Claas QUADRANT 2200 Operating instructions

R

NUAL

CAS

QUADNT 2200

QDNT 00 RO CUT

1 GENERAL NOTES INTRODUCTION .........................

INTRODUCTION TO THE

CLAAS REPAIR HANDBOOK ..............

EXPLANION OF GRAPHIC SYMBOLS ...

GENERAL NOTES ON REIR ............

TORQUE SPECIFICIONS

Tightening torque (in Nm) for

hexagonal bolts, cylinder head bolts

1.1 / 1

1.1 / 1

1.2 / 1

1.3 / 1

and hexagonal nuts . . . . . . . . . . . . . . . . . . . . . . . 1 .4 / 1

rque specifications for

hydraulic connections with O-ring seals

complying with ISO 6149 . . . . . . . . . . . . . . . . . . 1.4 / 2

SPECIFICIONS

Oil quantities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5 / 1

BASIC SETTINGS FOR THE DRIVES

Adjusting the drives to the markings ........ 1.6 / 1

BASIC SETTINGS FOR THE

TWINE WRAP DEVICE ......................... .

Setting up the knotter shaft and needles . . . . . 1 . 7 / 1

Checking the setting of the needles

to the piston . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1. 7 / 4

Opportunities for control checks

in the bale chamber ....................... 1.7 / 5

Needle yoke brake . . . . . . . . . . . . . . . . . . . . . . . 1. 7 / 6

Kn otter shaft brake . . . . . . . . . . . . . . . . . . . . . . . 1 . 7 / 6

Adjusting the springs for

the clamping plates . . . . . . . . . . . . . . . . . . . . . . . 1 . 7 / 7

Adjusting the springs for

the kn otter hooks . . . . . . . . . . . . . . . . . . . . . . . . . 1 . 7 / 7

Setting up the play on

the knotter pinion . . . . . . . . . . . . . . . . . . . . . . . . . 1. 7 / 7

Twine finger ............................. 1.7 / 8

Ram stop ............................... 1.7 / 9

Find manuals at http://best-manuals.com/search?&s=CLA-2981710

INTRODUCTION

INTRODUCTION TO THE

CLAAS REIR MANUAL

Q

The table of contents for each main section and subsection

will help you quickly find the description of each assembly

procedure.

Find manuals at http://best-manuals.com/search?&s=CLA-2981710

nation of ghic sbo

EXPLANATION OF GRAPHIC SYMBOLS

@

i

ll

QUADRANT 2200 / 2200 RC 1.2 / 1

Find manuals at http://best-manuals.com/search?&s=CLA-2981710

GENERAL NOTES ON REPAIR

5. Tighten up the steel roller chains

E5

6. Self-locking bolts

ith micro-encapsulated adhesive coating)

R-V-P

-P

q

--

q

q

q

-not

E

q-

-

-

QRNR

General notes on repa

5

7. Liquid bolt locking

-

q

q

q

q

q

q

q

8. Fitting the lock ring bearing correctly

NG-

RG

Find manuals at http://best-manuals.com/search?&s=CLA-2981710

General notes on repa

9. Cutting ringscrew connections to hydraulic

connections

1 O. Repairs can be made quickly and correctly if

the following points are observed:

