CIRCULAR SOLUTIONS CS-BRT20 User manual

Belt Rip/Tear Detector

User Manual

Document No. CS-BRTD101

01/2021

Revision 2

PREFACE

Document No. CS-BRTD101 Page 2 of 36

Revision 2

CONTENTS

1. PREFACE.............................................................................................................................5

1.1. Features.....................................................................................................................5

1.2. Application.................................................................................................................6

1.3. Additional Information..............................................................................................7

1.4. References ................................................................................................................7

1.5. Support.......................................................................................................................7

2. INSTALLATION....................................................................................................................8

2.1. Module Overview......................................................................................................8

2.1. Sensor Alignment...................................................................................................10

2.2. Connection...............................................................................................................11

2.2.1. Direct Sensor Wiring Option..........................................................................11

2.2.1. Sensor Wiring Via Junction Box Option (Preferred)..................................12

2.3. Power........................................................................................................................13

2.3.1. DC Input............................................................................................................13

2.3.2. AC Input............................................................................................................14

2.4. IO Connections.......................................................................................................15

2.4.1. Digital Inputs ....................................................................................................15

2.4.2. Digital Outputs.................................................................................................16

2.4.3. PLC Interface...................................................................................................17

2.5. EtherNet Port...........................................................................................................17

2.6. DIP Switches...........................................................................................................18

2.6.1. System DIP Switches.....................................................................................18

2.6.2. Mode DIP Switches.........................................................................................19

2.6.3. SW3 DIP SWITCHES.....................................................................................19

3. SETUP ...............................................................................................................................20

3.1. Install Configuration Software...............................................................................20

3.2. Network Parameters..............................................................................................21

3.3. Logix Integration.....................................................................................................25

3.3.1. Add Module to I/O Configuration..................................................................25

4. LOGIX MAPPING...............................................................................................................27

4.1.1. Input Assembly................................................................................................27

PREFACE

Document No. CS-BRTD101 Page 3 of 36

Revision 2

4.1.1. Output Assembly.............................................................................................28

5. MODBUS TCP MAPPING ..................................................................................................29

5.1.1. Holding Registers............................................................................................29

5.1.1. Monitor Discrete Inputs ..................................................................................31

5.1.1. Control Outputs................................................................................................31

6. DIAGNOSTICS ...................................................................................................................32

6.1. LEDs.........................................................................................................................32

7. TECHNICAL SPECIFICATIONS............................................................................................34

7.1. Enclosure Details....................................................................................................34

7.2. Electrical...................................................................................................................34

7.3. Sensors....................................................................................................................35

7.4. Ethernet....................................................................................................................35

7.5. Digital Inputs............................................................................................................35

7.6. Relay Outputs .........................................................................................................36

PREFACE

Document No. CS-BRTD101 Page 5 of 36

Revision 2

1. PREFACE

1.1. FEATURES

The CS-BRT20 Belt Rip and Tear Detector provides a highly effective means of

detecting belt Rip and Tear conditions on conveyor belts. The unit is equipped with a

photoelectric beam that passes underneath the conveyor belt. When the beam is

broken by torn belt sections, the unit operates and issues a trip command.

The units are ideally placed after both load and offload points on a conveyor belt to

ensure early detection close to the most likely damage points. Effective placement

has proven to detect most rip/tear conditions and significantly reduce the length of

damaged belt.

The CS-BRT20 unit is designed operate from either AC (110V or 220V option) or DC

(24VDC) power. Comprehensive internal and component diagnostics are integrated

into the unit to ensure ongoing reliable operations. These diagnostics include

validation of the photoelectric beam functioning as well as an anti-sabotage feature

which prevents the reset button from being permanently engaged/forced. The status

of the unit can be monitored via communications or alternately via a hardwired output

on the unit.

The Belt Rip and Tear Detectors can be easily integrated into control systems via

EtherNet/IP, Modbus-TCP or alternately via hardwiring.

The units are housed in robust polycarbonate housings to ensure maximum resilience

in the harsh and normally damp conditions around conveyor belting. Each unit consist

of two sensor housings, one positioned on either side of the belt and one control unit.

