Clarke CDM 85 User manual

Other Clarke Multimeter manuals

Clarke

Clarke CDM 25 User manual

Clarke

Clarke CDM80C User manual

Clarke

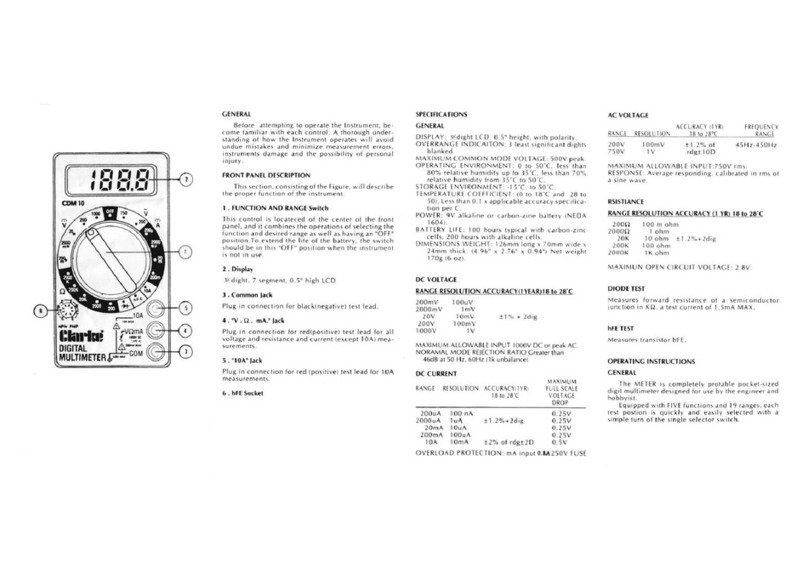

Clarke CDM 85 Operating instructions

Clarke

Clarke CDM35C User manual

Clarke

Clarke CDM 15 User manual

Clarke

Clarke CDM-50 User manual

Clarke

Clarke CDM-35 User manual

Clarke

Clarke CDM10C User manual

Clarke

Clarke CDM20 User manual

Clarke

Clarke CDM3 User manual

Popular Multimeter manuals by other brands

Gossen MetraWatt

Gossen MetraWatt METRAmax 6 operating instructions

PeakTech

PeakTech 4000 Procedure of calibration

YOKOGAWA

YOKOGAWA 90050B user manual

Gossen MetraWatt

Gossen MetraWatt METRALINE DMM16 operating instructions

Fluke

Fluke 8846A Programmer's manual

Tempo Communications

Tempo Communications MM200 instruction manual