°

Find manuals at http://best-manuals.com/search?&s=CLA-2981710

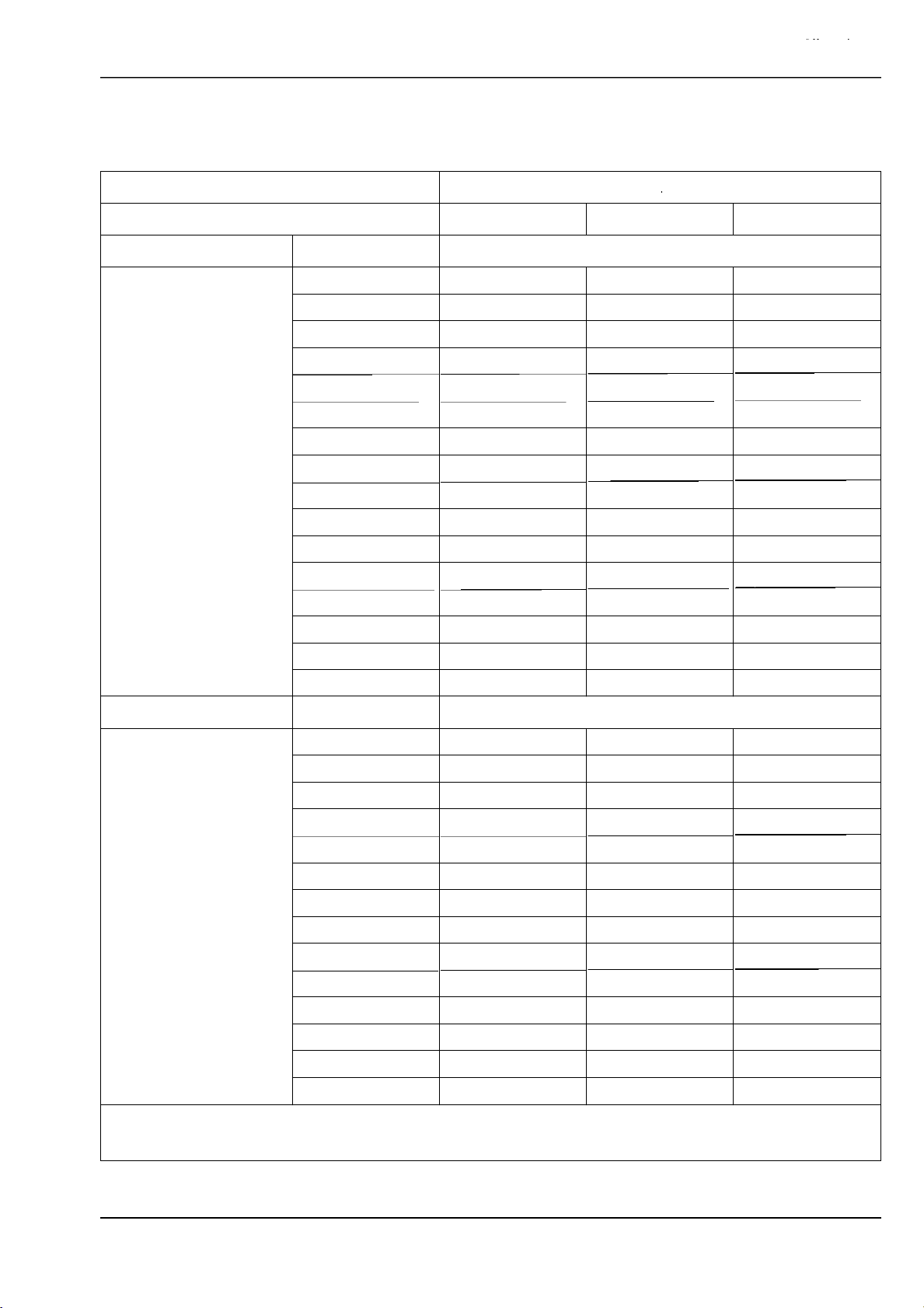

rque specans

TORQUE SPECIFICATIONS

Tightening torque (in Nm) for hexagonal bolts, cylinder head bolts and hexagonal nuts

Bolts and Nuts Blackened, Phosphated or Galvanized

Strength Class 8.8 10.9 12.9

Dimensions Standard Metric Thread

M4 2.7 3.8 4.6

M5 5.5 8.0

9.5

M6 10.0 14.0 16.0

hexagonal bolts M8 23.0 33.0 40.0

DIN 931 M 10 45.0 63.0 75.0

DIN 933 M 12 78.0 110.0 130.0

M 14 122.0 175.0 210.0

M 16 195.0 270.0 325.0

cylinder head bolts M 18

DIN 912 260.0 370.0 440.0

M 20 370.0 525.0 630.0

M 22 510.0 720.0 870.0

hexagonal nuts M 24 640.0 900.0 1080.0

DIN 934 M 27 980.0 1400.0 1650.0

M 30 1260.0 1800.0 2160.0

Dimensions Fine Metric Thread

M 8 x 1

25

35 42

M 10 x 1.25

48

67 80

M 12 x 1.25 88 125 150

hexagonal bolts M12x1.5 82 113 140

DIN 960 M14x1.5 135 190 225

DIN 961 M16x1.5 210 290 345

M 18 x 1.5 300 415 505

M 20 x 1.5 415 585 700

hexagonal nuts M 22 x 1.5 560 785

945

DIN 934 M 24x2 720 1000 1200

M 27x2 1050 1500 1800

M 30x2 1450 2050 2500

CAUTION! Cadmium-and copper-plated nuts and bolts are to be tightened up to a torque

which is 25 % below the stated values.

