8

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

NOTE: When "l " is shown on the LCD, it means the measurement has

exceeded the allowable range. A higher range should be

selected.

NOTE: When the scale of the value to be measured is unknown, select

the highest range first and lower the range accordingly.

DC/AC CURRENT MEASUREMENT

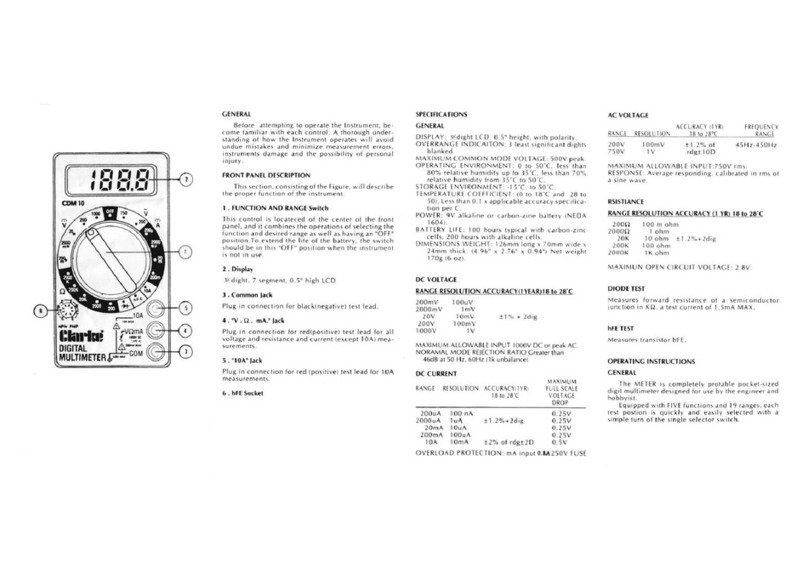

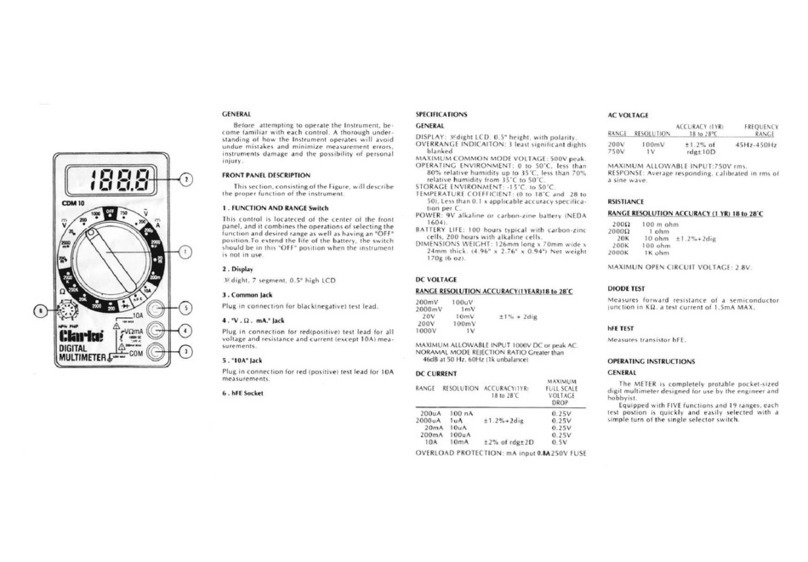

1. Plug the black test lead into the "COM" jack.

2. When the current to be measured is under 200mA, plug the red test lead

into the "mA" jack; when the current to be measured is over 200mA but

under 10A, plug the red test lead into the "10A" jack.

3. Set the rotary switch to the "A-" position for DC measurement and "A~" for

AC measurement and at the proper range.

4. Connect the test leads to the circuit.

5. Read the value on the display.

6. The polarity symbol denotes the polarity of the red test lead.

• The polarity symbol denotes the polarity of the red test lead.

NOTE: When ‘1’ is shown on the LCD, it means the measurement has

exceeded the allowable range; a higher range should be

selected.

NOTE: When the scale of the value to be measured is unknown, select

the highest range first and then lower the range accordingly.

NOTE: " " indicates the maximum current of the mA jack is 200mA and

the maximum current of the 10A jack is 10A. At either jack, current

exceeding the limit will blow the fuse.

RESISTANCE MEASUREMENT

Plug the black test lead into the "COM" jack and the red test lead into the "V Ω

Hz" jack.

WARNING: USE CAUTION WHEN MEASURING HIGH VOLTAGE CIRCUITS TO

AVOID ELECTRICAL SHOCK AND INJURY. DO NOT TEST VOLTAGES HIGHER

THAN 600V DC/AC. TO

AVOID ELECTRICAL SHOCK AND INJURY POWER OFF THE CIRCUIT AND

DISCHARGE THE CAPACITANCE BEFORE MEASURING CURRENT.

WARNING: TO AVOID ELECTRICAL SHOCK AND INJURY POWER OFF THE

CIRCUIT AND DISCHARGE THE CAPACITANCE BEFORE MEASURING

RESISTANCE.