battery types. After installation test the voltage

from the unit is the desired voltage. Ensure you remove

at least 1 wire from the battery temperature sensor as

the product voltage may be higher ( if in cold climate )

or lower ( if in warm climate ) than the preconceived

voltage. The voltage requirements of the battery

company will override our recommendations as it is them

who are supporting the battery warranty.

Changing charging profile during operation.

While the unit is running, simply hold down the SETUP

and SELECT buttons for 10-20 seconds and let go. The

LEDs on the left column shall light up. The procedure

hereafter is the same as above.

*Lithium profile has reverse polarity protection

disabled. **All voltages shall be 0.1V higher for the

first 3 minutes of the chargers operation.

Output Voltage

15.4V

15.0V

14.6V

14.2V

13.8V

13.4V

13.0V

12.6V

12.2V

16

14

12

10

8

6

4

2

0

840

720

600

480

360

240

120

30

0

High Volt in (fl) / out (S)

High temp trip (fl)

No Fault (S) / P.Pack (fl)

Regen timer off (S) / on (fl)

Batt. Sense on (S)

Volt drop sense (fl)

1/2 power (S) / night (fl)

Low Volt in (fl) / out (S)

Bulk / Abs. Cond. Float Min | Abs. | Max

Volts

14.00

14.10

14.40

14.40

14.60

14.80

15.10

15.50

14.40

Custom Charging Profile

Volts

13.70

13.40

13.60

13.80

13.70

13.30

13.60

--------

13.80

Mins

60

60

120

720

60

60

60

240

30

Mins

600

480

480

1440

480

480

360

240

30

Volts

13.85

13.75

14.15

14.00

14.10

14.00

14.30

--------

13.80

Options

1) Gel I

2) AGM I

3) Sealed

4) Gel II

5) AGM II

6) Open

7) Calcium

8) De-sulphation

9) LiFePO4

10) Custom

First Time Use (when wiring up)

If battery temperature sensor is connected then

all voltages are based on 20 Deg C. If sensor

senses less than 20DegC = increased voltage.

Higher than 20DegC = decrease voltage. The

further from 20DegC in either direction leads to

proportional increase or decrease in the

voltage. (x2 for 24V | x3 for 36V | x4 for 48V)

High bat temp (fl) SVEM (S)

9

Sterling Power Products

Copyright

Force unit to operate without output battery connected

( i.e. as a power pack / live output ).

This mode shall allow the unit to operate without needing a

voltage on the output terminal. Hold down SETUP/ENTER

button for 15+ seconds and let go. The boost, absorption

and float LEDs shall flash. A green LED (18) on the right

panel should appear and this indicates that voltage check

is on (default mode) to change it to off (power pack) press

the SELECT button and a red LED (24) below should turn

on. With the red LED on the unit shall now operate without

the need for an output voltage. Press both buttons together

to save this setting or wait 30 seconds for the unit to reboot.

On reboot, the comes on for HIGH BATT TEMP LED(24)

to confirm power pack mode.

Force to Float :

Before accessing float mode please be sure you know

what float mode is and what voltage float mode is for your

profile. Simply hold both buttons down for 2 seconds and

let go. This will lock the charger into float (BLUE LED - top

right - number 15 shall come on). The charger shall now

remain in float and resume bulk/absorption on restarting.

To force the unit out of float repeat the procedure.

Force unit off / on:

This shall deactivate the unit, output goes to 0.0V. Hold

both setup and select buttons for 5 - 9 seconds. LEDs shall

turn off, the Bulk LED (blue) shall flash once every 5

seconds. The unit will remain off, even with normal engine

cycling on and off (although if the unit’s negative is

disconnected from the input battery then it will resume

normal operation on re-connection). To turn the unit back

on, hold the 2 buttons for 5-9 seconds. When OFF, the user

can not access charger’s normal functions.

Force unit to ½ power (stays on until unit is turned off):

This will reduce the units power by about 50%. Hold setup

button only for 5-9 seconds. To confirm the power reduction

LED shall flash 5 times. This function will help reduce noise

in the long term. To return to full power, press the setup

button again for 5-9 seconds.

Force unit to ½ power / low speed fan for 8 hours only

(night mode):

This will reduce the unit’s power by around 50%

for about 8 hours. Hold select button only for

2-4 seconds, power reduction shall be confirmed when the

1/2 power and night LED flashes 4 times. This function will

help reduce fan noise in the short term, in the evenings, for

example. The unit will revert back to full power after 8 hours

automatically. Please note that night mode has to be set

every single time you wish to use it. It can NOT be set to

come on at a certain time daily.