QUADRANT 2200 / 2200 RC 1.4 / 1

Find manuals at http://best-manuals.com/search?&s=CLA-2981710

rque specans

Torque specifications for hydraulic connections with 0-ring seals complying with ISO 6149

Dimensions Torque specification in accordance with ISO 6149

+2

+

+

+

+

+

+

+22

+2

+

+

+

+

+2

+2

+

+2

+

Specans

SPECIFICATIONS

Oil quantities

-

2

- _

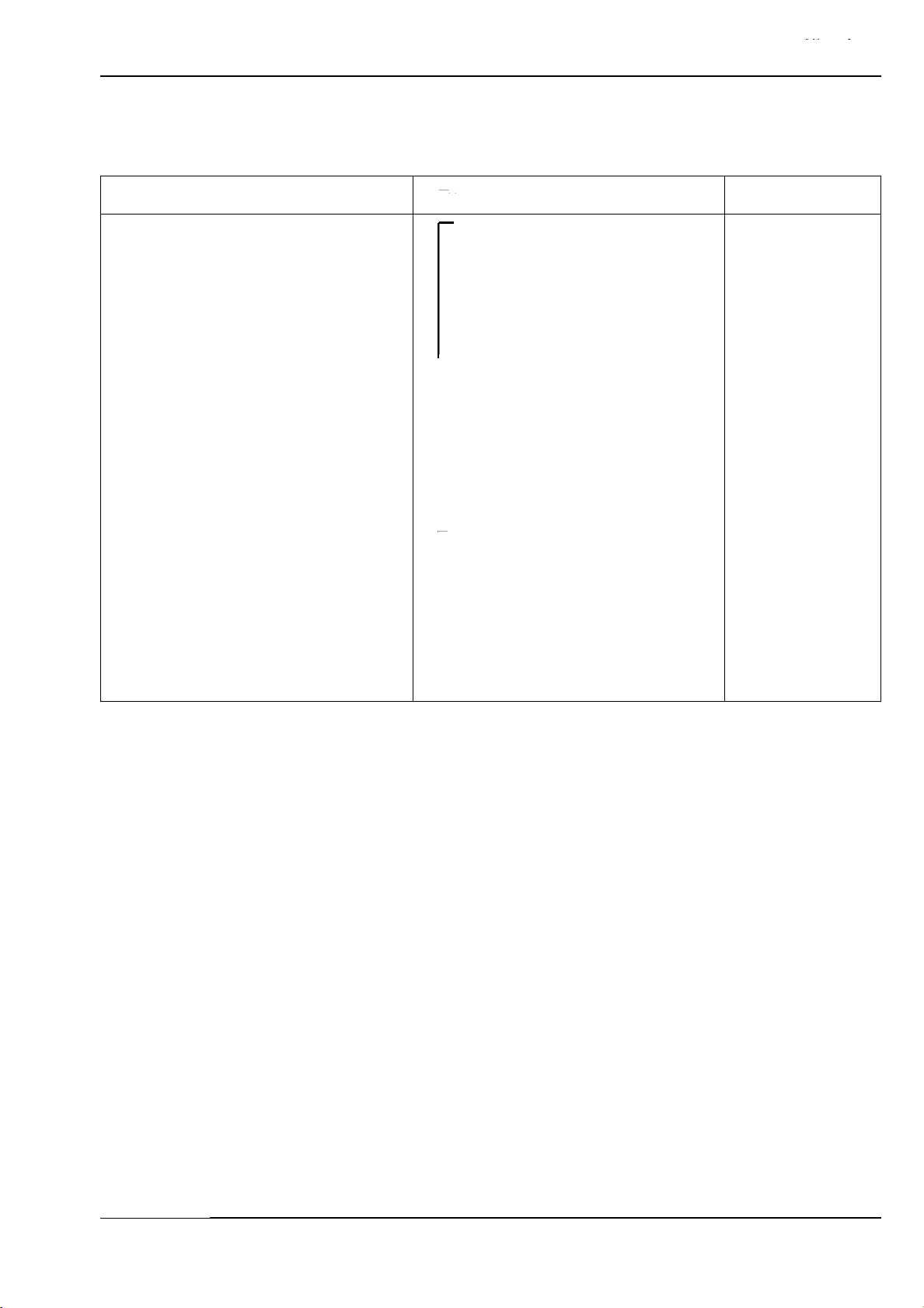

BASIC SETTINGS FOR THE DRIVES

Adjusting the drives to the markings

x

Bas setgs r the s

Bas setgs r the s

3

5

6

Note:

