Claas 529 Series Installation guide

Information and Basic Field

Settings for 1050-1230 type

529 Headers VERSION 1 2016

1

Introduction

This quick reference guide has been produced to aid operators with

familiarisation and settings of CLAAS combine harvesters’ cutterbars.

CLAAS cutterbars are designed for output and efficiency but this can only be

achieved with correct operation and maintenance of the machine.

This guide is not designed to replace the Operator’s Manual but merely as a

reference document. More in depth information is available in the Operator’s

Manual.

ALWAYS READ THE OPERATOR’S MANUAL BEFORE OPERATING YOUR COMBINE.

Down time costs output

To get the most from the machine, the wheels/tracks must be turning. In order to

keep downtime to a minimum, it’s vital that routine maintenance is not

neglected. As well as servicing the machine according to the operator’s manual, a

good check of the machine is essential.

It is false economy to put off the replacement of worn parts until they break. For

example, a cracked knife section will take 5 minutes to change before starting

work, but usually a minimum of 10 minutes output will be lost, once work has

begun.

Abbreviations

Throughout this guide the following abbreviations are used:

‘LHS’ and ‘RHS’ refer to the left hand side and right hand side of the machine

respectively, taken from the rear of the machine facing in the direction of travel.

2

Safety

Safety is of the utmost importance whilst you are operating and maintaining

your cutterbar. Make sure that all of the risks are assessed to reduce the

likelihood of an accident.

Make sure you are familiar with the controls and operation of the machine and

have read the operator’s manual.

The cutterbar has many moving parts. Guards are designed to keep you safe;

please ensure that all guards are kept in place and in good condition when

operating the machine.

When doing any maintenance work or making adjustments outside of the

machine, make sure that the engine is switched off and the battery isolator key is

removed or have the cutterbar situated on the trolley.

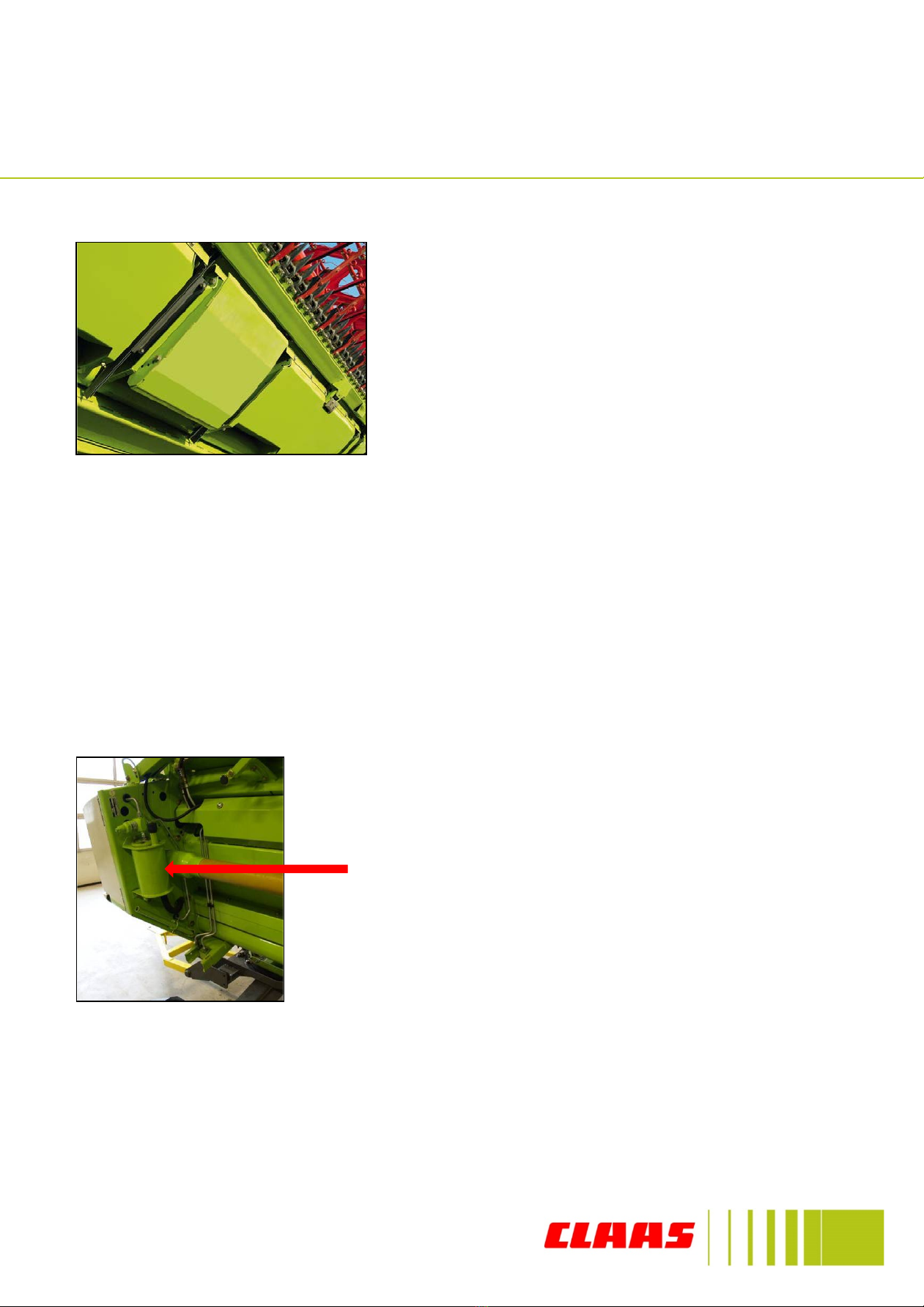

If you need to go underneath the cutterbar whilst it is on the machine to make

adjustments etc. make sure that the cutterbar lift cylinder lock is in place.