STERLI G

POWER

STANDBY AND SLEEP MODE

NEED TO BE ENTERED AND

EXPLAINED PROPERLY.

Force Options

3

Quick Guide to the

buttons on the front panel

Force unit to float. On/off toggle.

Turn unit on / off toggle.

Battery type select.

Input cut off voltage.

Reset unit to default.

30+

20+

Toggle Power Supply mode

(provides live output voltage)

15+ Display software version

battery temp

sensor

Regen timer adjustment: default 240 seconds

(Regen low voltage timer time).

The default auto Regen time is 240 sec. = 4 min.

The timer is prepped at 13.2V-19.0V on the input.

If the input voltage then falls below 13.0V (x2 for 24V)

the auto regen timer starts to count. If the voltage does

not rise above 13.2V the timer will not reset and the unit

will switch off, however, as soon as the voltage rises

above 13.2V the auto regen timer will automatically reset

to the set value (default = 240sec).

To deactivate the auto regen mode set the auto regen time

to 0 seconds.

By pressing the Setup / Enter only button for more than 10

seconds you will enter the Auto Regen Time Setup. During

the whole Auto Regen Setup the “Absorption” LED will

flash.

1. Absorption LED flashing and actual saved auto Regen

time will be displayed on the right bar. Use the 0 to 840

scale. If the unit is out of the factory the 240 (default)

should be displayed.

2. Press right button to increase or left button to decrease

value.

3. To deactivate the auto regen function set timer value to

0. When happy with your choice either wait 30 seconds or

press both buttons at the same time for 2 seconds.

4. Absorption LED, AGM II and Auto Mode LEDs will flash

10 times to confirm value saving.

5. Unit will restart with new Auto Regen time as default and

will remain there until changed again.

Important: If you have changed the cutoff voltage

remember that the auto regen counter reset functions

must see 0.2V on top of the new cutoff voltage.

I.e. You set the new cut off voltage at 14.0V. To reset

the Auto Regen timer the voltage must rise above

14.2V.

SVEM - Stationary Vehicle Engage Mode.

If your usage pattern is mostly stationary, e.g. You are at

the side of the road and you start the vehicle just to run an

inverter - the problem is that the vehicle’s alternator may

only be at 13.1V (and not give a high voltage boost) and

stay there, in this case the Pro Batt Ultra would not engage

as it needs greater than 13.2V to start. The ideal solution

is to have fitted the ignition feed mode (as per explained in

these instructions). However, if the auto mode was used

and the ignition feed had not been installed then you could

use the Stationary vehicle engagement mode.

This mode allows the product to engage at a much lower

voltage (13.1V) and disengage below (13.0V). To select

this mode: Press SELECT button for 15+ seconds and let

go, No Fault LEDs should be on solid and the Regen timer

LED should be solid. To remove this setting then do the

same again.

Warning: setting is the Stationary Vehicle Engage Mode

operating the unit at voltages which may cause problems

in the winter to the starting of the vehicle - please bear this

in mind we do not have enough history with this setting to

make any guarantees that it shall complement winter

conditions - as low voltages could cause vehicle starting

problems.

10

0

0

0

1

1

0

1

0

1

12 13 14 15

1 26

Display software version

By pressing SELECT for 10-15

seconds certain LEDs on this column

shall briefly illuminate to denote the

software version in binary. From the

top -> down ‘on’ LEDs = 1 and ‘off’

LEDs = 0.

For example, if LEDs 8,7,5,3 are on

then the binary is 000110101 which, in

decimals = 53. Use a calculator.

Desulph

Calcium

Open

AGM II

GEL II

Sealed

AGM I

GEL I

Custom

11

10

9

8

7

6

5

4

3

binary #

Sterling Power Products

Copyright

Press and hold both buttons for 12-14 seconds.

All Left LEDS flash

Press setup to move LED down to custom. Hold both buttons for 2 seconds to confirm.