lwl,

wb

(F

Fbl

(bw

bblb

(F

bb

(bwb

b

(F9

(

ll(

(bw

bbl

(F, 9

Bas setgs r the s

Bas setgs r the s

QUADRANT 2200 / 2200 RC

3

1

23408

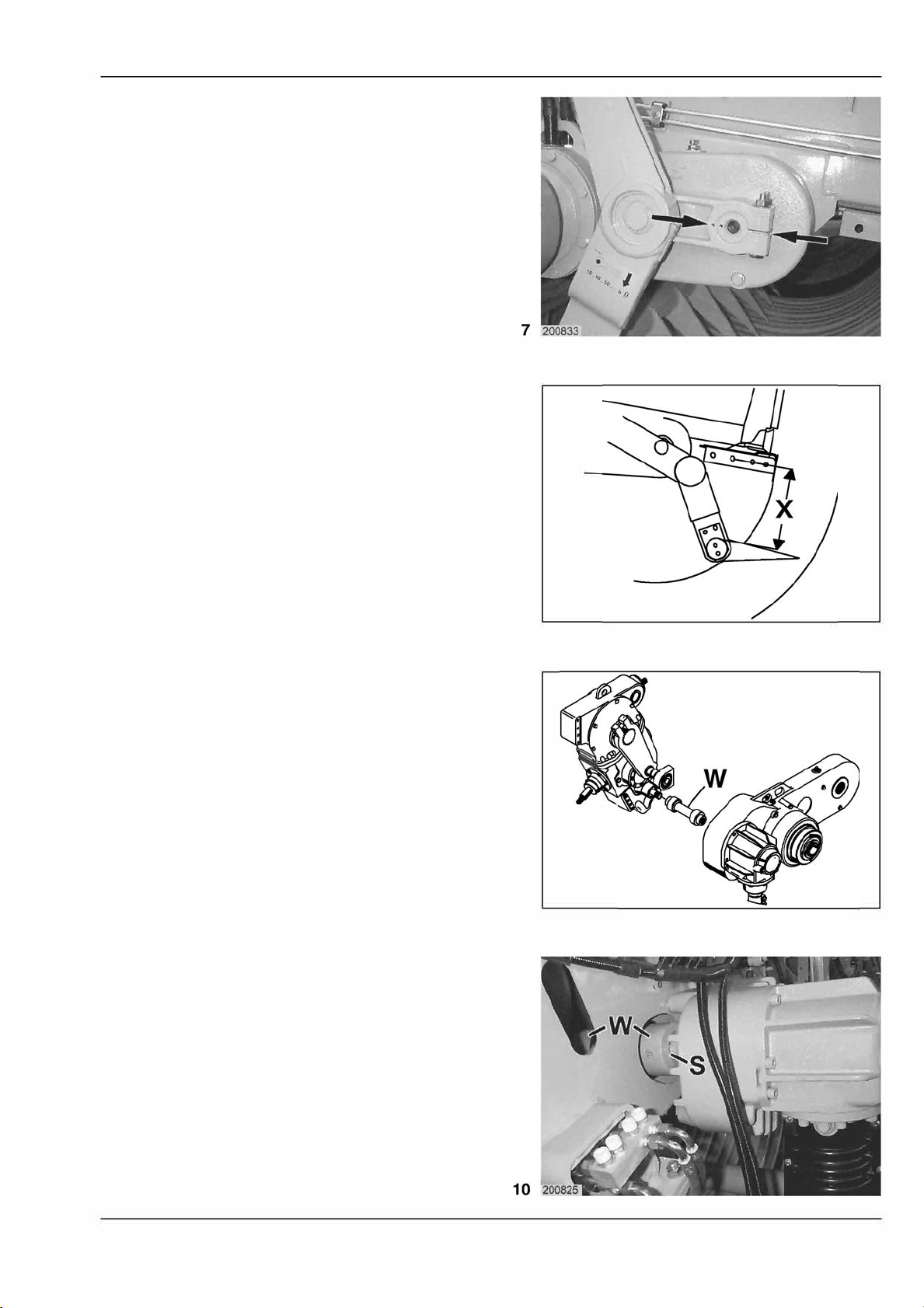

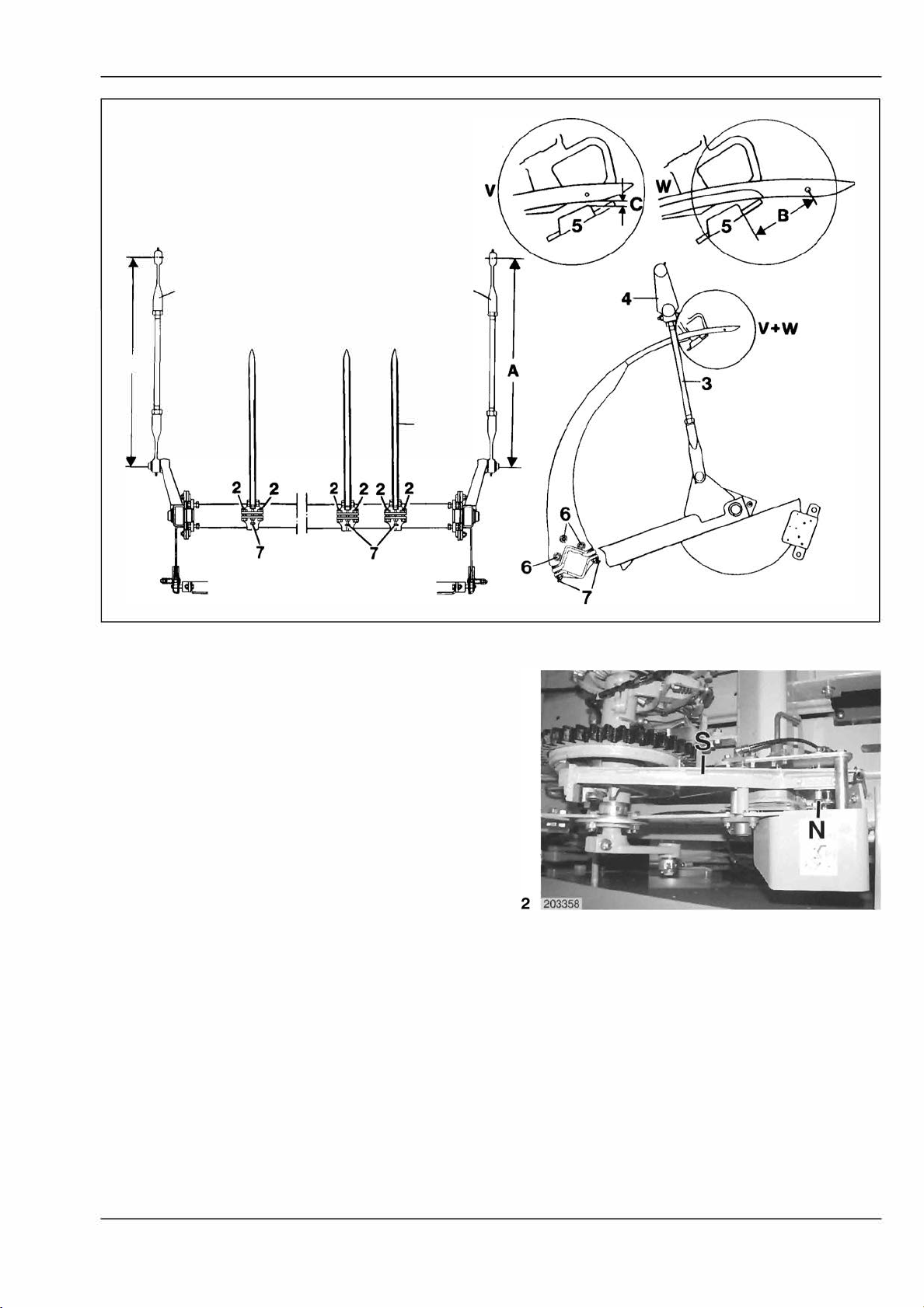

Setting up the knotter sha and needles

3

PLEASE NOTE!