The housings have an ingress protection of IP66 and an IK10 impact rating (Equivalent

to impact of 5kg mass dropped from 400 mm above impacted surface).

PREFACE

Document No. CS-BRTD101 Page 6 of 36

Revision 2

1.2. APPLICATION

The CS-BRT20 Belt Rip and Tear Detectors are applied on medium to long conveyor

belts in industrial and mining applications. They are positioned after loading and

offloading points on the conveyor belt, as these are the points where damage is most

likely to occur.

Once the photoelectric beam has been broken by a torn piece of conveyor belting, the

unit operates and issues a trip output to trip the conveyor belt. This trip output status

is sustained, thus preventing the belt from restarting until it has been reset via the

Reset pushbutton.

Should the Reset button be forced in the ON position for longer than 10 seconds –the

unit will issue a Fault output. The trip output will not be disabled and will still operate

under a belt rip condition.

Figure 1.1 –Typical installation positions

The units can accommodate both AC and DC power inputs thereby reducing required

spares holding. They are modular in design so are easily serviced.

The Belt Rip and Tear Detector is configured for local use via onboard DIP switches

or for remote connectivity via the Circular Configurator application. This software

utility can be downloaded from www.circularsolutions.co.za free of charge.

RIP

TEAR

LOADING

POINT

BELT

RxTx

PREFACE

Document No. CS-BRTD101 Page 7 of 36

Revision 2

1.3. ADDITIONAL INFORMATION

The following documents contain additional information that can assist the user with

the module installation and operation.

Resource

Link

Circular Configurator

Installation

http://www.circularsolutions.co.za/configurator

User Manual,

Datasheet

Example Code & UDTs

http://www.circularsolutions.co.za/belt-rip-detector

Ethernet wiring standard

www.cisco.com/c/en/us/td/docs/video/cds/cde/cde205_220_42

0/installation/guide/cde205_220_420_hig/Connectors.html

Table 1.1 –Additional information

1.4. REFERENCES

Resource

Link

Modbus

http://www.modbus.org

Table 1.2 –References

1.5. SUPPORT

Technical support is provided via the Web (in the form of user manuals, datasheets

etc.) to assist with installation, operation, and diagnostics.

For additional support the user can use either of the following:

Resource

Link

Contact Us web link

www.circularsolutions.co.za/contact-us

Support email

Table 1.3 –Support details

INSTALLATION

Document No. CS-BRTD101 Page 8 of 36

Revision 2

2. INSTALLATION

2.1. MODULE OVERVIEW

The CS-BRT20 Belt Rip and Tear Detector comprises two small sensor enclosures

which are installed oneither side of the conveyor belt and one control unit. The sensor

enclosures are wired back to the control unit which can be mounted in a more

accessible location. The control unit houses the primary control unit/board and is the

primary interface for the operator as well as to the control system (hardwired and

communications). This configuration allows for individual components to be easily

replaced should they become damaged.

Figure 2.1 –Receiver and Emitter Enclosures

Figure 2.2 –Main Control Enclosures (closed and open)

INSTALLATION

Document No. CS-BRTD101 Page 9 of 36

Revision 2

All of the enclosures (control unit as well as sensor enclosures) are designed for harsh

conditions and offer both high ingress protection (IP66) as well as a high impact rating

(IK10) (equivalent to impact of 5kg mass dropped from 400 mm above impacted

surface).

The Emitter Unit –Enclosure containing emitter sensor complete with 2m sensor

cable. This cable should be connected to the Control Unit (either directly or via junction

box).

The Receiver Unit –Enclosure containing receiver sensor complete with 2m sensor

cable. This cable should be connected to the Control Unit (either directly or via junction

box).

The Control Unit –Enclosure containing control board and communications ports.

This unit connects to emitter and receiver and serves as the interface to the PLC. It

requires a power supply of 24V or 110V (220V on request). This unit is usually

mounted to the side of the conveyor where it is easily accessed and the indications

and reset button are accessible.