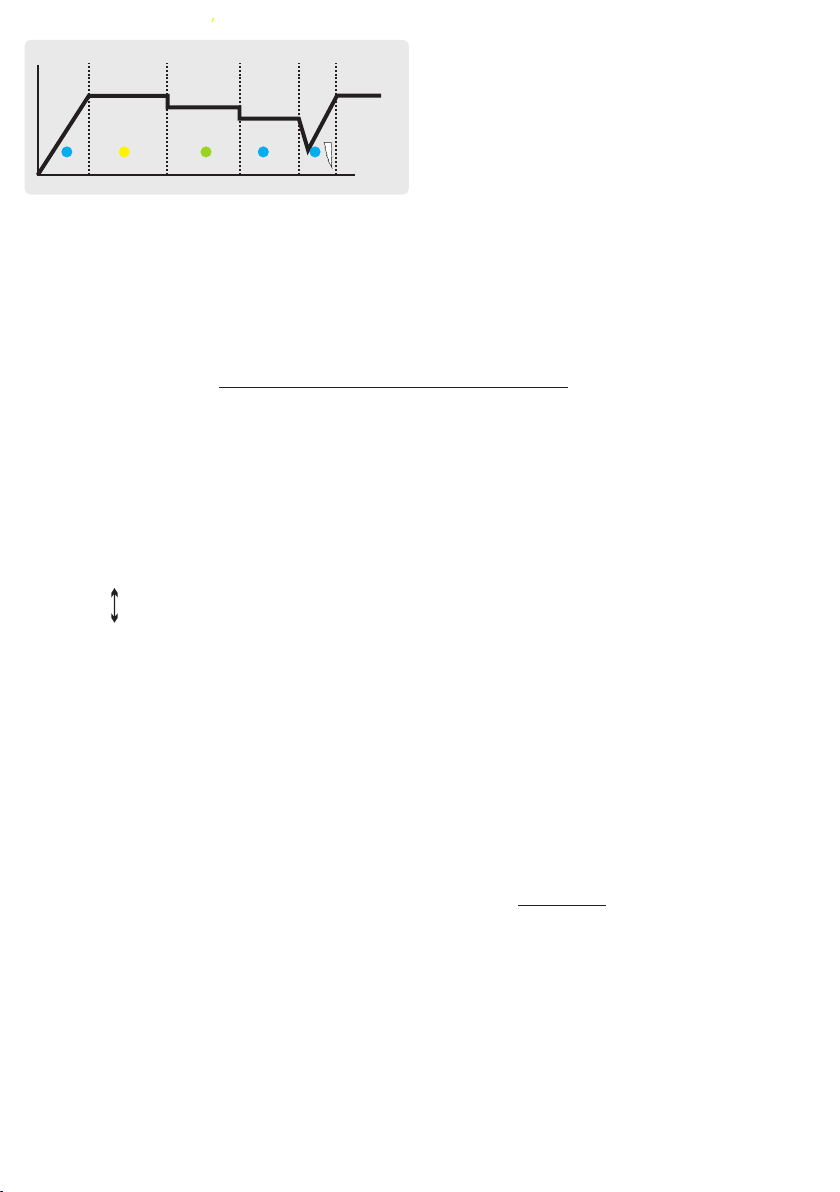

Opportunity to adjust Fast Charge voltage.

Red Custom LED will flash for 3 seconds to confirm. Custom LED will come on constant,

green Fast charge LED will flash (section 1 on graph).

Adjust Fast Charge by increasing the on label. Select button will increase green voltage

voltage whilst setup will lower.

Wait 30 seconds or press both buttons to confirm this.

Opportunity to adjust conditioning charge voltage

Red Custom LED will come on constant and Green Conditioning LED will flash (section 3

on graph).

Adjust Conditioning Charge by increasing the on label. Select button will green voltage

increase voltage whilst setup will lower.

Wait 30 seconds or press both buttons to confirm this.

Red Custom LED will come on constant and Float LED will flash (section 4 on Blue

graph)

Adjust Float by increasing the on label. Select button will increase voltage green voltage

whilst setup will lower.

Wait 30 seconds or press both buttons to confirm this.

Opportunity to adjust Time factor

Red High Temp LED will come on constant, Green Fast Charge LED will flash and blue

Float will flash (section 1 and 4 on graph).

Adjust Time Factor by increasing or decreasing the on label. Select brown scale (0-960)

button will increase time whilst setup will lower.

Wait 30 seconds or press both buttons to confirm this.

Opportunity to adjust Minimum absorption time factor

Red High Temp LED will come on constant, Absorption LED will flash and Yellow blue

Float will flash (section 2 and 4 on graph).

Adjust Time Factor by increasing or decreasing the on label. Select brown scale (0-960)

button will increase time whilst setup will lower.

Wait 30 seconds or press both buttons to confirm this.

Opportunity to adjust Maximum absorption time factor

Red High Temp LED will come on constant, Green Conditioning LED will flash and blue

Float will flash (section 3 and 4 on graph).

Adjust Time Factor by increasing or decreasing the on label. Select brown scale (0-960)

button will increase time whilst setup will lower.

Wait 30 seconds or press both buttons to confirm this.

