Claind N2 LCMS 1 User manual

Other Claind Portable Generator manuals

Popular Portable Generator manuals by other brands

ETQ

ETQ PG30P11 owner's manual

NSM

NSM PMG-GS Use and maintenance manual

FREEFORCE

FREEFORCE ULTRALITE 600 user manual

Porter-Cable

Porter-Cable DTE325 instruction manual

Champion Global Power Equipment

Champion Global Power Equipment 100522 Operator's manual

Generac Power Systems

Generac Power Systems PowerPact 6561 Installation notes

SIGLENT TECHNOLOGIES

SIGLENT TECHNOLOGIES SDG1062X user manual

Generac Power Systems

Generac Power Systems 004920-0 owner's manual

DUROMAX

DUROMAX DUROSTAR DS11000DX user manual

Tektronix

Tektronix AVG1 user manual

Wacker Neuson

Wacker Neuson GH 3500 Operator's manual

Akron Brass

Akron Brass Genesis 3590 owner's manual

NARDA

NARDA PMM 1008 user manual

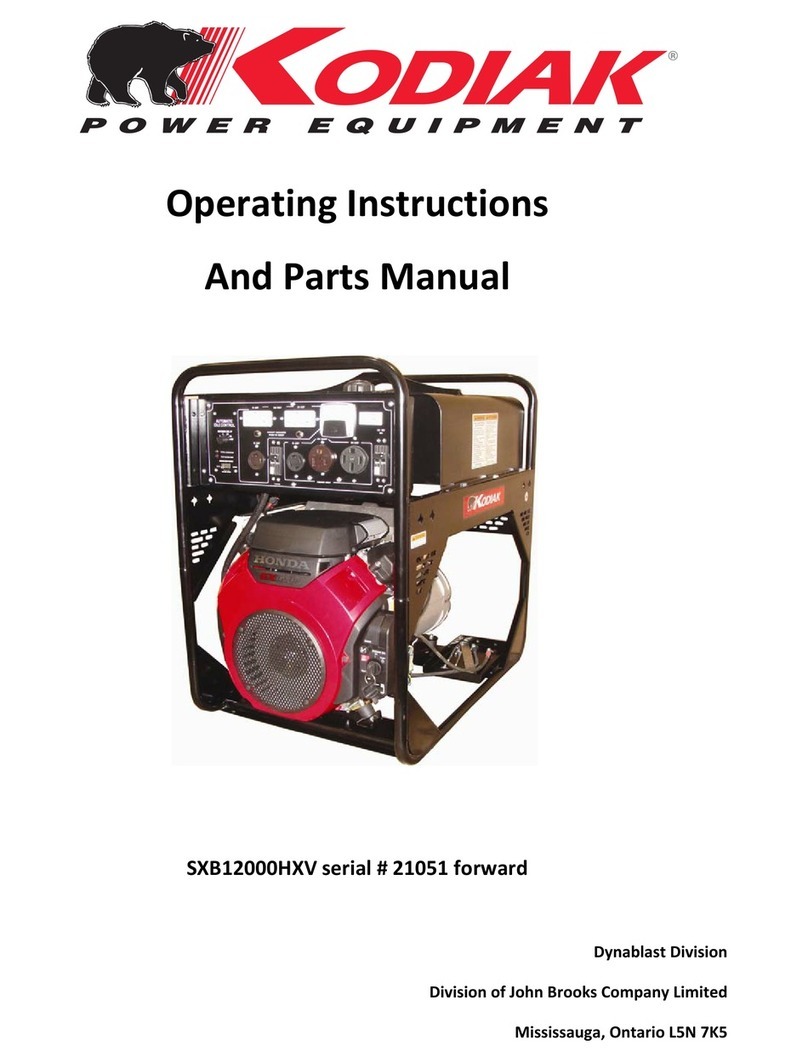

Kodiak

Kodiak SXB12000HXV Series operating instructions

Briggs & Stratton

Briggs & Stratton P3000 manual

Briggs & Stratton

Briggs & Stratton 030208-2 Illustrated parts list

iPower

iPower SUA10000EC owner's manual

Parks

Parks HP2000 XTREME Series Installation and operator's manual