The Belt Rip and Tear detector can operate in a standalone mode with “Trip” and

“Fault” outputs being hardwired directly to a PLC or MCC. Alternatively, the units are

equipped with onboard EtherNet//IP and Modbus TCP communications as a standard

to allow for complete integration into most control systems.

The units have comprehensive onboard self-diagnostics as well as built in sensor

testing. They can be easily coupled with the Prestart Warning (CS-PSW20) for visual

audible warning.

Anti-sabotage logic has been incorporated to prevent a forced sustained Reset.

Should the Reset button be forced in the ON position for longer than 10 seconds –the

unit will issue a Fault output. The trip output will not be disabled and will still operate

under a belt rip condition.

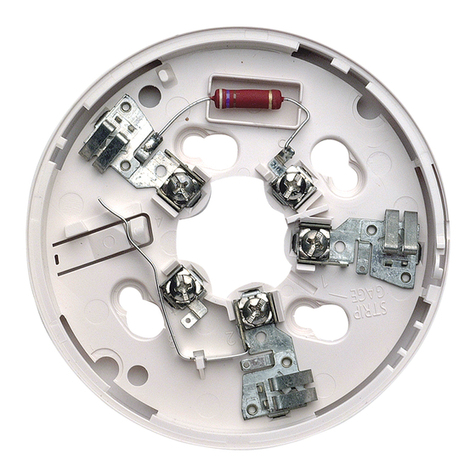

The Sensor Healthy (Green) and Trip/Fault (Red) LED’s on the primary (receiver) unit

are clearly visible to the operator to provide easy fault finding.

INSTALLATION

Document No. CS-BRTD101 Page 10 of 36

Revision 2

Trip/Fault

Reset Pushbutton

Sensor Healthy

Figure 2.3 –Control Unit Indications: Sensor Healthy (Green) and Trip/Fault Status (RED)

2.1. SENSOR ALIGNMENT

The Emitter and Receiver sensor enclosures are mounted on either side of the

conveyor belt. Once connected and power up, the alignment of the units is confirmed

when both the GREEN and YELLOW LED’s on the receiver sensor are ON (not

flashing). This indicates that the signal strength is at least twice that required to

energize the output. If the Green LED is flashing or if the Yellow LED is not on, the

sensors are not correctly aligned.

Figure 2.4 –Receiver sensor showing sensors are aligned

Ideally the beam should be set approximately 20-25mm underneath the conveyor

belt to achieve maximum effectiveness.

INSTALLATION

Document No. CS-BRTD101 Page 11 of 36

Revision 2

2.2. CONNECTION

The Belt Rip Tear units are pre-wired, pre-assembled and ready for use. The device

comprises two sensor units, which are mounted on either side of the conveyor belt,

and control unit which can be mounted in a more accessible location. Wiring of the

sensors can be either direct to the control unit or alternately via a small junction box.

The second option allows for more flexibility with location of the Control Unit.

2.2.1. DIRECT SENSOR WIRING OPTION

The two sensor enclosures can be wired directly to the control unit. Typical wiring

details for this option are shown in figures below:

TX RX

Control

Unit

Sensor

cabling

Figure 2.5 –Direct Wiring of Sensors to Control Unit

TX

RX

+24V

+24V

+0V

+0V

Gate

N/O Contact

N/C (not wired)

Sensor cables

1 2

1 32 4 1 32 4

PWR

+24V

+24V

+24V

+24V

+24V

+24V

+24V

DO0

DO1

DO2

C34

DO3

DO4

DI0

DI1

DI2

DI3

COM

AI+

0V

DO0

DO1

DO2

DO3

DO4

DI0 DI1

MODE

SYSTEM

DI2

DI3

ETH

OK

STS

CONTROL UNIT

Notes:

*1 - Emitter or Receiver 0V can also be wired to COM terminal with

DIP SW3-1 On

Note *1

Figure 2.6 –Connection for Direct Wiring of Sensors to Control Unit

INSTALLATION

Document No. CS-BRTD101 Page 12 of 36

Revision 2

NOTE: Ensure that the sensor units are connected with the correct

polarity. Incorrect polarity will damage the sensors.

2.2.1. SENSOR WIRING VIA JUNCTION BOX OPTION

(PREFERRED)

The two sensor enclosures can be wired to the Control Unit via a small junction box.