A green LED from the middle of each row will flash for around 8 seconds to confirm the

setup is completed. The unit will then restart.

A

B

D

E

F

CUSTOM BATTERY TYPE SETTING (for expert

use only - not required for general operation)

Before proceeding with this, please read and

understand all instructions as it is quite complex and

could take more than one attempt. There are timed

intervals of 30 seconds per setting so it is very

important to know exactly what you require before

starting. If any errors are made simply wait a few

minutes and you can start the cycle again. The

settings offered for adjustment in sequence:

A) Boost / absorption voltage (high voltage charge).

B)Conditioning voltage (medium charge rate

normally between boost and float voltage).

C)Float voltage (no longer charging, this will provide

voltage at a reduced level to maintain the batteries

and provide power for any loads applied).

D) Absorption time factor adjust. The length of time

spent in absorption can be adjusted by a factor 0-18.

This may be beneficial for different battery

chemistries. Gel, for example, tends to absorb

current at a low rate, thus, increasing the length of

time spent in absorption may be beneficial (set

nearer 18). AGM, the reverse (set nearer 0). If in any

doubt, ask your battery retailer or simply use one of

our preset values. To calculate the absorption time

from the time factor simply multiply the factor

number (0-18) by the length of time it takes for the

charging voltage to hit the absorption voltage

(typically 14.4V). If it takes 40 minutes to reach

absorption and you set your ATF to 4 then 4x40mins

= 160 minutes. The maximum time the unit can stay

in absorption is 24 hours 1440 minutes.

E) Minimum and maximum absorption times.

Here you can set the maximum and minimum time

the unit stays in absorption. For example, you may

have AGM that may need a maximum of one hour,

or GEL which could require a minimum of 720

minutes (12 hours).

We recommend that you write down your required

voltages and times in the space below. This is so

you know what to programme during setup.

Desired custom values - make a note.

Boost / bulk / absorption (V) ________

Conditioning (V) ________

Float (V) ________

Absorption Time Factor (0-18) ________

Absorption Minimum (0-960 minutes) ________

Absorption Maximum (0-960 minutes) ________

STERLI G

POWER

Operation

Press and hold both buttons for 10-20 seconds.

All Left LEDs shall flash

Press the setup/select button to move LED down to

custom. Hold both buttons for 2 seconds to confirm.

Opportunity to adjust Fast Charge / Bulk /

Absorption voltage.

Red Custom LED will flash for 3 seconds to confirm.

Red Custom LED will come on constant, Green Fast

Charge LED will flash (section 1 on graph). Adjust

Fast Charge voltage by using the Select and Setup

buttons to go up and down the right LED column to

select the correct Fast Charge voltage. Once content,

wait 30 seconds, or press both buttons to confirm. The

unit shall then proceed to Conditioning charge voltage

(next below).

Opportunity to adjust Conditioning charge

voltage

Red Custom LED will come on constant and Green

Conditioning LED will flash (section 3 on graph).

Likewise, adjust the conditioning voltage by using the

Select and Setup buttons to go up and down the right

LED column to select the correct Conditioning

voltage. Once content, wait 30 seconds, or press both

buttons to confirm. The unit shall then proceed to float

voltage set (next below).

Opportunity to adjust float charge voltage

Red Custom LED will come on constant and Blue

Float LED will flash (section 3 on graph). Likewise,

adjust the float voltage by using the Select and Setup

buttons to go up and down the right LED column to

select the correct Float voltage. Once content, wait 30

seconds, or press both buttons to confirm. The unit

shall then proceed to float voltage set (next below).

Opportunity to adjust absorption time factor

Red High Temp LED will come on constant. Green

Fast Charge LED will flash and will Blue Float LED

flash (section 1 and 4 on graph). This time, adjust the

time by using the Select and Setup buttons to go up

and down the right LED column (refer to the blue scale

scale 0-18) to select the correct time. Once content,

wait 30 seconds, or press both buttons to confirm. The

unit shall then proceed to minimum absorption time

factor (next below).

Why use Absorption Time Factor (ATF)?

ATF is simply a number (0-18) that can be used to

multiply by the length of time the charger takes to

reach the bulk/boost voltage from start. For example,

if the bulk voltage is reached in 10 minutes with the

ATF at 4, then 10mins x (ATF 4) = 40 mins of

absorption.

