A

Message

To

CLARK

Lift

TruckOperators

;

)

NOTES

Lift

trucks

are

specializedmachineswithuniqueoperatingcharacteristics

designed

to

performspecificjobs.Theirfunction

and

operation

isnot

like

a

car

or

ordinarytruck.Theyrequirespecificinstructions

and

rules

for

safe

operation

and

maintenance.

Safe

operation

of

lift

trucks

isof

primaryimportance

to

CLARK.

Ourex-

perience

with

lift

truckaccidents

has

shownthatwhenaccidentshappen

and

people

are

killed

or

injured

the

causesare:

1.

OPERATOR

NOT

PROPERLY

TRAINED

2.

OPERATOR

NOT

EXPERIENCED

WITHLIFTTRUCKOPERATION

3.

BASIC

SAFETY

RULES

NOT

FOLLOWED

4.

LIFT

TRUCK

WASNOT

MAINTAINED

INA

SAFE

OPERATING

CONDITION

For

thesereasons,CLARKwants

youto

knowabout

the

safe

operation

and

correctmaintenance

of

your

lift

truck.

This

manual

is

designed

to

help

you

learn

howto

operateyour

lift

truck

safe-

ly.

This

manualshows

and

tells

you

aboutoperatormaintenance

andtheim-

portantgeneralsafetyrules

and

hazards

of

lift

truckoperation.

It

describes

the

specialcomponents

and

features

ofthe

truck

and

theirfunction.

The

correctoperatingprocedures

are

shown

and

explained.Illustrations

andim-

portantsafetymessages

are

included

for

clearunderstanding.And,finally,

a

section

on

maintenance

and

lubrication

is

included

forthe

lifttruck

mechanic.

The

operator'smanual

isnot a

trainingmanual.

Itisa

guide

to

helpautho-

rizedoperatorssafelyoperatetheir

lift

truck

by

illustrating

the

correctpro-

cedures.

It

cannotcover

every

possiblesituationwhich

may

result

inanac-

cident.

You

must

watch

for

hazards

in

yourworkareas

and

correct

them.

Itis

importantthat

you

learn

the

information

in

this

manual

and

knowyourcom-

panysafetyrules!

Be

surethatyourequipment

is

maintained

ina

safecon-

dition

anddonot

operate

a

damagedtruck.Practicesafeoperationevery

time

youuse

yourlifttruck.Let'sjointogether

tosetnew

standards

in

safety.

Remember,before

you

start

operating

this

lift

truck,

be

sure

that

you

understand

all

drivingprocedures.

Itis

yourresponsibility,

anditis

impor-

tant

toyouand

yourfamily,

to

operateyour

lift

trucksafely

and

efficiently.

Andbe

awarethat

the

FederalOccupationalSafety

and

Health

Actand

state

laws

require

that

operators

be

completely

trained

inthe

safe

operation

of

lift

trucks.

And

letus

makethispoint,Clark

lift

trucks

are

built

to

takehardwork,

but

not

abuse.They

are

built

tobe

dependable,

but

they

are

only

as

safe

andef-

ficient

asthe

operator

andthe

personsresponsible

for

maintainingthem.

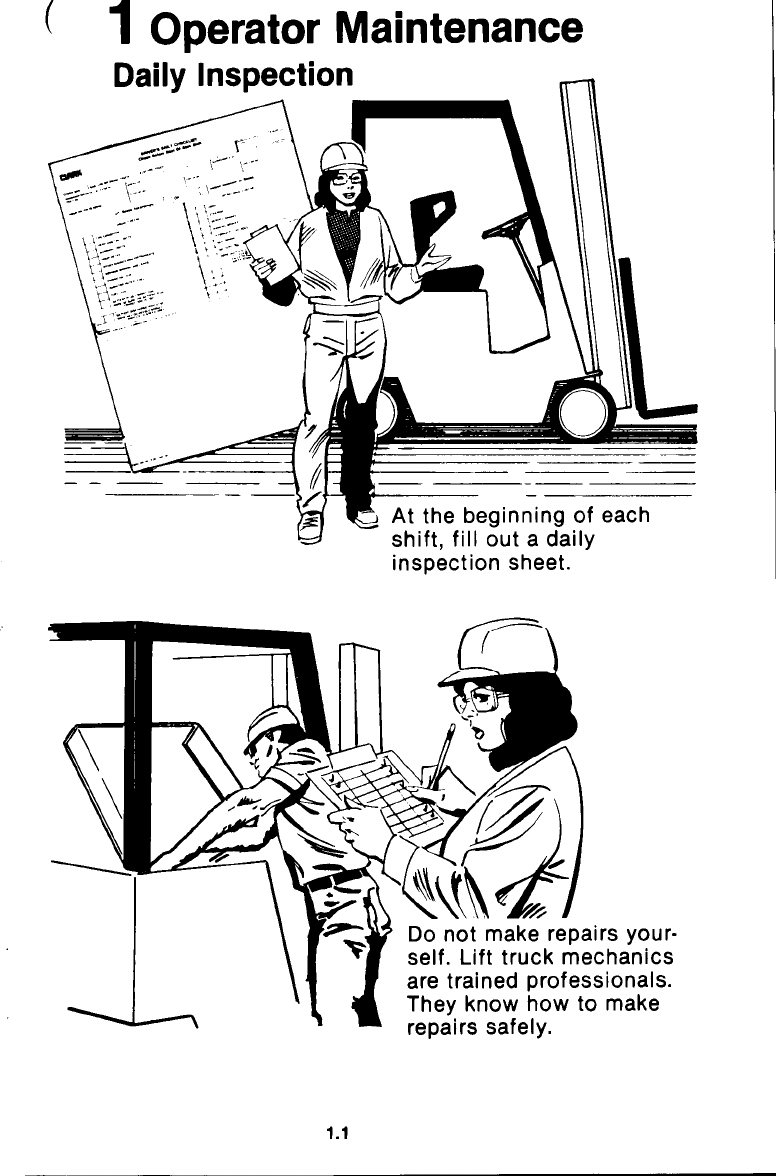

Do

not

make

any

repairs

to

this

truckunless

you

have beentrained

in

lift

truckrepairprocedures

and

authorized

by

youremployer.