This box is typically installed underneath the conveyor belt and allows for improved

flexibility of mounting Control Unit as the distance is not limited by the sensor cable

length. Typical wiring details for this option are shown in figures below:

TX RX

Control

Unit

CCG

Sensor

cabling

1 x 4C

Control Unit

Cable

Figure 2.7 –Wiring of Sensors to Control Unit via Junction Box

+24VDC

Gate

0V

+24VDC

TX

RX

+24V

+24V

+0V

+0V

Gate

N/O Contact

N/C (not wired)

1 2

1 32 4 1 32 4

PWR

+24V

+24V

+24V

+24V

+24V

+24V

+24V

DO0

DO1

DO2

C34

DO3

DO4

DI0

DI1

DI2

DI3

COM

AI+

0V

DO0

DO1

DO2

DO3

DO4

DI0 DI1

MODE

SYSTEM

DI2

DI3

ETH

OK

STS

N/O

Con tact

0V

Core 1

Core 2

Core 3

Core 4

JUNCTION BOX

CONTROL UNIT

Sensor cables

4 - Core Cable

Figure 2.8 –Connection for Wiring of Sensors via Junction Box

NOTE: Ensure that the sensor units are connected with the correct

polarity. Incorrect polarity will damage the sensors.

INSTALLATION

Document No. CS-BRTD101 Page 13 of 36

Revision 2

2.3. POWER

Each unit is equipped with both a 24VDC input as well as an AC input (either 110VAC

or 220VAC). Only one of the two options is required to be connected.

1 2

1 32 4 1 32 4

PWR

+24V

+24V

+24V

+24V

+24V

+24V

+24V

+24V

DO0

0V

DO1

DO2

C34

DO3

DO4

DI0

DI1

DI2

DI3

COM

AI+

0V

DO0

DO1

DO2

DO3

DO4

DI0

DI1

MODESYSTEM

DI2

DI3

ETH

OK

STS

TRANSFORMER

ETHERNET

SW-3

J5 J3 J2

1 2

1 32 4 1 32 4

PWR

+24V

+24V

Live

+24V

+24V

+24V

+24V

+24V

+24V

DO0

0V

Neut

DO1

DO2

C34

DO3

DO4

DI0

DI1

DI2

DI3

COM

AI+

0V

DO0

DO1

DO2

DO3

DO4

DI0

DI1

MODESYSTEM

DI2

DI3

ETH

OK

STS

TRANSFORMER

ETHERNET

SW-3

J5 J3 J2

FuseF1

AC POWER

DC POWER

Figure 2.9 –AC & DC Power Circuits

2.3.1. DC INPUT

A three-way power connector is used to connect Power+, Power–(ground), and earth.

The module requires an input voltage of 24VDC. Refer to the technical specifications

section in this document.

+24V

0V

Earth

Figure 2.10 –DC Power Connector

INSTALLATION

Document No. CS-BRTD101 Page 14 of 36

Revision 2

2.3.2. AC INPUT

A three-way power connector is used to connect AC Power Live, Neutral and Earth.

The unit is configured for either 220VAC or110VAC depending on option ordered. The

module will be labelled with specified AC supply voltage level. Refer to the technical

specifications section in this document.

Live

Earth

Neutral

Figure 2.11 –AC Power Connector

The unit is protected from AC supply disturbances by a replaceable 1A fuse as well

as a MOV.

The unit’s AC rated supply voltage should be confirmed from the label as a well as by

confirming the supply jumper configuration.

Figure 2.12 –AC Power - Jumper Configuration

NOTE: Ensure that the correct voltage is applied to the unit.

Connecting the incorrect voltage to the unit will cause damage and

ould result in personal injury.

INSTALLATION

Document No. CS-BRTD101 Page 15 of 36

Revision 2

2.4. IO CONNECTIONS

The Belt Rip and Tear Detector unit is equipped with four digital inputs and five digital

outputs which are connected directly on the labelled terminals on the PCB.