Custom Settings

11

Sterling Power Products

Copyright

Opportunity to adjust minimum absorption time

factor

Red High Temp LED will come on constant. Yellow

Absorption LED will flash and will flash blue Float

(section 2 and 4 on graph). This time, adjust the time

by using the Select and Setup buttons to go up and

down the right LED column (refer to the brown scale 0-

960) to select the correct time. Once content, wait 30

seconds, or press both buttons to confirm. The unit

shall then proceed to maximum absorption time factor

(next below).

STERLI G

POWER

During this particular setup procedure we have made

the voltage setup LED bar more sensitive so that the

adjustment can be made in 0.1V increments. For

example, for 13.1V the 13V LED is on and the 13.4V

LED is flashing. The same idea for 12.9V. The 13V

LED is on and the 12.6V LED is flashing. Remember

that you are adjusting the whilst Cutoff voltage

simultaneous adjusting the voltage, Charging

Lower voltage trip and the Low voltage trip.

13.4V 13.4V LED ON

13.3V 13.4V LED ON + 13.0V LED FLASHING

13.2V 13.4V LED ON + 13.0V LED ON

13.1V 13.4V LED FLASHING + 13.0V LED ON

13.0V 13.0V LED ON

12.1V 12.2V LED FLASHING

12.0V 12.2V LED FAST FLASHING

To enter the menu press (SETUP/ENTER) &

SELECT for more than 20 seconds.

BOOST CONDITIONING, , and ABSORPTION

FLOAT LEDs will flash to indicate Cutoff voltage

Setting Menu. At the same time the actual Cutoff

voltage will be displayed in the left LED voltage bar

according to the description above. To decrease

voltage press SETUP/ENTER and to increase

voltage press SELECT button.

The range you can choose is Cutoff voltage

between 12.0V-14.6V.

Charging voltage is always 0.2V higher.

Lower voltage trip is always 1.1V lower.

Low voltage trip (Mode 3) is always 3.0V lower.

If you do not touch any buttons for 30 seconds the

default voltage of 13.0V shall be restored and saved.

To confirm your custom voltage you must press

both buttons (SETUP/ENTER) and (SELECT)

simultanously for 2 seconds.

The chosen voltage will be saved and the unit will

restart. If you feel unsure do not touch any buttons.

The default value will be restored automatically.

10

If voltage drops

due to heavy

load in excess

off unit current

ability to support

Charging profile Information displayed on top 4 LEDs on main unit

Fast charge

constant current

mode

Stage 1

High absorption

charge rate constant

voltage mode

Stage 2

Lower conditioning

charge rate constant

voltage mode

Stage 3

Float / Power pack

mode, constant

voltage, full current

accessibility

Stage 4

Backlash voltage. If

charger power exceeded

and battery discharge

unit resets to stage 1

Stage 5

Time (Depending on battery size, type, state of charge and charger battery ratio - Digitally processed)

v

o

l

t

s

Flash

33

3

Modifying input on / off voltage thresholds.

The default input voltage thresholds to operate the Pro

Batt Ultra are as follows:

Activation voltage 13.3V-13.6V - the charger turns on

and charges. If the input voltage drops below 13.3V the

charger stop charging instantly. If the input voltage then

goes back to 13.3-13.6V the charger shall charge again.

13.6V+ - the charger turns on and charges. In addition, the

low voltage timer for regenerative braking activates. So,

now, if the input voltage drops to between 12.0V - Timer

activation V13.3V the default 120 second timer shall begin

and the charging shall continue for 120 seconds. To then

reset this timer the input voltage has to go above 13.6V+

again. If the input voltage only goes to 13.3V-13.6V the

charger shall start charging but shall not reset the timer. If

12.0V - 13.3V is maintained for longer than 120 seconds

the charger turns off.

12.0V - 13.3V - this is the regen. braking operational

window - only activated when the default 120 second timer

has been activated (input voltage at 13.6V+). Provided the

input voltage remains between 12.0V - 13.3V for over 120

seconds the unit shall stop charging.

Low voltage trip V<12V - below 12.0V shall result in the

charger turning off immediately - unless in operation mode

3.

11.5V - Low voltage cut off, applicable only when in

operational mode 3. The

Charging voltage 13.2V

13.0VCutoff voltage

Lower voltage trip 12.0V

Volt. trip w/ ign (Mode 3) 10.0V

CUSTOM INPUT CUTOFF VOLTAGE

SETTING:

(voltages x 2 for 24V)

Here you can adjust the input voltage

setting that prompts the unit into sleep

mode.

This unit has 3 different cut off preset

voltages. In Auto Mode the cut off

default is 13.3V and in Regen Braking

Mode the cut off default is 12.0V. The

higher figure (Auto Mode) and lower

figure (Regen Braking) are both pegged

together by a 1.3V gap. As these figures

are pegged, when you change Auto

Mode you change Regen voltage to be

1.3V lower.