When operating the machine be aware of the presence of people, particularly in

farmyards, always get someone to help you when manoeuvring the cutterbar on

or off the machine.

For more in-depth safety information please consult your operator’s manual.

Other information is available on the HSE website: www.hse.gov.uk

Always read the Operator’s Manual before using any new machine.

3

Cutterbar

Adjustments

The cutterbar is one of the most

important parts of the combine. It is

designed to cut and gather the crop from

the field. It then needs to feed the

material evenly, and preferably head first,

to the drum.

Dividers

The first part of the cutterbar to make contact with the crop are the dividers. There are

two types: the long divider or short divider.

Make sure that the height of the divider is set so it does not run on the ground. It is

recommended that the shoe (base of the divider) should be set to the same height as

the stubble.

Lifters

It is recommended that lifters should be fitted

to CLAAS cutterbars. The lifters should be

fitted by placing the first one on the fifth

finger from the RHS of the cutterbar, and then

on every fourth finger thereafter.

Lifters should be checked for wear/fatigue on

a daily basis and replaced if necessary. There

are two types of lifter available: the standard

lifter and the low cut lifter (for when lower

cutting heights are required e.g. peas).

4

Knife

Check that the knife is in good condition in order for it to work effectively. This involves

replacing damaged or broken sections, removing vertical movement by adjusting the

keeps and making sure that the fingers are not rounded or bent. Regular

checks/adjustments will aid cleaner cutting and reduced stress on the knife drive

system.

Table auger

The table auger is important for the

transportation of material to the

front elevator.

The timing of the retractable fingers

can be adjusted for different crops by

opening up the guard on the RHS for

V750 & V900 and both sides for

V1050 & V1200 cutterbars and

adjusting the lever with a spanner.

Use the top holes for short crops and

the lower holes for tall crops. The 3rd

hole from bottom is the standard

setting.

1. Adjust the stripper plates behind the auger.

2. Remove the intermediate retractable fingers along the length of the auger

leaving just the middle ones.

3. Alter the height of the auger within the trough of the cutterbar. There should

be a minimum gap of 20mm between the trough and the auger flights.

4. Alter the speed of the auger by swapping the sprocket on the LHS of the

cutterbar (V750 & V900) or changing the optional gears inside the auger drive

gearbox (V1050 & V1200).

Crop Wrapping

If a problem occurs with crop wrapping around the table auger in difficult conditions

there are a number of procedures that can be carried out, try one thing at a time.

V1050 & 1200

Cutterbar

Adjustments

5

Skids

The skids underneath the cutterbar should be set

to suit the local conditions i.e stones, loose soil

etc. It is recommended that they are lifted right

up in abrasive conditions.

VARIO

VARIO cutterbars allow the operator to vary the position of the knife to suit different

crop conditions. In short crops the knife can be retracted by up to 10cm and

extended by 20cm from its ‘normal’ position for taller crops. For extremely tall crops

such as Oilseed Rape the knife can be extended by 50cm from it’s normal position, in

conjunction with filler plates. (V1050 & V1200 require a auger drive shaft extension)

When using the cutterbar in normal conditions up to 4 knife positions can be

saved as part of the pre-set working positions, providing the function is

activated in CEBIS.

Check the hydraulic oil level in the oil tank on the

back of the cutterbar daily.

Cutterbar

Adjustments

6

When the filler plates are being used, ensure

that the knife is retracted against the filler

plates on a daily basis and make sure the

power switch for the cutterbar is SWITCHED

OFF.

TURN OFF ‘VARIO AUTOMATICS’ IN CEBIS WHEN USING FILLER PLATES.

When setting the knives after

fitting the filler plates. The

knives must be in the

outermost position.

Cutterbar

Adjustments

When fitting the filler plate kit. (1)retract Knife/table (2) unlatch pins on both sides.

(3)Remove the drive shafts from gearbox. (4) Push Knife/Table out to its maximum.

(5) Fit side fillers. (6) fit filler plates, starting with the middle working out and

making sure the outside plate seal is up. (7) when plates are located correctly,

retract the knife making sure the plates are locked in and turn off switch. (8) Latch

in pins on both sides. (9) fit side knife and hydraulic connections. (10) Fit the drive

extensions and time up knives. To remove filler plates carryout operation in

reverse.

7

Notes

8

Notes

CLAAS U.K. Ltd

Saxham

Bury St. Edmunds Suffolk

IP28 6QZ

Tel: 01284 763100

Fax: 01284 769839

www.claas.co.uk

This manual suits for next models

3

Other Claas Tractor Accessories manuals