1 2

1 32 4 1 32 4

PWR

+24V

+24V

+24V

+24V

+24V

+24V

+24V

+24V

DO0

0V

DO1

DO2

C34

DO3

DO4

DI0

DI1

DI2

DI3

COM

0V

DO0

DO1

DO2

DO3

DO4

DI0

DI1

MODE

SYSTEM

DI2

DI3

ETH

OK

STS

TRANSFORMER

ETHERNET

SW-3

J5 J3 J2

1 2

1 32 4 1 32 4

PWR

+24V

+24V

Live

+24V

+24V

+24V

+24V

+24V

+24V

DO0

0V

Neut

DO1

DO2

C34

DO3

DO4

DI0

DI1

DI2

DI3

COM

AI+

0V

DO0

DO1

DO2

DO3

DO4

DI0

DI1

MODE

SYSTEM

DI2

DI3

ETH

OK

STS

TRANSFORMER

ETHERNET

SW-3

J5 J3 J2

Fuse F1

DIGITAL

INPUTS

DIGITAL

OUTPUTS

Figure 2.13 –Input and Output Connection

2.4.1. DIGITAL INPUTS

The four digital input channels are optically-isolated sharing a common ground. A

voltage of between 10-32 VDC applied to an input will result in a logic on state for that

input.

Digital Input

Description

DI 0

Sensor beam received and healthy

DI 1

Reset Pushbutton.

DI 2

Reserved

DI 3

Reserved

Table 2.1 –Digital Input Description

INSTALLATION

Document No. CS-BRTD101 Page 16 of 36

Revision 2

NOTE: The Digital lnputs are optically isolated and thus the Digital Input

Common point is separate to 0V. These can be commoned by setting DIP

Switch SW3-1 on or by adding an external jumper.

Note *3

1 2

+24V

+24V

+24V

+24V

DI0

DI1

DI2

DI3

COM

0V

SW-3

12

AI

Figure 2.14 –Digital Input Wiring Example

2.4.2. DIGITAL OUTPUTS

There are five digital outputs of which three are used to control the BSR components

(Indication LED’s and Sensor Trigger). The remaining two relays (D03 & D04) are solid

state, normally open, single pole, connected with a single common as shown in figure

2.9 below. These are used for hardwired interfacing to the PLC or remote control

circuit.

Digital Input

Description

DO 0

Output for control of 24V SENSOR HEALTHY LED (Green). This LED is on

when a healthy beam signal is received by the receiver sensor. It indicates that

there is a clear path between emitter and receiver sensors.

DO 1

Output for control of 24V TRIP/FAULT LED (Red). This LED is on when a Trip

signal has been received (Sensor beam broken), the reset button has been

retained in the On position, or when an internal unit fault has been diagnosed.

Once triggered, it will remain on until the unit is reset locally or via

communications.

DO 2

Output for testing sensor operation. This output is used to trigger the emitter

sensor.

DO 3

TRIP Output to PLC. Operates when beam has been broken –belt rip detected.

This is a latched output and is reset via Reset pushbutton or viacommunication.

Used to trip conveyor belt. Contact can be selected a N/O or N/C via DIP

switches in Section 2.6.2

DO 4

FAULT Output to PLC. Operates for device fault (unit fault) or when reset

pushbutton is retained (forced in reset position). Output latches and is reset via

pushbutton or via communication. Contact can be selected a N/O or N/C via

DIP switches in Section 2.6.2

Table 2.2 –Digital Output Description

INSTALLATION

Document No. CS-BRTD101 Page 17 of 36

Revision 2

NOTE: Relays 3 & 4 are capable of switching a maximum dc current of

400mA.

C34

D03

D04

DO-3

DO-4

Figure 2.15 –Common Internal Connections of DO3 and DO4

2.4.3. PLC INTERFACE

As detailed in section 2.4.2 Digital Outputs, the hardwired PLC interface is via Digital

Outputs 3 & 4. Typical connection is as per Figure 2.16 –PLC Interface Wiring.