We have designed it, therefore, so you

can only tune the higher voltage (Auto),

this, then changes the lower voltage,

respectively (by 1.3V). The 3rd cut off

voltage is only relevant when in mode 3,

the low voltage trip is pegged at 1.8V

lower than the Auto Mode voltage.

For example, if you want the Regen

cutoff voltage to be 11.7V - set the

higher voltage to 13.0V (11.7V+1.3V).

The low voltage trip (if in mode 3) is then

11.2V.

Adjustment of operational voltages.

The 4 main control voltages below are inextricably linked.

The voltages can only be adjusted as a block (not

individually). For example, if you wish to reduce the Cutoff

voltage by 0.2V then all other voltages in the block shall

reduce by 0.2V.

Opportunity to adjust maximum absorption

time factor

Red High Temp LED will come on constant. Green

Conditioning LED will flash and will flash blue Float

(section 3 and 4 on graph). This time, adjust the time

by using the Select and Setup buttons to go up and

down the right LED column (refer to the brown scale

0-960) to select the correct time. Once content, wait

30 seconds, or press both buttons to confirm.

A from the middle of each row will flash green LED

for around 8 seconds to confirm the setup is

completed. The unit will then restart.

regen braking timer

All 4 voltages are always

linked. This block can be

adjusted by changing the

Cutoff voltage value up and

down. This subsequently

changes the other three

voltages by the same value.

Charging voltage (default 13.2V) (always 0.2V above

Cutoff voltage): At this voltage the charger starts

charging. After 5 seconds above 13.2V the regen braking

timer is set. If the input voltage drops to 11.9V - 13.0V this

timer begins. Timer reset when input voltage is 13.2V+.

Cutoff voltage (default 13.0V): This voltage is only

relevant after the charging voltage has been met and the

charger is charging. When the input voltage drops below

this cutoff voltage the charger stops charging and shall

eventually go to sleep. If the input voltage remains

between 13.0V-13.2V the charger shall continue charging.

The Cutoff voltage is the parameter that the user

changes. Cutoff voltageAs noted, by adjusting the you

change the other three voltages mentioned by the same

amount.

Lower voltage trip (default 11.9V) (always 1.1V below

Cutoff voltage): When the input voltage drops below the

Lower voltage trip the charger turns off. The 11.9V

threshold is only relevant if the is regen braking timer

activated. If not, then the low voltage trip is 13.0V. If in

mode 3, the low voltage trip is 10.0V.

Low voltage trip (default 10.0V) (Mode 3) (always 3.0V

below : Only when in operation mode 3 Cutoff voltage)

does the Pro Batt Ultra work down as low at this voltage.

Input voltage

12

Sterling Power Products

Copyright

Sterling Power Products

H Charge Float

In / Unit Out / Rem

Batt.

V12.2

Temp

Menu

Change

Volts

Select

Audible alarm on/off

hold > 3 sec

On / Off

hold>3 sec

Fault

Absorption

Cond.

menu

scroll

(unidirection)

6

7

5

1

2

3

4

8

9

Volts Select Button (left)

Quick push = back light on.

Short press ~1 second = input

voltage, press again for output

voltage, press again for remote

sense voltage.

Hold for 4 seconds to toggle

between buzzer on/off, bu2

should appear.

Remote control:

cut hole diameter

54mm

1) Volts select button.

2) Voltage displayed is voltage into product.

3) LCD screen with backlight.

4) Fast charge led indicator.

5) Condition battery stage.

Temp Menu Change (right

button)

Quick press = back light on.

Short hold ~1 second = switch

between unit’s temperature

and temperature sensor. If nc

appear it means that the

temperature sensor is not

connected.

Hold for 2 seconds to toggle

night mode on / off, nn should

appear. 1/2 power for 8 hours.

Hold button for 4 seconds

to enter the Setup Menu -

“rt” shall appear.

33

Both Left and Right buttons

Hold both buttons for 2 seconds

to force to float FtF, toggle on / off.

Press and hold both buttons for 4

seconds to enter standby mode,

Stb should appear. Repeat to turn

unit on.

Press and hold both buttons for 6

seconds to turn unit off. oFF shall

appear. Repeat to turn unit on.

Volts

Select Volts

Select

Temp

Menu

Change

Then the actual value. Press “change” button to increase value.