M

Bas setgs for e te dee

1

Bas setgs for e te dee

by hand

by hand

same length

(A),

78

Ryg yyby

hand

g

gg

y

gg

(W).

yg

g

g

QUADRANT 2200 / 2200 RC

Bas setgs for e te dee

1.7 / 3

Bas setgs for e te dee

y

200740

6

7

Checking the setting of the needles to the piston

by hand

This manual suits for next models

1

Table of contents

Other Claas Tractor Accessories manuals

Popular Tractor Accessories manuals by other brands

Original Tractor Cabs

Original Tractor Cabs 12244 Assembly instructions

SpeedEPart

SpeedEPart 45-02153 manual

MRF

MRF BS96 Operator's manual

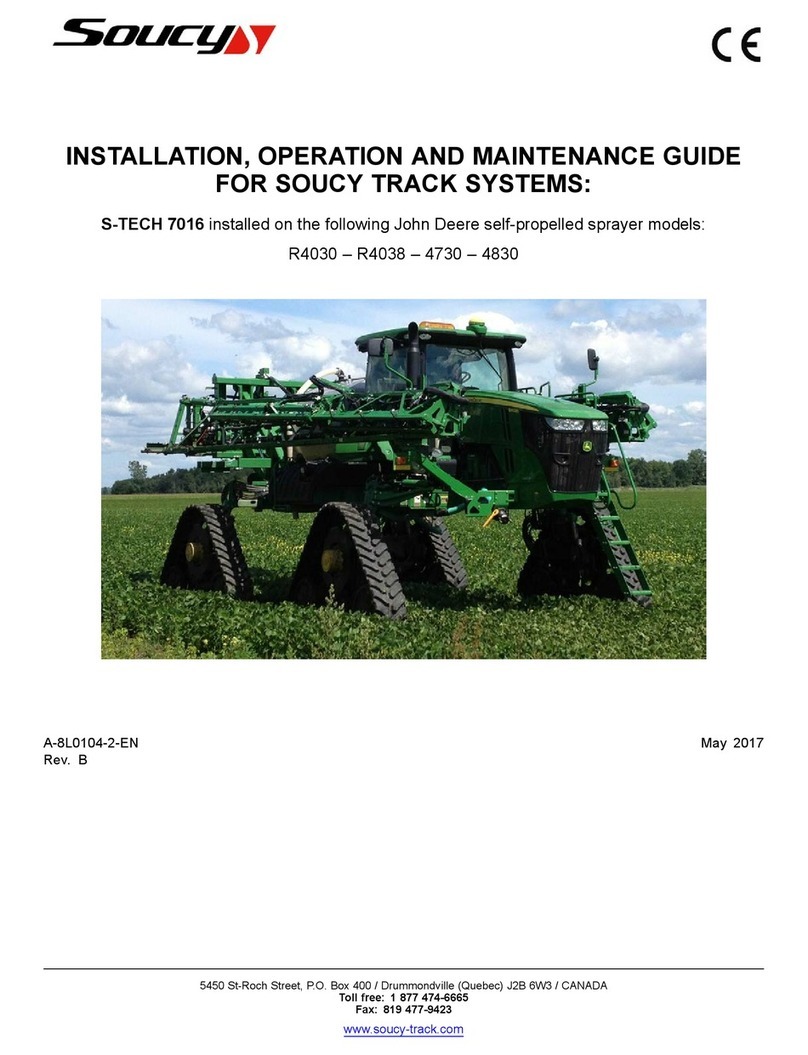

Soucy

Soucy S-TECH 7016 Installation, operation and maintenance guide

LS tractor

LS tractor LB2100 Series Operator's manual

Field Tuff

Field Tuff FTF-2GBF4S owner's manual