PLC +24V (PLC Supply)

PLC Fa ult Input

PLC Trip Input

1 2

1 32 4 1 32 4

PWR

+24V

+24V

+24V

+24V

+24V

+24V

+24V

DO0

DO1

DO2

C34

DO3

DO4

DI0

DI1

DI2

DI3

COM

AI+

0V

DO0

DO1

DO2

DO3

DO4

DI0 DI1

MODE

SYSTEM

DI2

DI3

ETH

OK

STS

CONTROL UNIT

Figure 2.16 –PLC Interface Wiring

2.5. ETHERNET PORT

The Ethernet connector should be wired according to industry standards. Refer to the

additional information section in this document for further details.

INSTALLATION

Document No. CS-BRTD101 Page 18 of 36

Revision 2

2.6. DIP SWITCHES

The module is pre-programmed with multiple different operating modes. These modes

are selected via dip switches on the PCB. Three sets of DIP switches are available

for configuration as shown in the figure below. These sets art lablled as “System”,

“Mode”and “SW3”. Detailed operation of these DIP switches are provided in the

following section.

1 2

1 32 4 1 32 4

PWR

+24V

+24V

Live

+24V

+24V

+24V

+24V

+24V

+24V

DO0

0V

Neut

DO1

DO2

C34

DO3

DO4

DI0

DI1

DI2

DI3

COM

AI+

0V

DO0

DO1

DO2

DO3

DO4

DI0

DI1

MODESYSTEM

DI2

DI3

ETH

OK

STS

TRANSFORMER

ETHERNET

SW-3

J5 J3 J2

Figure 2.17 –Location of DIP Switches

2.6.1. SYSTEM DIPSWITCHES

System DIP Switch Settings

DIP Switch

Description

DIP Switch 1

Used to force the module into “Safe Mode”. When in “Safe Mode” the module will

not load the application firmware and will wait for new firmware to be downloaded.

This should only be used in the rare occasion when a firmware update was

interrupted at a critical stage.

0 = Normal

1 = Safe Boot Mode

DIP Switch 2

This will force the module into DHCP mode which is useful when the user has

forgotten the IP address of the module.

0 = Normal

1 = Force DHCP

INSTALLATION

Document No. CS-BRTD101 Page 19 of 36

Revision 2

DIP Switch 3

This will force the module into a fixed IP address –192.168.1.100

0 = Normal

1 = Force Fixed IP

DIP Switch 4

This selects the PLC communications protocol.

0 = EtherNet/IP

1 = Modbus TCP

Table 2.3 –System DIP Switch Settings

2.6.2. MODE DIP SWITCHES

Mode DIP Switch Settings

DIP Switch

Description

DIP Switch 1

Reserved –to be set to 1

DIP Switch 2

Reserved

DIP Switch 3

Trip Output (DO3) contact status (*1)

0 = Contact closed for Healthy (no Trip)

1 = Contact open for Healthy (no Trip)

DIP Switch 4

Fault Output (DO4) contact status (*2)

0 = Contact closed for Healthy (no Fault)

1 = Contact open for Healthy (no Fault)

Table 2.4 –Mode DIP Switch Settings

Note 1: “Trip” condition is triggered and latched for a detected belt rip condition. This

is used to Trip the conveyor belt.

Note 2: “Fault” condition indicates a Reset Forced condition or a unit diagnostic fault

(Beam sensor fault or unit fault).

2.6.3. SW3 DIP SWITCHES

DIP Switch

Description

DIP Switch 1

Used to common the Digital input common (DI COM) to the internal 0V. When in the off

position, the DI COM is isolated from the internal 0V and the inputs are designed to

operate from an externalpower supply. In thismode, if no external power supply is used,

a bridge is required between DI COM and 0V.

0 = DI COM and 0V isolated

1 = DI Com and 0V common

DIP Switch 2

Not used for this device.

Table 2.5 –SW3 DIP Switch Settings

SETUP

Document No. CS-BRTD101 Page 20 of 36

Revision 2

3. SETUP

3.1. INSTALL CONFIGURATION SOFTWARE

All the network setup and configuration of the module is achieved by means of the

Circular Configurator device configuration environment. This software can be

downloaded from http://www.circularsolutions.co.za/configurator

Figure 3.1. Circular Configurator Environment

Table of contents