Hold “change” button to accelerate. When max. value reached

it will start with lowest value. Press “select” again to confirm

setting. Press “change” button to increase value. Hold “change”

button to accelerate. When max. value reached it will start with

lowest value. Press “select” again to confirm setting.

“b9b” change voltage from green to blue backlight 12.4 - *

16.0V (default 13.4V). Press “select” .First the lowest and the

hightest value will be displayed. Then the actual value. Press

“change” button to increase value. Hold “change” button to

accelerate. When max. value reached it will start with lowest

value. Press “select” again to confirm setting.

“Led” change LED on time 1 - 600 seconds, 0 = always on,

(default = 60). Press “select” .First the lowest and the hightest

value will be displayed. Then the actual value. Press “change”

button to increase value. Hold “change” button to accelerate.

When max. value reached it will start with lowest value. Press

“select” again to confirm setting.

“uId” display Unit ID. Press “select”. Value will be displayed for

5 sec.

“uSW” display unit software version. Press “select”. Value will

be displayed for 5 sec.

“rSW” display remote software version. Press “select”. Value

will be displayed for 5 sec.

“Loc” Unit lock code = 1 to 999 (default = 00 = unlocked).

WARNING This mode shall lock menu setting options of the

unit by virtue of a pass code, be careful. Press “select” to enter

“Loc” setting. Press “change” button to increase value, hold to

accelerate. Stop when on the number you require and press

“select” button to confirm. The software shall store this number,

then the display shall read: loc -> on -> #. # = number you have

stored. To remove loc, return to loc and re-enter the number,

Press “select” button and the display should read: loc -> off

(green back light). Please make a note of this loc code

here:_______.

“rSt” Resets remote to default values*. Press “select”. “NO”

will be displayed. Press “change” to toggle between “YES” and

“NO”. Confirm by pressing “select”. rSt will display if resetting.

“rSu” Resets the battery charger to default settings. Press

“ ” “NO” “ ”select . will be displayed. Press change to toggle

between YES and . “ ” “NO” Confirm by pressing “select”. rSt will

display if resetting.

“rt” displays remaining absorption or conditioning time

Press “select” button to see value.

“btY” displays battery profile type (0-9). This number

denotes which charging profile the charger is set to. Press

“select” to see value. (Ref: table labelled ‘Battery Chemistry

Selection’ on).

“coU” displays input cut off voltage (the voltage at which the

unit stops charging) (13.4V). Press “select” to see value.

“IoU” display input / output base voltage (12/24V). Press

“select”. First input voltage will be displayed with “in” LED on

for 3 sec. then output voltage with “out” LED on for 3 sec.

change from celcius to fahrenheit or back (default = “C/F” *

celcius). Press “select” button to enter setting. Then press

right button to change between Fahrenheit (FAH) and

Celsius (CEL). Confirm setting by pressing “select” button.

“CL” set current limit to 1/2 or 1/1 (full). Press “select” button

to see actual setting. Press “change” (right) button to

change setting. Press “select” to confirm setting.

“buC” turn Buzzer on / off (default = on). Press “select” to *

see actual setting. Press “change” button to change

between settings. Press „select“ again to confirm setting

Autoscroll on / off (default = off). Press “select” to see “Asc”

actual setting. Press “change” button to change between

settings. Press “select” again to confirm setting.

“Von” Voltage / temp display during standby and sleep.

Toggle between on and off, press “select” (left) button to

select.

“con” change contrast value from 0 to 7 (default = 3). *

Press “select”. First the lowest and the hightest value will be

displayed. Then the actual value. Press “change” button to

change settings. Press “select” again to confirm setting.

change backlight colour . off <- auto -> green -> red -“bLc” *

> blue (default = auto). Press “select” to see actual setting.

Press “change” button to change between settings. Press

“select” again to confirm setting.

“bLt” change backlight time . 1 - 600 seconds, 0 = always *

on, (default = 60). Press “select”. First the lowest and the

hightest value will be displayed. Then the actual value.

“br9” change remote display colour red to green voltage

threshold.* 8.0V-13.3V (default 12.4V). When below 12.4V

display is red and when 12.4V or above the remote goes

green. When Press “select”. First the lowest and the highest

value will be displayed.

6) Charge complete on float.

7) Voltage displayed is volts out of product.

8) Scroll menu button.

9) Screen display showing a unit fault.

Temp

Menu

Change

Temp

Menu

Change

Setup - Menu:

Toggling is unidirectional

to escape menu hold both buttons down until ‘END’

appears. Or, just leave the remote for 10 seconds.

Remote Error Codes

E00 = high input voltage

E01 = high output voltage

E02 = high unit temp

E03 = high batt. temp

E04 = no output voltage

13

Remote Control

14

Fault Finding | Troubleshooting

In the event that you feel there is a problem ( ie you aux battery is not charging ) you need to establish 2

things.

is the battery not charging because there is no charge or because its broken.

first check the voltage at the aux battery with the engine running for at least 2 mins, if you are getting 14-14.8

v then the unit is supplying the correct voltage to charge the batter, so if you getting say 14.4 v at the engine

battery and the battery does not seam to be charger then the simple fact is the battery is either full or scrap,

there is really no other answer to this, .

Assumming you voltage at the nattery is way down say 12 . 2 volts ( with the engine on ) then you need to

check the Battery to Battery charger

To help you with this the unit has a built in a feature to help you , after start up the 2 rows off leds turn into 2

volt meters , for the 60 amp and larger models the left hand side off the LEDS is the voltage in and the right

hand side is the voltage out , for the thirty amp version the top leds are the V in and the Bopttom are the V

out, so by a quick loo at the fron pannel you should be able to see the voltage in and the voltage out . If you

want to confirm these readings using a hand held volt meter then always measure the voltage in and out off

the unit AT THE TEREMINALS OFF THE UNIT, at the early stages off product fault finding the products

voltage are important not the battery voltages .

What should you find.

The most important thing is to confirm you have at least 14 volts going into the unit, if you don't have at least

14 v ( on a boat or vehicle ) the unit simply will not work, so if you only have say 12.5 volts with the engine

running ( for a boat or older vehicle then the alternator is simply not working, if you have 0 volts then there is

no connection between the unit and the starter battery so you inline fuse has blown or a wire has dropped off

. If you have a modern van with a euro 6+ engine then you need to wait a few mins as you may be on

regenerative mode and the alternator may be on low voltage mode, however after about 2-3 mins this voltage

should jump up to over 14 v on the vehicle engine.

so bottom line is if the input voltage is to low then the unit will not engege, you actually need a voltage

greater than 13.9 v to first engage the unit.

if the unit has over 13,9 volts ad there are no leds on then the unit is defective ( do just check the neg to

make sure its ok

assumming there is the correct input voltage to start the unit then we can now move to the output , again

check the voltage , all things being well you should be between 14-15 volts out ( this will depend on battery

load and state off charge ) if you are getting 14-15 volts ( the unit looks like it may be working , then check

the voltage at you aux battery, this should be the same voltage as the unit output battery voltage , if its not ie

2 volts lower then you may jave a defective fuse in the line or the wire has dropped off.

Negatives, people always focus on the positive cables and forget the negatives, this unit is designed for a

comm,on negative system, ie the neg from the auxillary system should be well connected to the neg off the

promart/starter battery, in the event off a vehicle do not relie on the cHASSIE AS THAT TENDS TO BE A BAD

NEG, YOU SHOULD RUN A HEAVY CABLE DIRECT TO BOTH NEGS

ALSO MEASURE THE VOLTAGE FROM THE NEG AT THE AUX BATTERY TO THE NEG AT THE

STARTER BATTERY THIS OBVIOUSLY SHOULD BE O-0,5 V if not check you negs

Firstly, ensure the Pro Batt Ultra (BB) is wired up as per

page 7. Ensure negatives are common and the BB

charger’s negative is connected to the starter battery’s

negative - avoid connecting to chassis negative.

Voltages between common negatives should be ~0V.

Secondly, to test the BB, remove (or turn off) any

secondary charging source like AC to DC battery

chargers or solar chargers going to the battery banks.

Leave the primary charger connected (alternator) -

ensure alternator is working. We also recommend

turning off any loads (inverters etc.).

How to test if the Pro Batt Ultra (BB) is charging:

With engine running (alternator charging), what is the

voltage on the input terminal of the BB? What is the

voltage on the output terminal of the BB? Measure these

voltages at the BB’s terminals, not at the batteries

terminals.

Even though, by default, the BB can work down at 12.0V

on the input; it still requires over 13.3V+ to turn on and

get going. If you are getting alternator voltage at the

input terminal (~14V) and 14V+ on the output terminal

the chances are your BB is working fine. If little to no

current is passing through the charger at these voltages

then the batteries are either full or they are deceased. If

the output voltage is between 13V-14V (but rising) then

you could have a situation where the output batteries

were very low in charge (or large in capacity) and the

charger shall be charging at maximum current. Provided

the voltage continues rising the BB is charging.

If your output voltage is less than 13V and your input

voltage is healthy, it could be three things:

1) You have a large load on your output bank - turn load